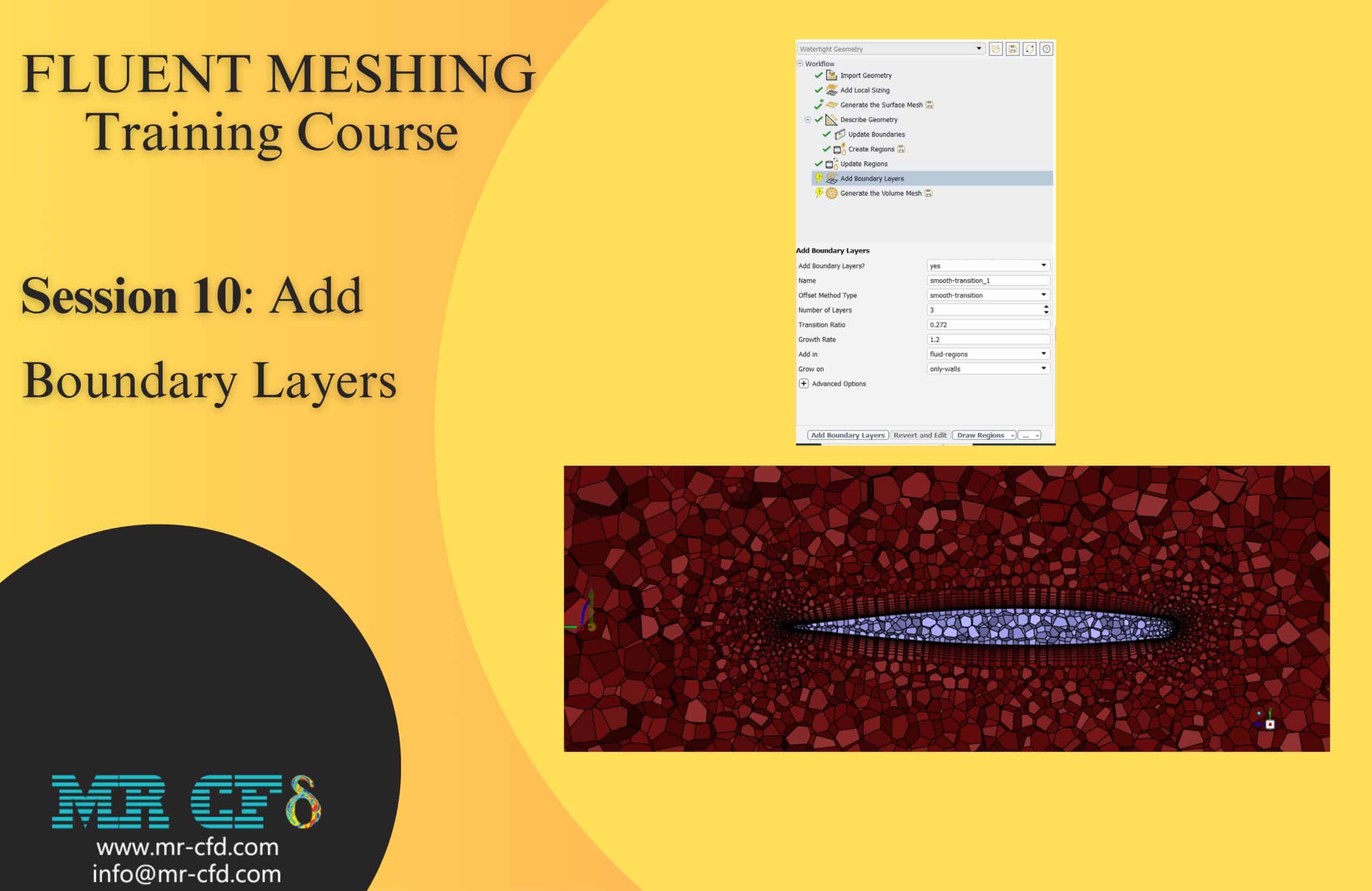

Fluent Meshing Training Course: Session 10, Add Boundary Layers

Free

- Boundary layers are thin regions near walls where fluid velocity and temperature gradients are strongest.

- Fluent Meshing provides several methods—Smooth Transition, Uniform, Last Ratio, and Aspect Ratio—to generate refined layers in these zones.

- Each method controls layer growth differently, impacting mesh quality, accuracy, and computational cost.

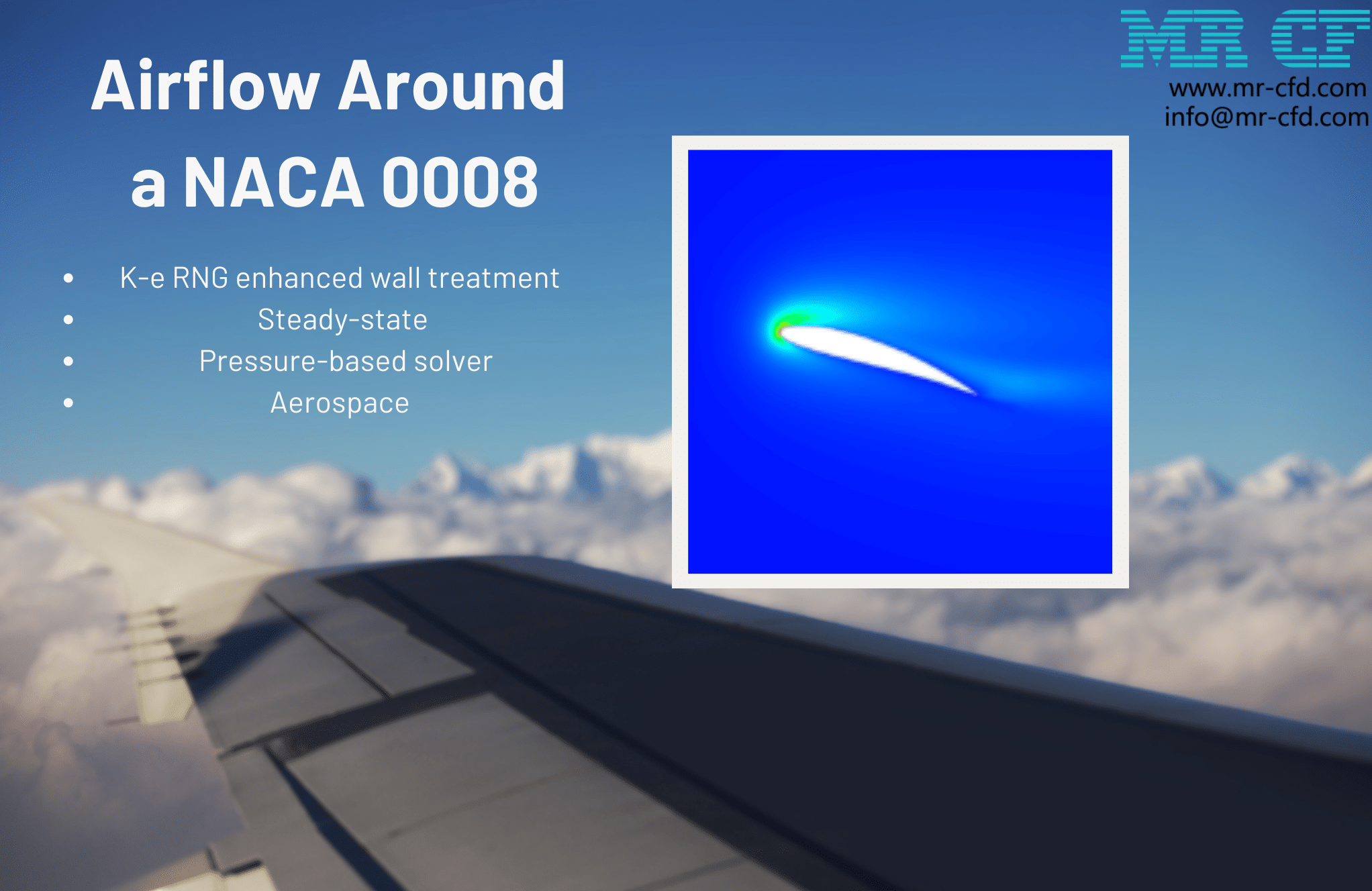

- Proper boundary layer meshing ensures reliable CFD predictions of drag, lift, shear stress, and heat transfer.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Fluent Meshing Training Course: Session 10, Add Boundary Layers

-

Introduction

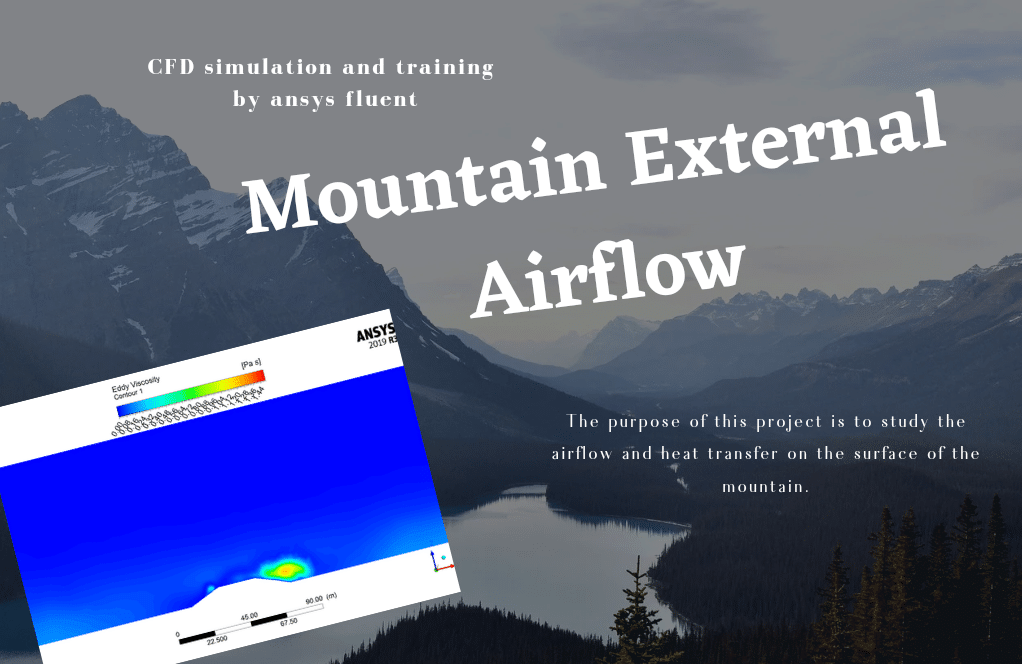

Boundary layers are thin regions near solid walls in fluid flow where velocity and temperature gradients are steep due to the no-slip condition at the wall. Capturing these gradients accurately in CFD simulations is essential for predicting critical flow characteristics such as wall shear stress, drag, lift, separation, and heat transfer. Fluent Meshing provides specialized tools to create structured boundary layer meshes that refine the near-wall region, thereby improving simulation accuracy while maintaining computational efficiency.

-

Geometry

In any CFD workflow, geometry definition is the foundation of mesh generation. The physical space where the fluid or solid interactions occur must be introduced into the pre-processing environment, often with named selections such as inlets, outlets, walls, and solid zones. These named regions allow clear identification of flow boundaries and facilitate targeted meshing operations, including boundary layer addition. Accurate geometry preparation ensures that the generated mesh conforms well to physical features and boundary conditions.

-

Add Boundary Layers

The boundary layer addition process in Fluent Meshing provides multiple options to refine meshes in the near-wall region. This refinement is essential since gradients in velocity, pressure, turbulence, and heat transfer occur predominantly next to walls. By strategically defining how layers are added, grown, and controlled through the available offset methods, users can strike a balance between capturing physics accurately and minimizing unnecessary computational cost.

3.1 Add In

The Add In setting determines in which regions the boundary layers are generated. Layers can be introduced in fluid zones, solid zones, or specifically named regions. Selecting the correct region is crucial because boundary layers are typically needed in fluid domains where wall-bounded phenomena occur. Deciding to extend layers into solids or limit them to fluids influences both computational requirements and the physical fidelity of the mesh.

3.2 Grow On

In the Fluent Meshing, the Grow On option specifies the precise surfaces or interfaces where boundary layers are applied. Common choices include applying layers only on wall boundaries, on all boundaries, or at specific interfaces between solid and fluid domains. This flexibility allows for tailored meshing strategies: for example, refining only walls for aerodynamic studies or applying layers at inlets where inflow profiles need added resolution. The choice impacts how smoothly the boundary mesh connects to the overall volume mesh.

3.3 Smooth Transition

The Smooth Transition method controls the gradual growth of layers from the wall toward the free stream using a parameter called the transition ratio. This parameter represents the thickness of the last layer relative to the total boundary layer thickness. A lower value generates a dense distribution of thinner cells, capturing fine gradients near the wall more precisely. A higher value reduces layer count and spreads them more widely, saving computational cost at the expense of resolution. This approach offers a balanced way of refining near-wall meshes while maintaining stable growth.

3.4 Uniform

In the Fluent Meshing, the Uniform method generates boundary layers of equal thickness throughout the inflation region. This approach is conceptually straightforward, providing evenly spaced mesh layers, but it does not account for the natural exponential-like growth of velocity profiles in real boundary layers. While simple, it is rarely optimal for practical CFD cases, since it may under-resolve near-wall gradients or over-resolve outer regions, increasing computational costs inefficiently.

3.5 Last Ratio

The Last Ratio method allows direct control of the outermost layer thickness relative to the overall inflation thickness. By specifying this ratio, the user defines how coarsely or finely the outer limit of the boundary layer zone connects to the surrounding mesh. This method is useful when the total boundary layer thickness is known or tightly constrained, such as in external aerodynamics or turbomachinery, where accurate resolution of the outer edge of the near-wall region can strongly affect flow predictions.

3.6 Aspect Ratio

In the Fluent Meshing, the Aspect Ratio method defines layer thickness based on the ratio between the first layer height and the characteristic size of the adjacent surface mesh. A proper aspect ratio ensures smooth gradation between the fine near-wall layers and the coarser bulk mesh. However, poor choices of aspect ratio (too high or too low) can result in abrupt transitions or distorted elements, leading to reduced mesh quality. Since aspect ratio directly ties surface and volume mesh scales, it has a significant impact on both accuracy and numerical stability.

You must be logged in to post a review.

Reviews

There are no reviews yet.