Water Jet Considering Cavitation, ANSYS Fluent CFD Simulation Training

$120.00 Student Discount

The present problem simulates the cavitation in a water jet by ANSYS Fluent software.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Project Description

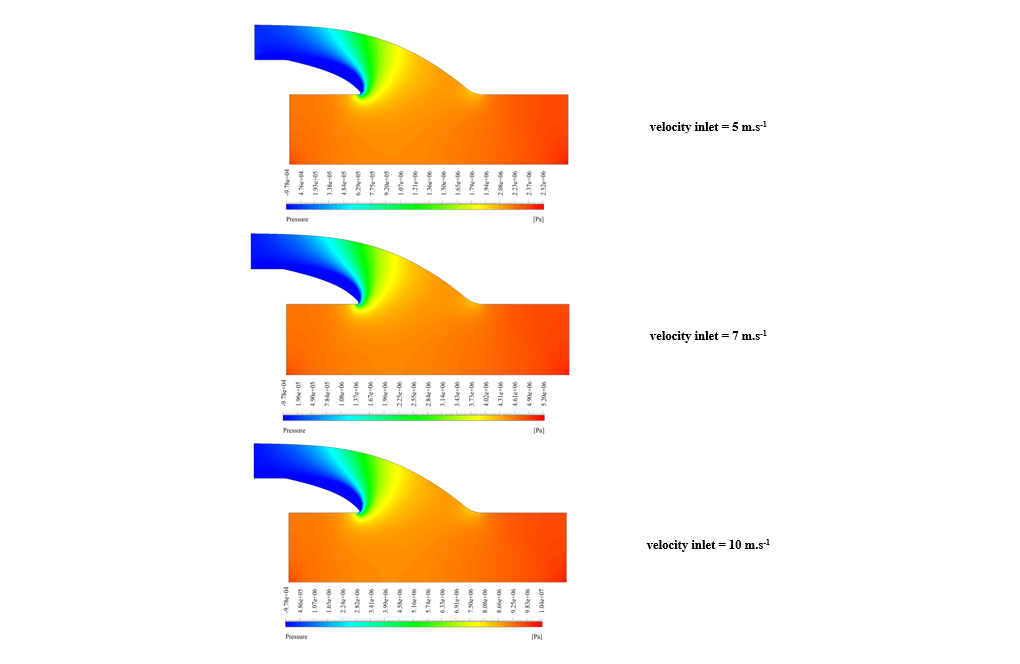

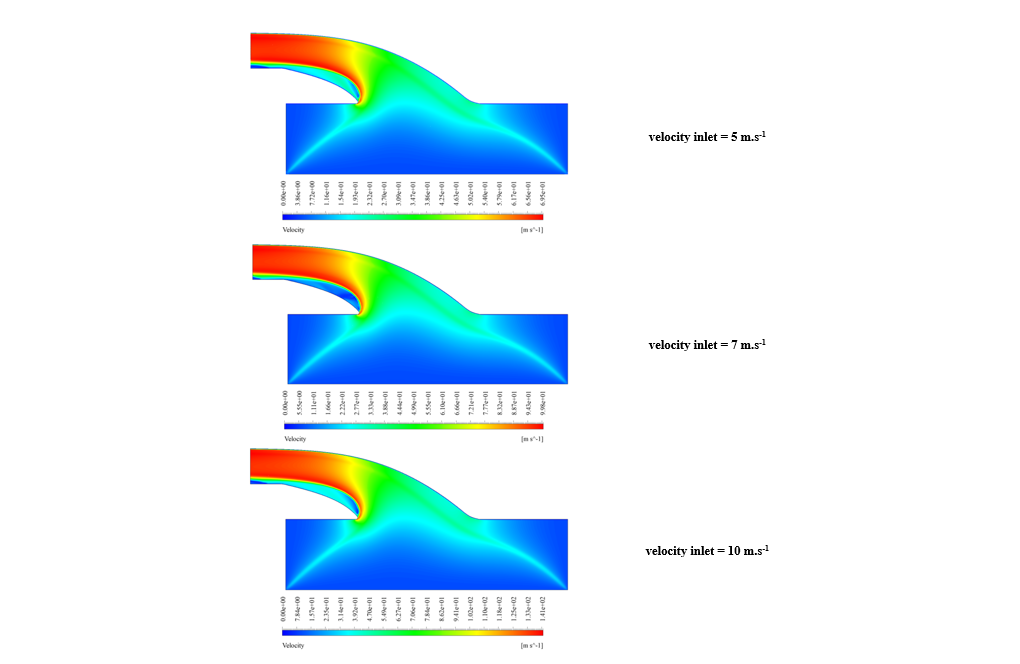

The present problem simulates the water flow in a water jet by ANSYS Fluent software. A water jet is a tool for creating a high pressure water flow for use in operations such as cutting or cleaning surfaces of objects. The working mechanism of this tool is that it consists of a thin layer of water at a very high speed to which an abrasive substance is injected to cut hard materials, and as a result, the mixture of water and abrasives can make a narrow cut on the piece. In the present model, the water flow enters the jet chamber at a velocity of 10 m.s-1 and exits the nozzle through a cross section.

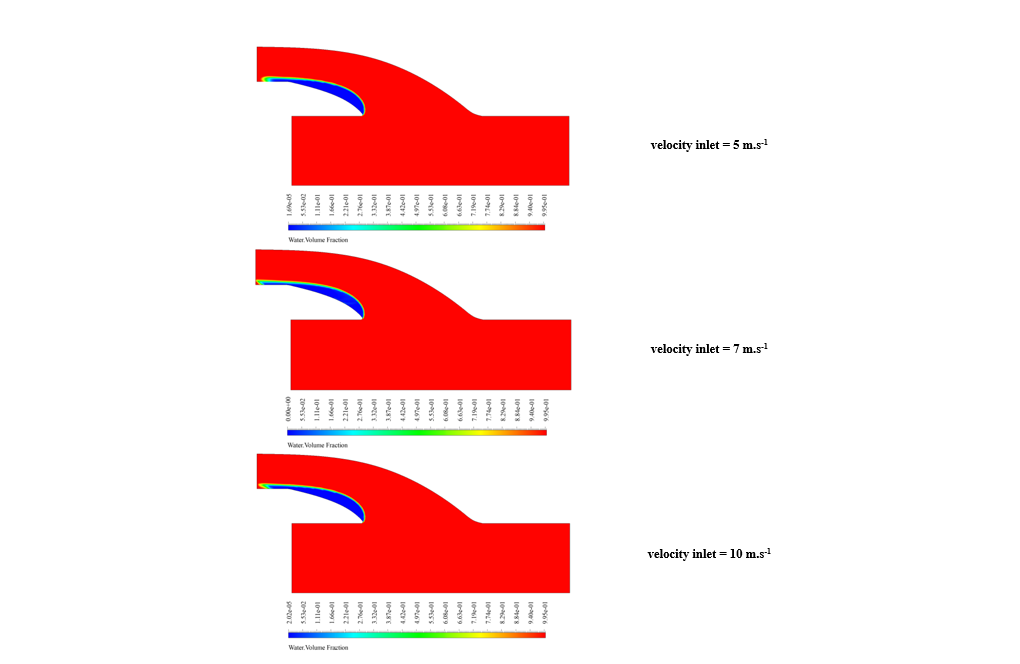

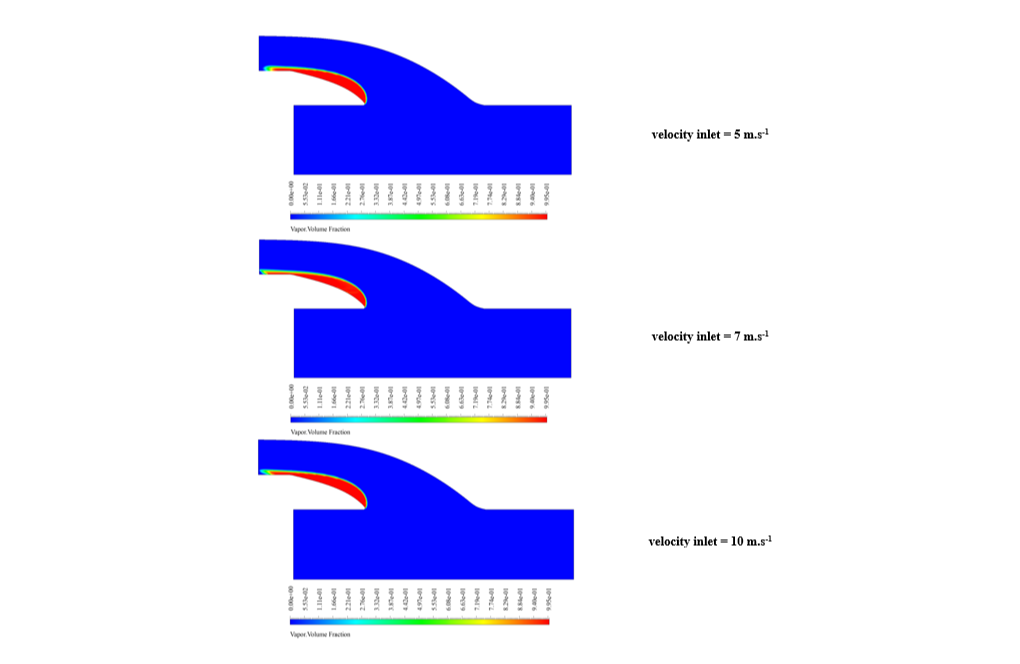

Since there is a possibility of pressure drop in this model, the cavitation phenomenon has been investigated in this model; Because this phenomenon occurs when the fluid pressure drops to its vapor pressure. Therefore, the model of two-phase VOF flow and mass transfer between two phases of water and water vapor is defined as cavitation at a vapor pressure equal to 3540 Pascal. The aim of the present work is to investigate the changes in the volume fraction of water and water vapor phases.

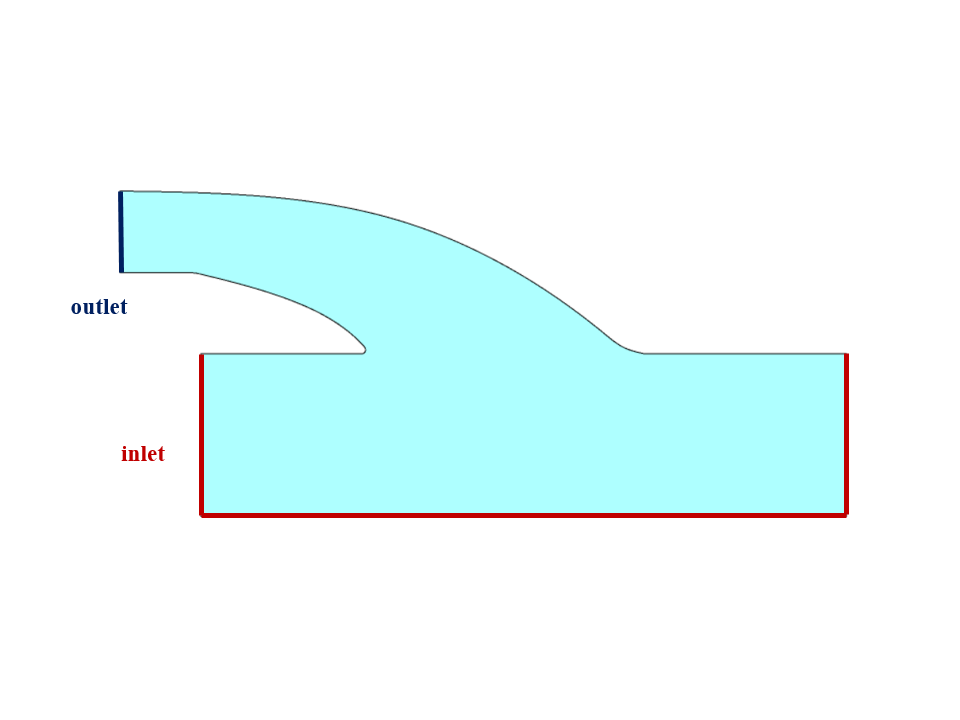

Water Jet Geometry & Mesh

The present model is drawn in two dimensions using Design Modeler software. The geometric structure of this model is such that it consists of three edges with a total length of 12 m as inlet and one edge with a length of 1 m as outlet. The following figure shows a view of the geometry.

The meshing of the model has been done using ANSYS Meshing software and the mesh type is structured. The element number is 57018. The following figure shows the mesh.

Cavitation in a Water Jet CFD Simulation

To simulate the present model, several assumptions are considered:

- We perform a pressure-based solver.

- The simulation is steady.

- The gravity effect on the fluid is ignored.

A summary of the defining steps of the problem and its solution is given in the following table:

| Models | ||

| Viscous model | k-epsilon | |

| k-epsilon model | RNG | |

| near-wall treatment | standard wall function | |

| Multi phase model | VOF | |

| phases | water & vapor | |

| interface modeling type | sharp | |

| formulation | implicit | |

| mass transfer mechanism between two phases | cavitation | |

| Boundary conditions | ||

| Inlet | Velocity inlet | |

| velocity magnitude | 10 m.s-1 | |

| volume fraction for water | 1 | |

| volume fraction for vapor | 0 | |

| Outlet | Pressure outlet | |

| gauge pressure | 0 Pascal | |

| Walls | Wall | |

| Wall motion | stationary wall | |

| Solution Methods | ||

| Pressure-velocity coupling | Coupled | |

| Spatial discretization | pressure | PRESTO |

| momentum | second order upwind | |

| volume fraction | compressive | |

| turbulent kinetic energy | first order upwind | |

| turbulent dissipation rate | first order upwind | |

| Initialization | ||

| Initialization method | Standard | |

| gauge pressure | 0 pascal | |

| vapor volume fraction | 0 | |

| x-velocity , y-velocity | 0 m.s-1 |

Results

At the end of the solution process, two-dimensional contours related to pressure, velocity, water volume fraction and water vapor volume fraction are obtained.

Reviews

There are no reviews yet.