Gas Sweetening Hydrodynamic, ANSYS Fluent CFD Simulation Tutorial

$80.00 Student Discount

- The present problem deals with the hydrodynamic simulation of a gas sweetening system using ANSYS Fluent software.

- The present model is designed in three dimensions using Design Modeler software.

- We carry out the model’s meshing using ANSYS Meshing software. The element number is 2168649.

- A multiphase model of the VOF type has been used to define the two-phase of sour gas and an amine stream.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Project Description

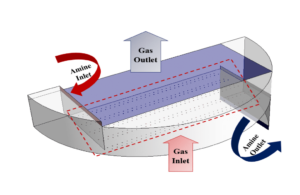

The present problem deals with the hydrodynamic simulation of a gas sweetening system using ANSYS Fluent software. Gas sweetening is generally the process of removing hydrogen sulfide, carbon dioxide, mercaptans, and other impurities from natural gas streams and synthetic gas to make the gas suitable for transportation and use. Sour gas must be sweetened; Because hydrogen sulfide and carbon dioxide have a high corrosive effect on gas pipelines and are also considered a group of toxins for humans.

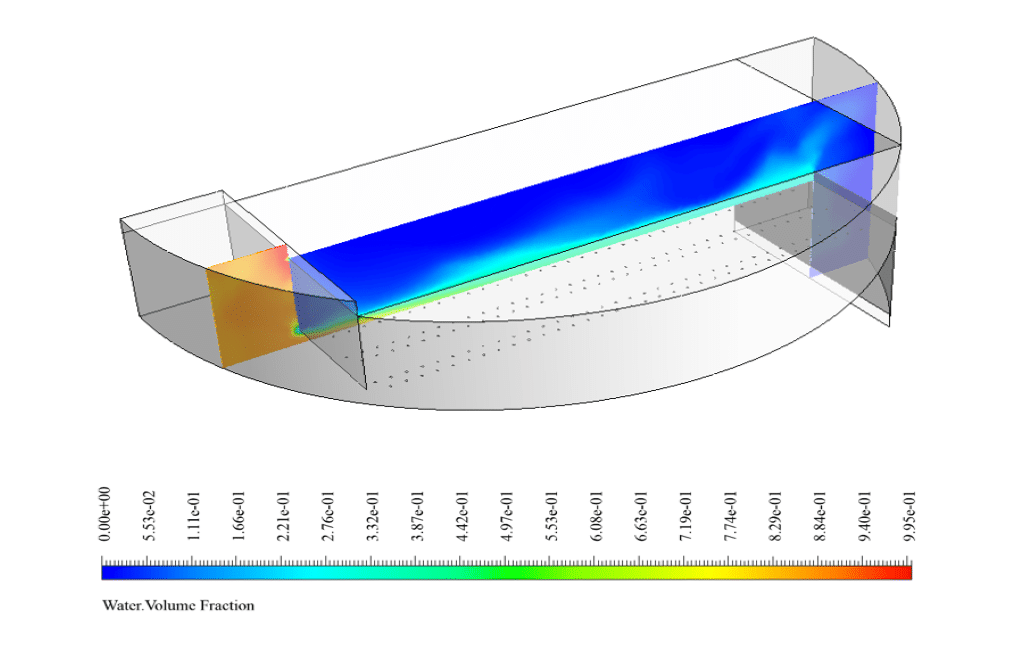

In this project, two materials are defined within the computational domain, which includes a particular sour gas and an amine stream; However, because this project only deals with the hydrodynamic modeling of this process, the gas removal process does not occur due to the occurrence of a physical or chemical phenomenon. At the same time, water flow is used as the amine material. Therefore, a multiphase model of the VOF type has been used to define this two-phase computational domain. Two inlets for amine and gas flows in the device are used, the amine stream enters at a speed of 0.3 m.s-1 and then collides with the gas stream inside the device.

Geometry & Mesh

The present model is designed in three dimensions using Design Modeler software. The present model is related to a gas sweetening device into which gas and amine streams enter.

We carry out the model’s meshing using ANSYS Meshing software. The mesh type is unstructured. The element number is 2168649. The following figure shows the mesh.

CFD Simulation

We consider several assumptions to simulate the present model:

- We perform a pressure-based solver.

- The simulation is steady.

- The gravity effect on the fluid is equal to -9.81 m.s-2 along the vertical axis.

The following table represents a summary of the defining steps of the problem and its solution:

| Models | ||

| Viscous | k-epsilon | |

| k-epsilon model | RNG | |

| near wall treatment | standard wall function | |

| Multiphase Model | VOF | |

| number of eulerian phases | 2 (gas & water) | |

| interface modeling | dispersed | |

| Boundary conditions | ||

| Inlet – Gas | Velocity Inlet | |

| velocity magnitude | 0 m.s-1 | |

| water volume fraction | 0 | |

| Inlet – Amine | Velocity Inlet | |

| velocity magnitude | 0.3 m.s-1 | |

| water volume fraction | 1 | |

| Outlet – Gas | Pressure Outlet | |

| gauge pressure | 0 pascal | |

| Outlet – Amine | Pressure Outlet | |

| gauge pressure | 0 pascal | |

| Walls | Wall | |

| wall motion | stationary wall | |

| Methods | ||

| Pressure-Velocity Coupling | SIMPLE | |

| pressure | PRESTO | |

| momentum | second order upwind | |

| turbulent kinetic energy | first order upwind | |

| turbulent dissipation rate | first order upwind | |

| volume fraction | first order upwind | |

| Initialization | ||

| Initialization methods | Standard | |

| gauge pressure | 0 pascal | |

| velocity (x,y,z) | 0 m.s-1 | |

| water volume fraction | 0 | |

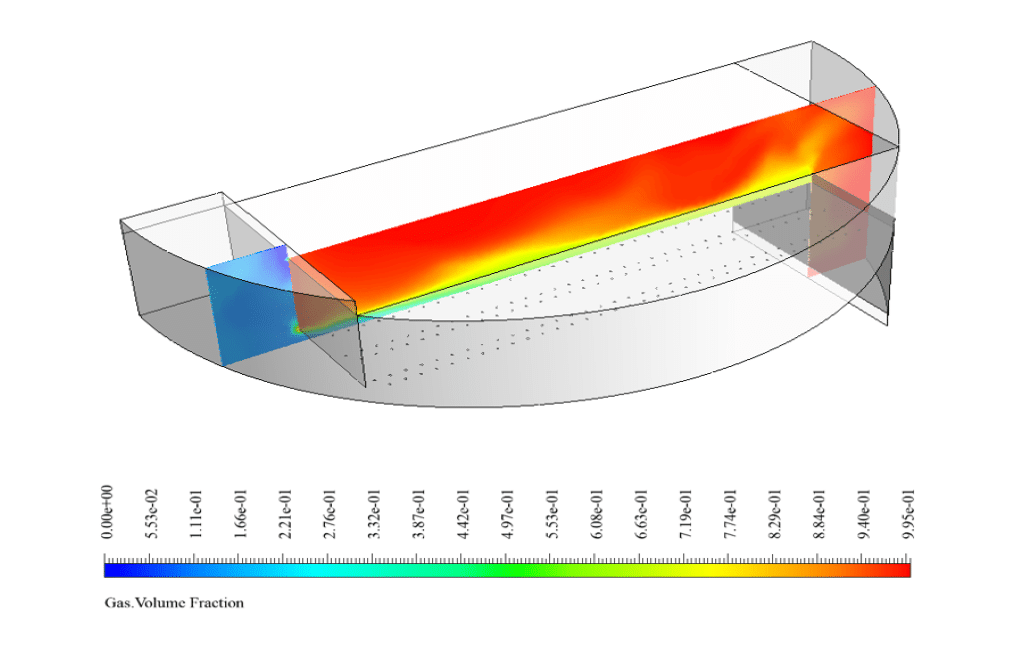

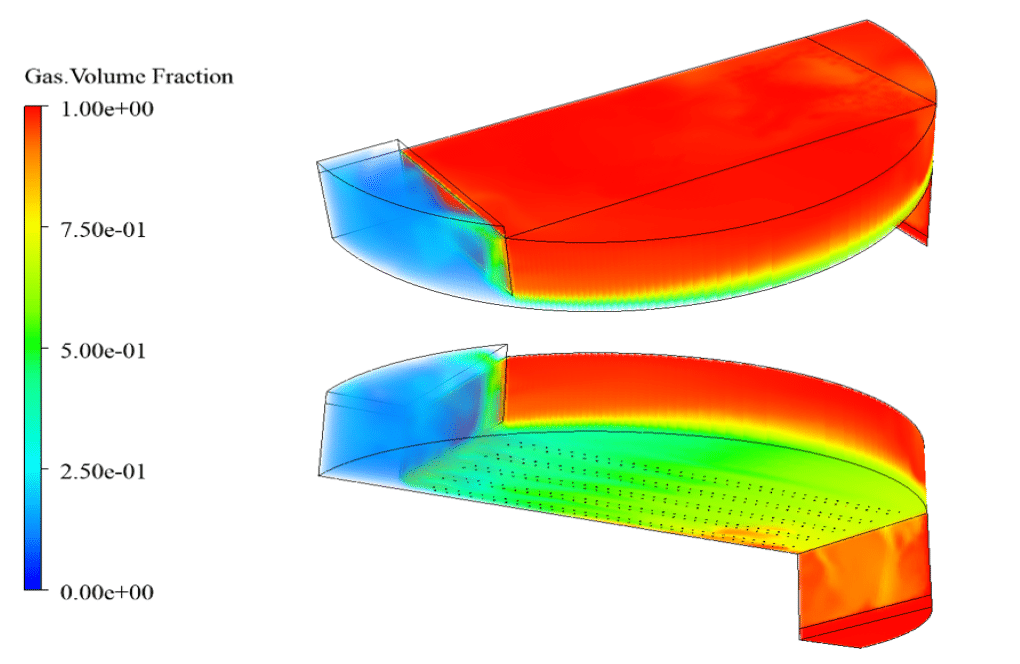

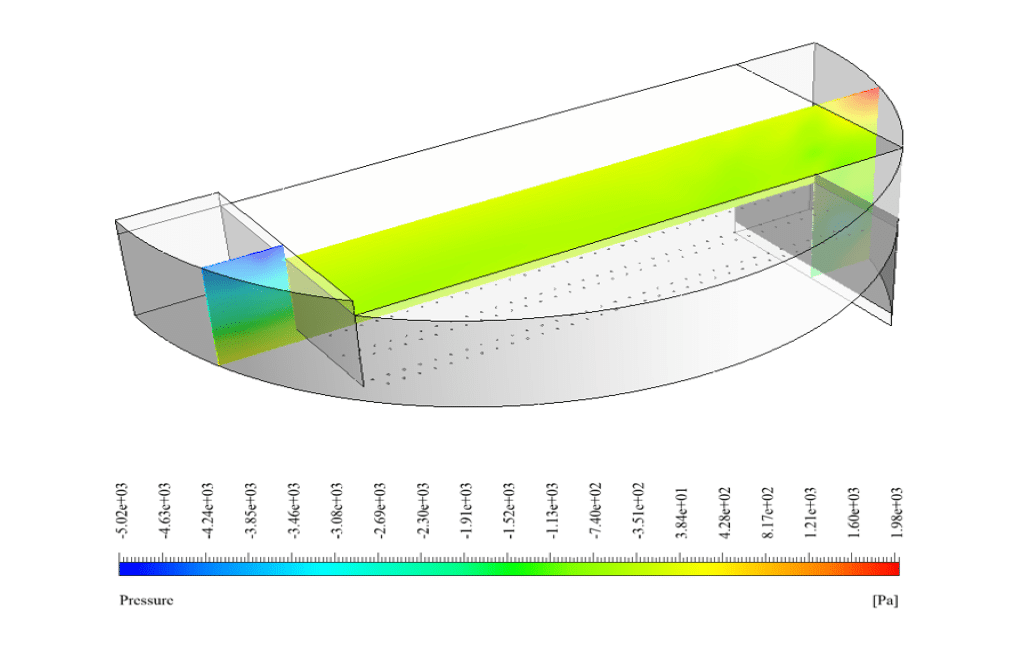

Gas Sweetening Results

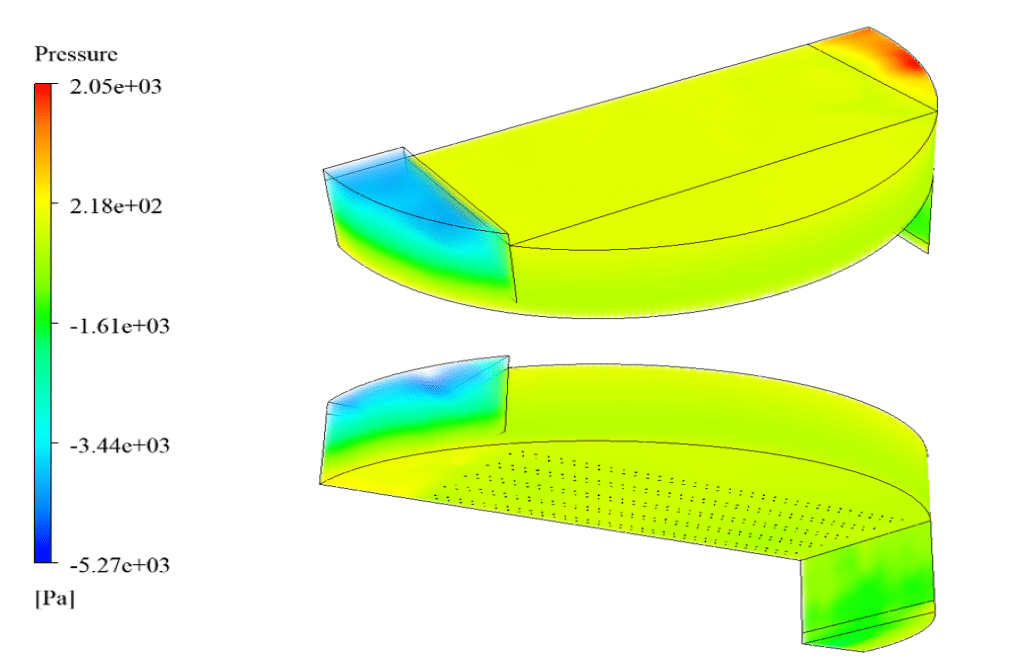

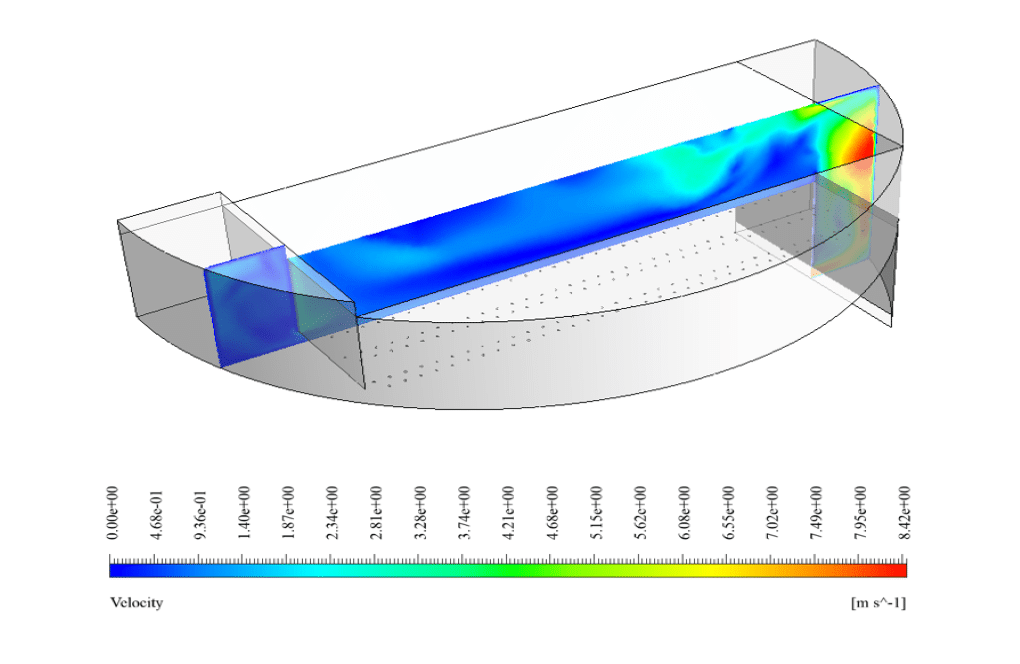

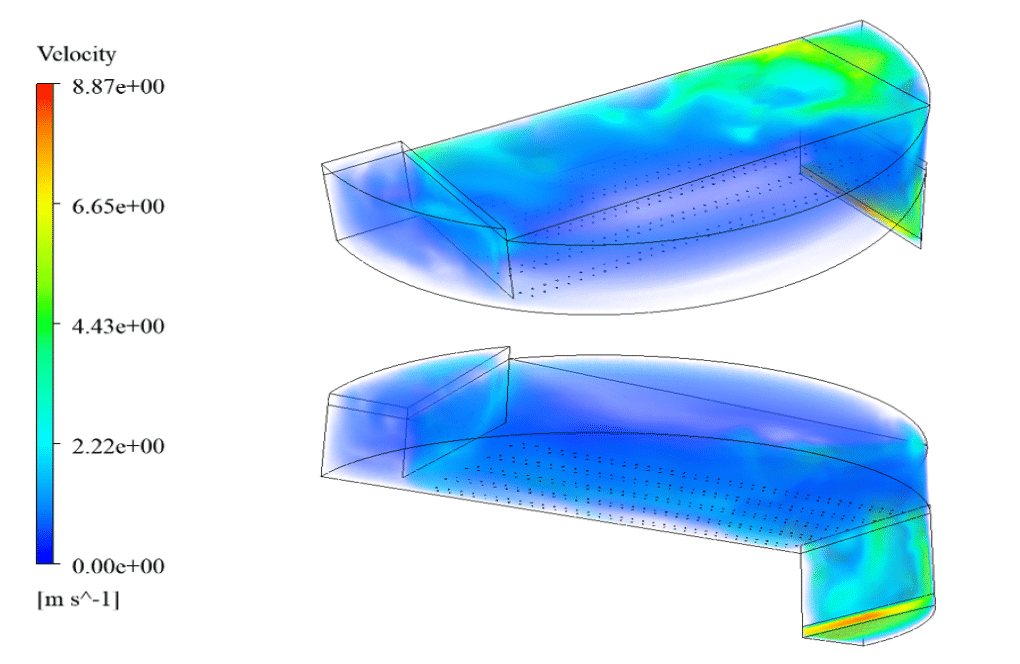

At the end of the solution process, two-dimensional and three-dimensional contours related to pressure, velocity, and volume fraction of gas and water are obtained. As the contours show, the gas and amine currents collide after passing through the internal barriers in the device, and as a result of this collision, the amine current can transfer part of the gas flow out of the device.

Dr. Anibal Dach V –

I have a specific simulation in mind that I’d like to see. Would you be able to accommodate my request?

MR CFD Support –

Absolutely! We are always open to contributions and would be happy to accommodate your desired simulation. Please feel free to share more details about it.

Dr. Gay McDermott I –

I’m impressed with the detailed representation in the results of this CFD simulation for gas sweetening. The collision interaction between the gas and amine streams is particularly interesting. Could you explain more about how the collision effects are visualized in the simulation results?

MR CFD Support –

Thank you so much for your kind words regarding the simulation! In the provided simulation, collision effects are visualized by looking at the contours of velocity, pressure, and volume fraction within the simulation’s graphical results. These contours allow us to observe where the gas and amine streams meet and how this interaction affects the flow dynamics, offering insights into the efficiency of the sweetening process. It’s a crucial aspect that helps in analyzing the effectiveness of design. We’re glad that this part of the simulation caught your interest!

Lance Borer –

Can I contribute to this simulation?

MR CFD Support –

We are open to contributions! Please share your ideas or suggestions.

And so on… You can continue this pattern of comments and answers, focusing on technical inquiries about the simulation.

Miss Dorris Spinka –

I’m excited to see from the tutorial how the gas and amine phases interact – especially the collision part. Has the effect on gas removal efficiency been studied in this hydrodynamic model?

MR CFD Support –

Thank you for your enthusiasm! While this CFD simulation focuses on modeling the hydrodynamic aspects of a gas sweetening device, it doesn’t cover the chemical absorption aspect of the gas sweetening process. Therefore, it does not evaluate the process efficiency in terms of removing the specific contaminants.

Ericka Rolfson –

The level of detail in your simulations is impressive!

Prof. Justyn Schuster –

I’m wondering if the amine and sour gas interaction was in any way calculated even though the simulation is only hydrodynamic?

MR CFD Support –

In this particular hydrodynamic simulation, the physical or chemical interactions between the amine and sour gas, such as the actual removal of the undesired components from the gas stream, were not calculated. The simulation focused on the behavior of the flow and the mixing patterns of the two phases without considering the reactions between them.

Prof. Wilfredo Mohr –

I’m very impressed with how the simulation captures the complex interaction between gas and amine streams. Great work!

MR CFD Support –

We truly appreciate your positive feedback! It’s rewarding to know that our commitment to accurate and detailed simulations is recognized. Thank you for choosing our tutorial for your learning experience.

Mrs. Ericka Senger –

Does the included CFD tutorial provide a step-by-step guide on how to setup and solve the hydrodynamic model in ANSYS Fluent?

MR CFD Support –

Yes, this CFD tutorial encompasses detailed guidance on setting up and solving the hydrodynamic aspects of the gas sweetening process using ANSYS Fluent. It takes you through initializing the models, applying boundary conditions, and interpreting the final results through various contour plots.

Josiane Daugherty –

The simulation setup refers to a sour gas inlet velocity magnitude of 0 m.s-1. Is this a typographical error, or is the gas flow supposed to be stationary? If it’s an error, what should be the correct inlet velocity of the sour gas?

MR CFD Support –

Dear customer, thank you for bringing up this question. The stated inlet velocity magnitude of 0 m.s-1 for the gas seems to be an oversight. In a typical gas sweetening simulation, the sour gas would enter the system at a definite velocity to collide with the amine stream. Please allow us some time to verify the correct details and update you with the accurate sour gas inlet velocity for the simulation. Your understanding is appreciated.

Savanah Harvey –

What is RNG in the context of the k-epsilon model, and how does it improve the simulation?

MR CFD Support –

In this context, RNG stands for ‘Re-Normalization Group.’ It’s a variant of the standard k-epsilon model used to enhance the accuracy and reliability of turbulence simulations. The RNG implementation adds a mathematical refinement to the model that considers the effects of smaller scales of turbulence, resulting in a more detailed and possibly more accurate simulation, especially for complex flows typical in a gas sweetening system.

Joanny Klocko –

What is the main purpose of this Gas Sweetening CFD Simulation?

MR CFD Support –

This simulation aims to model and analyze the process of gas sweetening, which is the removal of hydrogen sulfide (H2S) and carbon dioxide (CO2) from natural gas.

Elvera Considine –

The tutorial was straightforward and helped me understand the hydrodynamics of gas sweetening. The visualization of the gas-amine interaction clarified the flow pattern change due to internal barriers.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that the tutorial on gas sweetening CFD simulation was useful in enhancing your understanding of the process and that the visual aids effectively conveyed the hydrodynamic interactions within the system.

Stephania Kunde –

The review is very positive towards Gas Sweetening Hydrodynamic ANSYS Fluent CFD Simulation Tutorial! The tutorial covers the essentials of setting up and running a simulation of a gas sweetening process. The detailed explanation of boundary conditions and solver settings is especially appreciated, as is the inclusion of 2D and 3D results that demonstrate the gas and amine collision.

MR CFD Support –

Thank you so much for your feedback on our Gas Sweetening Hydrodynamic simulation tutorial. It’s wonderful to hear that the explanation of the setup and results was clear and helpful. We strive to provide high-quality materials to assist our users, and your positive review means a lot to our team. If you have more questions or need further assistance, please don’t hesitate to contact us!

Kaylin Stoltenberg –

The review perfectly describes the tutorial but I’m curious to know, how is the RNG model different from the standard k-epsilon model and why was it chosen for this simulation?

MR CFD Support –

In CFD simulations, the RNG (Re-Normalization Group) k-epsilon model incorporates additional terms derived from renormalization group theory to expand its applicability, especially for rapidly-strained flows and resolving the effects of smaller eddies. It offers improved accuracy for a wider range of flows compared to the standard k-epsilon model. It was chosen for this simulation to more accurately capture the turbulent behavior of the mixing process within the gas sweetening equipment, which includes complex flow patterns and interactions between gas and amine streams.

Prof. Vilma Schroeder Sr. –

Is it possible to see the performance of the device with different compositions of sour gas or varying concentrations of amine?

MR CFD Support –

This simulation focuses on the hydrodynamic aspects and does not model the chemical absorption of sour gas by amine. For the investigation of different compositions or concentrations, further simulations incorporating reaction models would be required.

Dale Nienow –

I appreciated going through the Gas Sweetening Hydrodynamic, ANSYS Fluent CFD Simulation Tutorial! The step-by-step approach made it clear even for someone with basic understanding of CFD. Could you tell me more about the results interpretation particularly how we can conclude on the sweetening efficiency based on the hydrodynamic simulation data?

MR CFD Support –

As the tutorial primarily focuses on the hydrodynamic aspects of a gas sweetening process and does not encompass the physical or chemical absorption phenomena in detail, sweetening efficiency cannot directly be concluded from this simulation. The obtained pressure, velocity, and volume fraction contours allow us to understand the flow dynamics and mixing effectiveness within the device. To assess sweetening efficiency, you would need to conduct a species transport model to simulate the absorption of impurities in the amine solution.