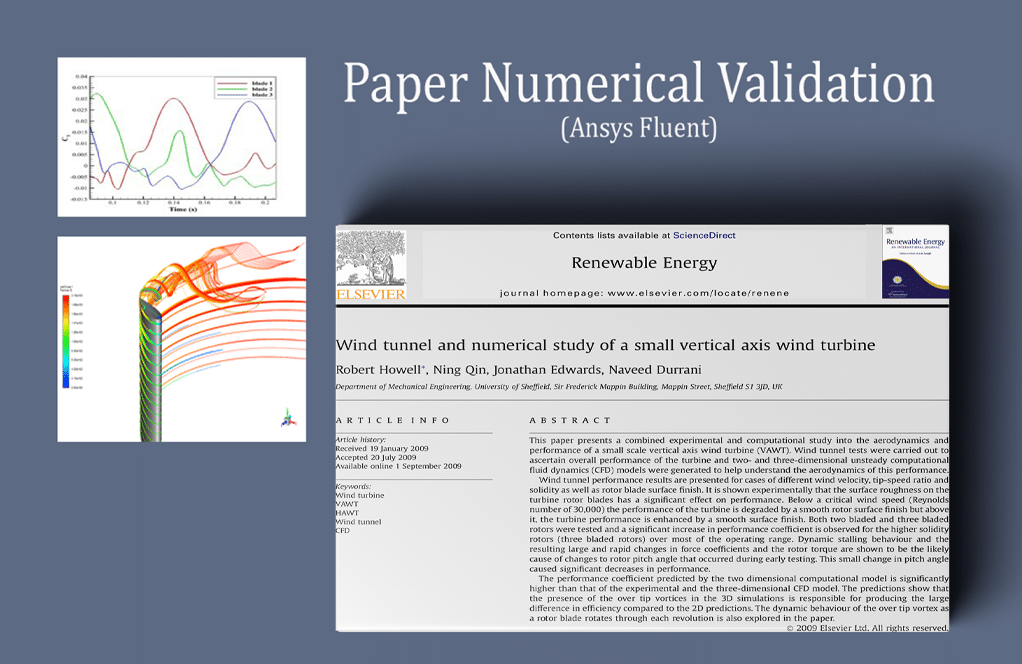

Vertical Axis Wind Turbine (VAWT), Paper Numerical Validation by ANSYS Fluent Tutorial

$320.00 Student Discount

- The problem numerically simulates Vertical Axis Wind Turbine (VAWT) using ANSYS Fluent software.

- This project is validated with a reference article.

- We design the 3-D model by the SpaceClaim software.

- We mesh the model with ANSYS Meshing software, and the element number equals 1,650,940.

- We perform this simulation as unsteady (Transient).

- We use the Mesh Motion method to define rotational motion.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

The present problem simulates the airflow passing over a Vertical Axis Wind Turbine (VAWT) by ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

The simulation is based on a reference paper, “Wind tunnel and numerical study of a small vertical axis wind turbine.” Its results are compared and validated with the results in the article.

The present model is designed in using SpaceClaim software. The generated model consists of a rectangular domain in which the rotating domain is placed.

The meshing of the model has been done using ANSYS Meshing software. The mesh type used for this geometry is structured, and the element number is 1650940.

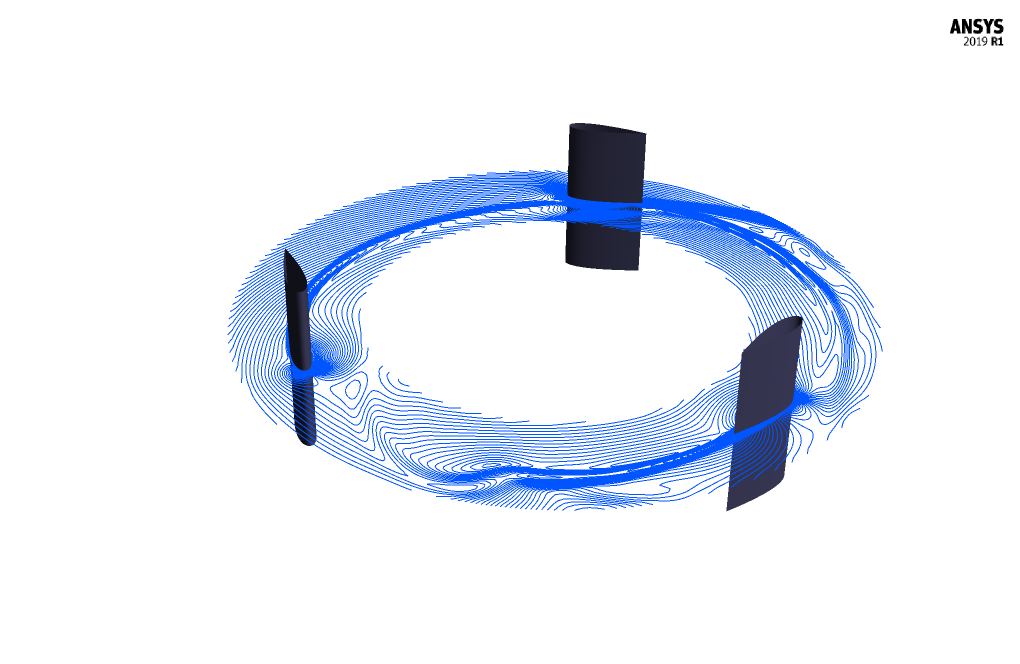

Also, the transient solver has been enabled due to the mesh motion option enabled.

VAWT Methodology

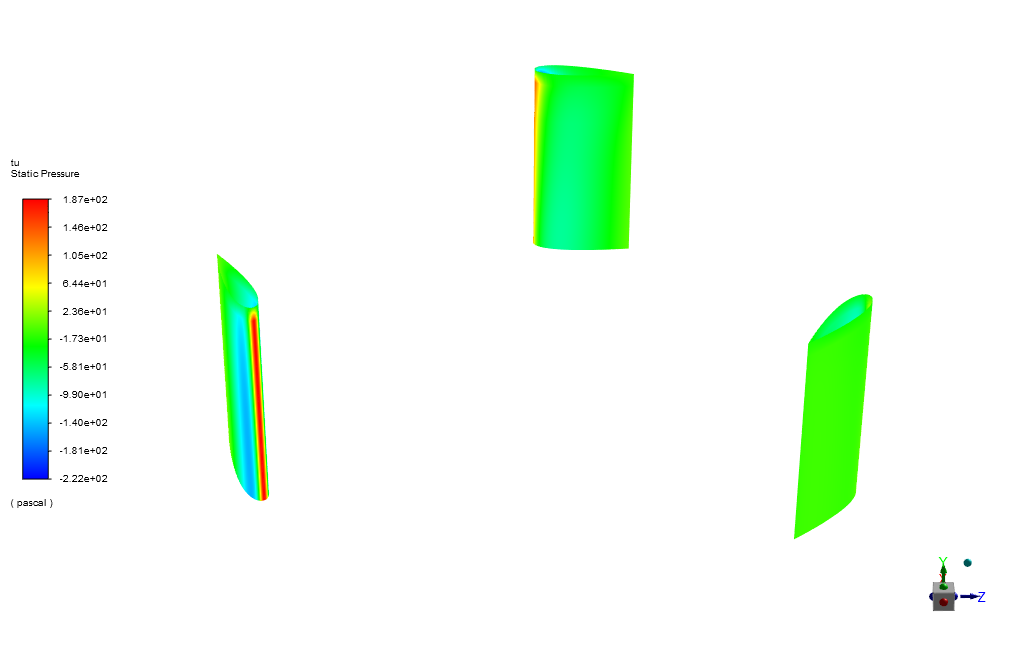

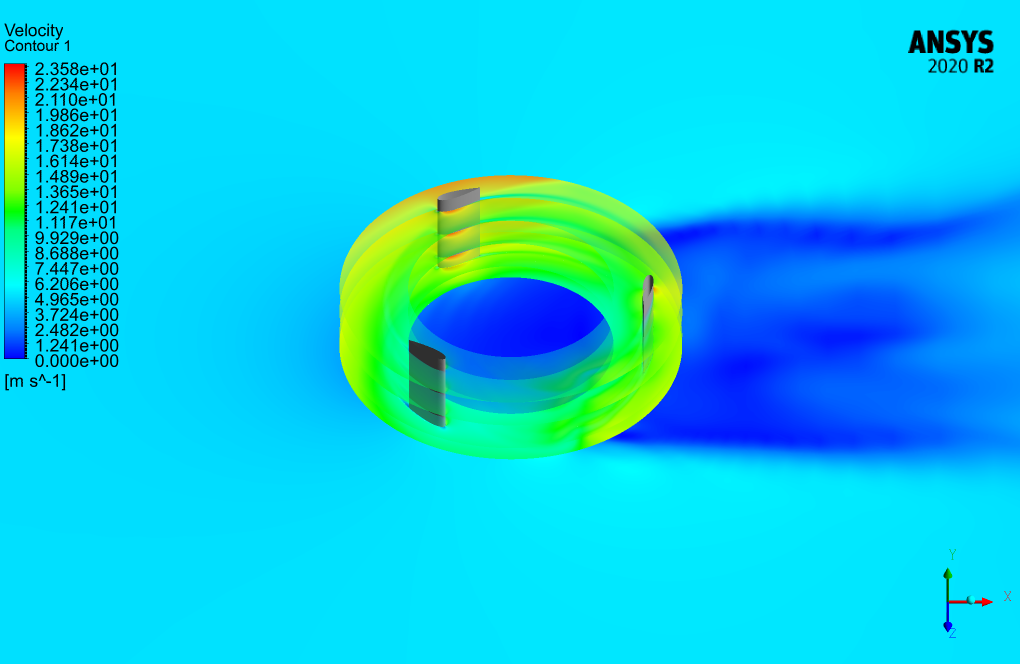

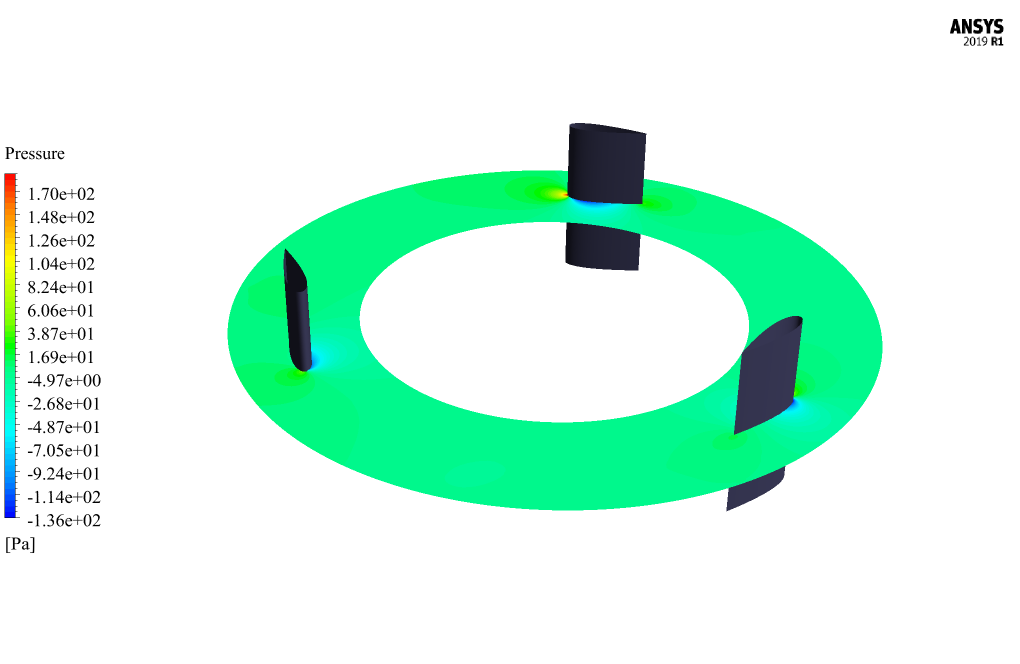

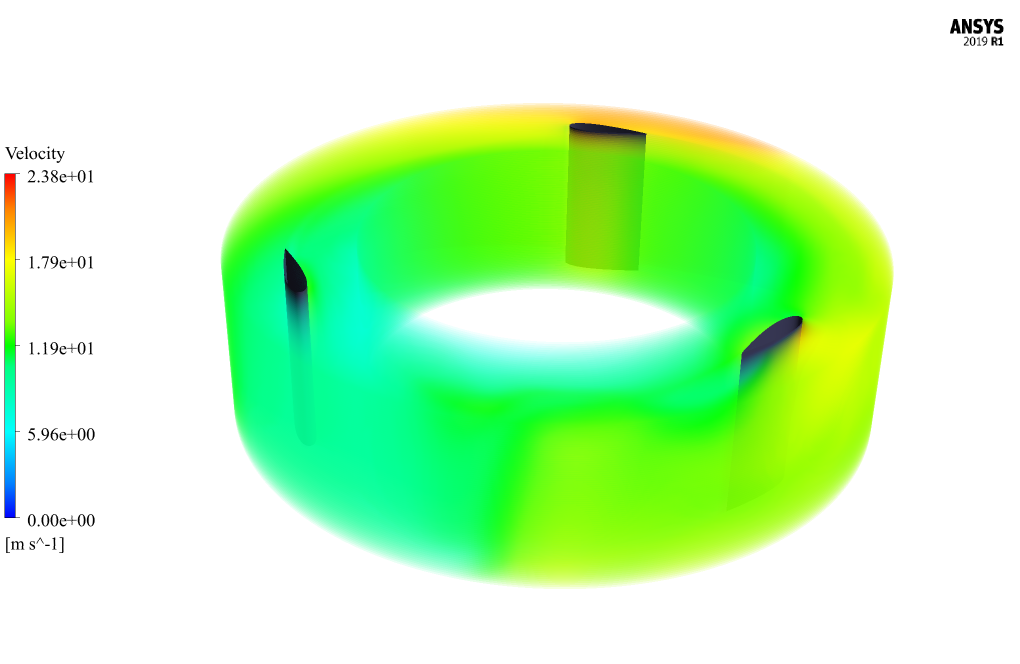

In this project, the Darrius wind turbine, a type of vertical axis wind turbine (VAWT), is simulated. The turbine consists of several curved airfoil blades mounted on a rotating shaft or framework.

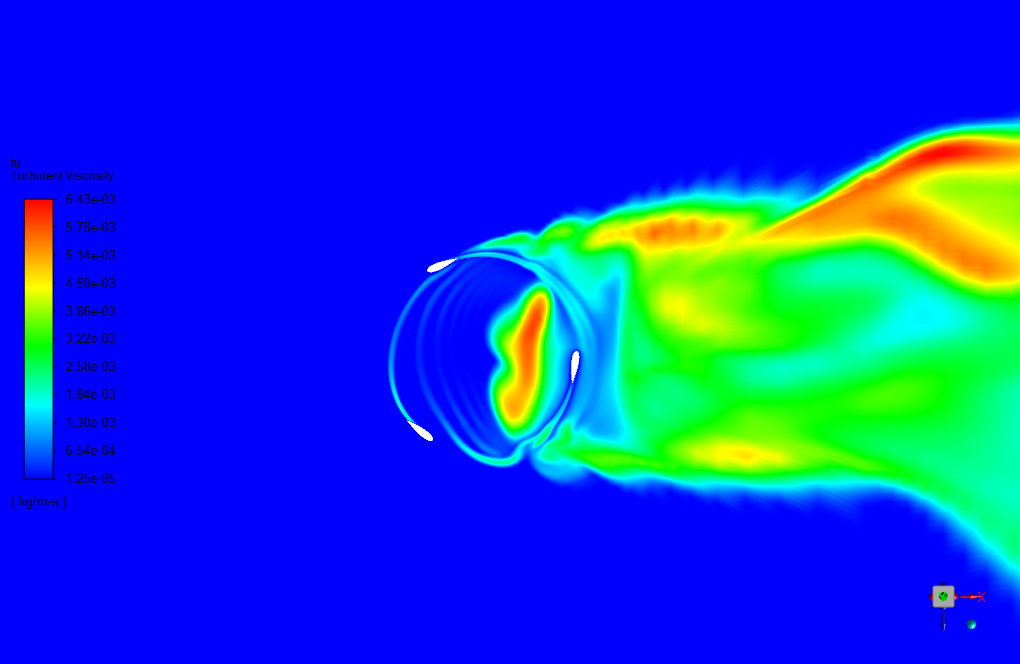

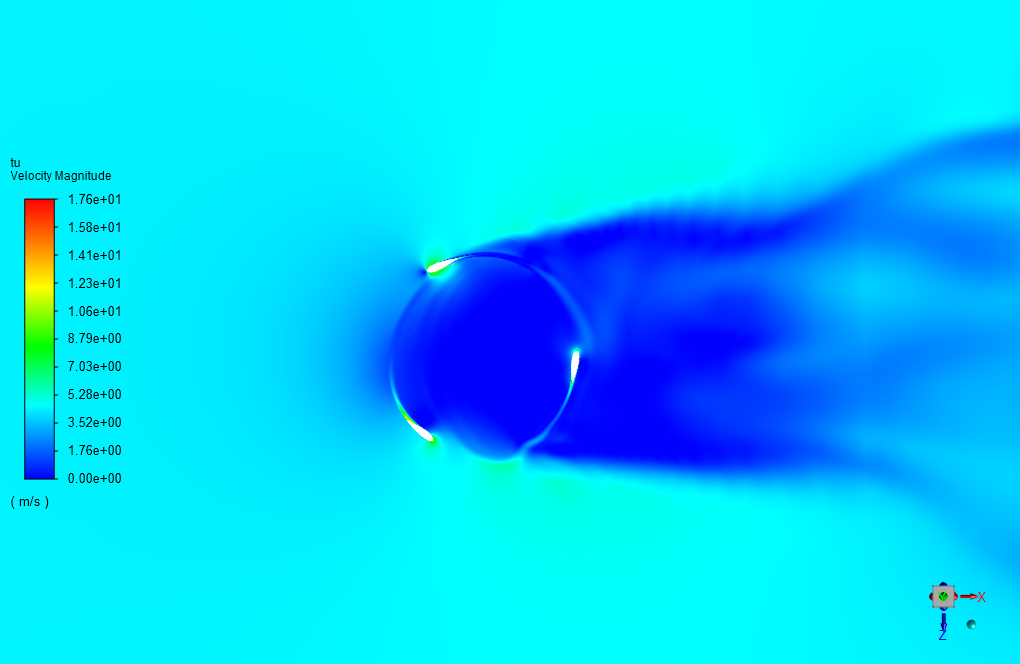

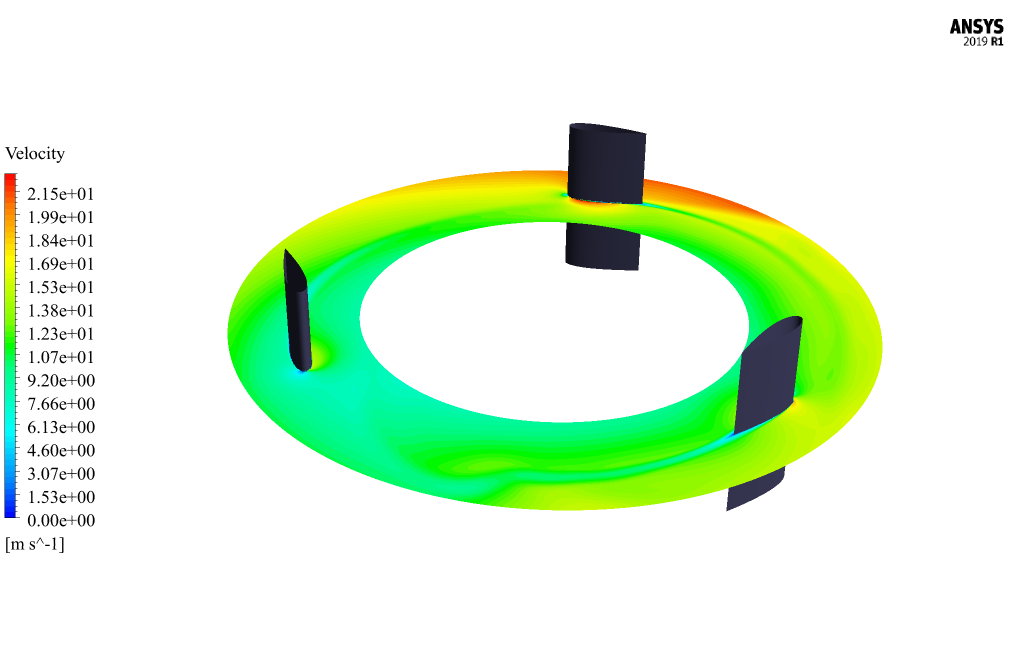

In this type of turbine, the main rotor is positioned vertically and can be installed near the ground. The airflow enters the computational domain with a velocity of 5.07m/s, and the RNG k-epsilon model is exploited to solve the turbulent flow equations, as the paper stated.

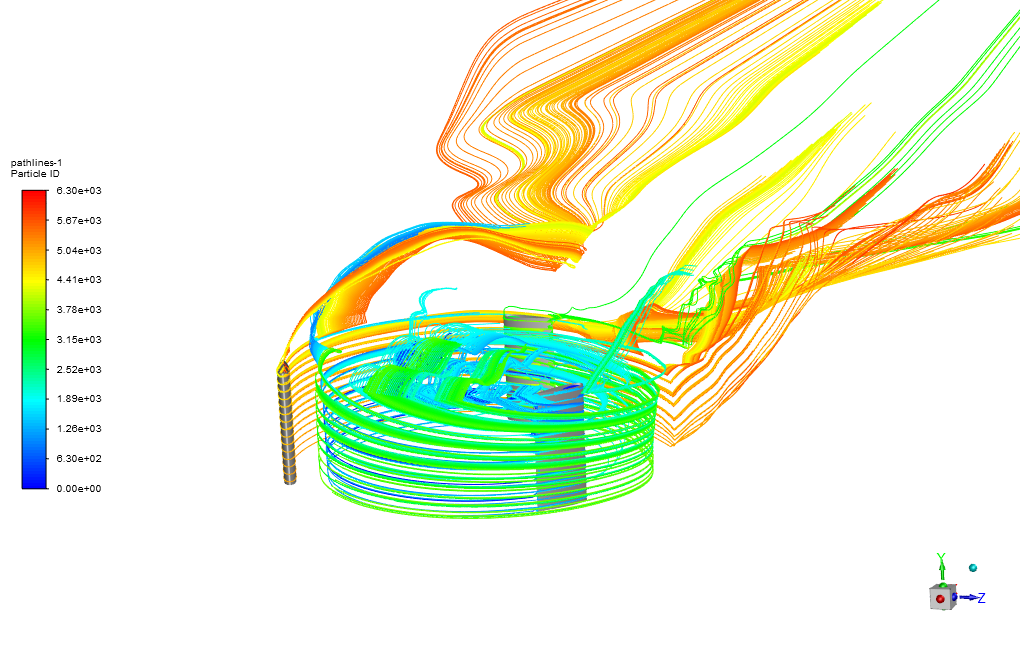

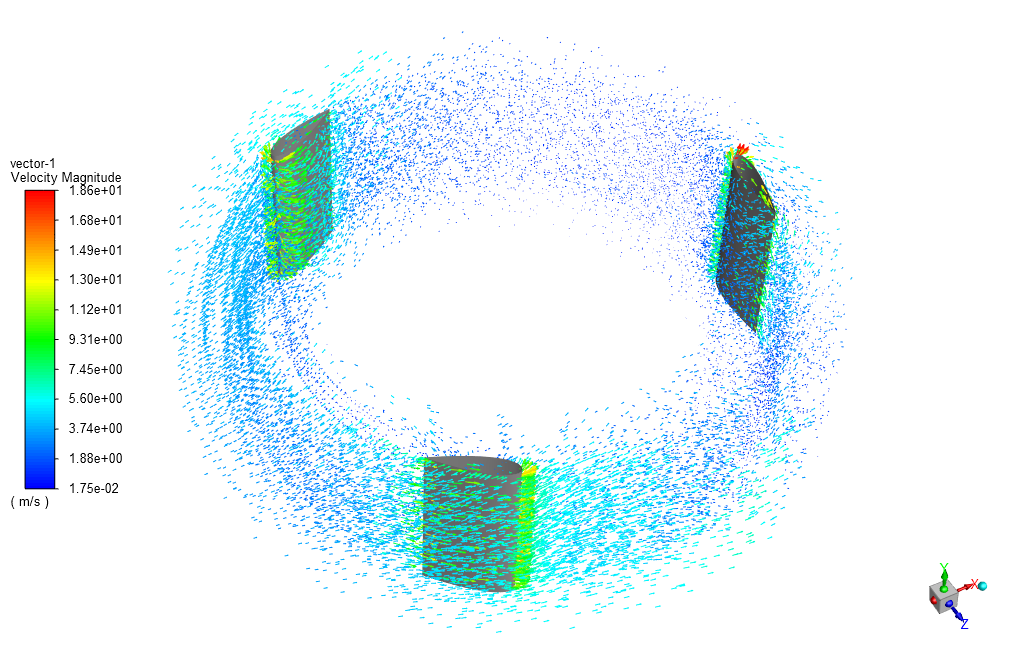

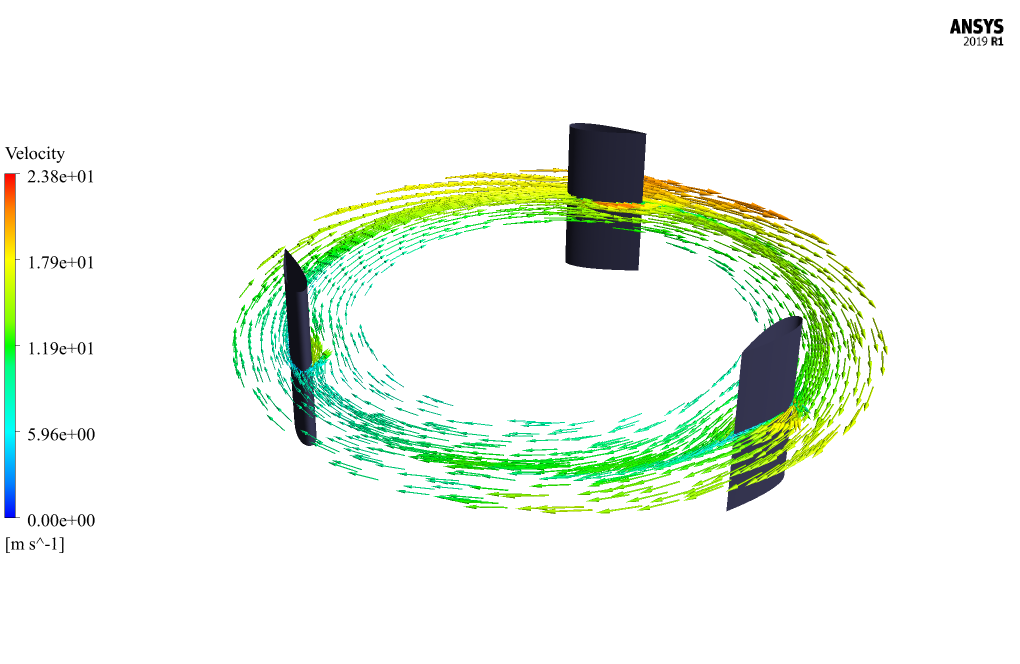

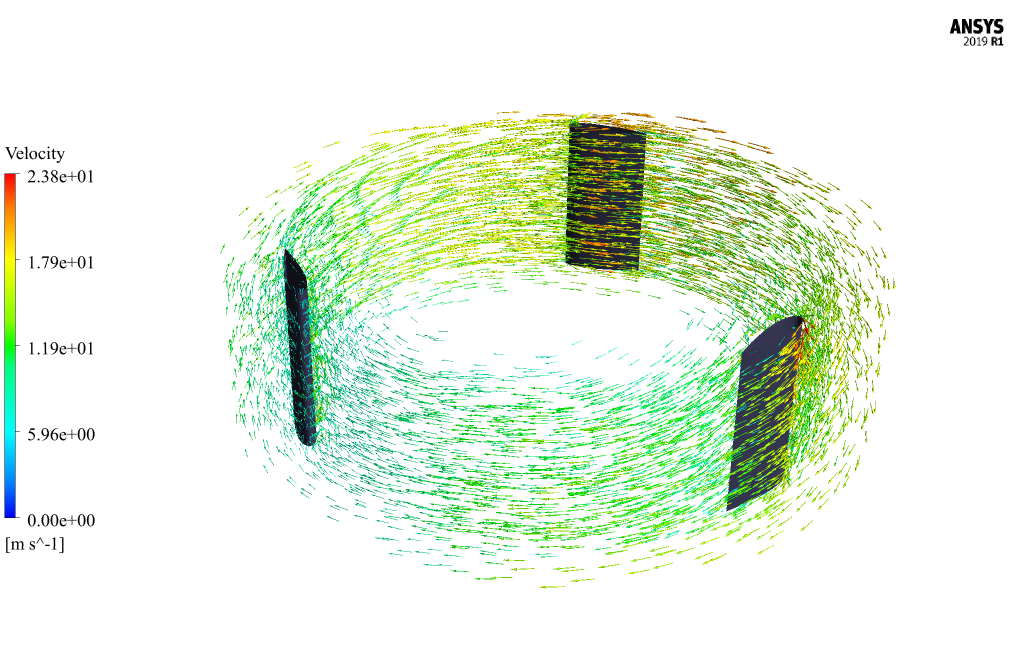

Also, it should be noted that the Mesh Motion option was enabled to simulate the rotating motion of turbine blades. The turbine blades rotate at 42.25rad/s.

VAWT Conclusion

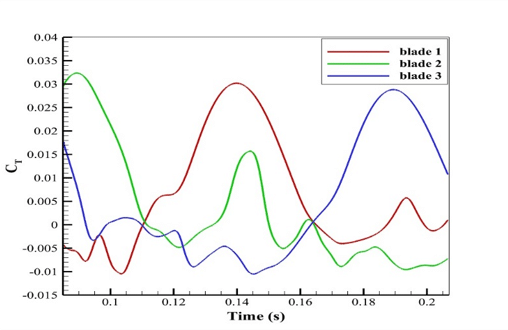

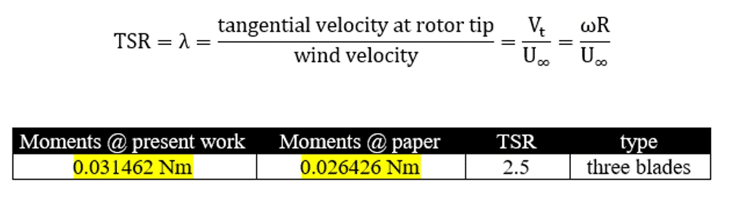

At the end of this simulation, we compared the present work results and validated them with the results obtained by the paper. For this purpose, we use the diagram in figure 14, which shows the Torque coefficient changes over time for each rotor blade.

The present work is done considering a three-blade turbine model, and the TSR value is considered equal to 2.5; The open-air velocity is equal to 5.07 m/s, the length of the blades or the radius of the turbine is equal to 0.3 m, and also the value of the rotational speed of the blades is equal to 42.25 rad/s.

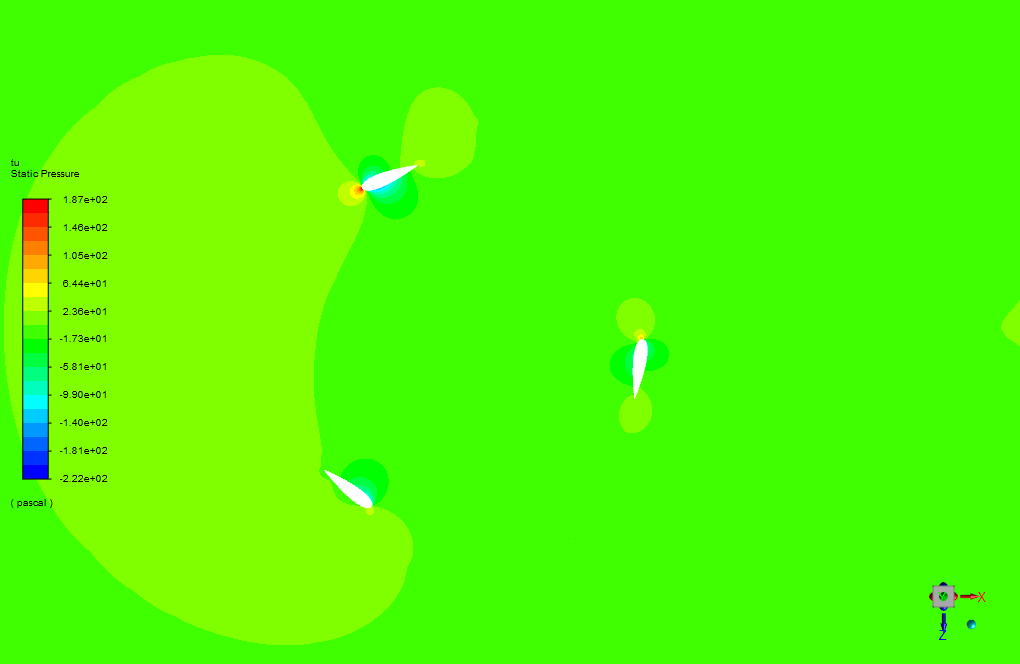

In pressure contours, due to constant variation of the blades’ position and their angle of attack, the blades’ pressure continually changes. These constant pressure changes bring up one of the significant challenges of VAWTs, which would be the dynamic stall.

Also, due to pressure changes, the blades of a VAWT are fatigue-prone due to the wide variation in applied forces during each rotation.

We can overcome these challenges by using modern composite materials and improvements in design, including aerodynamic wingtips that cause the spreader wing connections to have a static load since the vertically oriented blades can twist and bend during each turn, causing them to break apart.

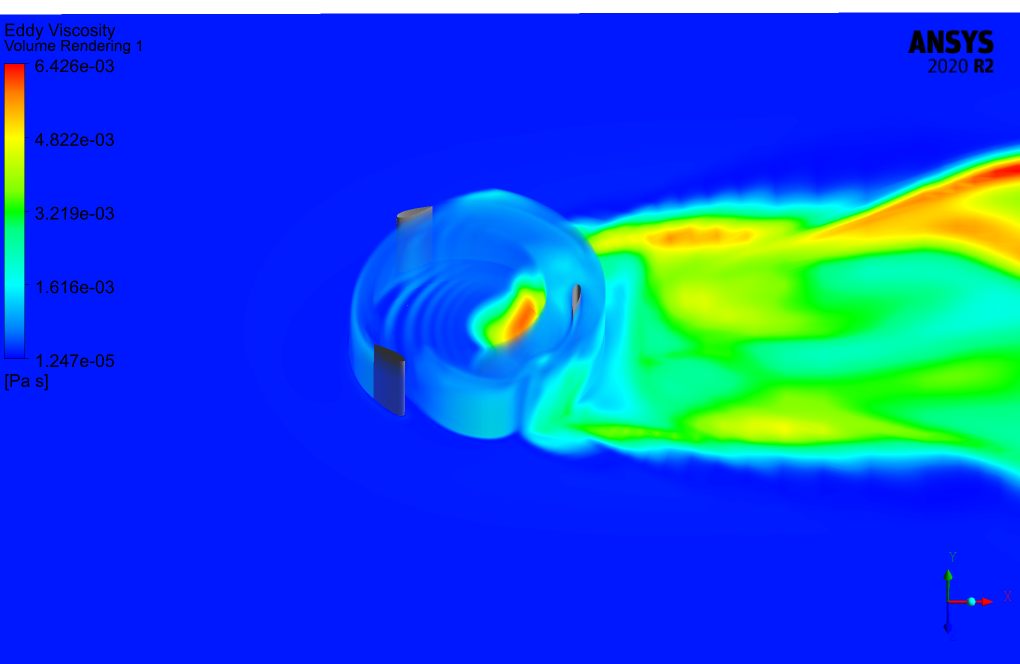

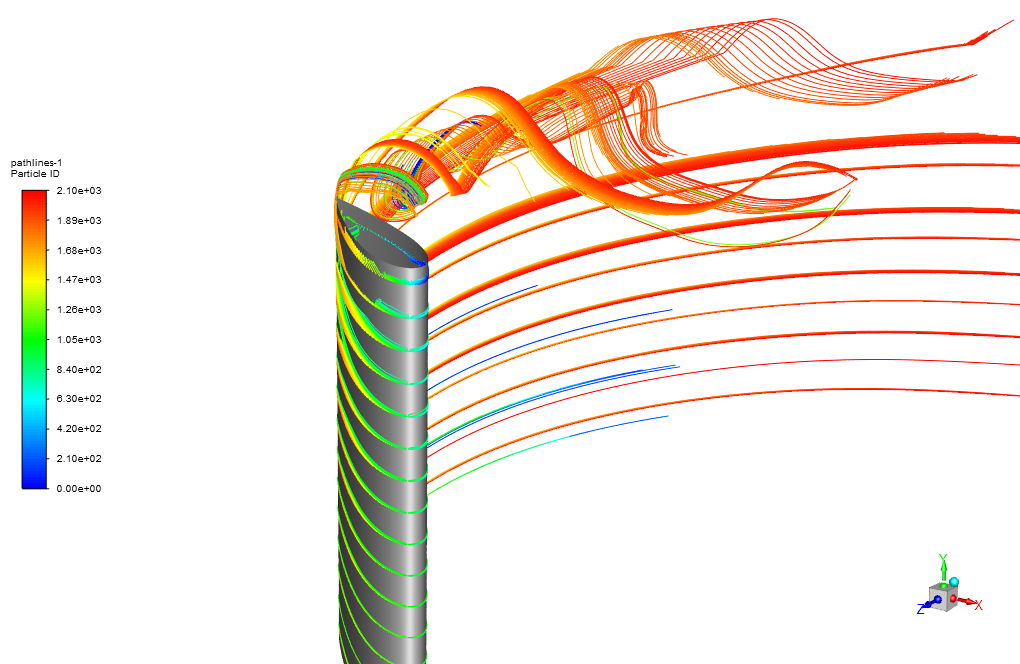

Another prominent factor regarding the rotation of VAWTs is the generation of tip vortexes on the blades’ top tip. The tip vortex’s strength is different based on each blade’s phase angle. The power of the tip vortex is a sign of lift force on each blade.

The stronger the tip vortex core, the stronger the lift force applied to the blade. This change in strength is due to the turbine rotor blade’s changing lift as it rotates through different phase angles.

We should note that there is likely to be a small delay between the maximum lift and the maximum strength of the tip vortex occurring. This will be due to the flow’s time to respond to the changing lift around the rotor blade.

Ramona Thiel I –

The attention to detail in matching the simulation parameters with the reference paper for validation is commendable. It clearly curates a reliable CFD experience.

MR CFD Support –

Thank you! It’s gratifying to know that our efforts to create precise and reliable simulations resonate with our users. We strive to deliver quality educational materials and appreciate the positive feedback.

Mr. Levi Treutel IV –

This VAWT simulation sounds very comprehensive, just one question about the validation process, were the simulation results in good agreement with those from the reference paper in terms of torque and pressure distribution?

MR CFD Support –

Yes, our simulation results showed a good correlation with the data from the reference paper regarding the torque and pressure distribution. This validates the accuracy of our CFD model for the simulation of VAWTs.

Prof. Wilton Abernathy DDS –

This VAWT simulation seems to be very comprehensive. Did the implementation of the RNG k-epsilon model for turbulence capture dynamic stall effects adequately in comparison to the paper’s results?

MR CFD Support –

In this particular simulation of the VAWT, the RNG k-epsilon model was selected based on the requirements of the referenced paper and it generally provides a good attempt at capturing dynamic stall effects. The simulation involves transient analysis which includes time-dependent features like dynamic stall. However, detailed comparison to the paper’s results is needed, involving an examination of the torque coefficient changes over time and the predicted dynamic stall occurrences, to fully determine the effectiveness of the turbulence model used in this context. Our results were benchmarked against the paper’s findings for validation, ensuring that our model behaves consistently with observed and published data.

Prof. Newton Toy Sr. –

I just completed the VAWT tutorial, and the simulations were so well-defined. It felt great to validate my simulations with the data from the referenced paper, and the entire learning experience was seamlessly enriching.

MR CFD Support –

We’re thrilled to know that the VAWT tutorial met your expectations and that you’ve had a positive and enriching learning experience. Validating your simulations against referenced papers is a great learning milestone. Thank you for taking the time to share your feedback!

Dalton Kulas –

I’m intrigued by the dynamic stall challenge mentioned for the VAWTs. Could you elaborate on how the simulation captured this aspect and if any specific analysis was performed to address the dynamic stall within the simulation?

MR CFD Support –

In this simulation, the dynamic stall is captured by using the transient solver with mesh motion to replicate the blades’ constant movement and their fluctuating angle of attack. Pressure contours were analyzed to observe the continual changes in blade pressure. Although not explicitly stated, it can be inferred that observing the variation in the pressure and lift forces over time helps identify aspects related to dynamic stall. The simulation’s ability to predict the different loading conditions on the blades as they rotate is crucial in understanding and addressing the dynamic stall phenomenon.

Dr. Connor VonRueden –

I learned a lot from this thorough tutorial. The comparisons to the reference paper’s results provided me with confidence in the simulation accuracy.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to know that our tutorial was informative and enabled you to see the accuracy of our simulation. Your trust in our content is highly appreciated!

Blake Brown –

This simulation work is incredibly detailed and does a great job comparing physical experiment results with the numerical method. Accurate validations like these really inspire confidence!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear you found the validation process detailed and convincing. Our goal is always to produce simulations that closely mirror experimental conditions for precise and actionable insights. If you have any more thoughts or need further information, please let us know!

Abbie Jacobson –

This product gave me an in-depth understanding of the dynamics involved in the simulation of VAWTs. I was particularly impressed with how well the simulation results aligned with those from the referenced paper, which added credibility to my own findings. It was an excellent tutorial for anyone looking to delve into the complexities of wind turbine simulation and understand the key aspects like torque coefficient changes, dynamic stall, and tip vortexes. Thank you for a great learning experience!

MR CFD Support –

Thank you for your positive feedback! It’s a delight to hear that our Vertical Axis Wind Turbine tutorial was enriching and clarified the intricacies of such complex simulations. We strive to deliver accurate and validated results to help our customers, and it’s satisfying to know we achieved this with you. Should you have more curious ventures into the world of CFD, we are always here to assist with high-quality learning resources. Again, thank you for choosing our product, and we look forward to supporting your future educational endeavors!

Dr. Ayden Rath –

I am really impressed with the level of validation and comparison with reference material in this tutorial. The attention to detail, thorough methodology, and comprehensive conclusion clearly indicate this is a valuable resource for learning how to perform complex CFD analyses on VAWTs. It’s also impressive how you’ve addressed potential challenges like dynamic stall and blade fatigue.

MR CFD Support –

Thank you so much for your kind words! We strive to ensure our tutorials are as informative and thorough as possible. We’re delighted to hear that you appreciate the detail and accuracy in our comparison and validations. Understanding the dynamics of VAWTs can be complicated, but we aim to make it more accessible. Your feedback is very encouraging to our team!

Vallie Howell I –

I am so impressed with the detail and the methodology used to validate the VAWT simulation against the reference paper. The challenges highlighted, such as dynamic stall and blade fatigue, showcase a deep understanding of the physical phenomena involved. Great job on illustrating both the simulation process and the practical implications of the findings!

MR CFD Support –

Thank you for your kind words and for recognizing the efforts involved in our simulation of the Vertical Axis Wind Turbine (VAWT). We strive to provide thorough and accurate analyses, and your feedback is greatly appreciated. If you need further information or have any questions about our products and methods, feel free to ask!

Patience Lueilwitz –

The VAWT tutorial was incredibly detailed and the validation with the reference paper added credibility. Thank you for the excellent explanations on how aerodynamics play a role in VAWT energy production efficiency.

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear that our Vertical Axis Wind Turbine tutorial met your expectations and provided helpful insights. Your appreciation for the detail and validation steps encourages us to continue delivering high-quality educational content. If you have any more questions or need further assistance, please don’t hesitate to reach out.

Dr. Bryce McLaughlin –

This tutorial sounds great! I’m impressed with how comprehensive the simulation is, especially with mesh motion and pressure change considerations. It’s especially exciting to see the critical challenges of VAWTs such as dynamic stall and fatigue addressed through simulation. Validation against a reference paper adds a lot of confidence in the results!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you appreciate the depth and detail of the VAWT simulation tutorial, especially the incorporation of reference paper validation for accuracy. If you have any further questions or need assistance, don’t hesitate to reach out.