Heat Sink Cooling Performance Using Water and Nanofluids (TiO₂, SiO₂, Fe₃O₄) in ANSYS Fluent

$160.00 $64.00 HPC

- This project presents a numerical study of heat transfer in a heat sink using ANSYS Fluent.

- Four cases were simulated, including pure water (single-phase) and three nanofluids (water mixed with TiO₂, SiO₂, and Fe₃O₄) using the mixture multiphase model.

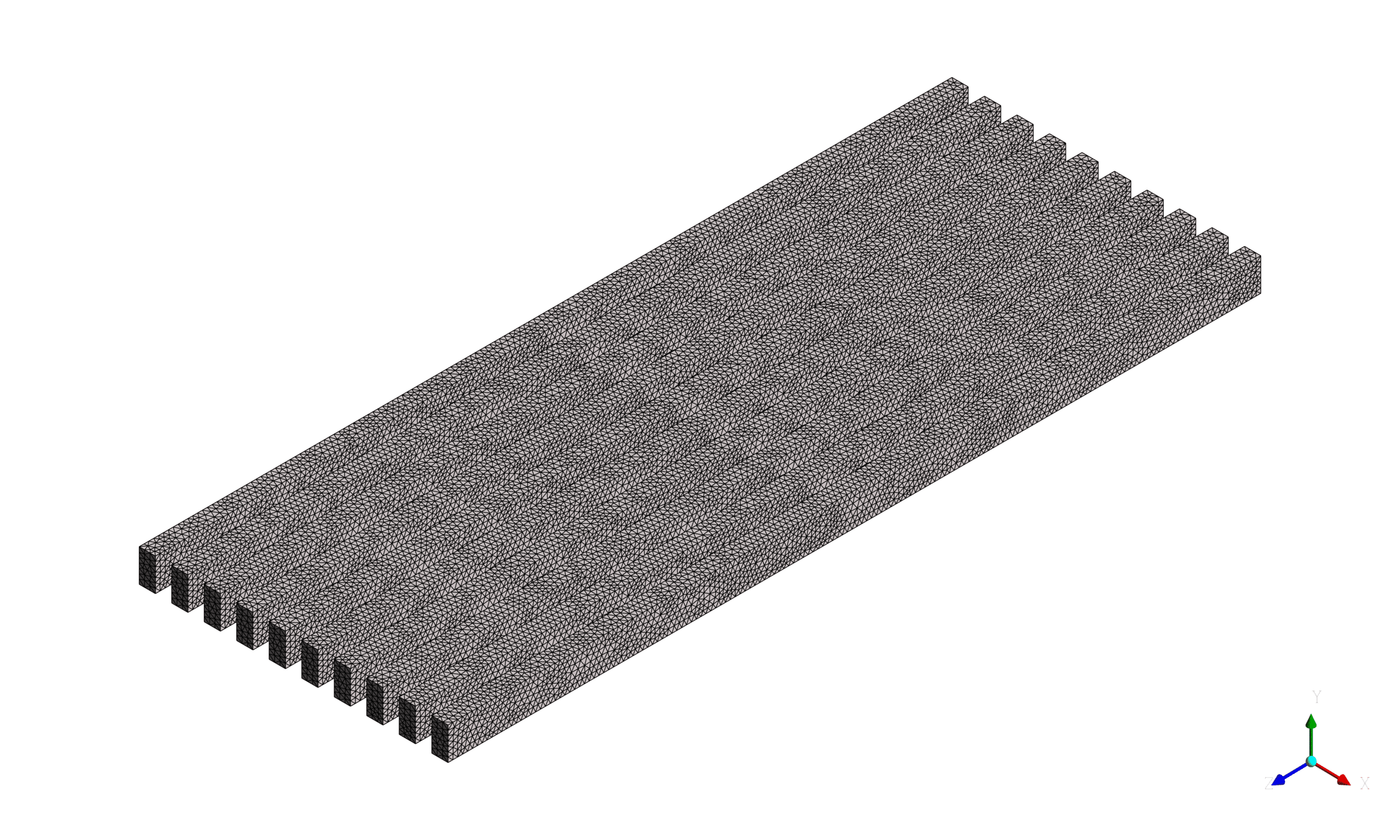

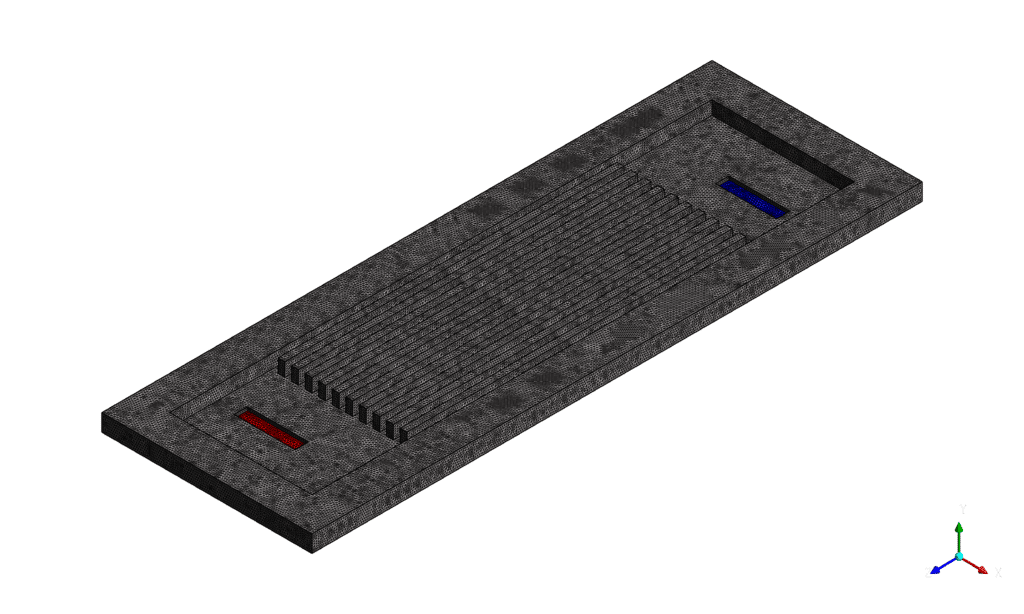

- The geometry was created in ANSYS DesignModeler, and a high-quality mesh of about 1.6 million elements was generated.

- A pressure-based, steady-state solver with the SIMPLE algorithm was applied. The results, illustrated in contour plots of velocity and temperature, show that nanofluids enhance cooling efficiency compared to pure water.

- Among the tested fluids, the Fe₃O₄–water mixture demonstrated the best thermal performance at the fins and base plate, highlighting its potential for advanced heat sink applications

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Heat Sink Cooling Performance Using Water and Nanofluids (TiO₂, SiO₂, Fe₃O₄) in ANSYS Fluent

Project Description

This project focuses on the numerical analysis of heat transfer and fluid flow through a heat sink using ANSYS Fluent. The primary objective was to investigate the influence of different working fluids, including water and nanofluids, on cooling performance. Four cases were examined: Case 1 with water (single-phase), Case 2 with water + TiO₂, Case 3 with water + SiO₂, and Case 4 with water + Fe₃O₄. For the nanofluid cases (Cases 2–4), the mixture multiphase model was used, with water defined as the primary phase and nanoparticles as the secondary phase.

The governing equations were solved under steady-state conditions using a pressure-based solver. The study aimed to compare velocity fields, temperature contours, and thermal distributions in solid and fluid regions. Numerical results in Table 1 (from Report.docx) summarize the values for the flow zone, solid zone, fin zone, and base plate across different cases.

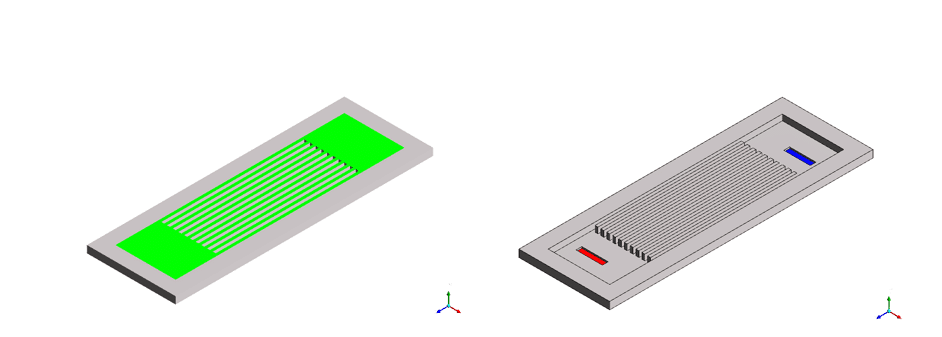

Geometry and Mesh

The computational domain represents a heat sink structure, consisting of one fluid zone and two solid zones (the base plate and fins). The geometry was created in ANSYS DesignModeler (Figure 1), providing a detailed model of both fluid and solid regions to capture the heat transfer process.

Figure 1: Geometry of heat sink

The meshing was performed in ANSYS Meshing, resulting in a high-quality mesh of approximately 1.6 million elements. The generated mesh, shown in Figure 2, captures small geometric details and ensures high accuracy in predicting flow and temperature gradients while maintaining reasonable computational cost.

Figure 2: Mesh of heat sink

Setup

The solver used was pressure-based and steady-state. For Case 1, a single-phase flow model was applied. For Cases 2 to 4, the mixture multiphase model was implemented to capture the interactions between water and nanoparticles (TiO₂, SiO₂, and Fe₃O₄). The SIMPLE algorithm was used for pressure–velocity coupling. Discretization schemes were carefully selected to minimize numerical diffusion.

Boundary conditions:

Inlet: Velocity inlet with 1.96 m/s

Outlet: Pressure outlet

Walls: No-slip condition with appropriate heat flux/temperature boundary assigned

The SIMPLE algorithm was used for pressure–velocity coupling. Discretization schemes were carefully selected to minimize numerical diffusion.

Results

The contour plots of temperature and velocity provide insight into flow and thermal behavior.

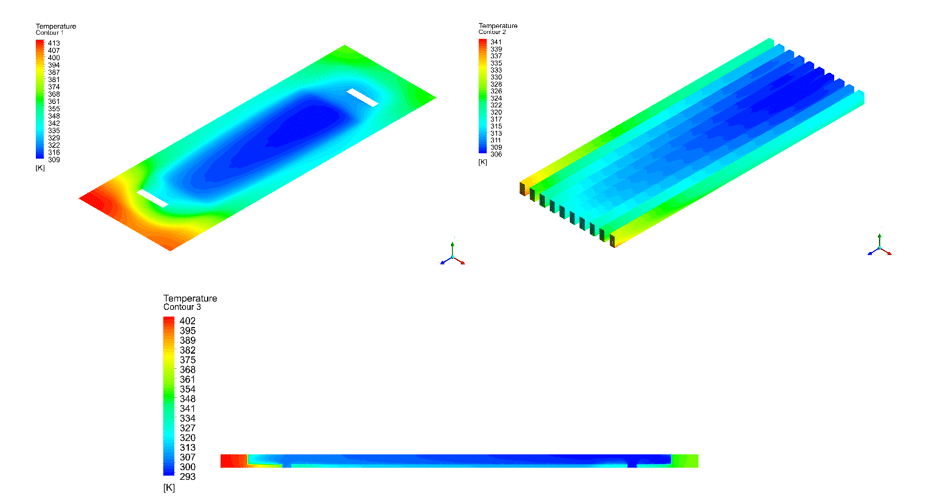

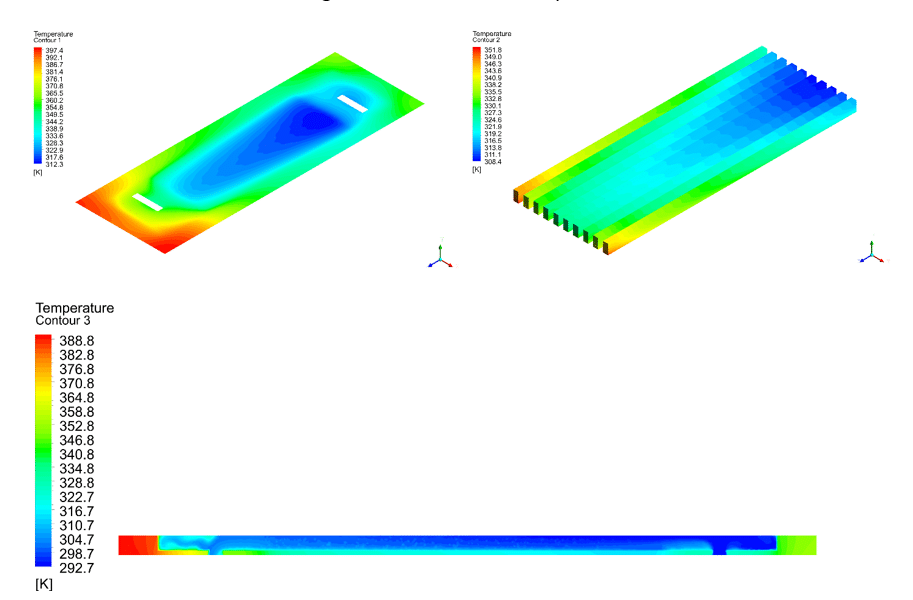

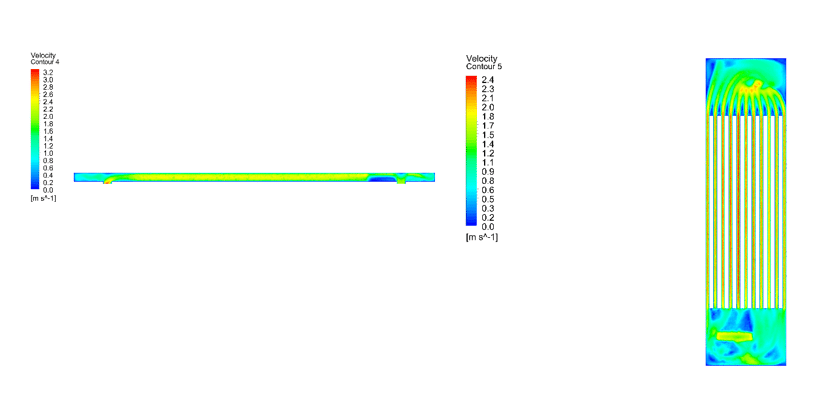

Figures 3 and 4 show the temperature and velocity distribution for Case 1 (water). These results serve as the baseline for comparison.

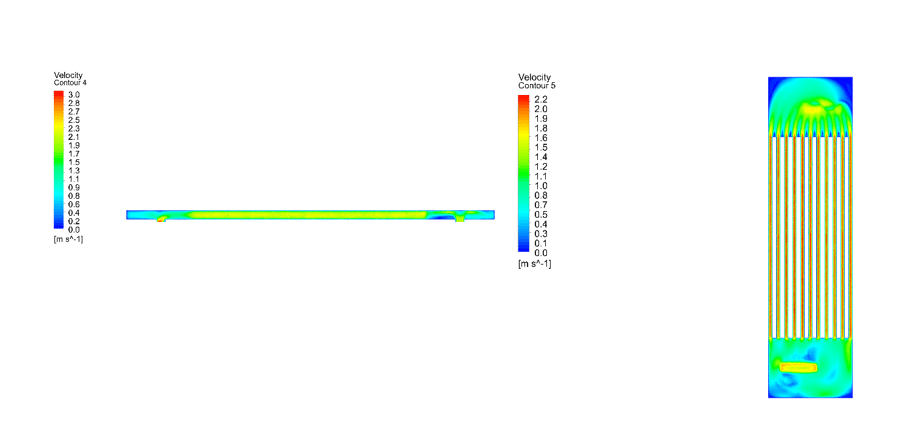

Figures 5 and 6 illustrate the contours for Case 2 (water + TiO₂). Improved heat dissipation is observed compared to pure water.

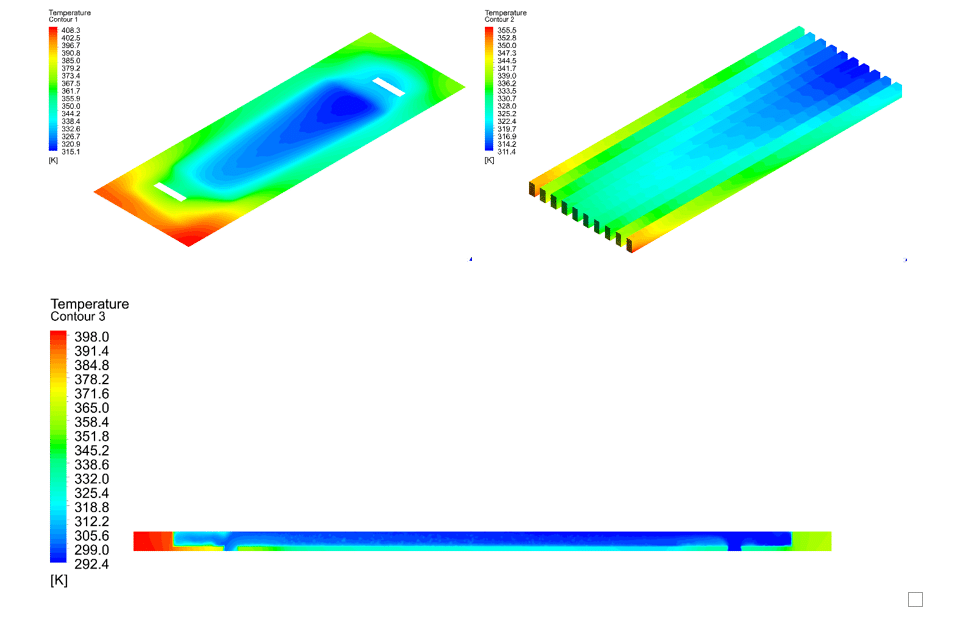

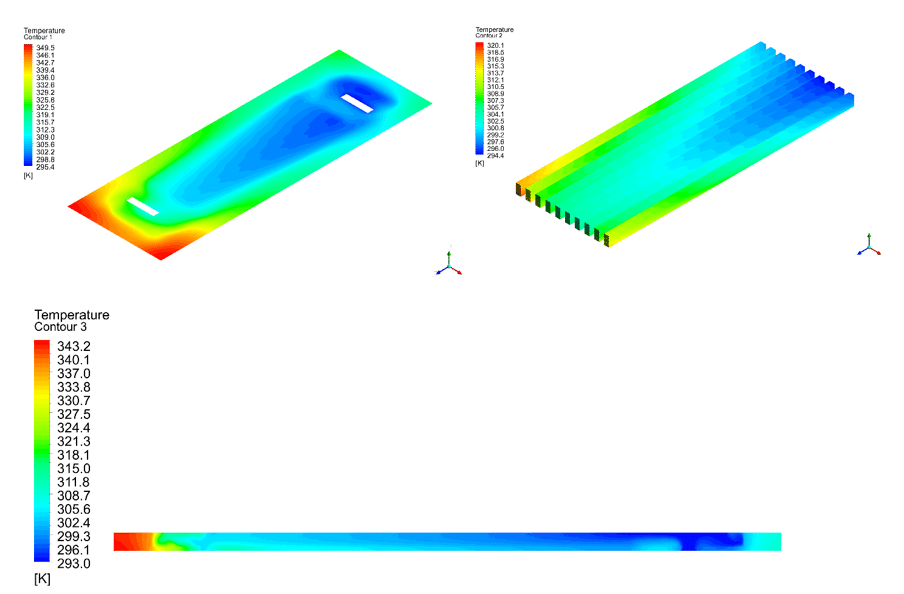

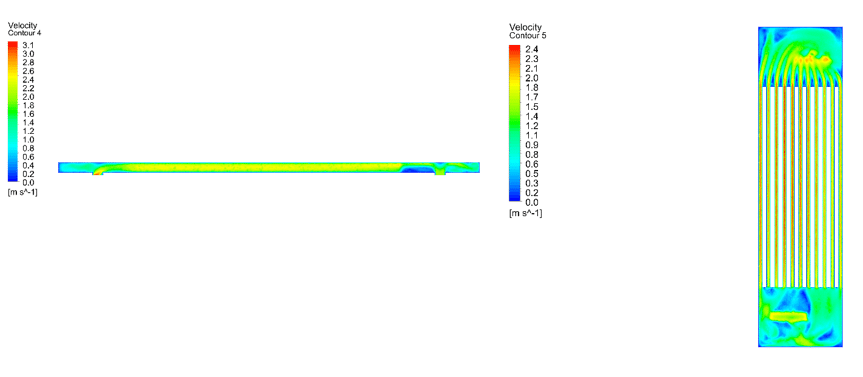

Figures 7 and 8 present the results for Case 3 (water + SiO₂), where better cooling performance is achieved due to the enhanced thermal conductivity of SiO₂ nanofluids.

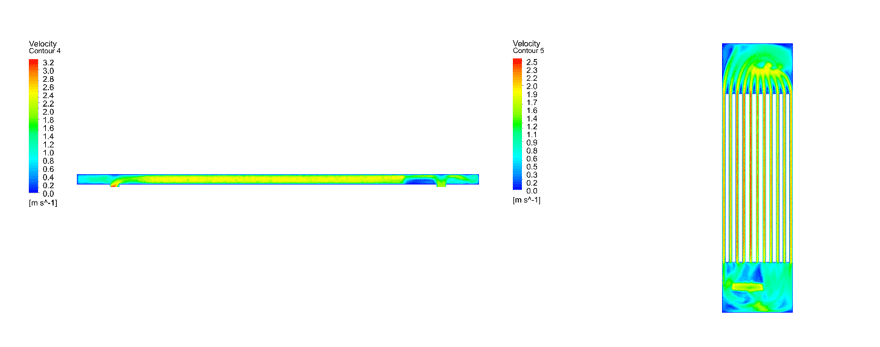

Figures 9 and 10 (velocity contour mislabeled as Figure 9 in the file) display the outcomes for Case 4 (water + Fe₃O₄), which showed considerable improvement in temperature reduction near the fins and base plate.

According to the summarized values in Table 1, the addition of nanoparticles led to reduced temperature in both the fin zone and the base plate compared to water alone. The heat distribution becomes more uniform with nanofluids, highlighting their effectiveness in enhancing cooling.

Table 1: Temperature at Zones and Base Plate

| Zone or BC | Cas1 | Cas2 | Cas3 | Cas4 |

| flow | 305.9175 | 306.4476 | 307.5105 | 305.0758 |

| solid Zone | 352.3579 | 361.5206 | 355.1456 | 319.7477 |

| fin Zone | 314.7335 | 326.4342 | 323.0922 | 303.2734 |

| Base Plate | 341.3839 | 351.2952 | 345.6522 | 314.7217 |

Figure 3: Contour of Temperature Cas1

Figure 4: Contour of Velocity cas1

Figure 5: Contour of Temperature Cas2

Figure 6: Contour of Velocity cas2

Figure 7: Contour of Temperature Cas3

Figure 8: Contour of Velocity cas3

Figure 9: Contour of Temperature Cas4

Figure 10: Contour of Velocity Cas4

Conclusion

The numerical simulations conducted in ANSYS Fluent demonstrated that nanofluids significantly improve heat sink performance compared to water alone. Pure water (Case 1) serves as the baseline coolant, but Cases 2, 3, and 4 reveal that adding TiO₂, SiO₂, and Fe₃O₄ nanoparticles enhances thermal conductivity, leading to better heat dissipation.

Among the tested fluids, Fe₃O₄–water nanofluid (Case 4) exhibited the most effective cooling performance in terms of temperature reduction at the base plate and fins, followed closely by SiO₂–water (Case 3) and TiO₂–water (Case 2). These results confirm the potential of using nanofluids as advanced coolants in heat sink applications, offering valuable improvements for thermal management in electronics and industrial systems.

You must be logged in to post a review.

Reviews

There are no reviews yet.