Mixing Tank with Helical Impeller CFD Simulation, ANSYS Fluent Tutorial

$100.00 Student Discount

- The problem numerically simulates the Mixing Tank with Helical Impeller using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler and create the mesh using ANSYS Meshing software.

- The mesh type is Polyhedra, and the element number equals 296,106.

- We perform this simulation as unsteady (Transient).

- The Mesh Motion option is enabled to define the rotational motion of the impeller.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

This project simulated a mixing tank with a helical impeller using the sliding mesh option.

The closed mixing tank contains water liquid while the helical impeller starts rotating with 200 rpm angular velocity and creates a massive vortex in the middle of the tank.

The 3D geometry was created in Design Modeler software. A helical blade is located at the top of a mixing tank. In addition, an unstructured mesh grid was carried out using ANSYS Meshing software, and overall, 1,442,934 elements were generated. Still, After hiring Ansys Fluent software’s “Make Polyhedral “capability, the number of elements has reached 296,106.

Methodology: Mixing Tank with Helical Impeller

The simulation is Transient(unsteady) in order to capture the behavior of fluid over time. The Pressure-based solver type is used due to the incompressibility of the working fluid. The gravitational acceleration effects are considered by defining 9.81 m/s^2 in the negative direction of Y. Also, the Mesh Motion option is enabled to model the rotational motion of the impeller.

Conclusion

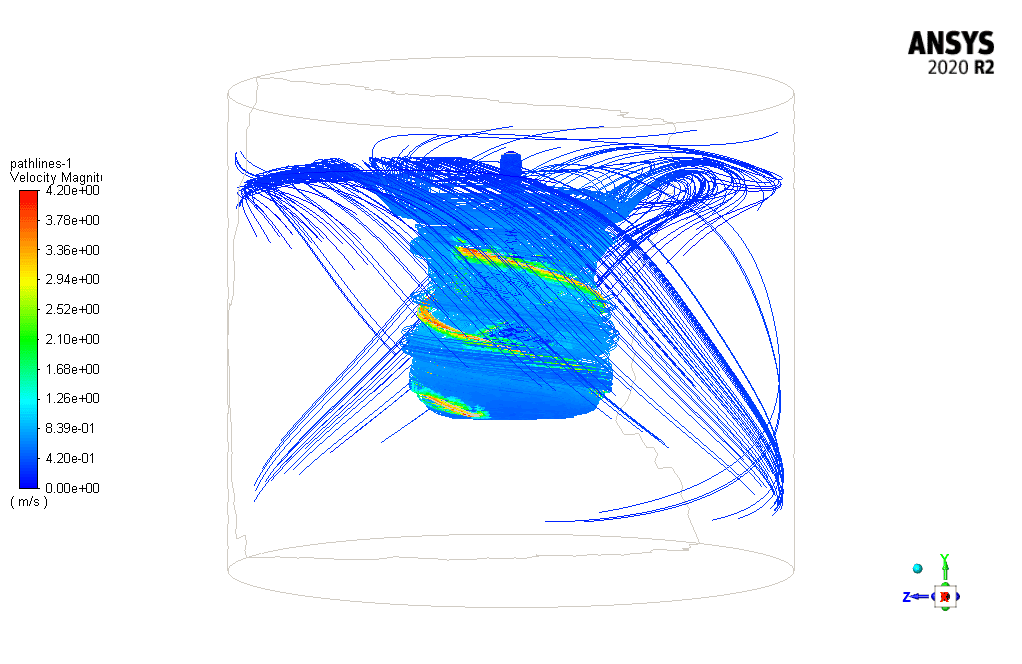

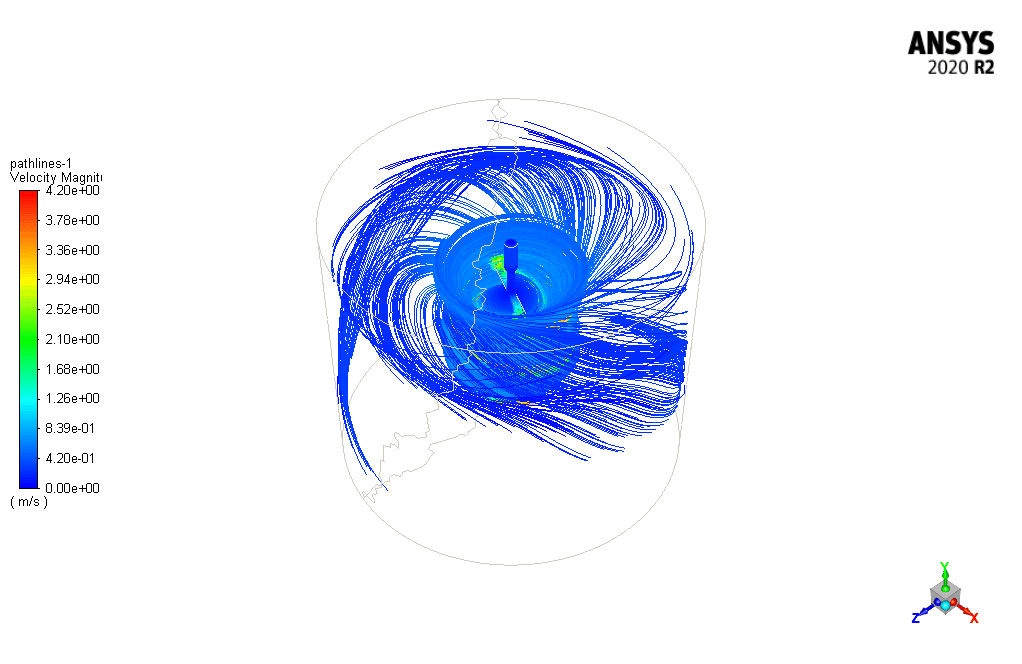

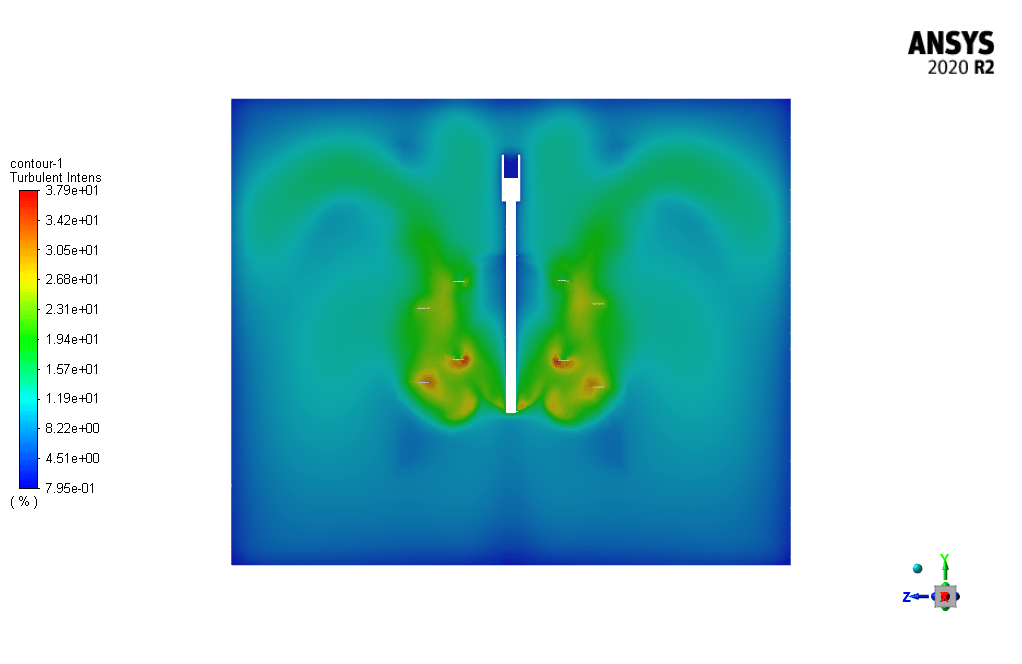

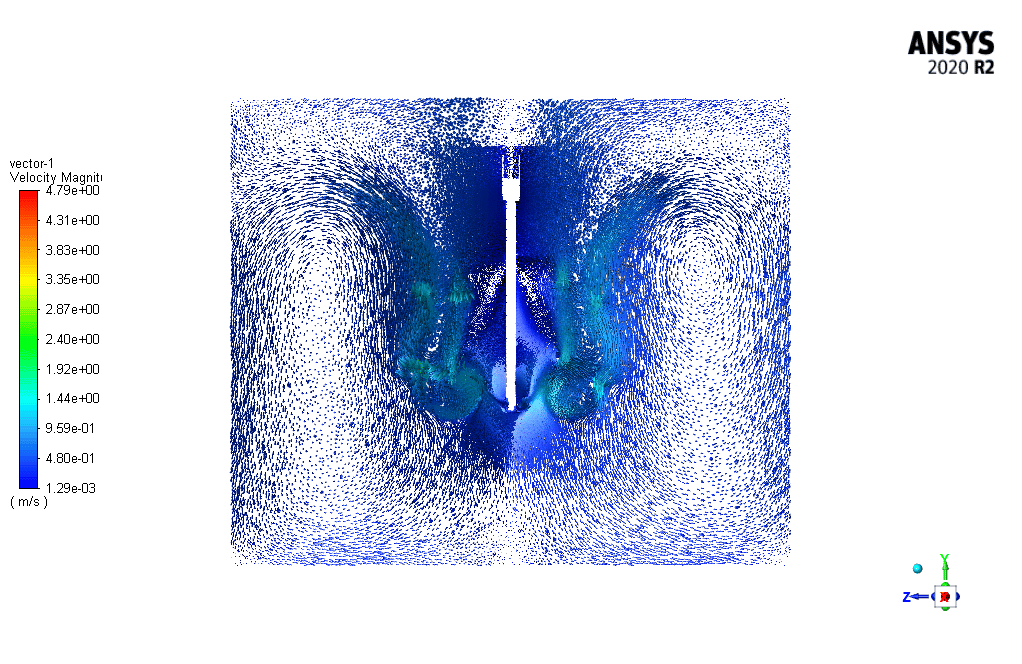

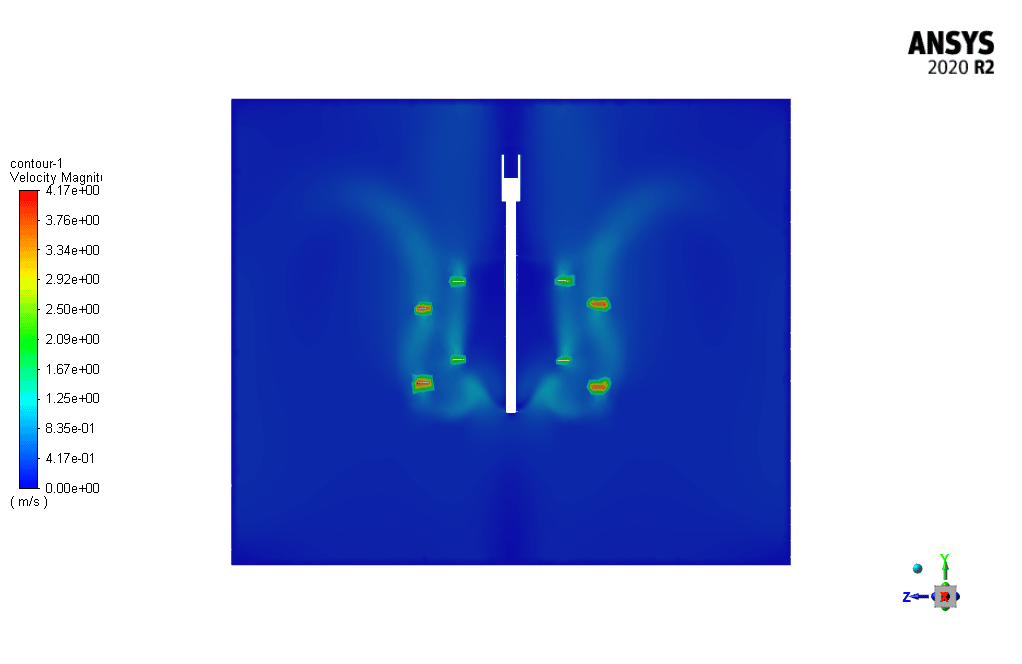

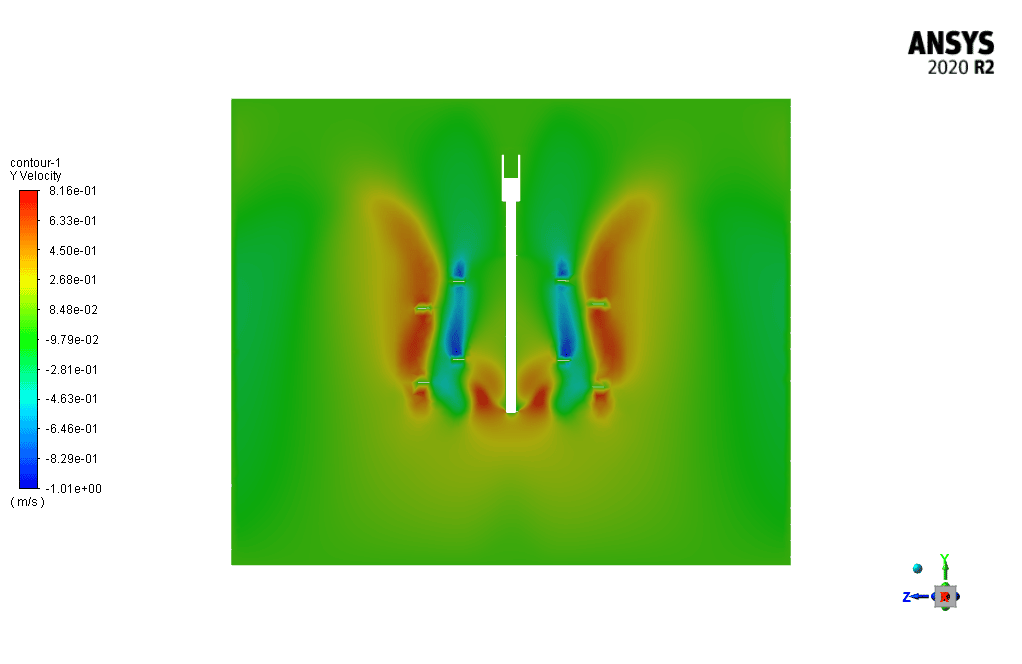

The cylindrical mixing tank is full of water liquid, while the helical impeller rotates with 200rpm angular velocity. The rotational motion creates a massive vortex in the middle of the tank and increases the mixing rate.

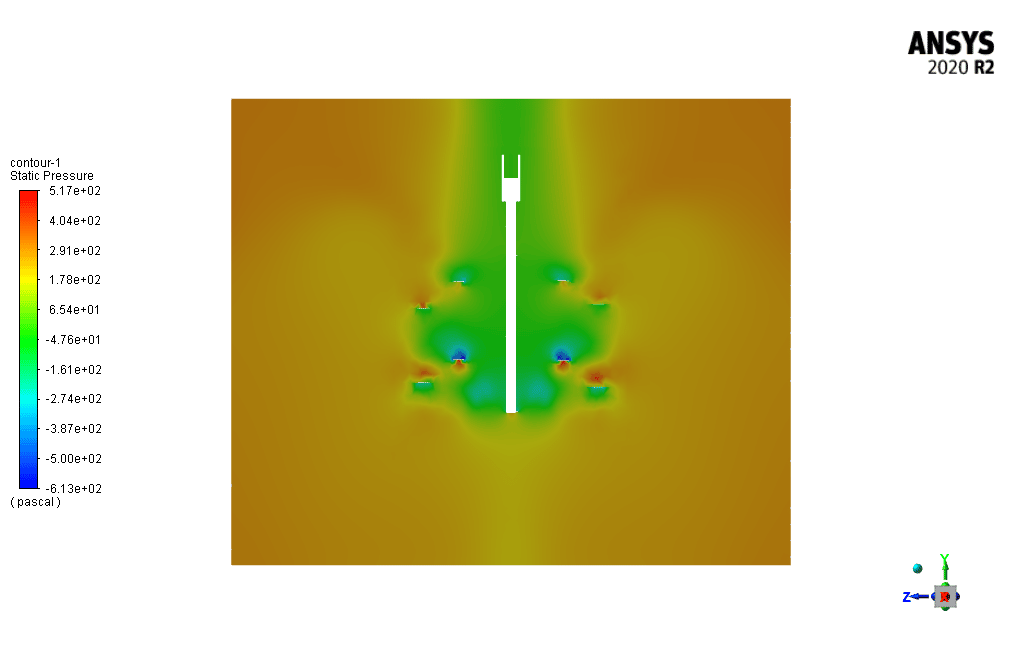

The streamlines which can be seen in the figures above, show the mentioned vortex clearly. Furthermore, the velocity is higher around helical blades, and a reduced pressure zone is shown in contours.

Margarett DuBuque –

The tutorial on the mixing tank was fascinating. I really appreciated the way it was instructive for my learning path, especially understanding the physics of mixing fluids. The visualizations with streamlines and pressure zones added greater depth to my study experience!

MR CFD Support –

Thank you so much for your kind words! We are thrilled to hear that our tutorial on the mixing tank with a helical impeller was both informative and engaging. It’s great to know that the visual aspects of the tutorial enhanced your understanding of fluid dynamics. Your appreciation truly motivates us to continue delivering high-quality learning materials. If you have any further feedback or need assistance with future projects, please do not hesitate to get in touch!

Aiyana Sauer –

The graphics and visualizations in the tutorial were very helpful for understanding the mixing process and flow patterns. Excited to apply these methods to my own projects!

MR CFD Support –

We’re delighted to know that the graphics and visualizations enhanced your learning experience! It’s great to hear that our tutorials are not only informative but also inspiring for your projects. Should you have any more questions or need further guidance, feel free to reach out. Thank you for your positive feedback!

Prof. Esther Collins –

I just finished studying the ‘Mixing Tank with Helical Impeller CFD Simulation, ANSYS Fluent Tutorial’ and it really helped me undertand the mixing process dynamics in industry-grade equipment. The explanation of the rotating mesh technique was particularly insightful!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to learn that our tutorial on the mixing tank with a helical impeller has enhanced your understanding of industrial mixing processes. It’s great to hear that the section on the rotating mesh technique was especially helpful. If you ever need further clarification or wish to explore more topics, we’re here to assist!

Kyleigh Monahan –

I’m truly in awe of the level of detail and clarity provided in this CFD simulation tutorial.

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to know that you found the tutorial to be detailed and clear. We strive to provide high-quality learning materials that are both informative and easy to follow.

Keara Rempel –

Seeing the result in the figures was amazing! The clarity of how the vortex forms and the effects of the helical impeller on the fluid dynamics is mesmerizing. Good job on showcasing the simulation!

MR CFD Support –

Thank you for your kind words and appreciation![🙂] Our team is thrilled to hear that you found the simulation and its results insightful. We constantly strive to provide clear and detailed insights into complex phenomena, like the fluid dynamics in a mixing tank with a helical impeller. Keep an eye out for more fascinating simulations![✨]

Dr. Curt Johnson –

I recently completed a simulation following this fantastic ANSYS Fluent tutorial on a mixing tank with a helical impeller. The process was not only insightful but also highly educational, and it allowed me to understand fluid behaviors in a mixing process more concretely. The polyhedral mesh generation certainly helped simplify the complexity without sacrificing quality. A job well done!

MR CFD Support –

We’re delighted to hear that our tutorial met your needs and helped deepen your understanding of fluid dynamics in mixing applications. It’s wonderful to know that the inclusion of the polyhedral mesh was beneficial to your learning experience. Thank you for taking the time to share your positive feedback with us!

Dameon Beer –

The tutorial was spot on! I followed every step and managed to replicate the simulation. The part about creating a massive vortex in the tank was incredible to see in action.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our tutorial was helpful and that you were able to successfully replicate the simulation and witness the vortex formation. If you ever have any questions or need further assistance, don’t hesitate to reach out.

Dustin Sporer –

The simulation of the mixing tank with the helical impeller was absolutely interesting! The clear vortex formation and the changes in velocity and pressure around the blade were particularly impressive.

MR CFD Support –

Thank you for your positive review! We’re glad to hear that the results of the simulation were clear and impressive to you. It’s always rewarding to know that our products can provide such valuable insights. If you need further assistance or information on our CFD products, please feel free to reach out.

Prof. Mazie Price MD –

I was amazed by the detailed results from the mixing tank simulation! The contours really helped me understand how the vortex forms.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that our simulation was able to provide you with clear insights into the mixing process. It’s wonderful that the visual aspects of our product enhanced your understanding of fluid behavior. If you have further questions or need more clarification, feel free to reach out!

Ms. Rowena Wolf –

Amazing guidance! The step-by-step instructions on setting up a transient simulation for a mixing tank were straightforward to follow. The details provided about the rotational motion setup using the Mesh Motion option greatly aided in understanding the concept of a sliding mesh. It was impressive to see how the polyhedral mesh reduced element count while retaining accuracy. Excited to apply this in my projects!

MR CFD Support –

We’re delighted to hear that you found our tutorial helpful and enlightening. Thank you for your positive feedback. It’s great to know that our instructions on the sliding mesh technique and polyhedral mesh optimization were clear and could be effectively utilized in your work. Should you have any further questions or need assistance in future projects, feel free to reach out to us. Your success is our goal, and we wish you the best in your CFD endeavors!

Prof. Rodrick Yost DDS –

What a fascinating study on fluid dynamics within a mixing tank! The description of how the helical impeller affects liquid vortex formation is particularly thought-provoking. It’s remarkable how modern simulation tools like ANSYS Fluent allow for such intricate analysis of fluid behaviors. I can only imagine how valuable these insights are for optimizing industrial mixing processes. Well done to the MR CFD Company in producing such a comprehensive and illustrative tutorial!

MR CFD Support –

Thank you for your positive feedback on our ‘Mixing Tank with Helical Impeller CFD Simulation,’ conducted with ANSYS Fluent. We are delighted to hear that our tutorial could provide you with valuable insights into fluid dynamics and its applications in industrial processes. If you have any further questions or need more information, please don’t hesitate to reach out to us. Your encouragement inspires us to keep creating high-quality, detailed simulations and tutorials!

Ludie Huels –

I must commend your detailed simulation; the model showcased the fluid dynamics in the mixing tank fantastically. The rendered streamlines and pressure zones near the helical blades provided a great visual insight into the mixing process. The massive vortex created was particularly impressive. Thank you for such an intricate and enlightening demonstration of fluid behavior in engineered systems.

MR CFD Support –

Thank you for taking the time to write such a positive review. We are thrilled to hear that our simulation has given you valuable insight into the fluid dynamics of the mixing tank. Understanding complex engineering systems is crucial, and we’re glad that our visuals and detailed analysis helped clarify these concepts for you. If you need further assistance or have more questions, feel free to reach out. Thank you again for your supportive feedback!

Astrid Schroeder –

The overall presentation and visualization provided in the review really put the complexity and thoroughness of the ANSYS Fluent simulation for the helical impeller into perspective. The description highlighted how the model accounts for the rotational movement and its effect on the mixing process. Impressive work!

MR CFD Support –

Thank you for your kind words and for recognizing the intricacies of the CFD simulation. It’s great to hear that our extensive work on modeling and visualizing the fluid behavior within the mixing tank with the helical impeller was both informative and impressive to you. Your feedback is greatly appreciated!

Gennaro Lindgren IV –

I was pleasantly surprised by the clarity of the streamlines and the demonstration of the vortex formation in the simulation. It brought a solid understanding of the mixing process.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that our tutorial effectively demonstrated the mixing process and the dynamics of the vortex. Your feedback is greatly appreciated – it helps us to ensure we are providing high-quality content that is both informative and clear.

Prof. Davon Hammes –

Just finished going through the ‘Mixing Tank with Helical Impeller’ tutorial from MR CFD, and I am thoroughly impressed with the clear-cut explanations and step-by-step guide. The results genuinely illustrated how the helical impeller generates the vortex and facilitates mixing. Additionally, it was fascinating to watch the expected structures of the flow in the tank come to life as the simulation processed the transient effects. The use of polyhedral mesh was a huge asset in reducing computational cost while maintaining accuracy. It’s evident a lot of expertise went into creating this tutorial!

MR CFD Support –

Thank you for taking the time to provide such a wonderful review! We are delighted to hear that our ‘Mixing Tank with Helical Impeller’ tutorial met your expectations and provided you with clear and helpful instructions. It’s particularly rewarding to know that the illustration of the flow structures and the computational efficiency of the polyhedral mesh were highlights for you. At MR CFD, we strive to deliver high-quality educational content, and your feedback validates our efforts. We appreciate your compliments and are grateful for customers like you!

Greta McCullough DVM –

The tutorial for the mixing tank with the helical impeller was exceptionally clear and thorough. I learned a lot about setting up a transient simulation and how the sliding mesh option works to model rotational movement. The visual depiction of the resulting vortex matched what I expected, and the change in pressure and velocity around the blades was fascinating to observe. Great application of CFD principles!

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that the tutorial was helpful and the results met your expectations. It’s wonderful to know that you have gained a deeper understanding of transient simulations and the sliding mesh technique. If you have any more questions or need further assistance with our products, feel free to reach out.

Issac Kshlerin –

The sliding mesh option and the rotational motion are vital parts of this simulation. I can clearly see them enhancing the mixing process as the helical impeller rotates. Great work demonstrating the fluid dynamics involved with such intricate geometry!

MR CFD Support –

Thank you for taking the time to review our mixing tank with a helical impeller CFD simulation tutorial. We’re pleased that the detailed demonstration and outcome of the fluid dynamics were clear and comprehensible. Your feedback is greatly appreciated!

Mrs. Carlee Johnston –

I’m really impressed with the helical impeller mixing tank simulation! It was clear and detailed, and watching the formation of the vortex in the animation was captivating. The use of a sliding mesh to capture the impeller’s rotation and its effect on the fluid’s behavior illustrated the dynamics within the tank brilliantly. I learned a lot from this CFD simulation, and the results certainly enhanced my understanding of fluid mixing in industrial applications.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our simulation tutorial on the mixing tank with a helical impeller met your expectations and helped you gain a deeper understanding of the fluid dynamics involved in mixing applications. Watching fluid behavior in motion and understanding the effects of the impeller’s rotation can indeed be fascinating and insightful. Should you have any more questions or need further tutorials, we’re always here to help!