Nano Fluid Heat Transfer in a Porous Heat Exchanger

$160.00 Student Discount

- The problem numerically simulates Nano Fluid Heat Transfer in a Porous Heat Exchanger using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 4148881.

- The Energy Equation is activated to consider heat transfer.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Nano Fluid Heat Transfer in a Porous Heat Exchanger, ANSYS Fluent CFD Simulation Tutorial

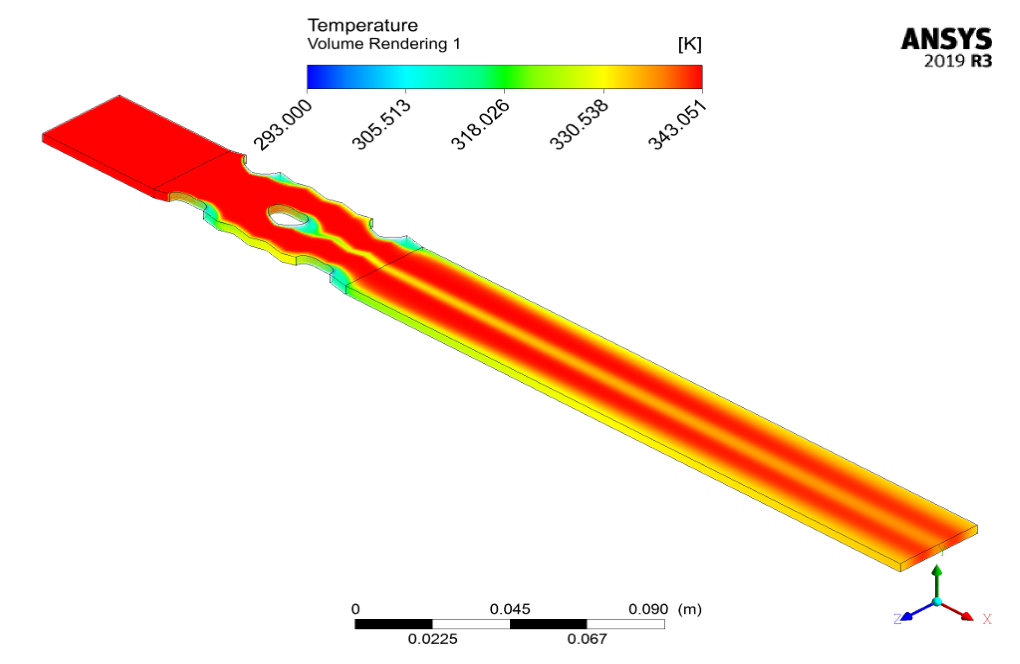

In this project, Nanofluid flow heat transfer in a porous medium heat exchanger is simulated and analyzed by ANSYS Fluent software.

In recent decades, many studies on fluid flow and heat transfer in porous media have been conducted by researchers. A porous medium is formed so that its volume includes pores and apertures.

Porous media have wide applications in industry, such as crude oil production, optimal insulation of buildings and heat exchangers with recovery, etc. (Nanofluid)

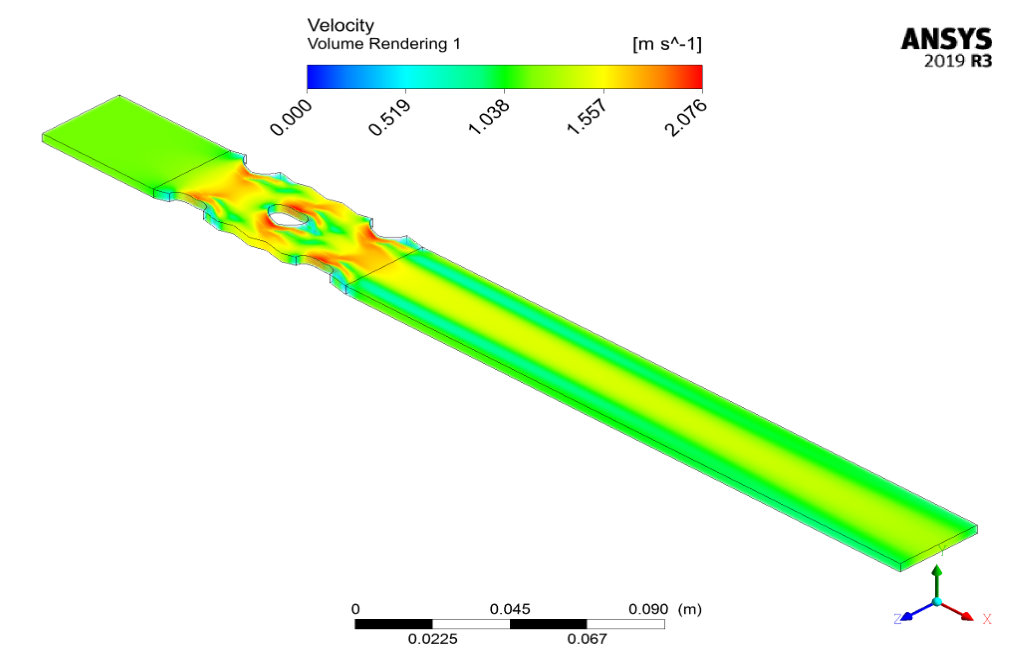

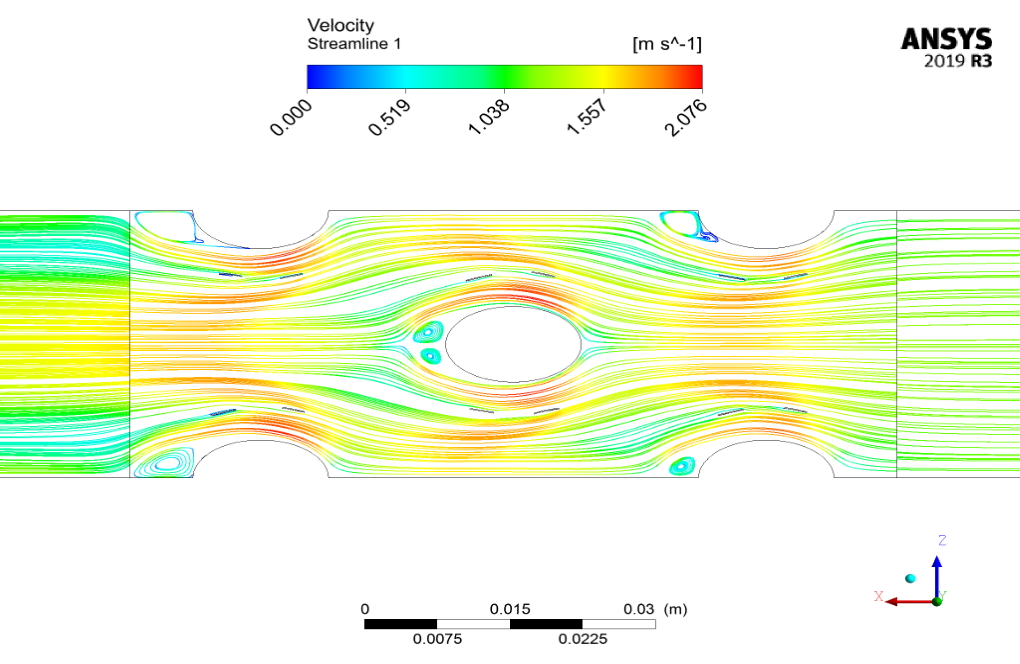

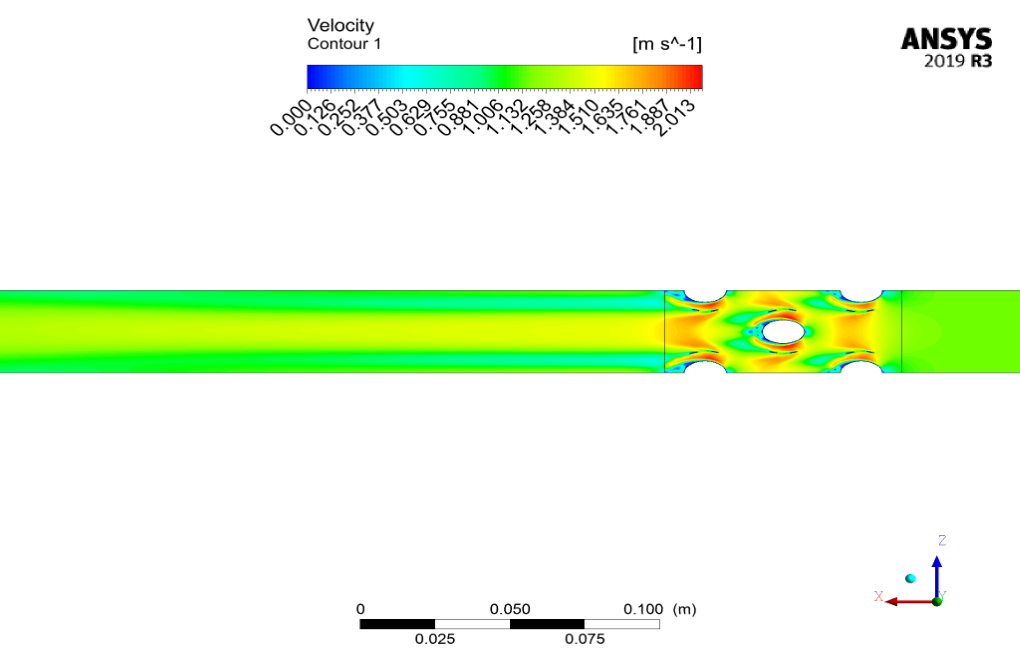

Incoming flow has a velocity of 1.63 m/s. Porous has a temperature of 343 k, and tube has a temperature of 293 k. The energy model is activated.

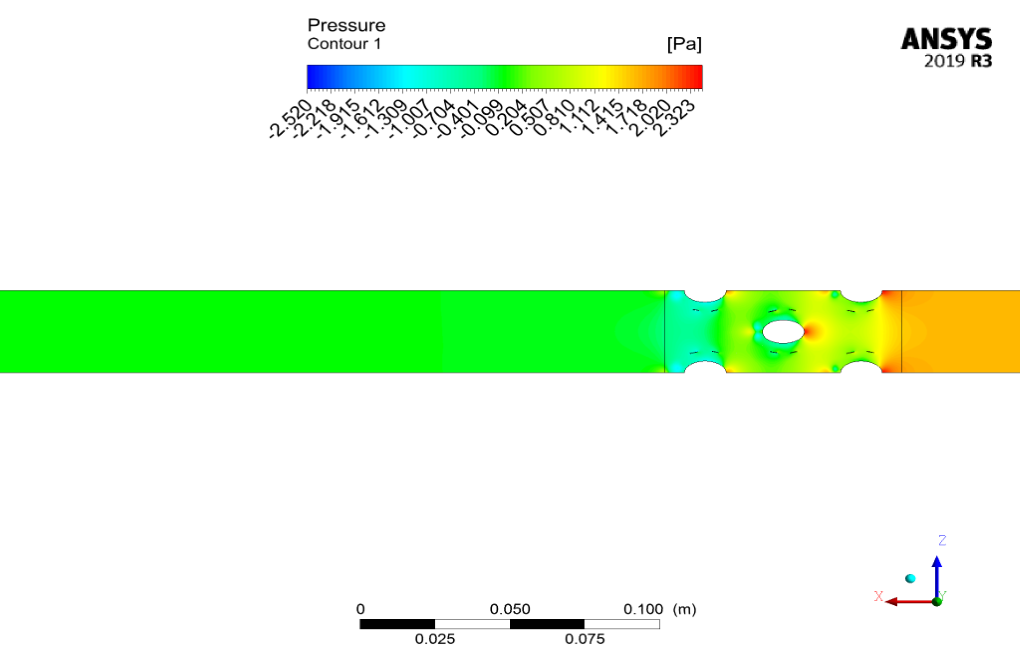

The geometry of this project is designed in ANSYS design modeler® and is meshed in ANSYS meshing®. The meshes used for this geometry are structured for the upstream and downstream parts of the domain and unstructured for the middle part of the geometry. The total number of mesh cells is 1901882.

Nano Fluid Methodology

We have used a nanofluid as an incoming fluid flow in this simulation. The energy equation is activated to compute temperature changes.

Nano Fluid Conclusion

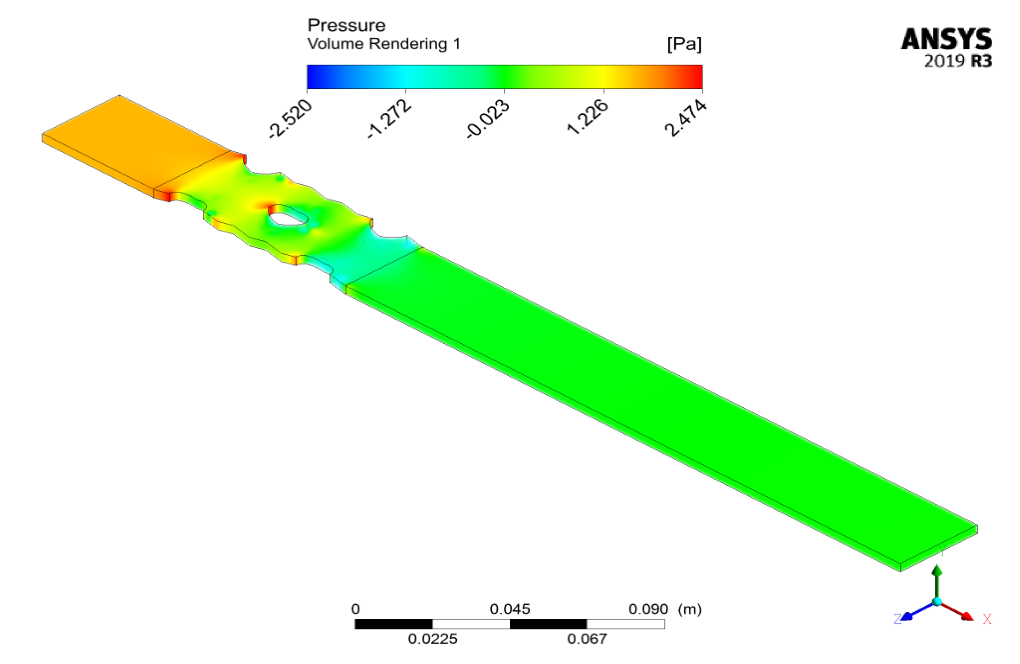

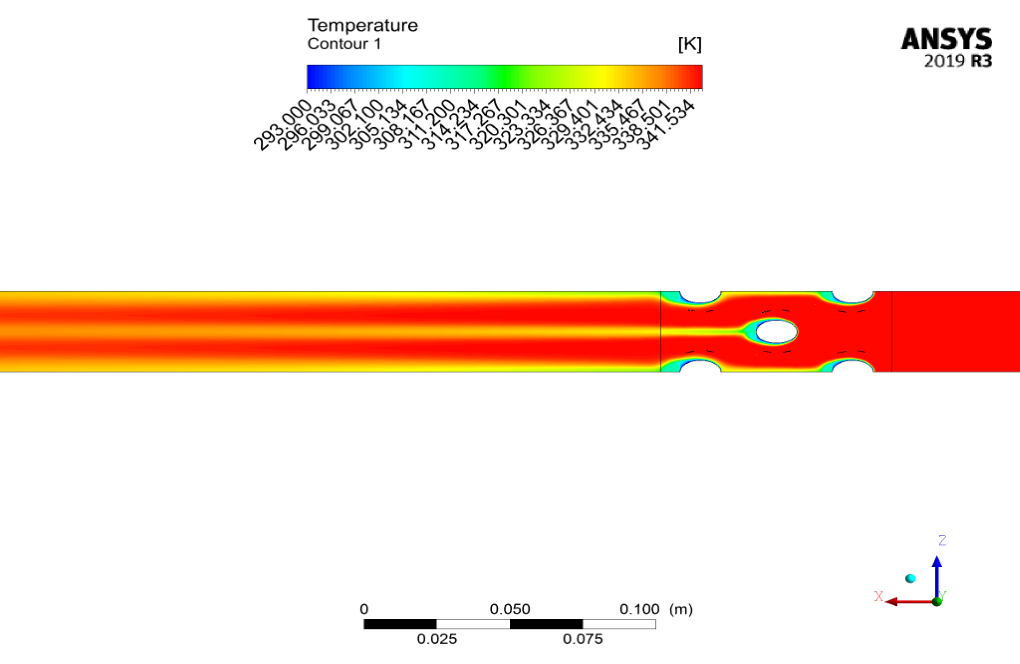

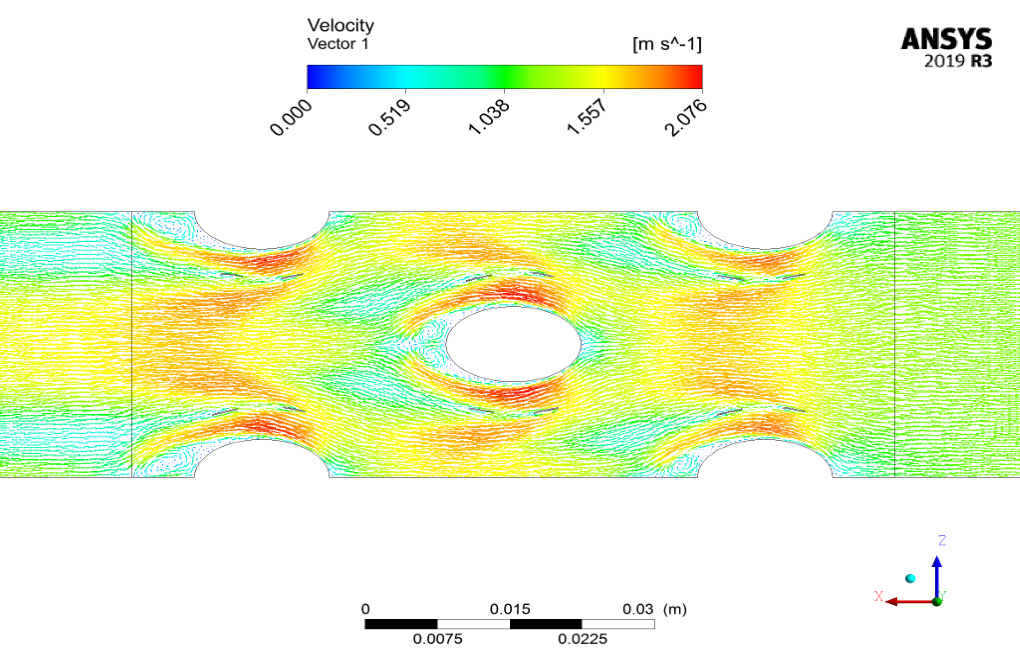

At the end of the solution, we obtain the contours of pressure, velocity, temperature, streamlines, and velocity vectors. The contours show temperature changes well. Especially in the area where there is prosthesis and velocity vectors are oriented according to the cavities.

Geo Swaniawski II –

How does the simulation handle the heat transfer between the nano-fluid and the heat exchanger walls?

MR CFD Support –

The simulation uses a sophisticated model to accurately capture the heat transfer between the nano-fluid and the heat exchanger walls.

Anibal Schneider –

How does the simulation model the properties of the nano-fluid?

MR CFD Support –

The simulation uses advanced models to accurately capture the unique thermal and flow properties of nano-fluids.

Dr. Rod Sawayn III –

Can the simulation model different types of nano-fluids?

MR CFD Support –

Yes, the simulation can be adjusted to model different types of nano-fluids by changing the properties of the base fluid and the nanoparticles.

Rosanna Roberts II –

I want to know how the simulation handles the interaction between the nano-fluid and the porous medium?

MR CFD Support –

The simulation uses a sophisticated model to accurately capture the complex interaction between the nano-fluid and the porous medium.