Bluff-Body Mild Burner CFD Simulation

$200.00 Student Discount

This project is the CFD simulation of combustion in a bluff body mild burner.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Bluff-Body Mild Burner CFD Simulation, ANSYS Fluent Training

This project is the CFD simulation of combustion in a bluff-body mild burner by ANSYS Fluent software. In fact, a burner is a device that combines a certain amount of air with fuel in a safe space, converting fuel energy into heat energy, which also produces some gas as a result of this combustion process. The flame produced in the burner is transmitted to the interior of the chamber by two methods of convection and radiation. Therefore, the Radiation (DO) model should also be used in the present model. Also, since the combustion process takes place within the combustion chamber, the Species Transport model is also used.

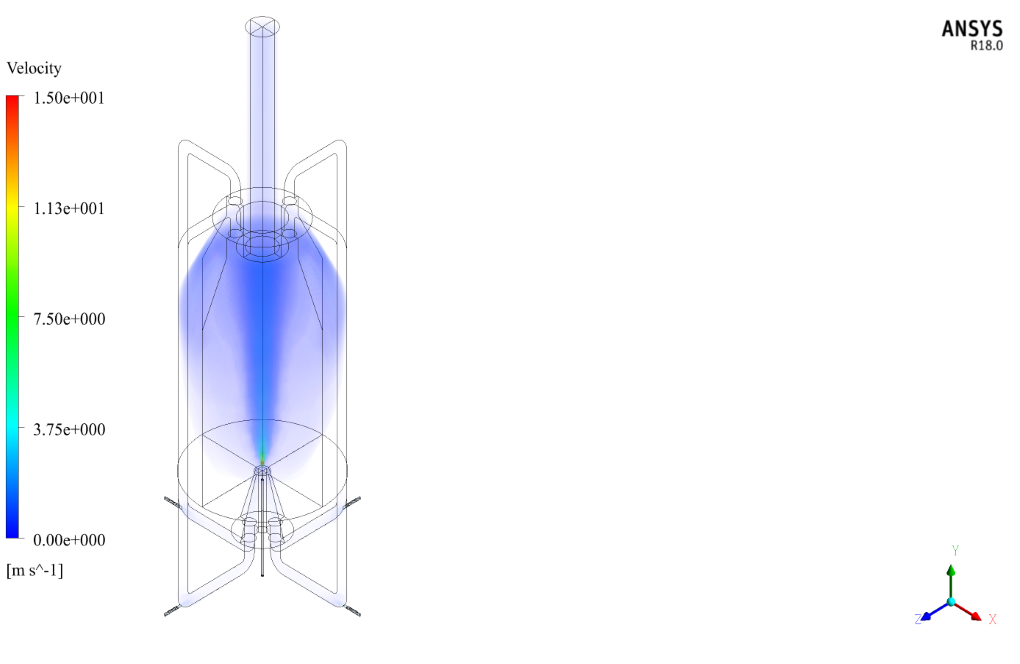

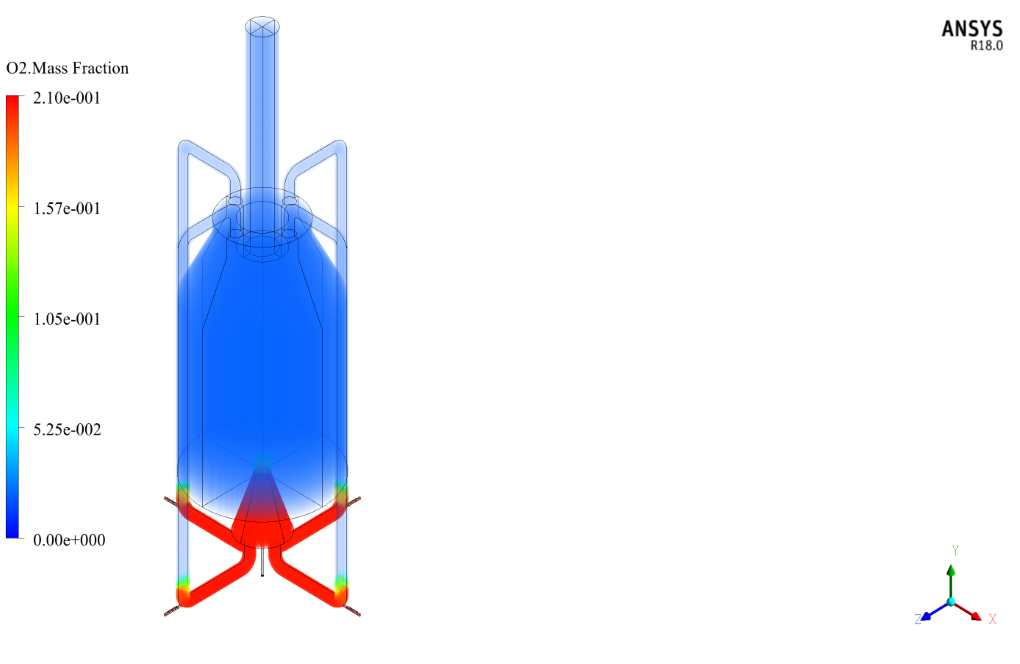

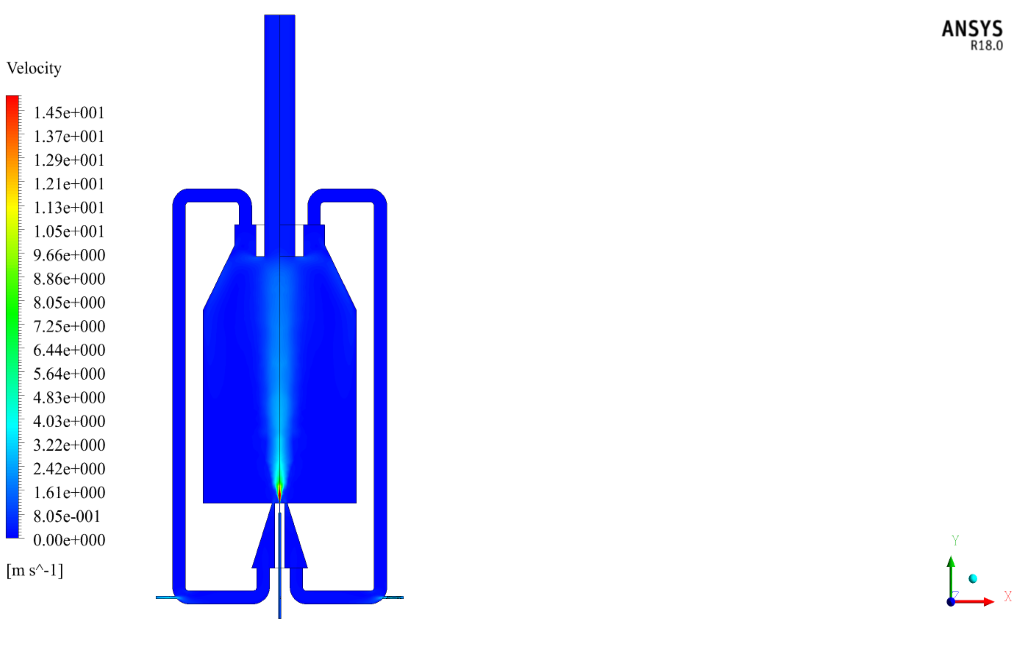

The way this burner works is that the fuel is sprayed through a special jet inlet into the chamber, and the gas flows symmetrically into the chamber in four directions, thus combining the fuel and air to form the flame. Also, the operating system of the enclosure is that the gas flow path inside the chamber is cyclic and some of it exits the exhaust section and another part of it returns to the enclosure from the same circular path.

Assumption

There are several assumptions used for the present simulation:

The simulation is Steady-State, the solver is Pressure-Based, and the gravity effect is ignored.

Geometry & Mesh (Bluff-Body Mild Burner)

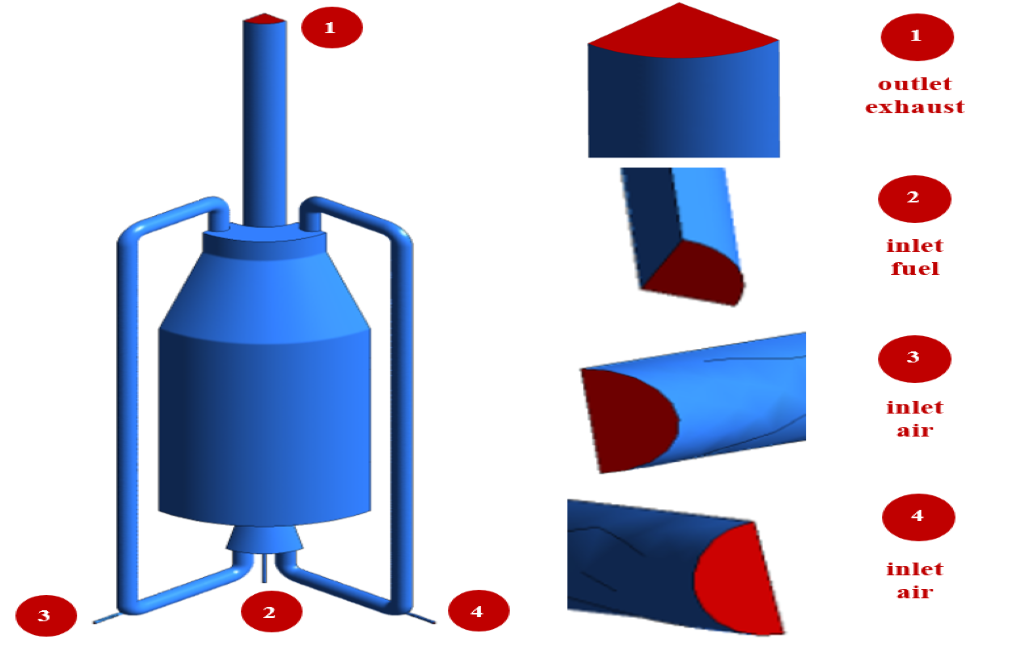

The 3-D geometry of the present model is designed by the Design Modeler software. Since the present model has a symmetrical structure, only one part of it is drawn at an angle of 90 degrees, and the two lateral surfaces of the present section act as symmetry boundaries. The model consists of three pipes with a small diameter called inlet ducts (two air inlets and one fuel inlet pipe) and one outlet pipe with a small diameter (exhaust).

The meshing of the present model is performed by ANSYS Meshing software. The mesh was unstructured and the element number was 1107286. In the inlet and outlet sections, the boundary layer mesh is used to increase the accuracy of fluid behavior.

CFD Simulation

Here are some summaries of the problem definition and problem-solving steps in the table:

| Models (Bluff-Body Mild Burner) | |||

| k-epsilon | Viscous model | ||

| Realizable | k-epsilon model | ||

| enhanced wall function | near-wall treatment | ||

| non-premixed combustion | Species model | ||

| discrete ordinate (DO) | Radiation model | ||

| on | Energy | ||

| Boundary conditions (Bluff-Body Mild Burner) | |||

| Velocity inlet | Inlet type | ||

| 2 m.s-1 | Velocity magnitude | air | |

| 300 K | temperature | ||

| 1 | Internal emissivity | ||

| 0 | Pollutant NO mass fraction | ||

| 0 | mean mixture fraction | ||

| 0 | mixture fraction variance | ||

| 1 m.s-1 | Velocity magnitude | fuel | |

| 300 K | temperature | ||

| 1 | Internal emissivity | ||

| 0 | Pollutant NO mass fraction | ||

| 1 | mean mixture fraction | ||

| 0 | mixture fraction variance | ||

| Pressure outlet | Outlet type | ||

| 0 Pa | gauge pressure | exhaust | |

| 1 | Internal emissivity | ||

| 0 | Pollutant NO mass fraction | ||

| 0 | mean mixture fraction | ||

| 0 | mixture fraction variance | ||

| wall | Walls type | ||

| 0 W.m-2 | heat flux | outer wall | |

| 1 | Internal emissivity | ||

| opaque | BC type | ||

| Solution Methods (Bluff-Body Mild Burner) | |||

| coupled | Pressure-velocity coupling | ||

| PRESTO | pressure | Spatial discretization | |

| second order upwind | momentum | ||

| second order upwind | energy | ||

| second order upwind | turbulent kinetic energy | ||

| second order upwind | turbulent dissipation rate | ||

| second order upwind | pollutant no | ||

| second order upwind | discrete ordinates | ||

| second order upwind | mean mixture fraction | ||

| second order upwind | mixture fraction variance | ||

| Initialization (Bluff-Body Mild Burner) | |||

| Hybrid | Initialization method | ||

Efren Kris –

I was wondering to ask you if the simulation models different tank shapes or sizes?

MR CFD Support –

Thanks for your question.The simulation is highly customizable and can be adapted to various tank shapes and sizes.

Kip Hoeger Sr. –

I’m impressed with the level of detail in the bluff-body mild burner CFD simulation using ANSYS Fluent. The use of various models, including the k-epsilon turbulence and DO radiation model, as well as the emphasis on accurate boundary conditions and meshing illustrates a thorough approach to capturing the combustion process adequately.

MR CFD Support –

Thank you so much for your positive feedback! We are delighted to hear that you appreciate the depth and detail of our bluff-body mild burner CFD simulation training. Your interest in our work inspires us to continue creating high-quality, informative simulations to support your learning journey. If you have any further questions or need more insight into our simulations or any other product, do not hesitate to reach out.

Prof. Gail Eichmann PhD –

The project model mentioned has a symmetrical structure, and only one section of 90 degrees was drawn. Could you clarify if each section accounts for 90 degrees to complete the whole 360-degree geometry through symmetry, or if there are more sections needed for the full model?

MR CFD Support –

In this simulation, the model indeed has a symmetrical structure. You are correct that each section drawn represents 90 degrees. Since the symmetry boundary conditions are applied, it means that only one section of the model (90 degrees) is needed to represent the full 360-degree geometry. There is no need for additional sections; the solver algorithmically understands the symmetrical nature and applies the calculations accordingly to simulate the entirety of the symmetrical structure.

Jodie Graham –

Thanks for the detailed guide! The inclusion of mesh details and boundary conditions really helps to understand the process!

MR CFD Support –

Thank you for your positive feedback! We’re glad that the detailed guide is helpful to you. If you have any further questions or need assistance with your projects, don’t hesitate to reach out.

Marcus McLaughlin –

After completing the simulation of the bluff-body mild burner, how would you identify areas where combustion is most efficient?

MR CFD Support –

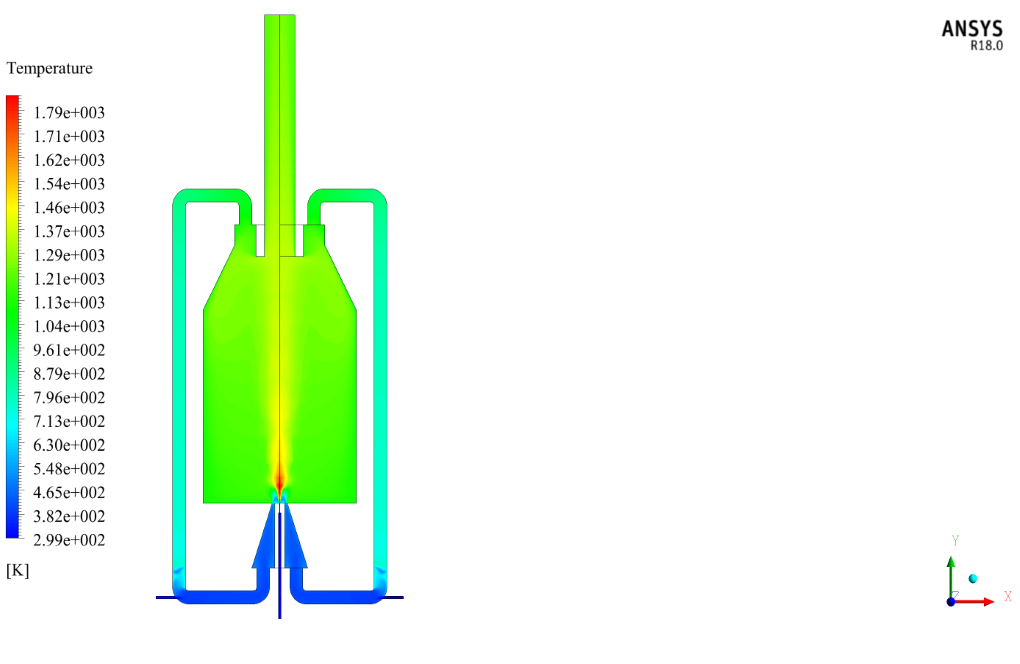

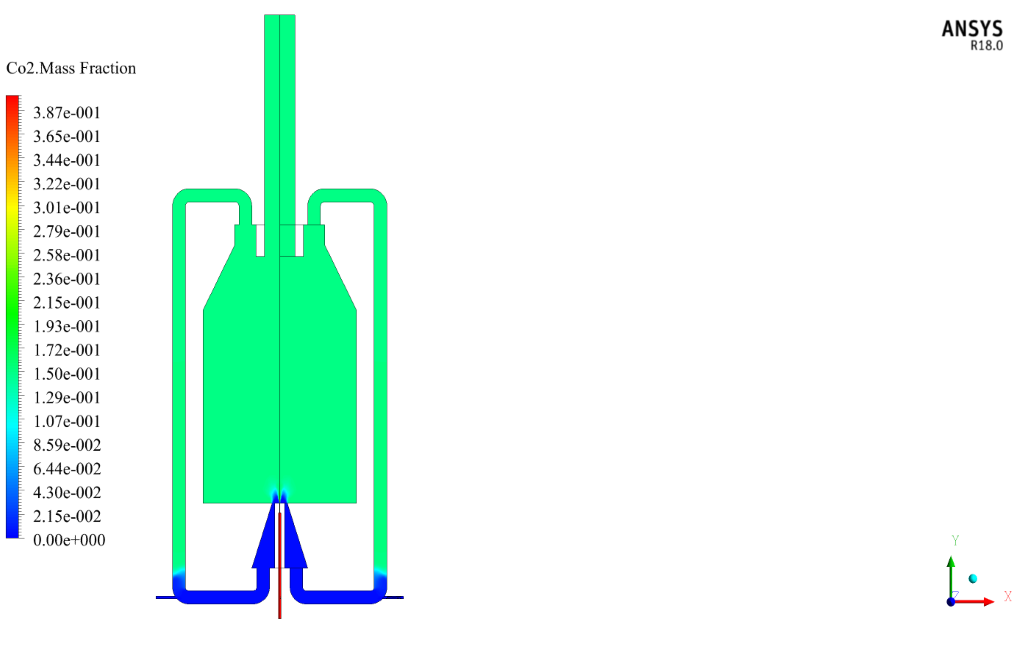

Upon completing the simulation, you can identify the most efficient combustion areas by analyzing the temperature distribution, species concentration, and the reaction rate contours. Study the temperature contours for high-temperature regions as these indicate areas of complete combustion. The species concentration results of the combustion products, such as CO2 and H2O, also indicate where the combustion is most effective. Additionally, reaction rate contours can reveal where the combustion reactions are occurring most vigorously.

Kristofer Langworth –

The attention to detail in the Bluff-Body Mild Burner CFD Simulation course enhanced my understanding greatly. The inclusion of various models, specifically the k-epsilon and the discrete ordinate (DO) radiation model, and boundary layer mesh was instrumental in illustrating complex combustion dynamics in an accessible manner.

MR CFD Support –

We’re thrilled to hear that our Bluff-Body Mild Burner CFD Simulation course provided you with the clarity and understanding you were looking for. It’s great that the detailed explanation of combustion models and the use of a boundary layer mesh contributed to your learning experience. Thank you for your positive feedback!

Mr. Emilio Zboncak –

The explanation of the products and the simulation process was quite in-depth! The attention to detail, from the geometry design to the boundary conditions and the solver settings, like the use of the coupled pressure-velocity coupling or the PRESTO pressure spatial discretization, and even the Initialization methods shows a truly comprehensive approach. Fantastic work!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you appreciate the depth and thoroughness of our CFD simulation work on the Bluff-Body Mild Burner. Our team works hard to ensure that every aspect of the simulation process is well explained and executed with precision. If you have any further questions or need more details, feel free to reach out. We appreciate your feedback!