Solar Desalination Considering Surface Evaporation CFD Simulation, ANSYS Fluent Training

$220.00 Student Discount

- This problem simulates the HVAC of an operating room by ANSYS Fluent software.

- The geometry of the present model is drawn by Design Modeler software and then meshed by ANSYS Meshing software.

- It’s a Structured mesh, and the cell number equals 938174.

- The VOF multiphase model is used for three phases: air, water vapor, and water fluid.

- Mass Transfer is applied to simulate Evaporation/Condensation.

- Also, a UDF file is used to determine the Surface Evaporation.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

This simulation is about surface evaporation in solar desalination via ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

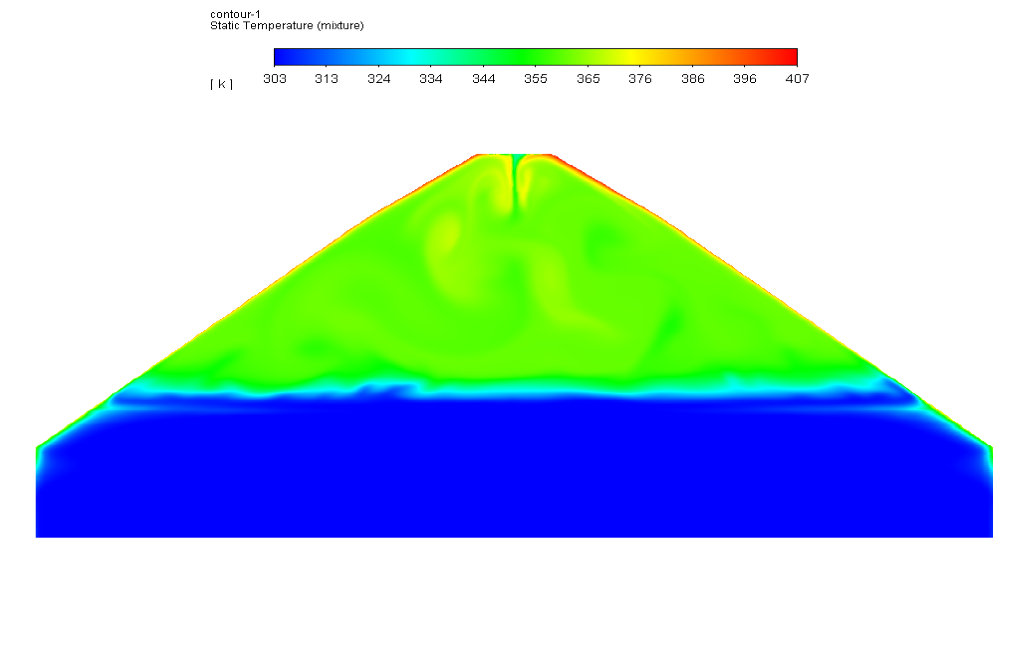

A simple solar still is designed in this simulation, consisting of inclined glass plates. Solar rays pass through the glass and reach the water’s surface inside the system. Heating the water surface causes surface evaporation.

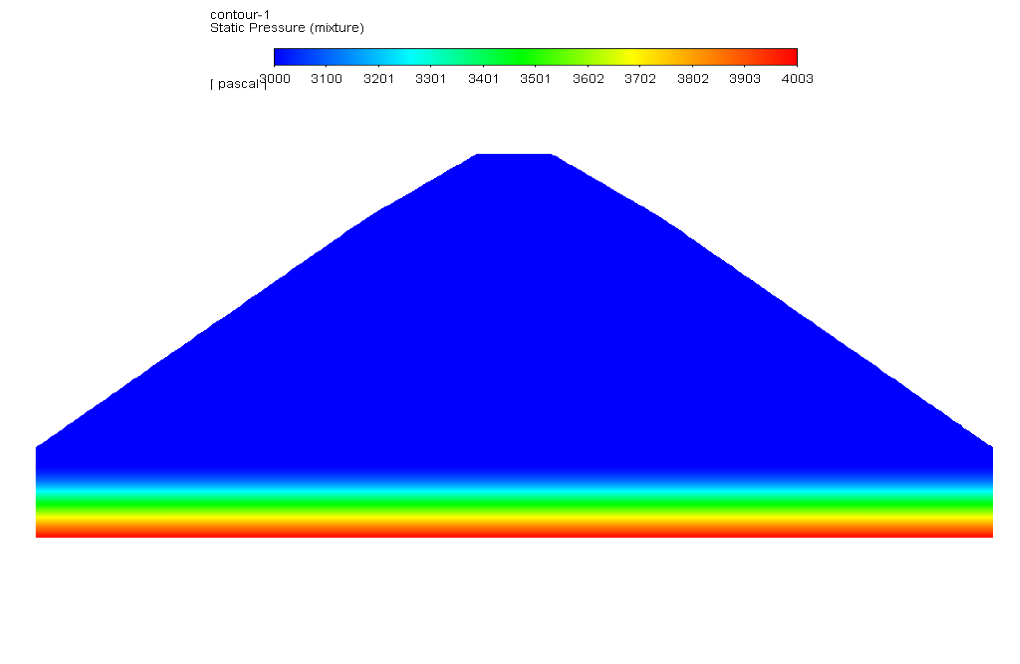

The produced steam is pure and impure materials settled at the bottom of the system. This pure steam hits the inner surface of the inclined glass and causes condensation by losing heat. The slope used for the glasses causes the drops of distilled water to slide on the surface of the glass and be directed to the system’s outlet.

The geometry of the present project is modeled in three dimensions with Design Modeler software. Then the model meshed with ANSYS Meshing software. The model’s grid is structured, and 938,174 cells have been created.

Methodology: Surface Evaporation considering Solar Desalination

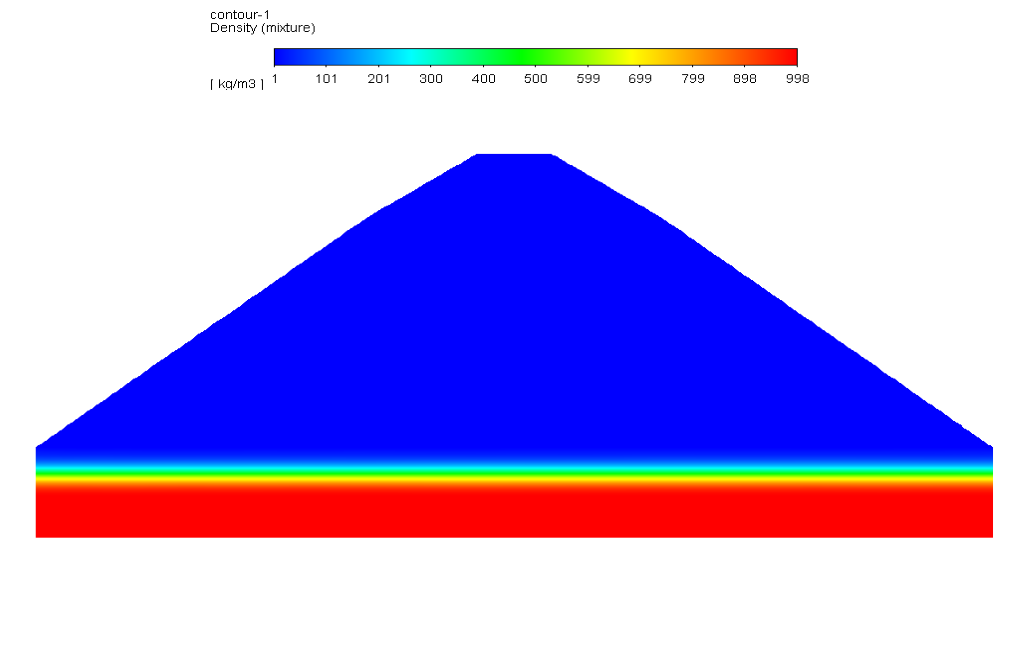

In this simulation, three different phases are used. In the initial state, the system is filled with air, and water is up to a certain level. After the solution process starts, the water gradually evaporates from the surface and creates vapor. So, to define the three phases simultaneously, it is necessary to use the Multiphase Model.

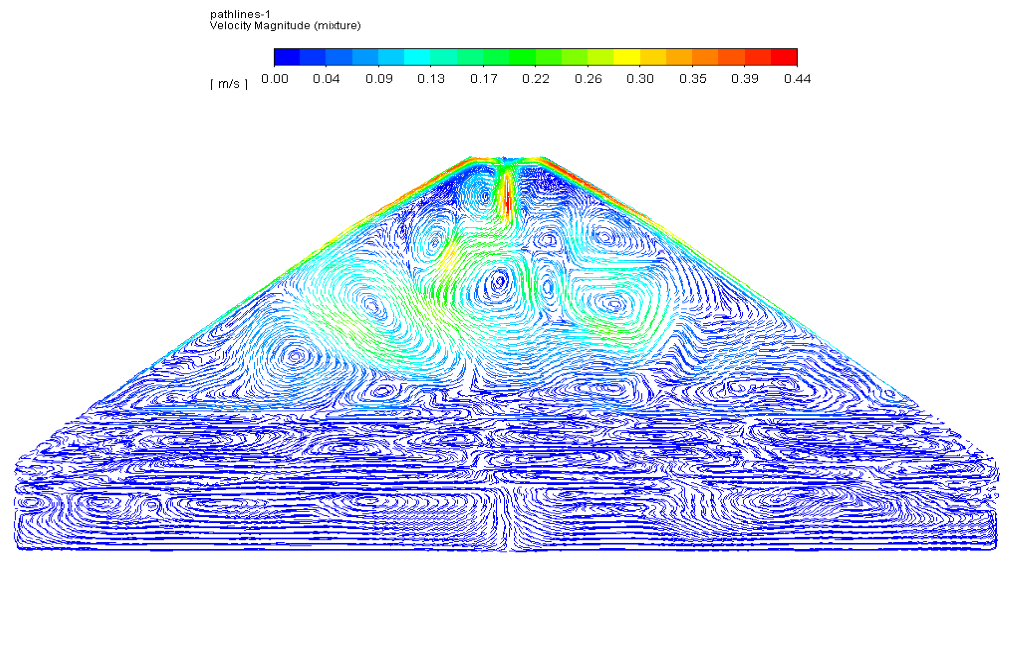

The VOF (volume of fluid) model has been used to define the multiphase model. This multiphase model can completely separate different phases from each other and display a distinct boundary between phases. Also, since the separation boundary between the two phases does not have a layer transition, the Sharp option has been used to interface between the phases.

Water liquid is defined as the primary phase of the model, and air and water vapor are defined as the secondary phases of the model. When the multiphase model is used, a parameter called volume fraction is provided for the secondary phases of the model to solve their transport equations.

Since a phase change occurs between the water and vapor phases, a Mass Transfer between these two phases is defined. This mass transfer is defined based on the Evaporation-Condensation mechanism. This mechanism deals with the phase change process between liquid and vapor.

A UDF function defines the rate of evaporation (water to steam). The equation used in this function is equivalent to the surface evaporation rate. The characteristic of surface evaporation is that it only happens on the surface of the water’s level, and it is possible at a temperature lower than the saturation temperature. At the same time, boiling is a volumetric phenomenon and only happens at the saturation temperature.

Conclusion

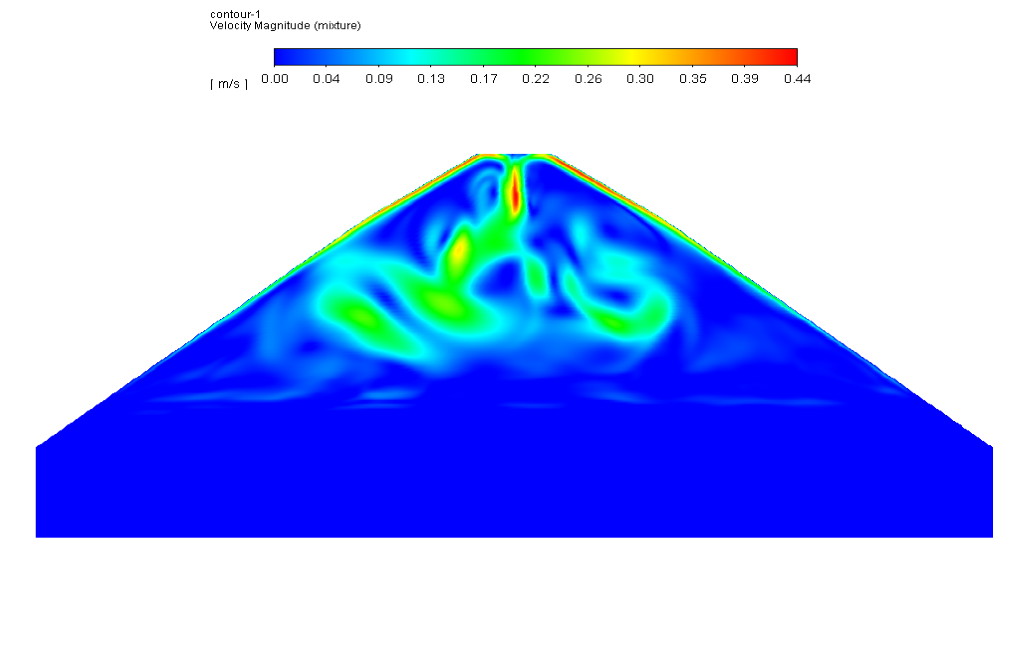

After solving, the contours of temperature, pressure, and volume fraction of each water, air, and vapor phase have been obtained. The results correctly show that the water starts to evaporate from the surface with time. For this reason, the water level decreases over time.

In addition, the results show that the mass transfer does not necessarily occur at the saturation temperature. So, it can be said that the surface evaporation mechanism based on the definition of the UDF has worked correctly.

Trevion Goyette –

cool

Kurt Jenkins –

With this training, I was able to learn Mass Transfer, Multi-Phase Flow, Renewable Energy, UDF and VOF at the same time.

Thanks to MR-CFD

Glenda Reichert –

So proud of you Mr-CFD 🔥👏

Modesto Armstrong –

What is the benefit of using CFD for analyzing the evaporation process in solar desalination systems?

MR CFD Support –

CFD allows for detailed analysis of the heat and mass transfer processes in solar desalination systems, providing insights that cannot be easily obtained through experimental tests.

Ferne Kutch –

Can this simulation be customized to model the evaporation process in different types of desalination systems and under different conditions?

MR CFD Support –

Yes, we can accommodate your desired simulations. Please share more details about your specific requirements.

Maia Heidenreich IV –

This is so informative

Meda Harber DDS –

The use of CFD in this simulation is truly innovative!

Katlyn Strosin –

I’ve been greatly intrigued by the simulation of surface evaporation in solar desalination using ANSYS Fluent. However, I’m wondering if the simulation takes into account the variation in solar radiation intensity throughout the day, and how such temporal changes might affect the evaporation rate in this model?

MR CFD Support –

In the described CFD project, a simplified model of solar desalination has been simulated. While the product description effectively demonstrates the basic mechanics, evaluating the impact of variable solar radiation intensity isn’t clearly stated. When using such a model in a real-world setting, it is indeed important to consider changes in solar intensity. This can be integrated into the simulation by implementing time-dependent boundary conditions to reflect the variability of solar irradiance. For this particular training scenario, if the variability isn’t acknowledged, it suggests that either a constant average solar intensity has been assumed for the sake of simplicity or that aspect of the model may need further refinement for more accurate performance predictions under real-world solar conditions.

Zakary Block MD –

The methodology in the description uses a UDF for evaporation rate, but how is the rate of condensation defined on the inner surface of the glass?

MR CFD Support –

The rate of condensation on the inner surface of the glass is not explicitly mentioned in the description. However, the process likely utilizes ANSYS Fluent’s heat transfer models in conjunction with the VOF model for phase change, where temperature and heat flux at the surface would dictate the rate of condensation. For an accurate response, please check with MR CFD for their specific approach.

Alyce Koelpin –

The detailed approach for surface evaporation in the solar desalination simulation is quite impressive! It’s clear a lot of thought went into making sure the process was accurately depicted.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you’re impressed with the thoroughness and accuracy of the simulation process for solar desalination and the mechanism of surface evaporation.

Ms. Mia Weber MD –

The UDF for evaporation rate seems quite important for this simulation. Can you provide more insight on how you implemented it and ensure its accuracy?

MR CFD Support –

The User-Defined Function (UDF) for the evaporation rate is crucial in capturing the physics of the surface evaporation process in this simulation. It’s implemented by writing a custom code snippet in C, which is then compiled and loaded into ANSYS Fluent. The function defines the mass transfer from water to steam based on physical properties, such as temperature, and other relevant factors related to the evaporation at the water surface. To ensure its accuracy, it’s typically validated against experimental data or proven evaporation models. The function is also quality-checked for consistency and accuracy within the simulation environment to ensure it behaves as expected under the conditions being analyzed.

Dr. Keira Harber Jr. –

The product seems like a useful resource for learning complex CFD analysis. I particularly appreciate the real-world application highlighted through this problem. Great work on detailing the steps involving solar desalination and surface evaporation simulation.

MR CFD Support –

Thank you for recognizing the efforts in creating this learning product for solar desalination CFD simulation using ANSYS Fluent. We’re glad that you find it useful and that it could effectively convey the steps and real-world application of the process. Your appreciation means a lot to us, and we hope our training will continue to be of great value to you.

Molly Littel –

I just finished going through the learning materials on solar desalination with surface evaporation using ANSYS Fluent and I have to commend the clarity of the tutorials. However, I was wondering if the UDF for the evaporation rate that was provided with the tutorials could be adjusted for different environmental conditions, such as humidity and temperature changes?

MR CFD Support –

Absolutely, UDFs (User-Defined Functions) provided in ANSYS Fluent tutorials can be adjusted to accommodate a wide range of environmental conditions. Temperature, humidity, and other parameters can be altered within the UDF script to match the specific requirements of different scenarios. This flexibility is why UDFs are so powerful in Fluent’s simulations, allowing engineers to closely replicate various operating conditions.