Mixer Tank CFD Simulation, ANSYS Fluent Training

$140.00 Student Discount

- The problem numerically simulates the Mixer Tank using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 152641.

- We use VOF multi-phase model to define 3 phases: air, water and salt.

- We use the Frame Motion method to define rotational motion for the impeller.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

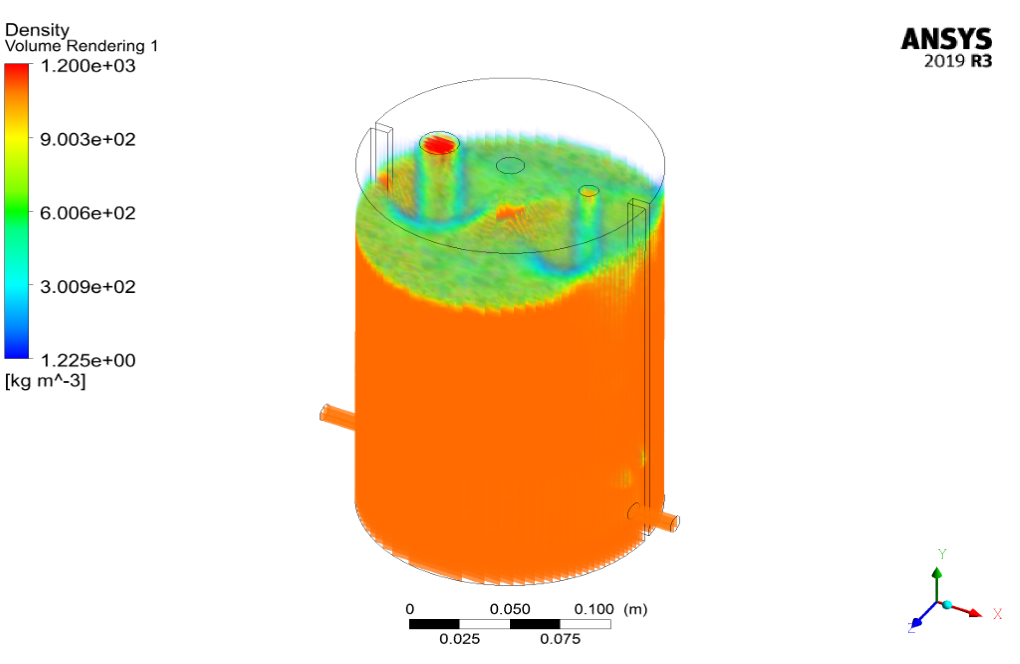

The present problem simulates the Mixer Tank by ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

In industry, mixing is an operation that involves the manipulation of heterogeneous materials with the intent to make them more homogeneous. Industrial Mixer is a machine that blends, homogenizes, and mixes different materials into a single substance.

Mixers combine virtually any solid or liquid necessary to form the final product. Mixing is performed to allow heat and mass transfer to occur between one or more components or phases. Modern industrial processing almost always involves mixing as it is needed during manufacturing or processing.

Their powerful motors and blades allow mixers to work with various materials. These machines are widely used across many industries, including pharmaceutical, chemical, agriculture, food, and beverage.

In this project, a mixer tank is modeled, and the effect of its rotating impeller on the mixing procedure is investigated. In this tank, we consider mixxing 3 phases. Water flow and salt inlet have a mass flow rate of 0.6 kg/s.

The geometry is designed in ANSYS Design Modeler and meshed by ANSYS Meshing. The mesh type used for this geometry is unstructured, and the total element number is 152641.

Mixer Methodology

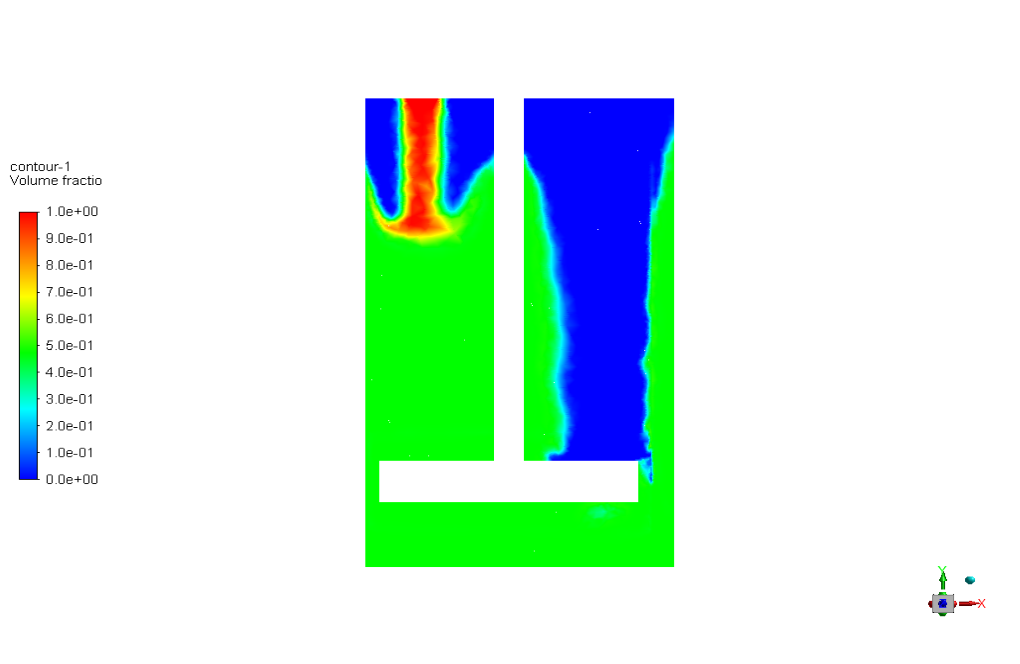

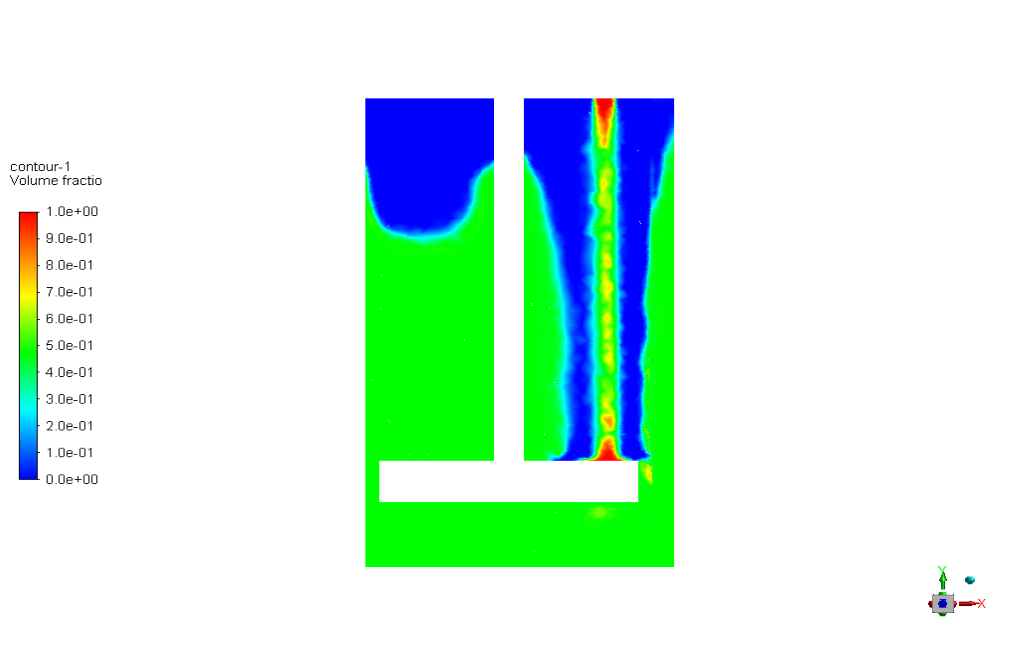

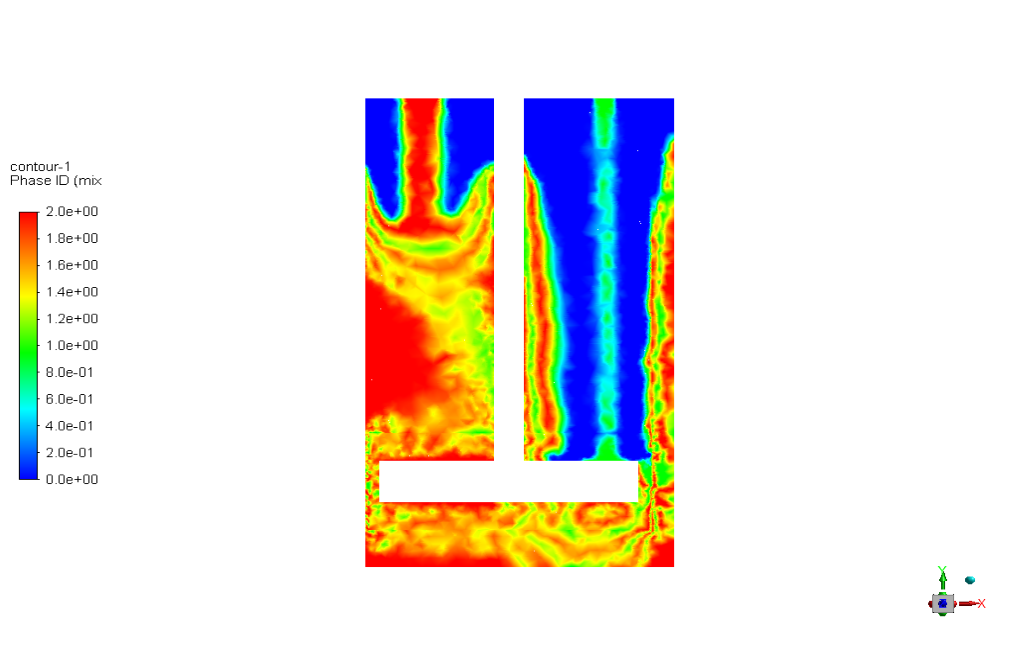

This simulation has been done in 3 phases: air, water, and salt. So, the simulation uses the VOF multiphase model for the three phases of air, water, and salt. MRF model is also used to model the rotation of the impeller.

The rotational speed of this tank is equal to 10 rpm.

Mixer Conclusion

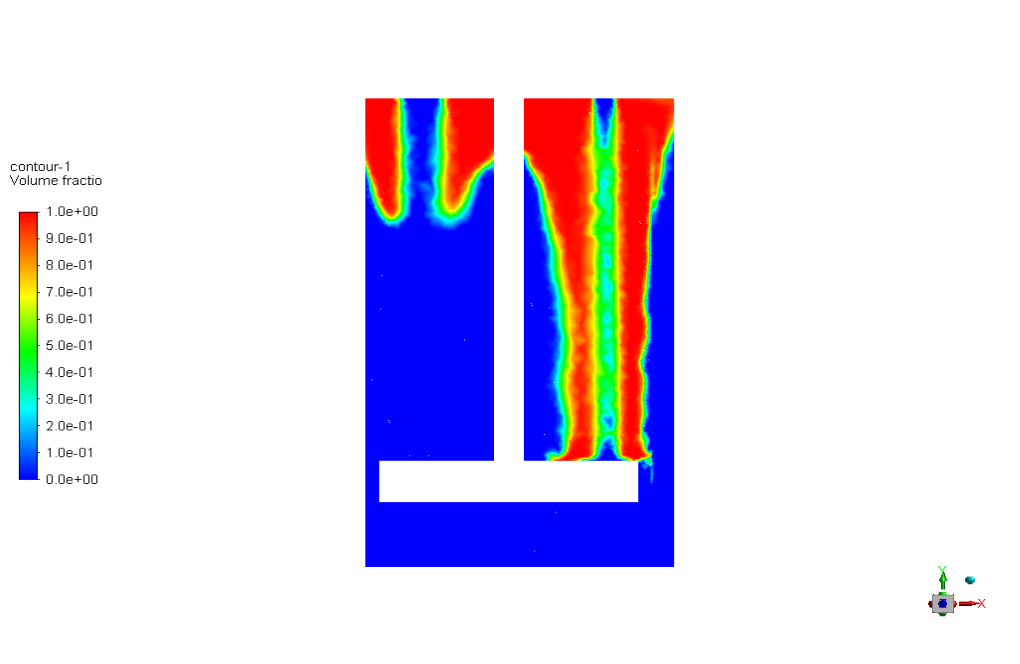

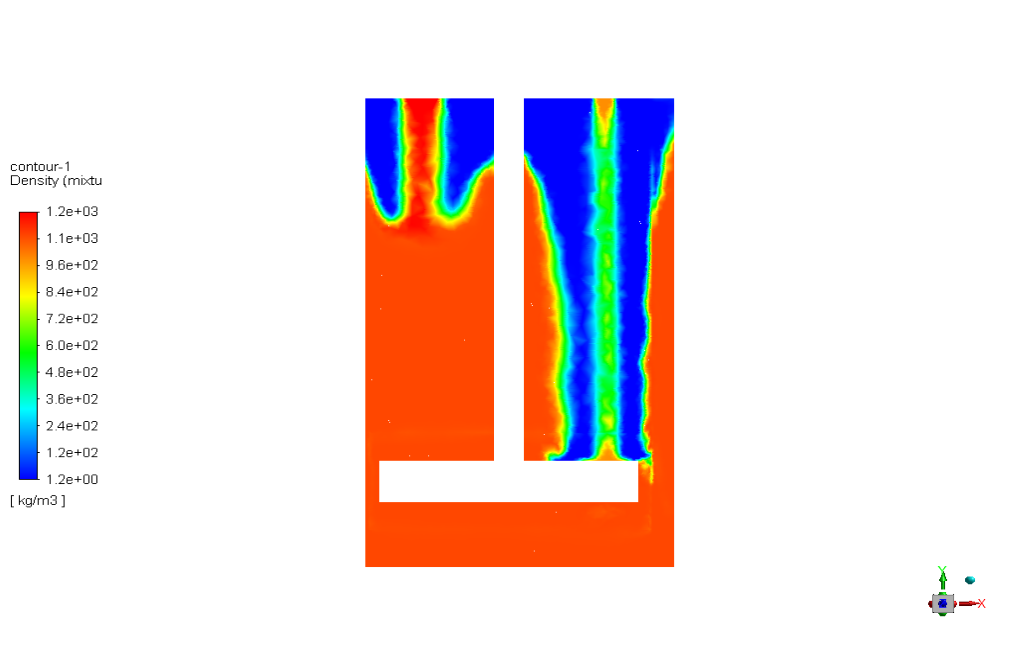

The contours of mixture density, velocity, phase ID, and volume fractions of water, air, and salt are obtained. As it is clear from the contours, due to the impeller’s rotation, the tank’s three-phase mixing phenomenon has occurred.

Sylvan Dach DVM –

So, how does the simulation deal with the impacts of different fluid characteristics?

MR CFD Support –

Well, the simulation has a model that’s spot-on at grabbing the impacts of different fluid properties, like density and stickiness, on the whole mixing thing.

Dr. Barney Will Sr. –

I have a question: Can the simulation deal with different mixer designs or types?

MR CFD Support –

Absolutely, the simulation is super flexible. It can be tweaked to handle all sorts of mixer designs and types.

Bill Cummerata –

This Mixer Tank simulation seems very comprehensive. Can you explain how the MRF model helps with simulating the impeller’s rotation, and how it affects the mixing process?

MR CFD Support –

The MRF (Multiple Reference Frame) model is used to simulate the rotational movement of the impeller without actually physically rotating the mesh. In this model, we define a rotating reference frame within our computational domain that encompasses the impeller. Inside this frame, the impeller ‘rotates’ by subjecting it to rotational flow conditions in accordance to the desired rotation speed (in this case, 10 rpm). It generates flow patterns that resemble those created by a real rotating impeller, leading to adequate simulation of the mixing process within the tank. The rotation introduces shear and mixing forces, which affect the mixing process, causing homogenization of the different phases within the tank.

Estella Douglas –

I’m interested in knowing how the solver determined the necessary iterations for convergence in this simulation. Does it use a predefined number of iterations, or is it adjusted dynamically?

MR CFD Support –

Convergence in a CFD simulation such as the Mixer Tank is usually assessed based on the residual levels of the governing equations and set monitors for key variables that indicate when a steady state has been reached, or the transient solution is adequately resolved. The solver does not necessarily have a predefined number of iterations; instead, it continues to iterate until the specified convergence criteria have been met. These criteria are often user-defined and may include factors such as the continuity, momentum, and species conservation residuals falling below a certain threshold, as well as monitored quantities like mass and energy imbalances or specific flow parameters reaching a steady or repeatable pattern in a transient analysis._dynamicmesh

Eloise Sanford MD –

The thoroughness of the different phase interactions is impressive. Well done on such an intricately detailed simulation leveraging the VOF model and showing the effects of impeller rotation!

MR CFD Support –

Thank you for your positive feedback! We’re glad you appreciate the intricate details of our multiphase modeling and the effects of mechanical operations in the CFD simulation. It’s always rewarding to see our customers recognize the efforts made to ensure accurate and detailed simulations. If you have any further insights or queries, don’t hesitate to reach out!

Justen Stokes DVM –

I’m thrilled with how engaging the training was on the Mixer Tank CFD Simulation! Besides what was mentioned in the Conclusion, did the training cover how to interpret results for different operating conditions or how to scale up the process for industrial applications?

MR CFD Support –

Thank you for your positive feedback! We’re pleased to hear you found the training engaging. Yes, the training includes how to interpret the results under different operating conditions. For scaling up the process, it generally involves more in-depth analysis and considerations; however, this can be explored further by applying the fundamentals learned in this course to larger-scale systems. We’re committed to providing detailed instructions that assist learners in developing the skills needed for numerous applications, including industrial scaling. Thank you for choosing our training, and we are here to support your ongoing learning journey!

Carlee Upton –

Great results in the mixer tank simulation. Seeing the three-phase mixing phenomenon occur due to the impeller’s rotation is quite impressive. The successful capture of mixture density, velocity, phase ID, and various volume fractions in the contours is particularly noteworthy. Kudos to the team for their meticulous work on this project.

MR CFD Support –

Thank you so much for your kind words and for appreciating the efforts put into the Mixer Tank CFD Simulation project. It’s great to hear that the simulation results met your expectations and provided insightful observations into the mixing process. Your encouragement fuels our passion for delivering high-quality simulations and training. If you have any more feedback or need further assistance with your CFD learning journey, feel free to reach out to us.

Gaetano Ruecker V –

The tutorial for the Mixer Tank simulation was incredibly insightful, especially the impressive detail on the interaction between impeller rotation and fluid dynamic properties. Thumbs up to the MR CFD team for the crystal clear visual presentation of the mixture density and phase distribution!

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that our Mixer Tank simulation tutorial met your expectations and provided valuable insights. It’s fantastic to know the visual aspects of the simulation were particularly helpful for you. If you have further questions or need assistance with similar projects in the future, feel free to reach out to us.

Bernie Swift MD –

I’m very impressed with how the three-phase mixing is visualized in the simulation! It clearly shows the mixer’s efficiency. Can you also provide insights about how the mixture’s homogeneity changes over time?

MR CFD Support –

Thank you for your kind words! While the specific time-dependent homogeneity changes are not detailed here, generally, the simulation demonstrates how these phases interact and mix in response to the impeller’s motion. To gain insights on how homogeneity changes over time, the simulation results can be analyzed at various time steps to observe the evolution of the mixture’s uniformity.

Dr. Ted Bartell III –

I am deeply fascinated by the complexity of the mixer simulation and how it manages to represent various phase interactions. The results you have gained, especially the density and velocity contours, undoubtedly reveal the dynamic behavior within the tank. Excellent job on bringing those fine details to light!

MR CFD Support –

We truly appreciate your enthusiasm and positive feedback about the mixer tank CFD simulation! It’s heartening to know that our efforts in delivering a comprehensive representation of the mixing process have resonated well with you. Thank you for recognizing the hard work and detail that went into this simulation. We strive to continue providing high-quality learning materials to help further your understanding. If you have any more insights or questions, feel welcome to reach out!

Dr. Aniya Blanda –

How does the simulation model the interaction between the mixer and the fluid?

MR CFD Support –

The simulation uses a robust model to accurately capture the interaction between the mixer and the fluid, including the effects of turbulence and viscosity.

Mr. Danny Corwin –

I am impressed with how the Mixer Tank simulation captures the intricate details of the mixing process across different industries. The visualization of mixture density and phase interactions is especially enlightening and shows the effectiveness of the system. Well done on delivering such an informative and detailed study!

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that you found the Mixer Tank simulation informative and the visualization of the mixing process enlightening. Our goal is to provide comprehensive and realistic simulations to aid in understanding complex industrial systems. Your appreciation means a lot to us!

Lisette Kulas –

Outstanding training on Mixer Tank CFD Simulation using ANSYS Fluent. The multi-phase modeling and rotation effects on the mix showcasing the mixture density and velocity variations are particularly impressive.

MR CFD Support –

Thank you for your positive review and feedback on the Mixer Tank CFD Simulation training using ANSYS Fluent! We are thrilled to hear that you found the multi-phase modeling and the effects of the impeller’s rotation to be well demonstrated and informative. We appreciate you choosing our training for your learning experience.

Reed Walker –

The Mixer Tank tutorial was clearly explained and easy to understand. The visuals of how the impeller affects the mixing process were particularly impressive. I appreciated the attention to detail and the step-by-step guidance throughout the simulation process. Great work on demonstrating the multiphase flow concept effectively!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you found the Mixer Tank CFD Simulation tutorial informative and visually impressive. Our goal is always to provide comprehensive guidance to ensure concepts are understood clearly. It’s fantastic to know that we’ve hit the mark for you. If you have any further questions or need assistance in future projects, don’t hesitate to reach out. Thank you for choosing our learning products!

Gracie Towne –

This Mixer Tank CFD simulation tutorial sounds thorough. The aspects of emulating the industrial mixing process and leveraging the multi-phase capabilities in ANSYS Fluent could significantly enhance learning and practical application skill sets for many industries.

MR CFD Support –

Thank you for your positive feedback on our Mixer Tank CFD simulation tutorial. We are thrilled to hear you recognize the educational value and the real-world applicability of this training module! Ensuring that our training is thorough and useful for industry professionals is a high priority for us. If you have any further comments or require assistance with your CFD projects, don’t hesitate to reach out.

Ruthe Turner –

This training course has greatly enhanced my understanding of CFD in practical, industrial applications. The comprehensive study of the mixer tank, from mode design to the sophisticated three-phase mixing analysis, brought theory to life for me. The utility of the MRF model to mimic the impeller’s rotation is fascinating, and seeing how mediums like water, air, and salt interact in different phase fractions is incredibly informative.

MR CFD Support –

Thank you very much for your positive review! We’re thrilled to hear that our Mixer Tank CFD Simulation training has been so beneficial for you. Understanding the dynamics of mixing three different phases and the application of the MRF model is key for many industries, and we’re glad that it resonated with you. If you have any more questions or need further assistance in your CFD journey, don’t hesitate to reach out.

Mr. Ernest Pollich –

I recently completed the Mixer Tank simulation using ANSYS Fluent. The step-by-step learning approach really helped me to understand the mixing process, and seeing the density variation and mixing efficiency in the contours was enlightening. Witnessing the three-phase mixing occurrence due to the impeller’s action was intriguing.

MR CFD Support –

Thank you for your positive feedback on the Mixer Tank simulation! We’re delighted to hear that our training module was efficient in enhancing your understanding of the mixing processes and that the practical application of the simulation met your expectations. If you have any future questions or need further assistance, don’t hesitate to reach out. We value your engagement with our learning resources!

Elyse Nikolaus –

The Mixer Tank CFD Simulation tutorial was highly informative. The animation showing the mixer in operation and the elucidation on the contours of mixture density and phase interactions was thoroughly enriching.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you found the Mixer Tank CFD Simulation tutorial to be informative and helpful. If there’s anything more you wish to learn about CFD simulations, please don’t hesitate to ask.

Mrs. Naomi Sanford Jr. –

I’m delighted by how the Mixer Tank CFD Simulation was able to improve my understanding of heterogeneous material mixing in industrial applications. The demonstration of the impeller’s effects on three-phase mixing was particularly invaluable.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our Mixer Tank CFD Simulation could provide you with a clearer understanding of the mixing process and the role of an impeller in industrial applications. If you have further inquiries or need additional support, feel free to reach out.

Bethany Walker –

The Mixer Tank CFD Simulation course was incredibly informative. I understood every part of the process and lesson. The visual presentations of the density and phase changes helped me grasp the mixing mechanisms effectively. Great job on creating a thorough and comprehensive training module!

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that our Mixer Tank CFD Simulation course proved helpful and that the visual elements enhanced your understanding of the mixing process. We strive to provide comprehensive and informative training, and your feedback reaffirms our commitment to quality education. If you ever have any more questions or need further assistance with CFD simulations, don’t hesitate to ask. Cheers to your continuous learning journey!

Alexander Harvey –

Fantastic learning experience! The content was well explained and the hands-on simulation for the Mixer Tank using ANSYS Fluent was truly insightful. It helped me understand the intricate details of CFD analysis in three-phase mixing scenarios.

MR CFD Support –

Thank you for your kind words! We’re glad to hear that you had a fantastic learning experience and that our Mixer Tank CFD Simulation training helped deepen your understanding of multiphase CFD analysis. Your feedback motivates us to continue providing high-quality learning materials!