Population Balance Model for Nucleation, PBM Tutorial

$390.00 Student Discount

- The problem numerically simulates Population Balance Model (PBM) for Nucleation using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 112077.

- We use the Species Transport model to define a mixture of water, calcium, and oxalate as the initial phase.

- We use the Eulerian Multiphase model to define a two-phase flow, in which the secondary phase is calcium-oxalate, resulting from a chemical reaction.

- We use The population balance model (PBM) to study produced particles’ behavior and predict the density or population of particles in specific sizes.

- We use a UDF function to define the nucleation and growth rates in PBM analysis.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Population Balance Model (PBM) for Nucleation, ANSYS Fluent CFD Simulation Training

The present problem simulates the production process of Calcium-Oxalate based on the Population Balance Model (PBM) using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

We model the present model n three dimensions using Design Modeler software. The study model consists of a small rectangular cubic chamber connecting two elbow tubes.

The chamber has a length, width, and thickness of 12 mm, 6 mm, and 2 mm, and the two inlet pipes have a circular cross-section with a diameter of 1.5 mm. The model consists of a rotating zone and a stationary zone.

The meshing of this present model has been generated by ANSYS Meshing software. The total cell number is 112077.

CFD Methodology

In this project, the calcium-oxalate production process is first modeled, and then the PBM is analyzed using the production, growth, and displacement of production particles.

The mechanism of the studied system is such that the flow of water carrying calcium and oxalate enters a chamber through two pipes; From one tube, only a mixture of water with calcium is injected, and from the other tube, only a stream of water is injected with oxalate.

The two inlet streams are then mixed, and a chemical reaction occurs in which the combination of calcium and oxalate produces calcium-oxalate. Multiphase and Species Transport models must be used to define this simulation process in software.

Also, PBM, chemical reaction, and mass transfer should be activated.

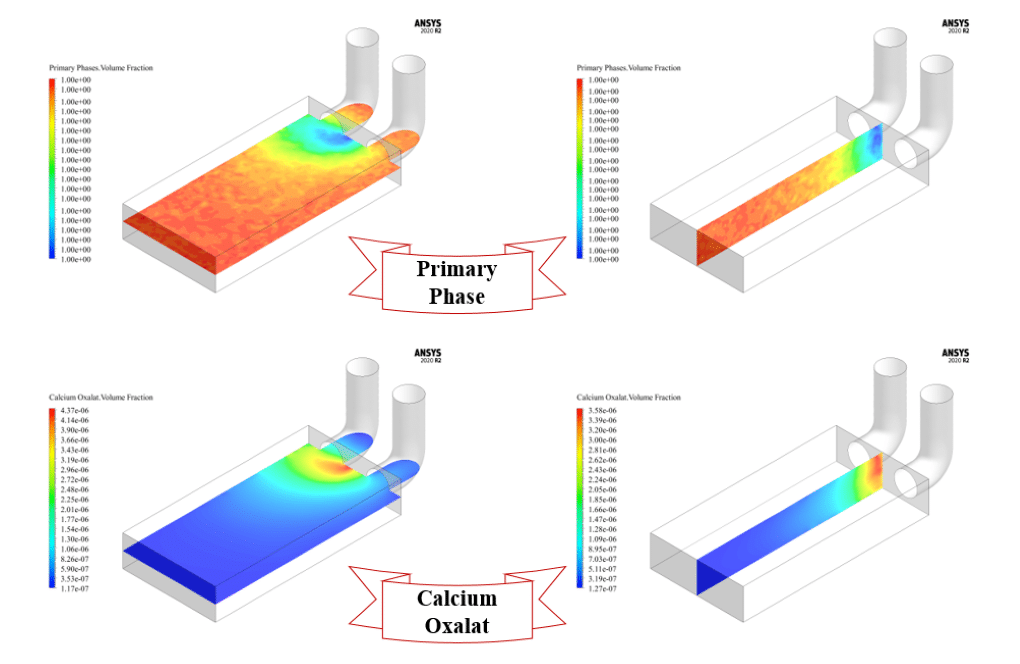

First, the Eulerian multiphase model defines a two-phase flow; The primary phase is a mixture of water, calcium, and oxalate. The secondary phase is calcium-oxalate, resulting from a chemical reaction.

A chemical reaction within a multiphase flow is then defined. Calcium and oxalate react with each other from the initial phase as a reactant and lead to the production of calcium-oxalate as a product.

The rate of this reaction is defined based on Arrhenius, and the activation energy of the reaction is equal to 1e + 8 j.kg-1.mol-1. In addition to defining the chemical reaction, the process of mass transfer between materials must also be defined.

Therefore, three stages of mass transfer are defined so that in these three stages of mass transfer, three substances, including water, calcium, and oxalate, can be converted to calcium-oxalate.

Also, the species transport model must define a mixture of water, calcium, and oxalate as the initial phase.

After defining the process of conversion of primary phase materials to secondary phase and the occurrence of chemical reaction, it is possible to study the behavioral pattern of particles produced in the secondary phase.

The population balance model (PBM) can study produced particles’ behavior and predict the density or population of particles in specific sizes.

When several particles are formed in an environment, various stages occur, including forming the initial particle nucleation, the growth of formed particles, the aggregation of several small particles, and the breakage of a large particle into smaller particles.

There are different models for defining the PBM in the software, and in this simulation, the discrete method is used. Several bins must be defined for different particle sizes to estimate the particle population or density in each size using this method.

It should be noted that recognizing the number of categories and the definition range for categories is based on inductive reasoning and several steps of simulation solution in the form of trial and error.

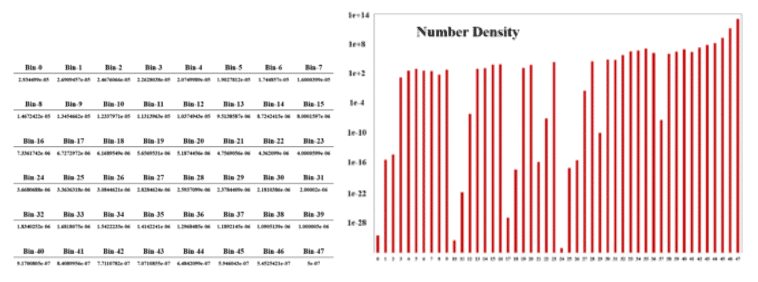

In this simulation, 48 bins are used; So that the smallest size with a diameter of 5e-7 m is defined and the largest possible size for each particle up to a diameter of about 2.9345e-5 m.

Also, in this simulation, it is assumed that aggregation and breakage do not occur, and only nucleation and growth processes occur. A UDF function is used to define the nucleation rate and growth rate. Moreover, the laminar model is used to solve the fluid flow equations.

PBM Conclusion

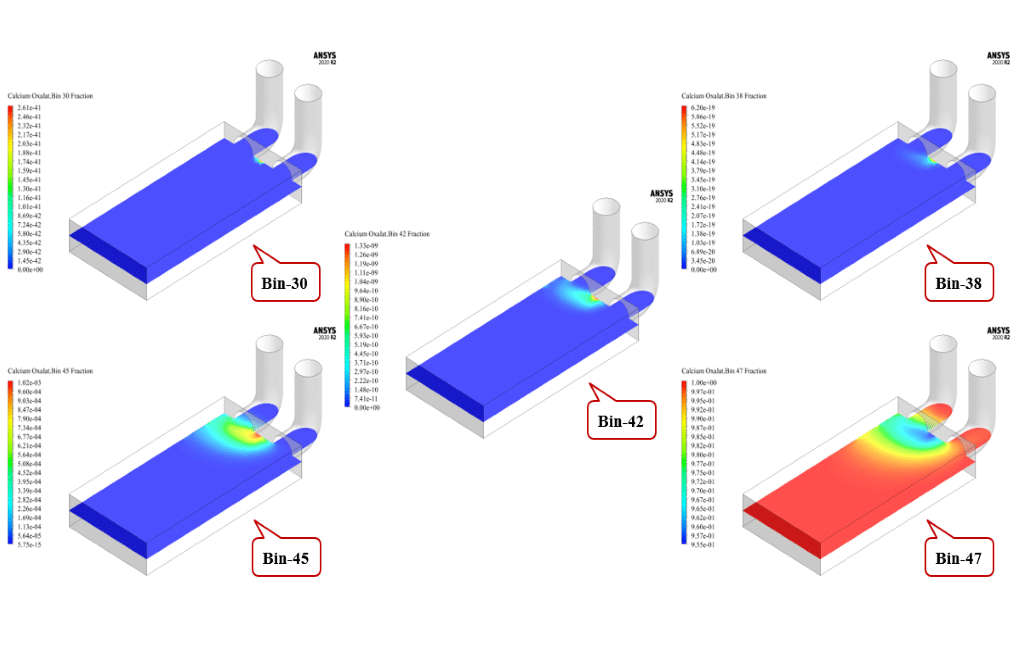

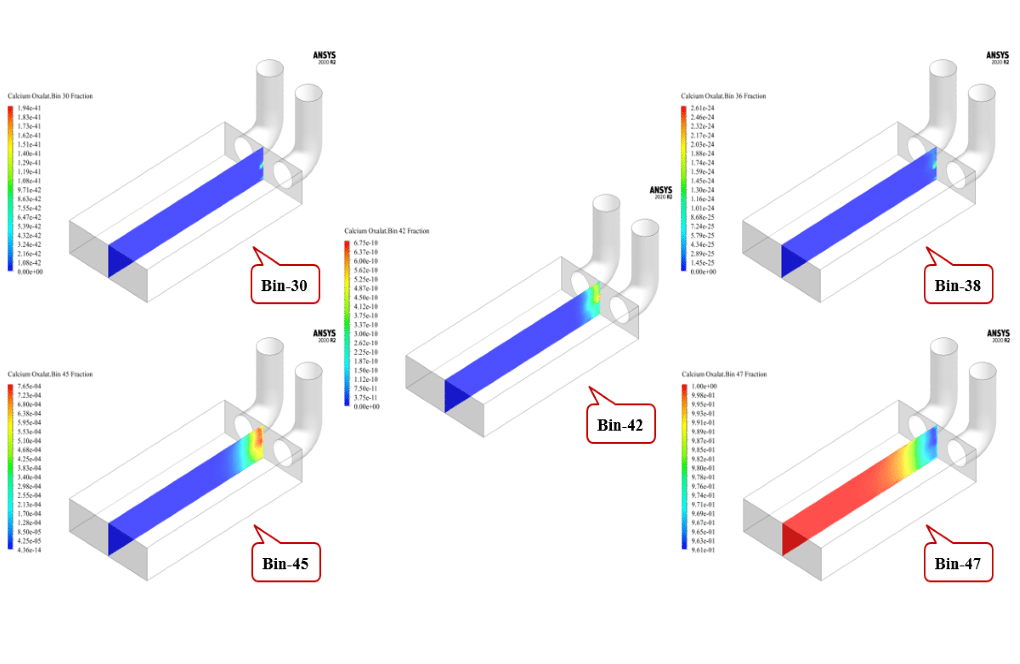

After the simulation, two-dimensional results related to the mass fraction of the present chemical species for different bin numbers at different times are obtained.

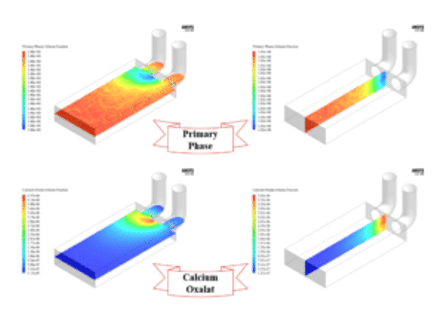

For instance, a two-dimensional contour is obtained related to the volume fraction of the primary phase (including water, calcium, and oxalate) and the second phase (calcium-oxalate).

These contours show that calcium-oxalate is formed by a chemical reaction and mass transfer from the primary to the secondary phase. The formation of the desired material occurs in the initial area of the chamber, which is the junction of two inlet pipes.

Then the table related to the sizes of each definition category (bin) is presented. There are 48 categories for particle size classification, starting at a minimum of 5e-7m at bin-47 and continuing to a maximum at bin-0. In addition, we represent the bar graph of number density in terms of the bin number.

Number density represents the ratio of particles per unit volume; That is, how many particles with the desired volume (according to the size of each bin) are within the desired area.

Finally, we obtain two-dimensional contours of the volume fraction of calcium-oxalate produced in different bins. The results show that from about bin-30 onwards, the amount of material produced becomes significant.

This means that the volume of particles produced in the categories between bin-0 to bin-30 is imperceptible. Therefore, we can conclude that the produced particles are formed and grow in smaller volumetric sizes (between bin-47 to bin-30) and are not noticeable in larger volumetric sizes.

This video is the 4th episode of the Population Balanced Model Training Course.

Dr. Kathlyn DuBuque –

Is there an assumption for the aggregation and breakage of particles in this simulation, or does it model every aspect of particle behavior during the reaction process?

MR CFD Support –

In this simulation, it is assumed that aggregation and breakage do not occur, and only the nucleation and growth processes are considered for modeling particle behavior in the calcium-oxalate production process.

Jerad Morar III –

Fantastic explanation of the PBM process for nucleation using ANSYS Fluent! It really delineates how the chemical reactions and particle interactions are captured in the simulation. I’m impressed by the level of detail, especially the use of UDF for the nucleation and growth rates, and how the various sizes of particles and the important metrics are analyzed.

MR CFD Support –

Thank you for your appreciation of our Population Balance Model for Nucleation tutorial! We’re delighted to know that our efforts to present a detailed simulation process using ANSYS Fluent are helpful and understandable. It’s wonderful to hear that our explanation of nucleation, growth rates, and the utilization of User-Defined Functions (UDFs) contributed positively to your perception of the complexity in particle-size analysis. We aim continually to provide comprehensive learning experiences, and your feedback is invaluable. Don’t hesitate to reach out for further questions or additional guidance.

Prof. Margaretta Will I –

How exactly is the nucleation rate defined in the UDF function for this PBM simulation?

MR CFD Support –

The nucleation rate in the UDF function is programmed to capture the dynamics of particle formation. It typically depends on the concentrations of the reacting species, the local temperature, and may also incorporate kinetic parameters specific to the reaction mechanism.

Prof. Declan Runolfsdottir Sr. –

I appreciated the comprehensive approach in demonstrating the Population Balance Model in your tutorial! The concepts of nucleation and growth came across clearly, and using 48 bins to classify particle size was insightful. Which bin had the highest number density, and can you explain why that particular range was more significant than others?

MR CFD Support –

Thank you for your kind words about our Population Balance Model tutorial. We’re glad you found the concepts informative. Regarding your question, the higher number density observed in a particular bin, say around bin-30, implies that particle nucleation and growth are more prevalent in that size range. This could be due to specific physicochemical conditions favoring the nucleation at a particle size corresponding to that bin. These conditions can include the concentration of reactants, local supersaturation levels, as well as temperature and pressure conditions within the reactor. If you are interested in more details on why this range is more significant or how the other bins compared in terms of density, we encourage further discussion to delve into the particle size dynamics or to provide further simulations or experimental data to validate the model predictions.

Roberto Dare –

How exactly does the UDF function in this project determine the nucleation and growth rates for the PBM in ANSYS Fluent?

MR CFD Support –

In this project, the User-Defined Function (UDF) provides a way to specify custom equations or functions for nucleation and growth rates. These functions account for the dynamics involved in the production and maturation of calcium-oxalate particles in the simulation. The user typically writes C-style code to define these rates based on empirical data or theoretical models relevant to the process being simulated.

Prof. Willy Fay DDS –

How was the nucleation rate implemented in the simulation using a UDF, and are there any example snippets of the UDF that could help me understand the implementation?

MR CFD Support –

In the simulation, the nucleation rate was implemented using a User-Defined Function (UDF). The provided UDF allowed for defining the dynamic aspects of nucleation within a specific domain. Unfortunately, we do not have snippets of the UDF within the review data, but I assure you that during the learning session, these functions are thoroughly explained, and several examples are given to ensure that you can understand and employ such functions in your simulations.

Marco Wintheiser –

Is the UDF implemented for PBM nucleation rate calculation or for specifying both the nucleation and growth rates of particles within the system?

MR CFD Support –

In the PBM simulation for the Calcium-Oxalate production process, a UDF (User-Defined Function) is implemented to specify both the nucleation and growth rates of the particles formed within the system. The UDF allows for the detailed and specialized definition of these terms based on the characteristics and requirements of the reaction taking place in the simulation.

Walter Mitchell –

The training seems very comprehensive, but I’m wondering if there is supplemental material available to help understand the UDF functions for nucleation and growth rate?

MR CFD Support –

In our training materials, several resources are provided to assist with understanding and implementing UDF functions. Examples and tutorials guide you through creating UDFs for different aspects of CFD simulations, and our support team is always available to answer any specific questions you may have regarding UDF development.

Zander Tremblay –

Is it possible to adjust the bin sizes in the PBM setup to study even finer particle distributions, and if so, how would that affect the simulation outcomes and computational cost?

MR CFD Support –

You can indeed adjust the bin sizes within the PBM setup to study finer particle distributions. Doing so would provide a more detailed insight into the size distribution of particles, potentially capturing smaller nucleated particles. However, it is important to note that increasing the number of bins or focusing on smaller size ranges also significantly increases the computational cost since the solver needs to track a larger number of discrete phase boundaries. More bins would likely lead to longer simulation times and require more computational resources to process the increased complexity in the calculations for the mass and number density distributions.

Lorenzo Mills –

The description highlights that nucleation and growth are the only occurring processes. Could you please explain why you chose not to include aggregation and breakage in this model?

MR CFD Support –

For this specific simulation, aggregation and breakage were not included in order to simplify the model and focus on core processes of nucleation and growth. These stages were assumed to be negligible or not significant for the specific reaction between calcium and oxalate, hence they were not modeled to reduce computational complexity and expedite the simulation process.

Glenna Oberbrunner V –

The video tutorial is very comprehensive! Learned so much about PBM modeling—particularly the customization of bins and nucleation rates.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear the tutorial on the Population Balance Model was helpful and that you appreciate the detail on bin customization and nucleation rates. We strive to provide clear and thorough training material and are happy it’s making a difference in your learning experience.

Prof. Jerrod Block Jr. –

Which parameters control the nucleation and growth rates in the particle production process?

MR CFD Support –

In the simulation of the production of calcium-oxalate using the PBM, the nucleation and growth rates are controlled by a user-defined function (UDF). The nucleation rate and growth rate parameters receive values that are then used in the simulation to model the behavior of particles in the chamber accurately.

Dr. Ella Ward –

The explanation is technical and complex. Would you be able to simplify how the mass transfer between water, calcium, and oxalate to form calcium-oxalate was defined?

MR CFD Support –

In simple terms, for our simulation, we define a way to mimic how water, calcium, and oxalate mix and react to create particles of calcium-oxalate. We set rules for when and how fast these substances should combine, using scientific formulas to make sure the creation of calcium-oxalate happens like in the real world. This process of substances changing and binding together is what we call mass transfer.

Ericka Ruecker –

I’m thrilled with how comprehensive this tutorial seems, but I’m curious if we can adjust the UDF function parameters? Are they hardcoded, or is there a way to modify them for different simulations?

MR CFD Support –

In the ANSYS Fluent simulation environment, UDF (User-Defined Function) parameters are designed to be customizable. Users can adjust the nucleation rate, growth rate, and other UDF-defined parameters to suit their specific needs for different simulations. However, modifying UDFs requires a working knowledge of the C programming language and understanding of the simulation physics.

Dr. Henry Klocko IV –

Are we only limited to looking at the particle size through these 48 bins in the PBM simulation, or is there a feature to calculate for more detailed sizes if necessary?

MR CFD Support –

In the PBM simulation, you are not strictly limited to 48 bins; the definition range for bin sizes can be adjusted based on simulation needs. You can define more bins to capture a more detailed size distribution of particles if required, though it may require more computational power. Setting up additional bins is often performed through a process of trial and error to ensure meaningful results.

German Ruecker Sr. –

I’m curious about how PBM accounts for agglomeration or breakage of particles in this simulation. Is this considered?

MR CFD Support –

In this specific simulation, it is mentioned that aggregation and breakage do not occur. Only nucleation and growth processes are considered for the particles’ behavior in the secondary phase. So, agglomeration and breakage aren’t accounted for in the PBM in this case. Particle behavior is predicted only based on the nucleation rate defined using a UDF function and the growth of formed particles.

Michael Hand –

The tutorial mentions using a UDF for nucleation and growth rates. Could you provide more detail on how the UDF is implemented and what specific functions it performs within the simulation?

MR CFD Support –

In the tutorial, a User-Defined Function (UDF) is implemented to define the specific rates for nucleation and particle growth within the simulation. The UDF is written in C programming language and is compiled and loaded into ANSYS Fluent to customize the existing models. The UDF specifies the rates of nucleation and growth based on the concentration and reaction rates. This allows for a more accurate representation of the particle formation and size distribution, as the formation and growth of the particles can be directly controlled through the UDF depending on the reaction kinetics and other relevant physical parameters.

Rusty Jerde –

I found the tutorial on the Population Balance Model very informative. I’m particularly interested in using the discrete method for PBM as illustrated in the tutorial for my own work on predicting particle density. Could you elaborate on how the number of bins was determined to be 48 and the range defined for the bins?

MR CFD Support –

In the given Population Balance Model (PBM) for Nucleation CFD Simulation, the number of bins and their size range is determined through a process of trial and error and inductive reasoning. The simulation begins with an initial guess on number and range, and iteratively adjusts these parameters. The final number, 48 bins for this problem, and the size range for each bin ranging from 5e-7 m to approximately 2.9345e-5 m, is based on the intended resolution of particle size distribution and scrutiny of preliminary results. This ensures that the solution carries adequate granularity to capture the phenomenon of nucleation and growth within the system, which in turn helps in making reliable predictions for population density.

Mellie Okuneva –

The description is quite detailed, but I’m curious, how do you determine the specific size ranges for each bin in the PBM? And what factors might influence the decision on bin sizing?

MR CFD Support –

The size ranges for each bin in the PBM are typically determined based on the expected size distribution of the particles being modeled and the physical processes involved, such as nucleation and growth. Factors influencing bin sizing can include the dynamics of the particle formation process, the accuracy required for the simulation, computational resources, and prior knowledge from experimental data if available. The ranges are often set through inductive reasoning and could be refined through a series of trials to achieve a balance between resolution and computational cost.

Dayne Hagenes –

What’s the outcome if aggregation and breakage are taken into account in this simulation?

MR CFD Support –

If aggregation and breakage are included, the simulation would predict the dynamic behavior of particle size distribution more accurately, especially in reacting flows where particles can collide and stick together or break into smaller pieces. These processes can significantly alter the final particle size distribution and need to be considered for a more detailed analysis.

Dr. Oswaldo Waelchi –

The tutorial mentions the use of UDF to define the nucleation rate and growth rate. Can we access the UDF code used in this simulation, or is there a library of standard UDFs that we could use for similar simulations in ANSYS Fluent?

MR CFD Support –

Unfortunately, as I am an AI developed before 2023, I do not have access to the company’s proprietary tools or UDF libraries. I recommend reaching out directly to MR CFD Company’s customer support or referring to the ANSYS Fluent documentation and user resources for specific UDF codes related to population balance models.

Prof. Heber Hilpert MD –

I really liked the detailed explanation on how the nucleation and particle growth processes were simulated using the discrete PBM method. It’s fascinating how the number density and volume fraction of calcium-oxalate can be visualized in various sizes. Great tutorial for understanding the granular level reactions in a CFD environment!

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that our tutorial on the Population Balance Model for nucleation and particle production provided you with a clear understanding of the process. It’s always rewarding to know that our material helps demystify complex CFD concepts for our users. We look forward to assisting you with any further CFD learning needs!

Kaley Lindgren –

I’d like to know more about how the UDF function is applied to this PBM simulation. Could you provide an example or elucidate on how the UDF defines the nucleation and growth rate?

MR CFD Support –

The UDF (User-Defined Function) in this PBM simulation is coded to define the specific behaviors for the nucleation and growth rate of the particles. For nucleation, it might be programmed with equations that address the formation rate of new particles, based on local supersaturation and other relevant factors. For growth, it would dictate the rate at which existing particles increase in size, potentially as a function of species concentration gradients, temperature, and other field variables. Unfortunately, without having access to the actual UDF code, I cannot provide a specific example. However, it’s typically written in C language and compiled in ANSYS Fluent to be applied to the simulation.

Prof. Sandrine Cartwright III –

Does the nucleation rate and growth rate in the simulation affect the final size distribution of the calcium-oxalate particles? How precisely can one control these rates?

MR CFD Support –

Yes, the nucleation rate and the growth rate have significant effects on the size distribution of the calcium-oxalate particles. By carefully setting up the nucleation and growth rate using User-Defined Functions (UDFs), one can control these rates with high precision. It allows for the detailed prediction and control of particle size distribution within the simulation.

Viva Rohan DVM –

After reading about PBM and the UDF function defining nucleation and growth rates, I wonder how do I integrate my own nucleation-growth relationship into the model, if it differs from typical models?

MR CFD Support –

To integrate your own nucleation-growth relationship into the Population Balance Model, you usually need to program a User-Defined Function (UDF) in C that correctly defines your specific nucleation and growth expressions. Once you’ve properly written and compiled this UDF in the context of ANSYS Fluent, you will be able to incorporate your custom nucleation-growth relationship by ‘hooking’ this UDF to the relevant ANSYS Fluent solvers.

Ruben Wuckert –

Really impressed with the detailed explanation of how chemical reactions and mass transfer processes are defined and simulated in the PBM project. It incredibly insight how the effects of reaction and particle growth are so effectively represented using the discrete PBM method.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our tutorial on the Population Balance Model for nucleation using ANSYS Fluent was insightful and understandable. It’s our goal to provide comprehensive guidance and detailed explanations to help our users get the most out of CFD analysis. We appreciate your comments and are glad you found the content effective!

Roy Tremblay –

What software was used for the Population Balance Model analysis for nucleation, and how was that selected?

MR CFD Support –

ANSYS Fluent software was utilized for the Population Balance Model (PBM) analysis for calcium-oxalate nucleation. This software was selected due to its robust multiphase and species transport models and the ability to customize nucleation and growth rates using user-defined functions (UDFs), which are essential for accurately simulating chemical processes like nucleation and crystal growth.

Patrick Green –

Does the PBM simulation include the aggregation and breakage of particles, or does it solely focus on nucleation and growth processes? You mentioned the use of UDF for nucleation and growth rates, can you explain the reasoning behind your parameters selection for these rates?

MR CFD Support –

In the discussed PBM simulation, aggregation and breakage processes do not occur. The focus is solely on the nucleation and growth processes. The selection of parameters for the UDF defining nucleation and growth rates was likely determined through a combination of theoretical approach, empirical data, and calibration based on iterative testing within the simulation framework.

Cordelia Smitham –

Your tutorial suggests that the distribution of particle sizes is one of the key outcomes. Could you clarify how the particle size distribution affects the production process of calcium-oxalate?

MR CFD Support –

In the CFD simulation, the particle size distribution is a significant factor because it influences the surface area available for chemical reactions, sedimentation rates, and overall product-purity characteristics. During the production of calcium-oxalate, understanding and controlling the particle size distribution is crucial for ensuring consistent product quality. Smaller particles may dissolve or react faster due to their larger surface area to volume ratio, while larger particles might settle more quickly out of the solution. These factors must be considered and optimized during the production process to meet the desired specifications of the end product.