FSI Analysis and Turbine Vibration: CFD Simulation Training Package, 5 projects by ANSYS Fluent

$399.00 $159.60 HPC

- FSI Two-Way Analysis in Wind Turbine Blades

- Water Turbine Vibration CFD Simulation

- HAWT Turbine Vibration (Two-Way FSI)

- Vertical Axis Water Turbine with MRF Method

- HAWT Turbine Vibration (One-Way FSI)

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Fluid-Structure Interaction in Turbine Systems: Complete CFD Training with ANSYS Fluent

This comprehensive training package provides hands-on experience in advanced Fluid-Structure Interaction (FSI) analysis applied to turbine systems using ANSYS Fluent. Through five carefully designed projects, you’ll master both one-way and two-way FSI coupling techniques to analyze structural dynamics, vibration behavior, and performance optimization in wind and water turbines.

What You’ll Learn:

This course bridges the gap between fluid dynamics and structural mechanics, enabling you to simulate real-world turbine behavior under operational conditions. You’ll explore:

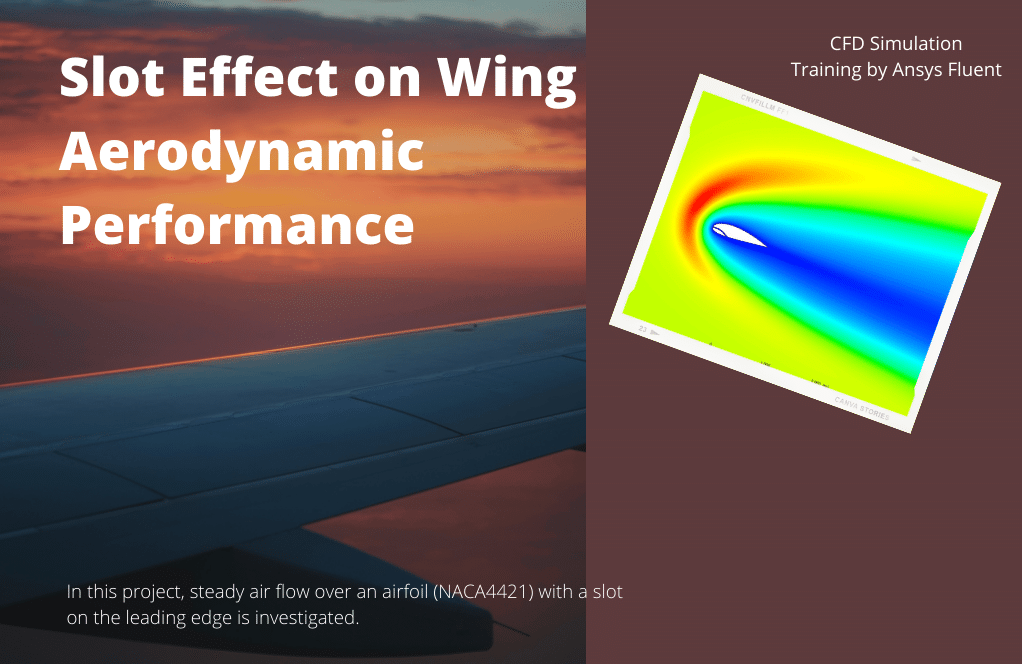

- Two-Way FSI Coupling: Master bidirectional interaction between fluid flow and structural deformation in wind turbine blades, understanding how aerodynamic loads cause deflection and how that deflection affects flow patterns

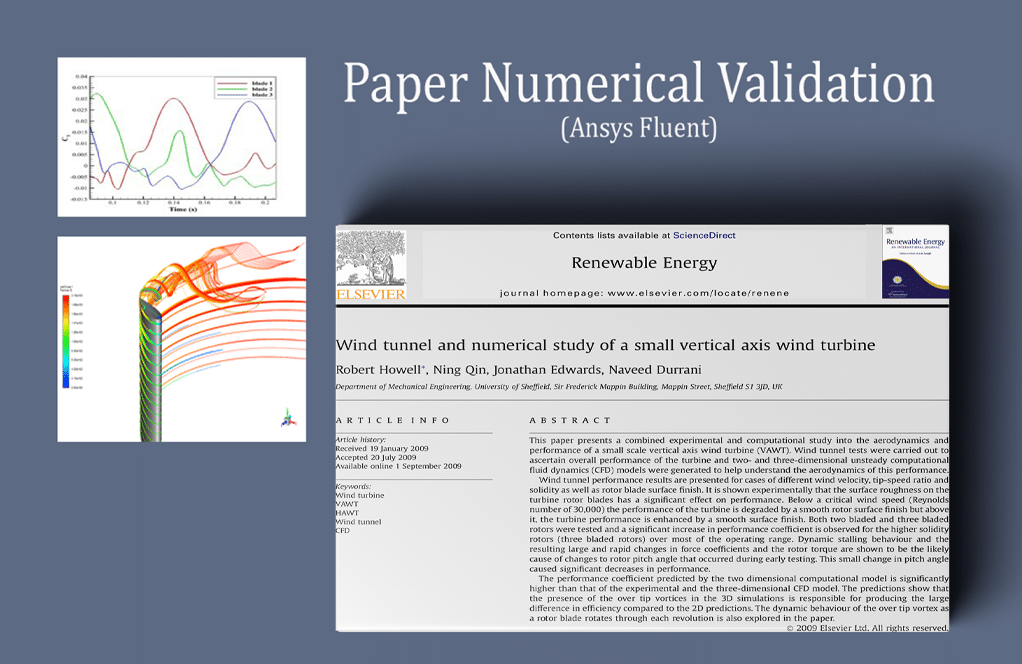

- Vibration Analysis: Investigate structural vibration in both Horizontal Axis Wind Turbines (HAWT) and Vertical Axis Water Turbines (VAWT) under fluid loading conditions

- One-Way FSI Analysis: Learn when and how to apply simplified one-way coupling for efficient preliminary design analysis

- Moving Reference Frame (MRF) Method: Simulate rotating turbine components combined with FSI to capture realistic operational scenarios

- Water Turbine Applications: Analyze fluid-structure dynamics in hydraulic turbines, focusing on vibration prediction and structural integrity

Course Projects:

- FSI Two-Way Analysis: Understanding Fluid-Structure Dynamics in Wind Turbine Blades – Deep dive into bidirectional coupling, mesh deformation, and iterative solution strategies

- FSI Method for Water Turbine Vibration CFD Simulation – Apply FSI techniques to hydraulic turbines, analyzing vibration modes and frequency response

- Fluid-Structure Interaction over HAWT Turbine Vibration (Two-Way) – Complete analysis of horizontal axis wind turbines including blade deformation and performance impact

- Fluid-Structure Interaction in a Vertical Axis Water Turbine using MRF Method – Combine rotating reference frames with FSI for VAWT systems

- Fluid-Structure Interaction over HAWT Turbine Vibration (One-Way) – Compare one-way coupling approach with two-way analysis for computational efficiency

Who Should Take This Course:

- Mechanical and Aerospace Engineers working in renewable energy sector

- CFD analysts specializing in turbomachinery design

- Structural engineers interested in fluid-induced vibrations

- Graduate students and researchers in wind/water turbine technology

- Design engineers in power generation and energy industries

Prerequisites:

- Basic knowledge of ANSYS Fluent and CFD fundamentals

- Understanding of structural mechanics principles

- Familiarity with turbine aerodynamics (recommended)

- Experience with ANSYS Workbench environment (helpful but not required)

What’s Included:

✓ Complete geometry files and CAD models for all 5 projects ✓ Step-by-step video tutorials with detailed explanations ✓ Pre-configured case and mesh files ✓ Post-processing templates and result analysis guides ✓ Troubleshooting tips and best practices ✓ Validation data and benchmark comparisons ✓ Lifetime access to course materials and updates

Learning Outcomes:

By the end of this course, you will be able to:

- Set up and execute complex FSI simulations in ANSYS Fluent

- Choose appropriate coupling methods (one-way vs. two-way) based on project requirements

- Analyze and interpret vibration data from turbine simulations

- Optimize turbine designs considering fluid-structure interactions

- Apply MRF techniques for rotating machinery FSI analysis

- Validate simulation results and ensure solution convergence

- Implement best practices for computational efficiency in FSI problems

Software Requirements: ANSYS Fluent 2020 or newer (Student, Academic, or Commercial license)

You must be logged in to post a review.

Reviews

There are no reviews yet.