Heat Transfer in Vertical Shell and Spiral Tube Heat Exchanger, ANSYS Fluent Training

$80.00 Student Discount

- The problem numerically simulates Heat Transfer in Vertical Shell and Tube Heat Exchanger using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 3915382.

- The Energy Equation is activated to consider heat transfer.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

The present problem simulates the heat transfer process inside a vertical helical shell and tube heat exchanger using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

The present model is designed in three dimensions using Design Modeler software. The model is a shell-tube heat exchanger with spiral tubes designed vertically.

The cylindrical shell of the thermal model has a height of 500 mm, and a diameter of 60 mm, the spiral tube inside the shell has a diameter of 3 mm, and the step of the screw around the central axis of the shell is equal to 18 mm.

The meshing of the model has been done using ANSYS Meshing software. The element number is 3915382.

Heat Transfer Methodology

This heat exchanger consists of a vertical cylindrical shell with a spiral tube inside. The hotter part of the heat exchanger is related to the spiral tube of the heat exchanger, and the colder part is related to the shell of the heat exchanger.

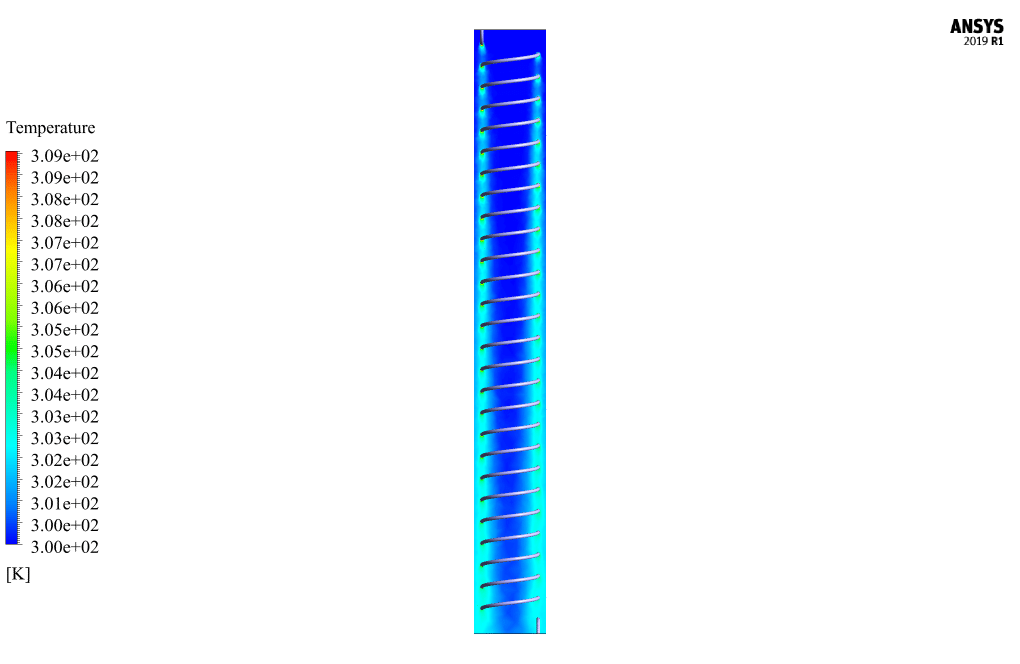

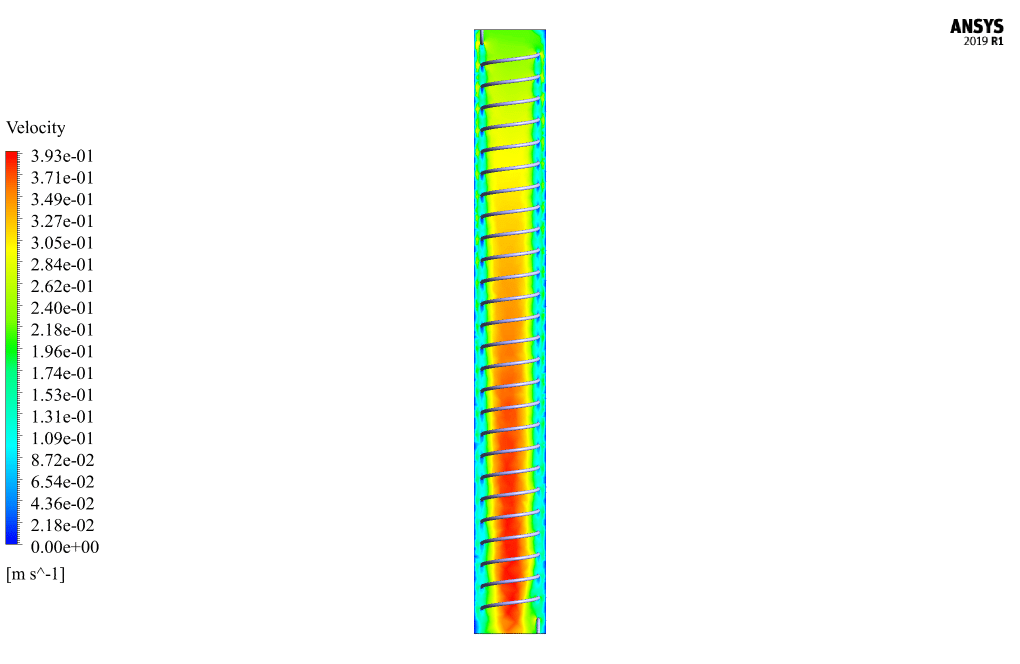

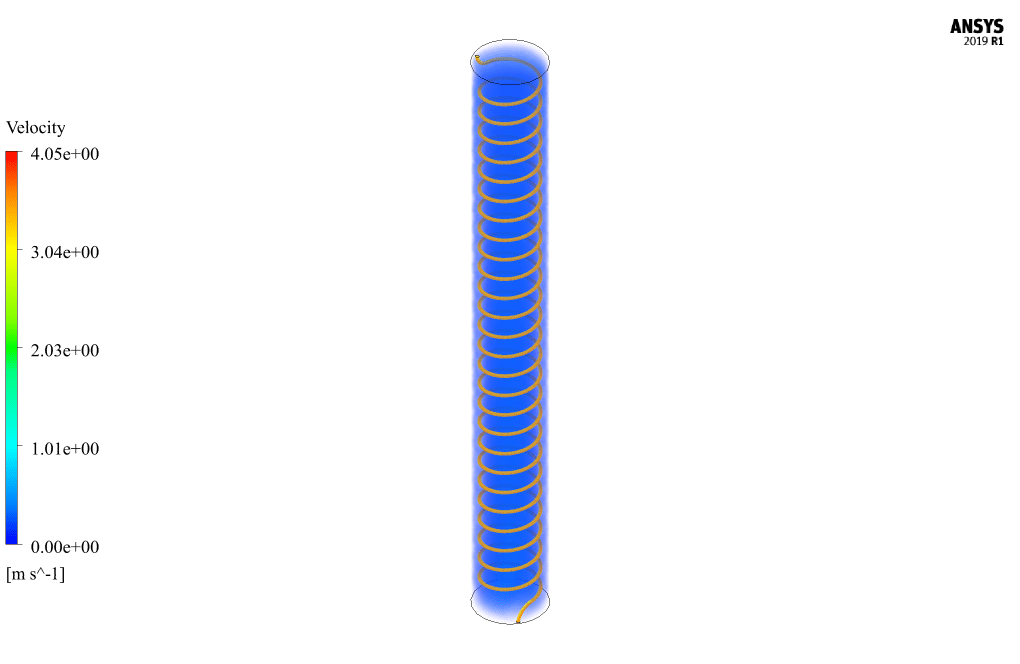

Hot water flows with a velocity of 3.34 m/s and a temperature equal to 350 K from the upper part of the heat exchanger and enters the spiral tube. Cold water flows with a velocity equal to 0.216 m/s and a temperature equal to 300 K from the upper part.

The transducer enters the inner space of the shell. This work investigates the heat transfer process between the two sides of the heat exchanger.

Moreover, the RNG k-epsilon model and energy equation are enabled to solve turbulent fluid equations and calculate temperature distribution within the domain.

Heat Transfer Conclusion

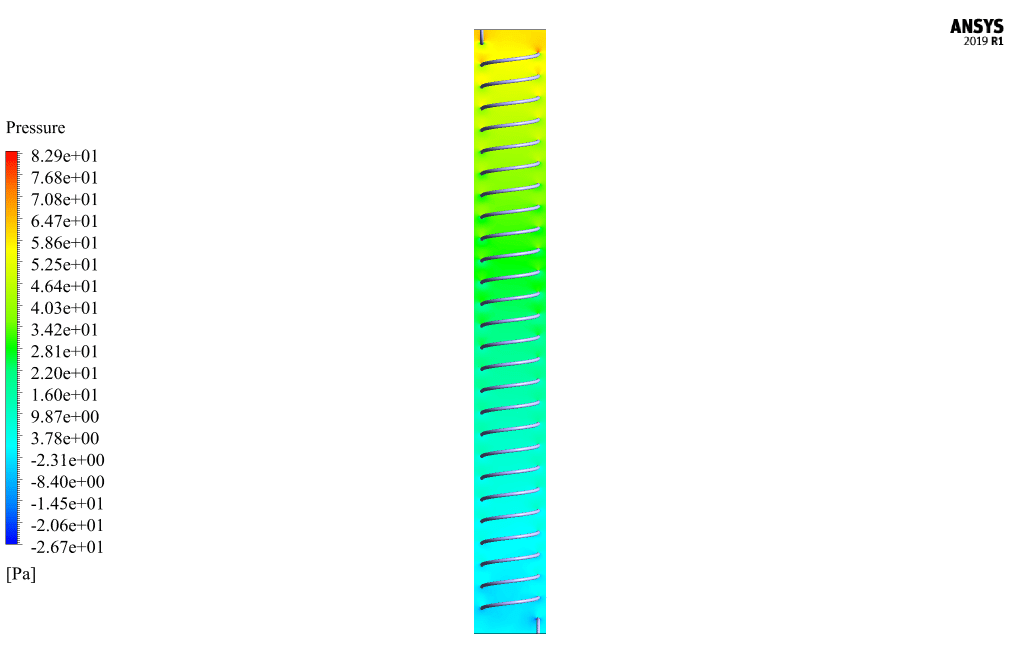

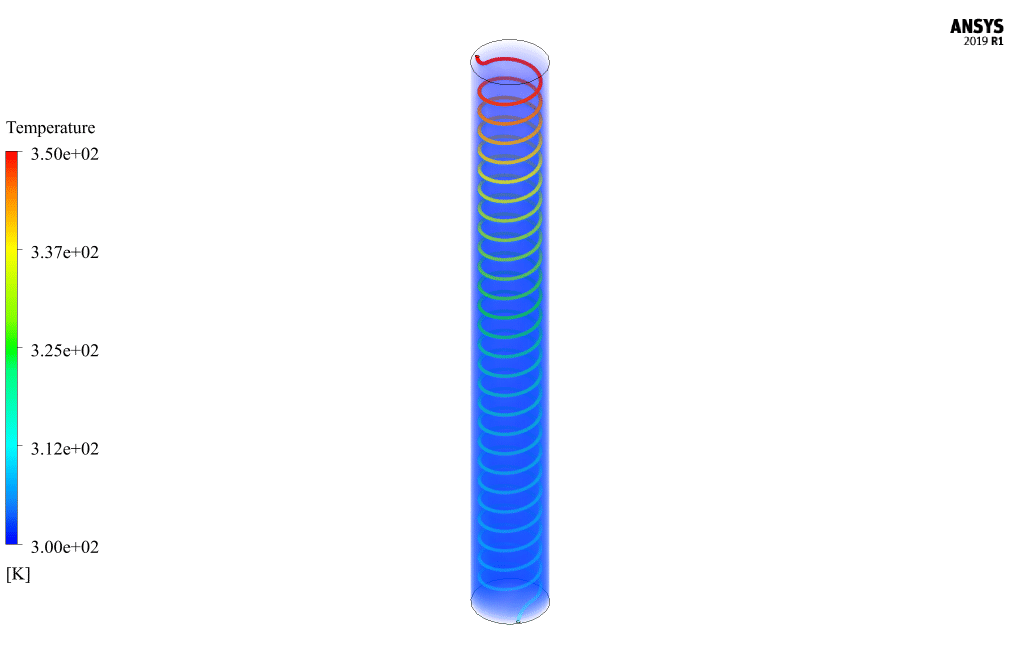

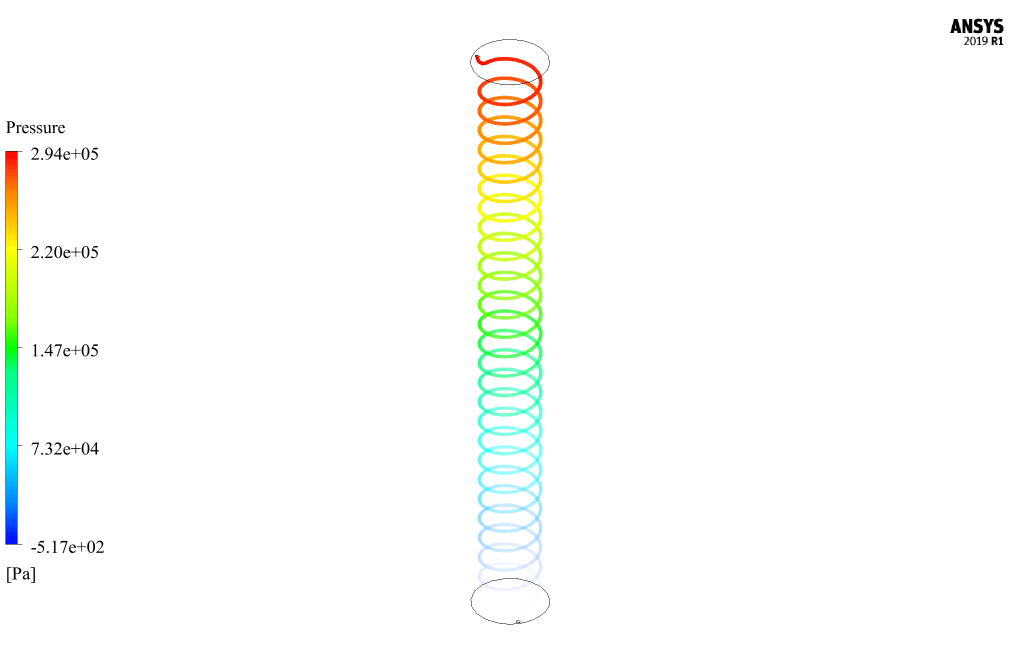

At the end of the solution process, two-dimensional and three-dimensional counters related to pressure, velocity, and temperature inside the heat exchanger are obtained.

Two-dimensional contours are obtained on a plane passing through the center of the heat exchanger on both sides of the shell and the spiral tube.

The results show that heat transfer is done between the two sides of the shell heat exchanger and the spiral tube, and the heat is from the hot part of the exchanger (spiral tube) to the cold part of the exchanger (shell).

Justice Tromp –

The clarity of the explanations regarding the boundary conditions and modelling of the heat exchanger was exceptional! It made understanding the complexities of heat transfer much more approachable.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our efforts in making the heat transfer principles in a shell and tube heat exchanger clear and understandable have been successful. We strive to provide comprehensive and well-explained simulations, and it’s great to know we’ve made it accessible to users like you.

Mrs. Kyra Mante –

I’m impressed with the detail presented in the simulation results for the heat transfer in the vertical shell and tube heat exchanger! The temperature and velocity contours really helped me understand how efficient the design is for heat exchange.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our detailed simulation results have provided you with a clear understanding of the heat exchanger’s performance and efficiency. It’s our aim to offer comprehensive information to help our customers fully grasp the intricacies of such complex systems.

Ms. Eldridge Bayer II –

I’ve seen other heat exchanger simulations, but this one looks unique with a vertical setup and spiral tubes. The detail in the analysis is incredible!

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that our simulation on the vertical shell and spiral tube heat exchanger stood out to you. Our team strives to provide detailed and unique analyses to help our customers understand complex systems better. If you have any further questions or need assistance with similar simulations, don’t hesitate to reach out to us!

Elias Stehr –

I truly appreciate how thorough this course on vertical shell and spiral tube heat exchangers was! It has deepened my understanding of heat transfer applications in CFD.

MR CFD Support –

Thank you for your kind words! We’re glad to hear that our course on heat transfer in vertical shell and spiral tube heat exchangers met your expectations and enhanced your understanding. Your satisfaction is our top priority!

Johnathon Corkery –

I’m really impressed with the level of detail provided in the heat transfer analysis of the vertical helical shell and tube heat exchanger. The spiral tube design is fascinating, and it seems like your CFD simulation has done an excellent job in capturing the intricate heat exchange processes.

MR CFD Support –

Thank you very much for your kind words! We’re thrilled to hear that you appreciate the detailed analysis provided by our CFD simulation of the vertical shell and spiral tube heat exchanger. If you have any further inquiries or need assistance with similar simulations, please feel free to reach out to us.

Larissa King –

The level of detail in the results and provided methodology is impressive! The use of the RNG k-epsilon model for capturing the turbulence within the heat exchanger must have provided detailed insights into the flow dynamics. Also, the temperature distribution insights sound quite valuable for evaluating the heat exchanger’s performance.

MR CFD Support –

Thank you so much for your positive feedback! We’re thrilled to hear you found the use of the RNG k-epsilon model in simulating the heat exchanger helpful. It’s our goal to provide comprehensive and detailed insights into our CFD projects, and we’re glad you’re satisfied with the results. If you have any further questions or need assistance with similar projects, feel free to reach out.

Marcia Roob –

The ANSYS Fluent training for the heat transfer in a vertical shell and spiral tube heat exchanger was very insightful. It helped me understand the intricate processes involved in such systems. The training content was clear, and the examples were practical and easy to follow. I particularly appreciated the detailed explanation of the RNG k-epsilon model and energy equation integration.

MR CFD Support –

Thank you for your wonderful feedback! We are thrilled to learn that our training on heat transfer in a vertical shell and spiral tube heat exchanger was useful to you. It’s great to hear that the practical examples and detailed explanations added value to your learning experience. If you have any further questions or need more guidance on similar CFD analyses, please feel free to reach out. Happy learning!

Josephine Bednar –

This course made learning about heat exchangers much easier. Thanks to the thorough CFD analysis and the clear explanation of the heat transfer process in a vertical shell and spiral tube heat exchanger, I now understand the intricacies involved. The visual aids were helpful in grasping complex concepts.

MR CFD Support –

Thank you for sharing your positive experience with our vertical shell and spiral tube heat exchanger course. We are thrilled to hear that the CFD analysis and the provided explanations contributed to your understanding of the heat transfer process. Your satisfaction with the training material and the visual aids is greatly appreciated.

Chyna Rowe –

The spiral tube heat exchanger design is fascinating. The detail provided in the CFD analysis helped me grasp how efficient this setup must be. Liked how the simulation captured the complexities of heat transfer with precise temperature distribution.

MR CFD Support –

We appreciate your positive feedback on the quality of the CFD analysis and design detail of our vertical shell and spiral tube heat exchanger model. It is gratifying to hear that the simulation met your expectations and was able to convey the efficiency and complexity of this heat transfer system effectively. Thank you for taking the time to share your thoughts.

Kraig Bartell –

I found the training session extremely insightful. The real-world application of the heat transfer within the shell and tube heat exchanger was elucidated perfectly with the clear visualizations provided. The explanation of how the temperature gradients establish themselves was particularly helpful. Great job on providing a comprehensive CFD analysis using ANSYS Fluent.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you found the training session on the heat transfer in the vertical helical shell and tube heat exchanger insightful. Visualising the complex heat transfer processes and making the CFD analysis comprehensible is our ultimate goal. We appreciate your recognition of the efforts to provide clear explanations and real-world applications. If you need further assistance or have more questions, feel free to reach out to us!

Miss Zoie O’Kon DDS –

I’ve always been intrigued by how spiral tube designs enhance heat transfer. The training material seems very comprehensive. The three-dimensional analysis must reveal insightful patterns about heat distribution. I bet seeing the temperature gradients in action is fascinating!

MR CFD Support –

Thank you for your kind words! We are pleased to hear that our training on the vertical shell and tube heat exchanger using ANSYS Fluent effectively demonstrates the thermal gradients and heat transfer patterns. It’s great to know our comprehensive CFD project and intricate three-dimensional modeling provided the insightful analysis you were looking for. Should you have more inquiries or need further assistance, feel free to reach out.

Noble McDermott –

I’m fascinated by the helical design! Can you tell me how the spiral design impacts the heat transfer efficiency compared to traditional straight-tube exchangers?

MR CFD Support –

The spiral design in helical shell and tube heat exchangers increases the efficiency of heat transfer usually due to enhanced turbulence as the fluid moves through the spiral path. The continuous curved shape leads to secondary flows and increased surface area, which contributes to better thermal contact between the fluids. Furthermore, the design can minimize ‘dead zones’ where fluid motion is stagnant, leading to more uniform temperatures across the fluid flow paths.