Methane Combustion in a Gas Stove CFD Simulation, ANSYS Fluent

$140.00 Student Discount

- In this project, the combustion of methane in a gas stove was modeled using ANSYS Fluent.

- Methane mechanism was chosen for reaction mechanism and eddy dissipation model used for turbulence-chemistry.

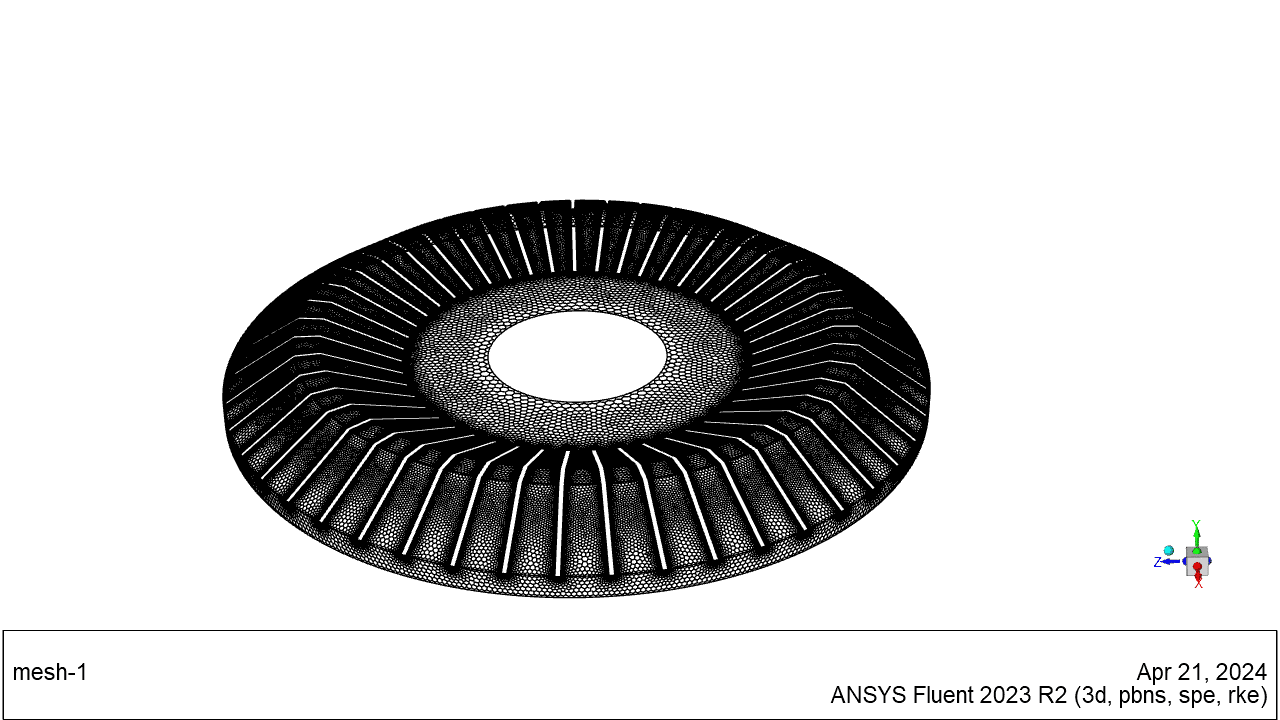

- The geometry was created in Design Modeler, and a mesh consisting of 5,533,297 elements was generated using Fluent Meshing.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

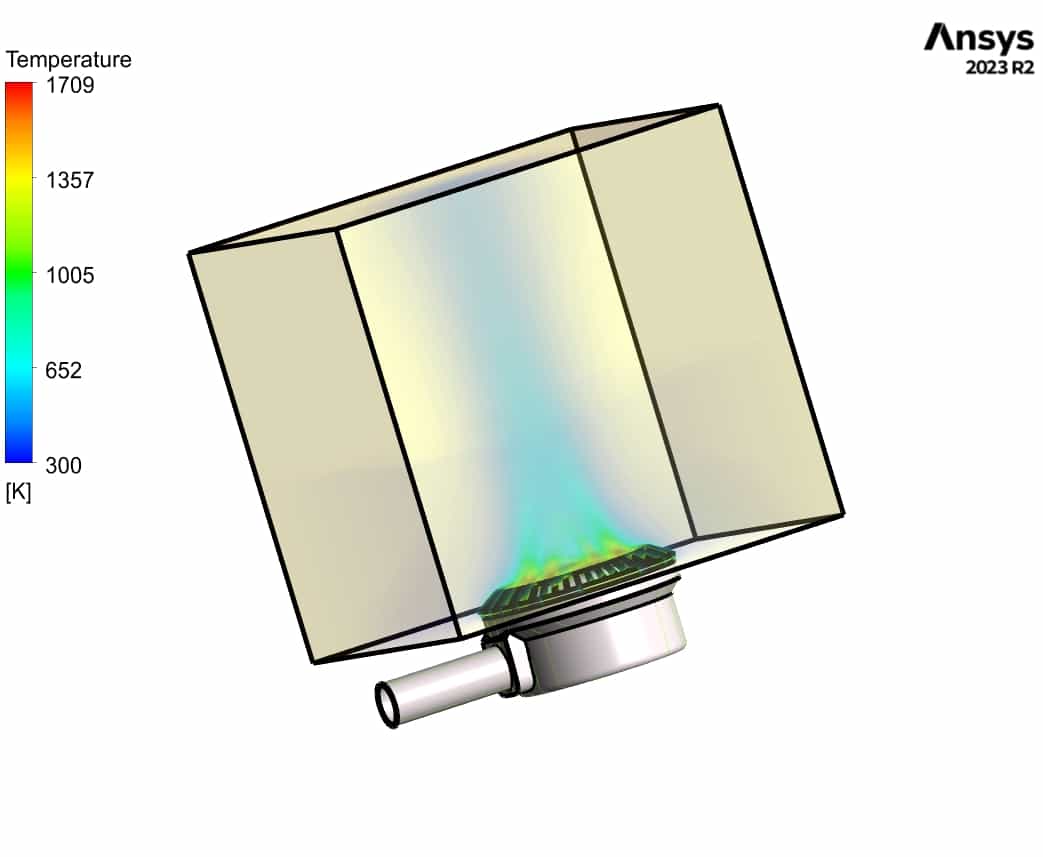

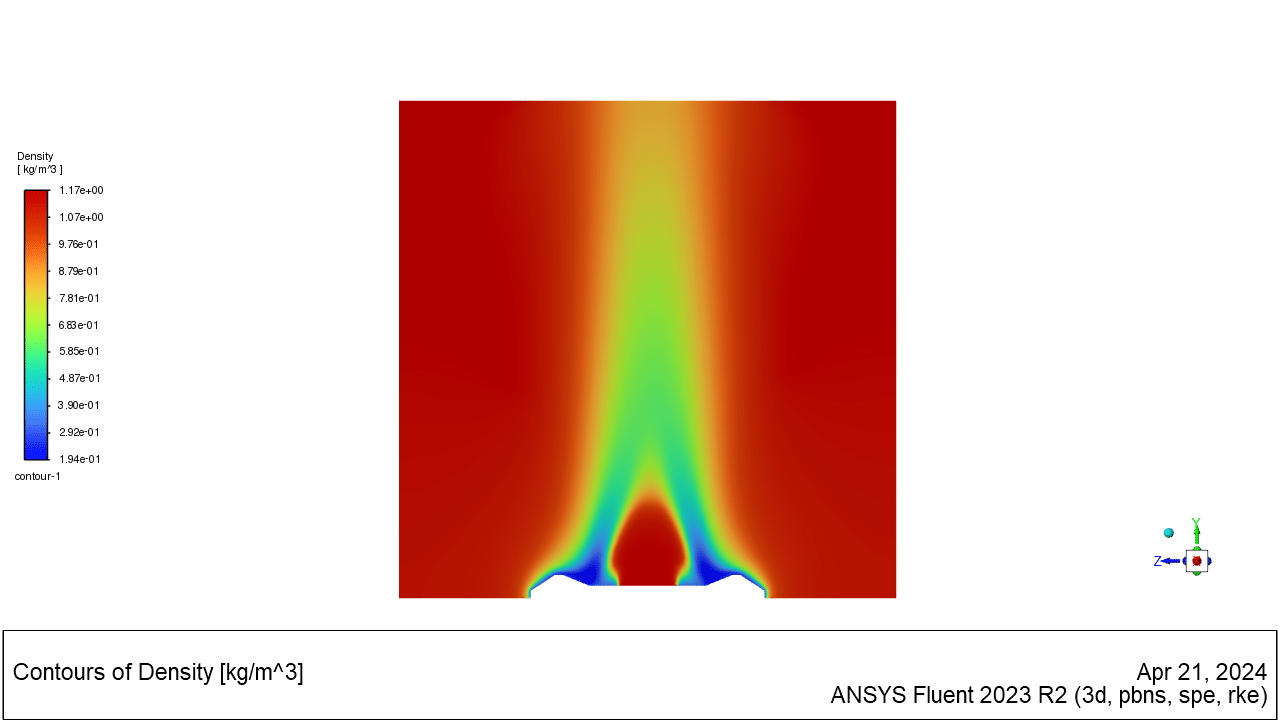

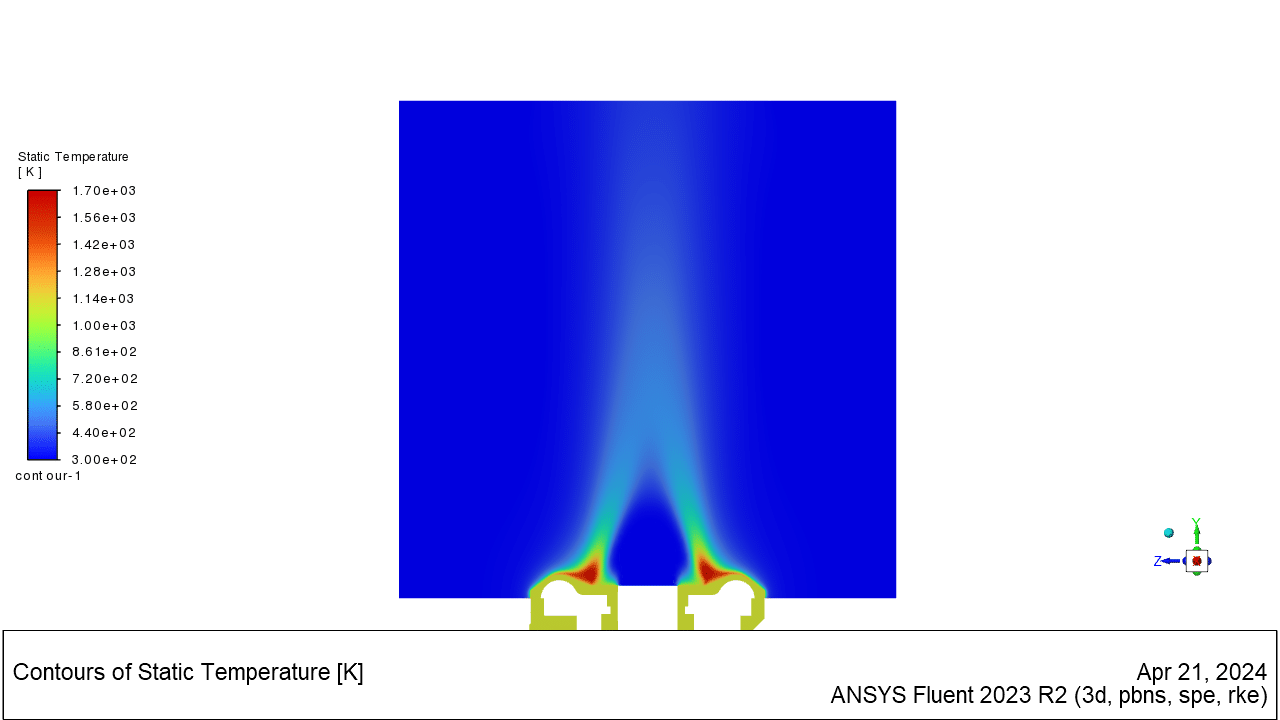

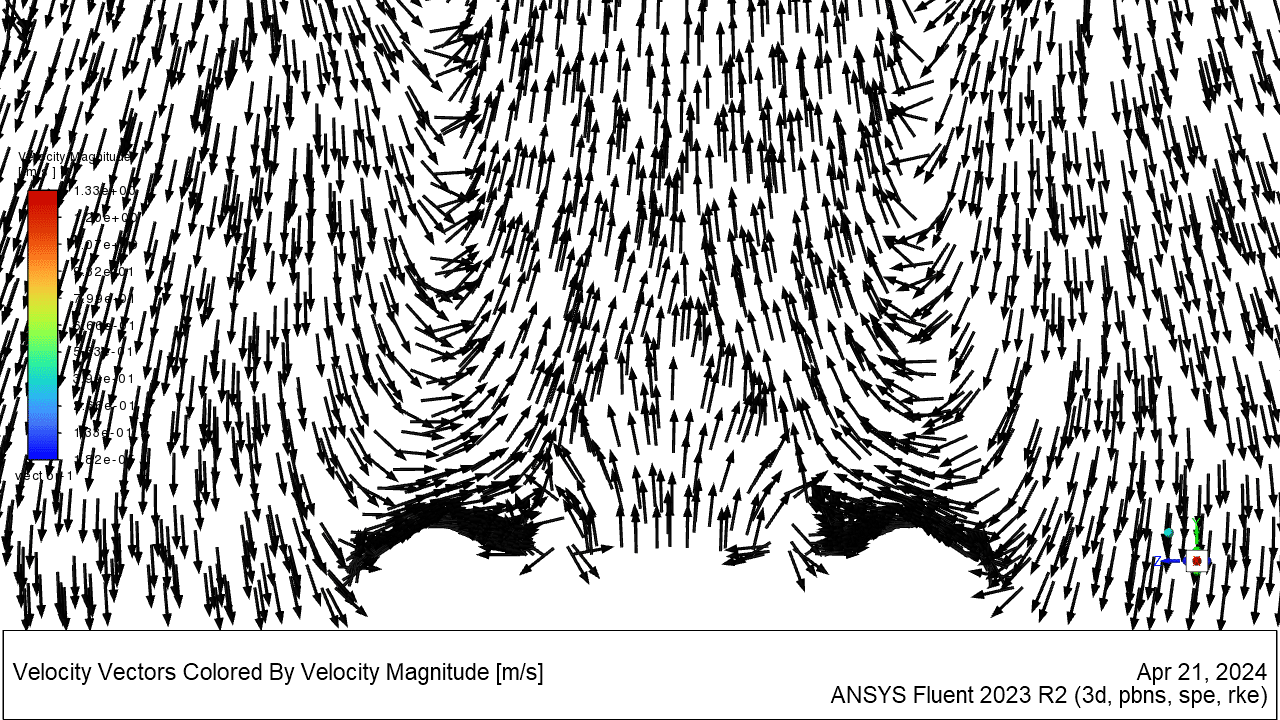

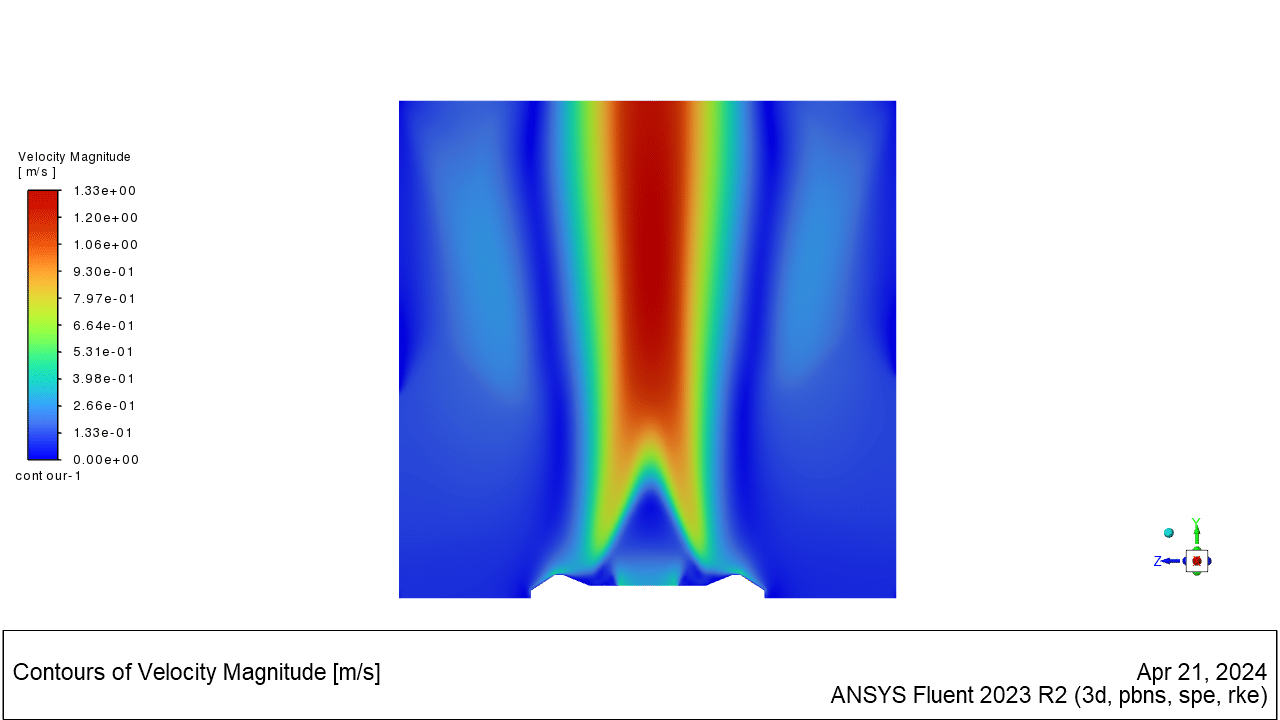

Modeling the combustion process in a gas stove is crucial for various reasons such as design, optimization, and enhancing safety and efficiency. In this project, we simulate combustion and heat transfer in a gas stove. When methane burns in a gas stove, it increases the temperature, which in turn decreases the air density. Consequently, the exhaust gases rise due to the buoyancy effect, and fresh, denser air is drawn in to sustain combustion.

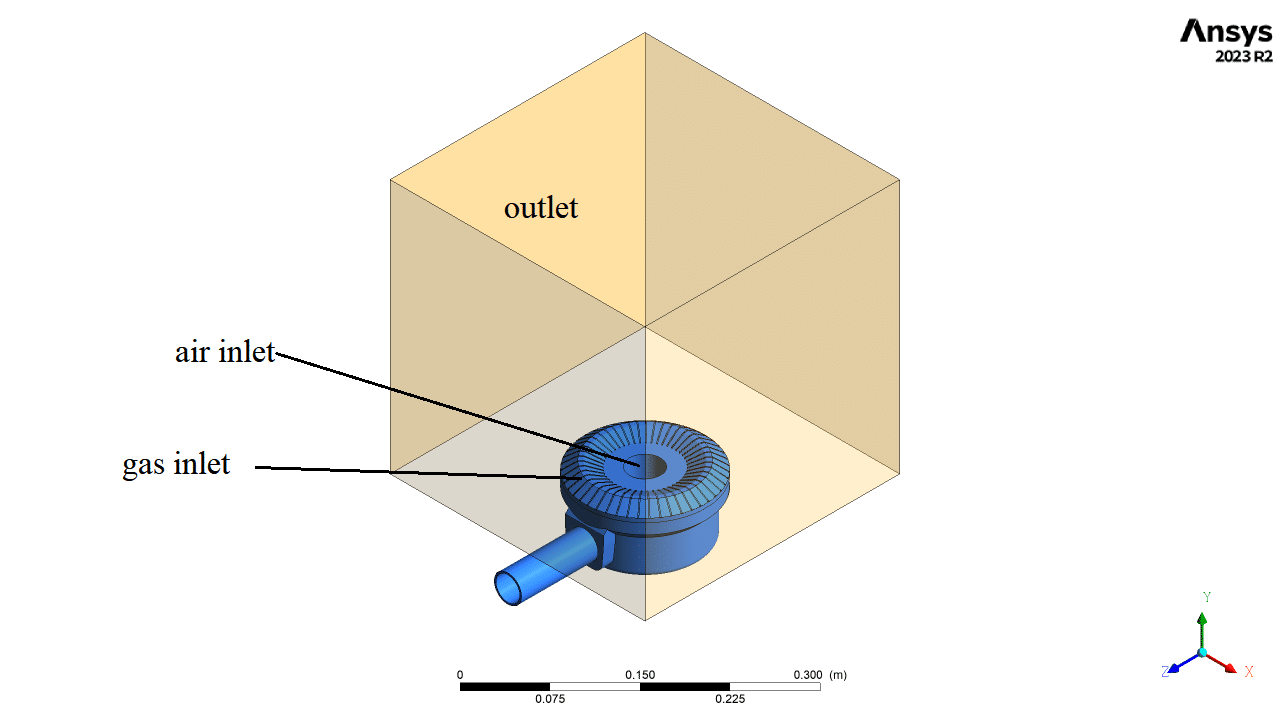

The gas stove is modeled in 3D. The fuel velocity at the inlet is set at 0.03 m/s, and the ambient temperature is specified as 300K. The air inlet boundary condition is defined as a ‘Pressure Inlet‘, which allows air to flow into the domain naturally due to the pressure difference.

The geometry is designed in Design Modeler® and meshed using Fluent Meshing®. The mesh type is unstructured, with an element count of 5,533,297.

Methodology

In this simulation, the k-ε Realizable model was selected for modeling the turbulence of the flow due to its accuracy in predicting the combustion process and its low computational cost. The Energy equation was also activated.

In the Species tab, the methane mechanism was chosen, and the turbulence-chemistry interaction was defined as eddy dissipation.

Results

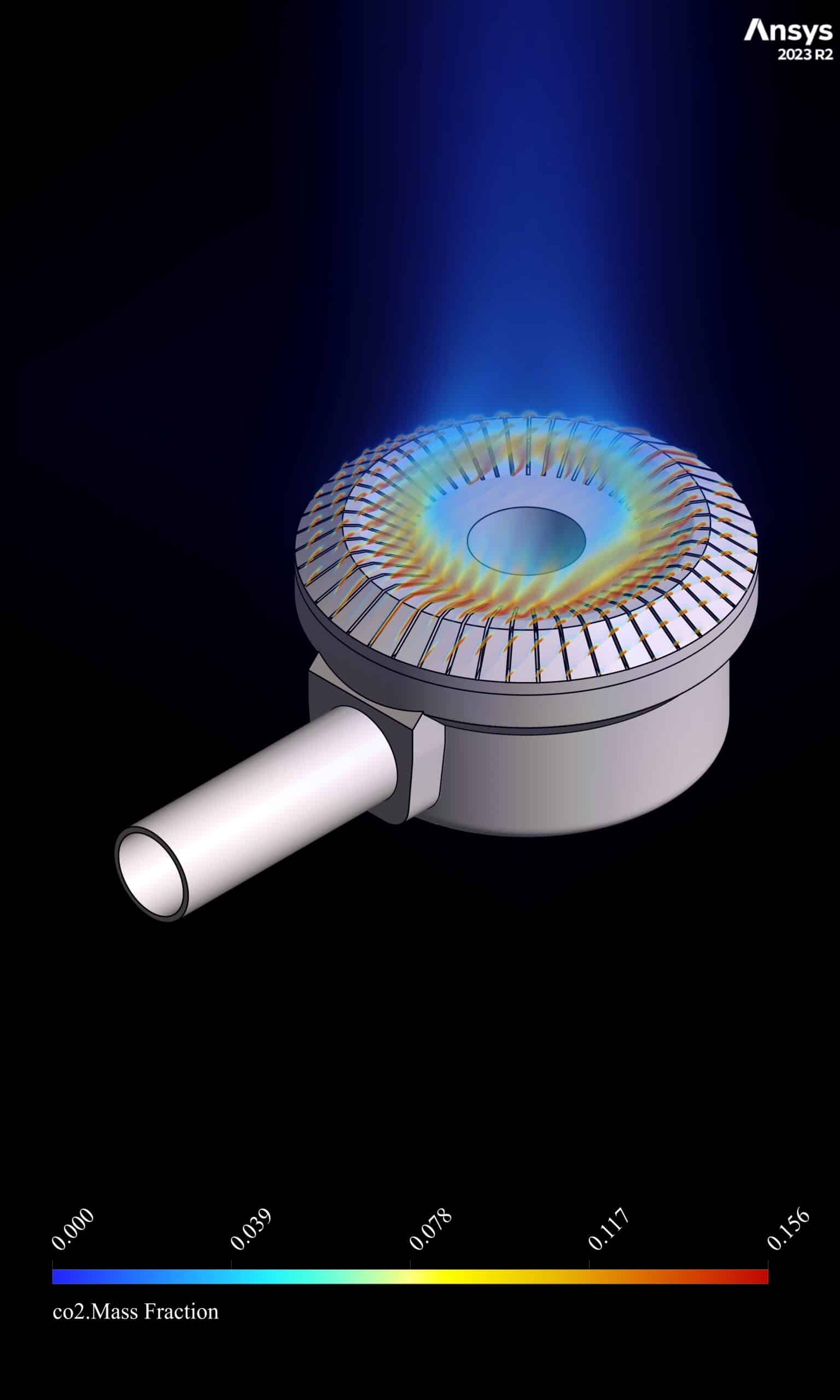

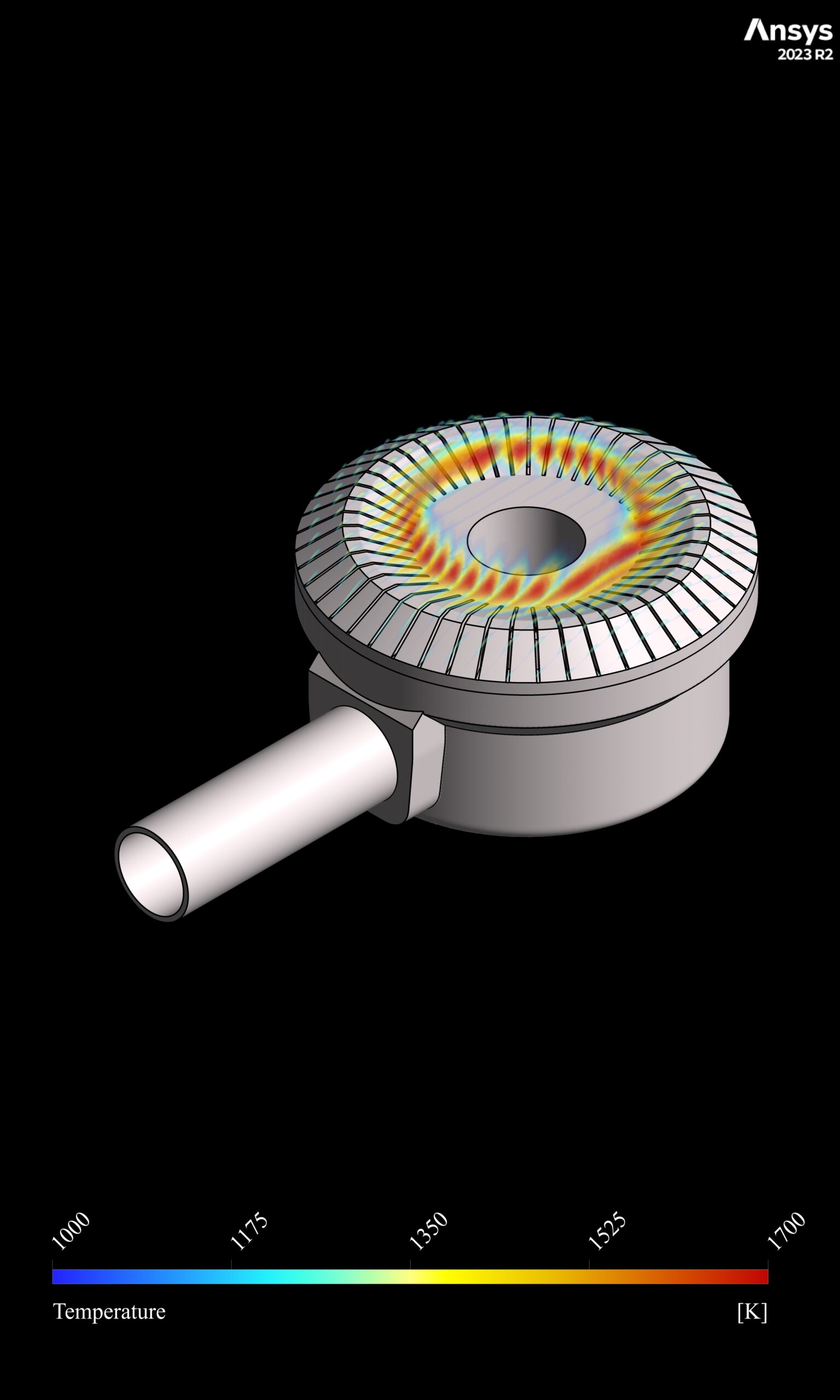

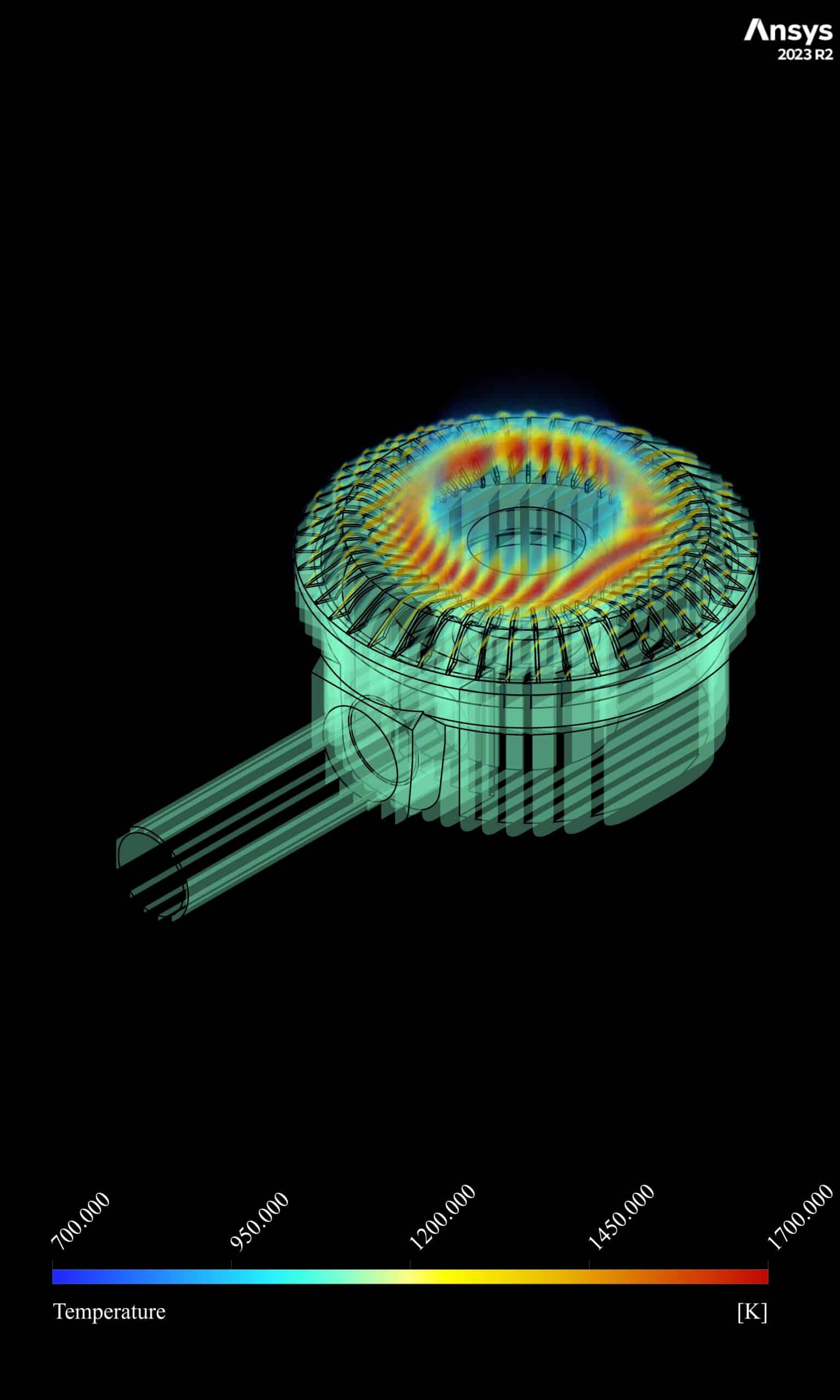

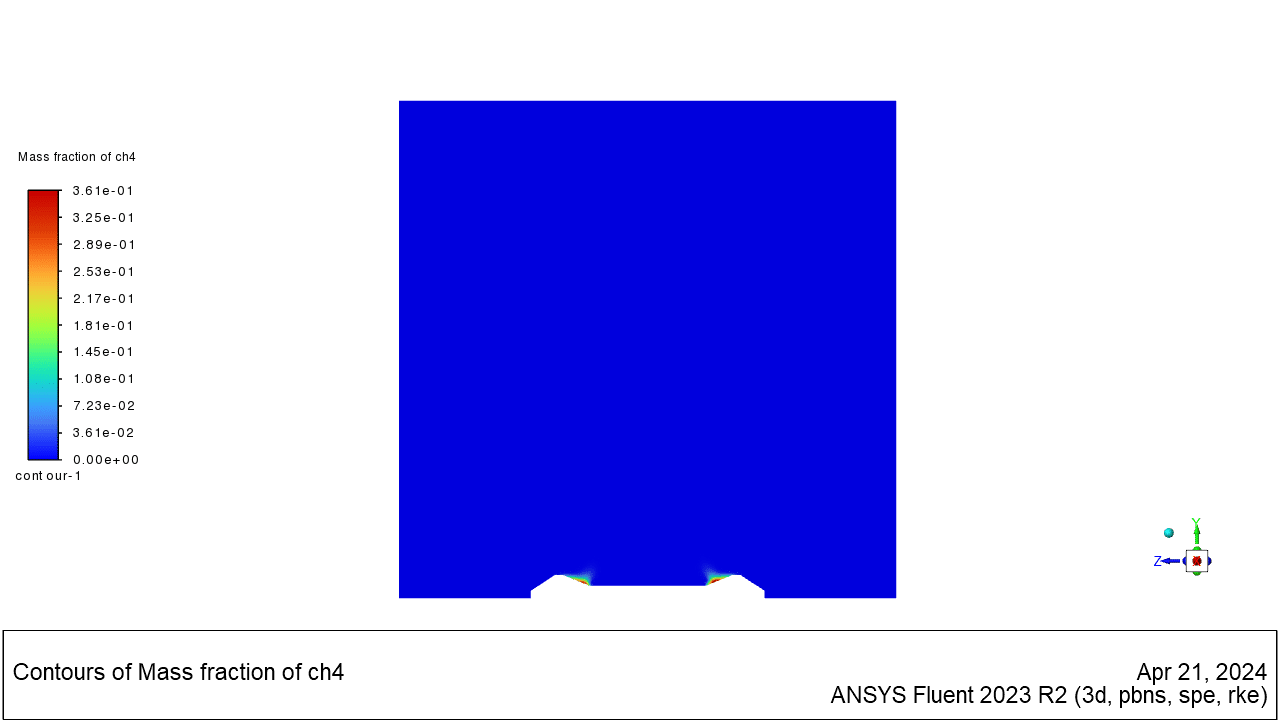

Contours of temperature, CO2 mass fraction, and velocity are presented in the axial plane. The maximum temperature in the combustion region reaches 1709 K, and the fuel mass flow rate is 1.22 * 10^-5 kg/s. The maximum velocity, attributed to buoyancy effects, is 1.33 m/s. Three-dimensional (3D) contours of temperature and CO2 mass fraction are also depicted.

Reviews

There are no reviews yet.