Laser Processing CFD Simulation Using Gaussian Heat Source Distribution in ANSYS Fluent

$300.00 $120.00 HPC

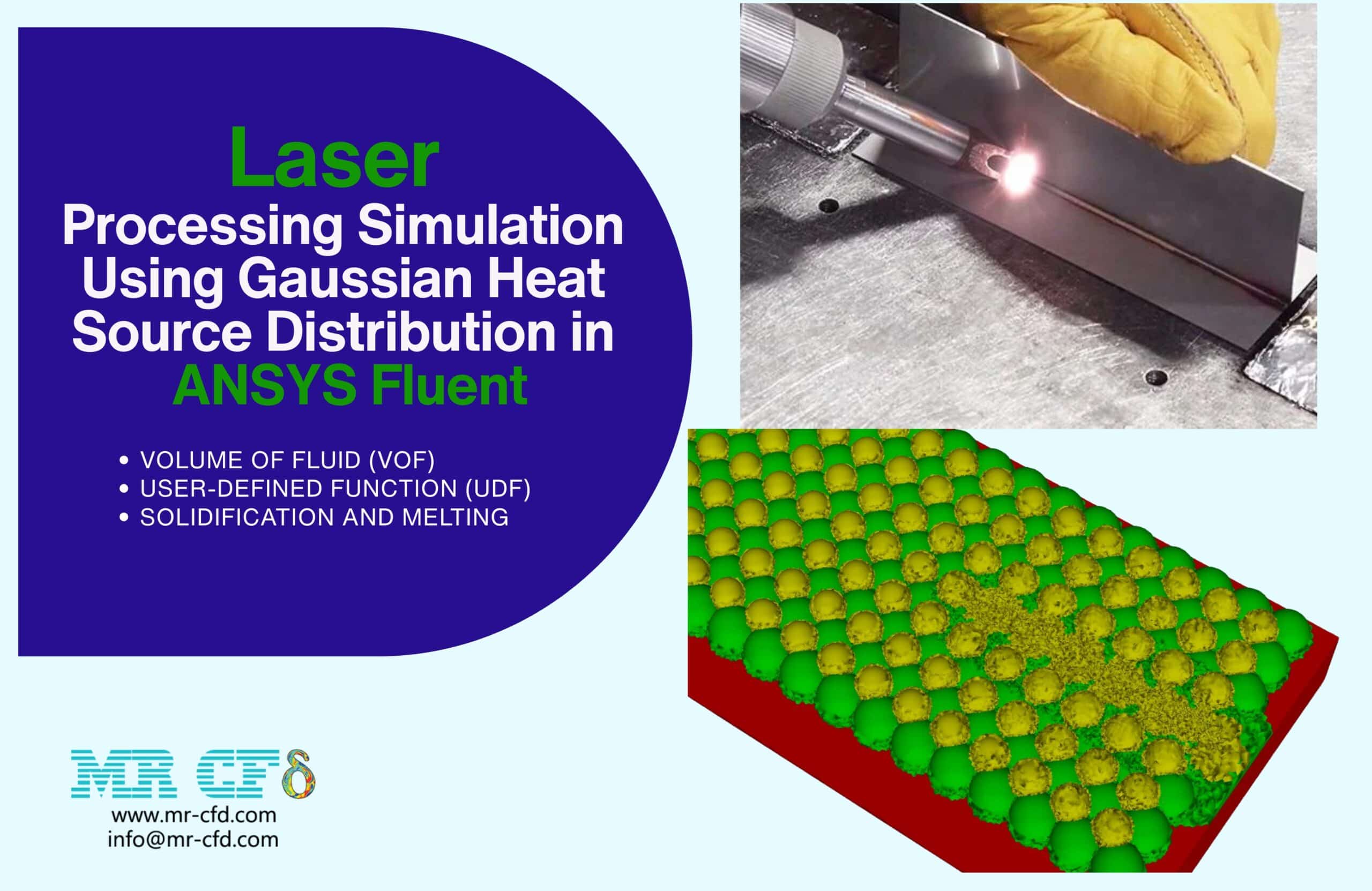

- In Laser Processing project, we have simulated the laser-induced selective melting of bi-material particles using ANSYS Fluent software.

- Three-dimensional modeling was performed using Design Modeler software with a computational domain of 1.0 × 0.5 × 0.4 mm dimensions.

- The meshing of the model was accomplished using ANSYS Fluent Meshing software, generating approximately 800,000 computational cells with refined regions around the particle bed.

- The transient simulation employs VOF multiphase model, Solidification and Melting model, and a User-Defined Function (UDF) implementing the moving Gaussian laser heat source with laminar flow characteristics.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Laser Processing CFD Simulation Using Gaussian Heat Source Distribution

Project Description

This project focuses on the numerical simulation of a laser processing technique using ANSYS Fluent software to model the selective melting of particles arranged on a substrate. The simulation investigates the behavior of bi-material particles consisting of two different material types with distinct thermal and optical properties when subjected to laser irradiation. The primary objective is understanding the melting dynamics and phase change phenomena during laser processing operations, such as selective laser melting or laser sintering.

The simulation employs a User-Defined Function (UDF) to implement a moving Gaussian heat source representing the laser beam characteristics. Instead of moving the laser beam, the substrate undergoes motion while the laser remains stationary, which is a common approach in industrial laser processing applications. This methodology allows for accurately modeling the thermal effects and material phase transitions during the laser-material interaction process.

Geometry and Mesh

The computational domain was designed with dimensions of 1.0 × 0.5 × 0.4 mm, representing a microscale laser processing environment. The geometry consists of spherical particles arranged in a regular pattern on a multi-layered substrate, with particles composed of two different materials having distinct properties. The geometry was created using ANSYS Design Modeler, ensuring precise particle arrangement representation and substrate configuration representation.

The mesh generation was performed using ANSYS Fluent Meshing, resulting in approximately 800,000 computational cells. The mesh was designed as an unstructured grid with refined regions around the particles to capture the thermal gradients and phase change phenomena accurately. Special attention was given to the coordinate system origin placement, significantly affecting UDF accuracy. The mesh quality was optimized to ensure proper resolution of the laser-material interaction zone while maintaining computational efficiency.

Setup Configuration

The simulation was configured using a pressure-based transient solver with gravity effects enabled to account for natural convection and potential fluid motion during melting. The Volume of Fluid (VOF) multiphase model was implemented to track three distinct phases: the surrounding air/gas phase and two different particle materials. The laminar viscous model was selected based on the microscale nature of the domain and expected flow characteristics.

The Solidification and Melting model was activated to capture the phase change behavior of the particles during laser heating. The SIMPLE algorithm was employed for pressure-velocity coupling, ensuring stable and accurate solution convergence. A User-Defined Function was implemented to create the Gaussian laser heat source with specific parameters, including laser intensity of 10¹⁵ W/m³, scanning velocity of 0.2 mm/s, and pulse frequency of 20 Hz. The UDF incorporates 60% and 17% material-specific absorption coefficients for the two different particle types, enabling selective melting behavior.

Results

The simulation results successfully demonstrate the bi-material particle system’s laser-induced melting process and phase change behavior. The results indicate that the laser energy distribution follows the expected Gaussian profile, creating localized heating in the laser interaction zone.

The Liquid Fraction contours reveal the progressive melting behavior of particles as they are exposed to laser energy. The results show selective melting characteristics, with different materials exhibiting varying responses to laser irradiation due to their distinct absorption coefficients implemented in the UDF. The simulation captures the temporal evolution of the melting process, showing how particles transition from solid to liquid state in the laser-affected region. The pulsed nature of the laser (20 Hz frequency) creates intermittent heating cycles, which Are evident in the dynamic behavior of the liquid fraction distribution. These results provide valuable insights into the fundamental physics of laser processing and demonstrate the capability of the numerical model to predict real-world laser-material interactions.

You must be logged in to post a review.

Reviews

There are no reviews yet.