Non-premixed Combustion, Steady Diffusion Flamelet, ANSYS Fluent CFD Training

$140.00 Student Discount

- The problem numerically simulates the Non-Premixed Combustion in a combustion chamber using ANSYS Fluent software.

- We design the 2-D model with the Design Modeler software.

- We mesh the model with ANSYS Meshing software.

- The mesh type is Structured, and the element number equals 63280.

- We use the Non-Premixed Combustion model to define a Combustion reaction.

- We use a Chemkin mechanism and the SteadyDiffusion Flamelet.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

The present problem simulates the non-premixed combustion in a combustion chamber by ANSYS Fluent software. In the present case, it is assumed that the fuel and air enter the chamber from distinct boundaries and hence are considered Non-premixed.

The geometry of the present model is two-dimensional and has been designed using Design Modeler software. We do the meshing of the present model with ANSYS Meshing software. The mesh type is Structured, and the element number is 63280.

This CFD project is the 4th episode of the Combustion Training Course.

Non-Premixed Methodology

Non-premixed combustion model is used to model the combustion process. Non-adiabatic energy treatment and a steady diffusion flamelet model are used to model the combustion process.

First, a Chemkin mechanism is read in Fluent and used to create the flamelet (models a turbulent flame brush as an ensemble of discrete, steady laminar flames).

Next, a PDF table is generated to store data related to changes in temperature, density of mixture, and different chemical species mass fractions before simulation to be used during the main calculations.

Also, the Energy equation is On to calculate the changes in temperature due to the combustion process, and the Viscous is set as the Standard k-epsilon model.

Non-Premixed Conclusion

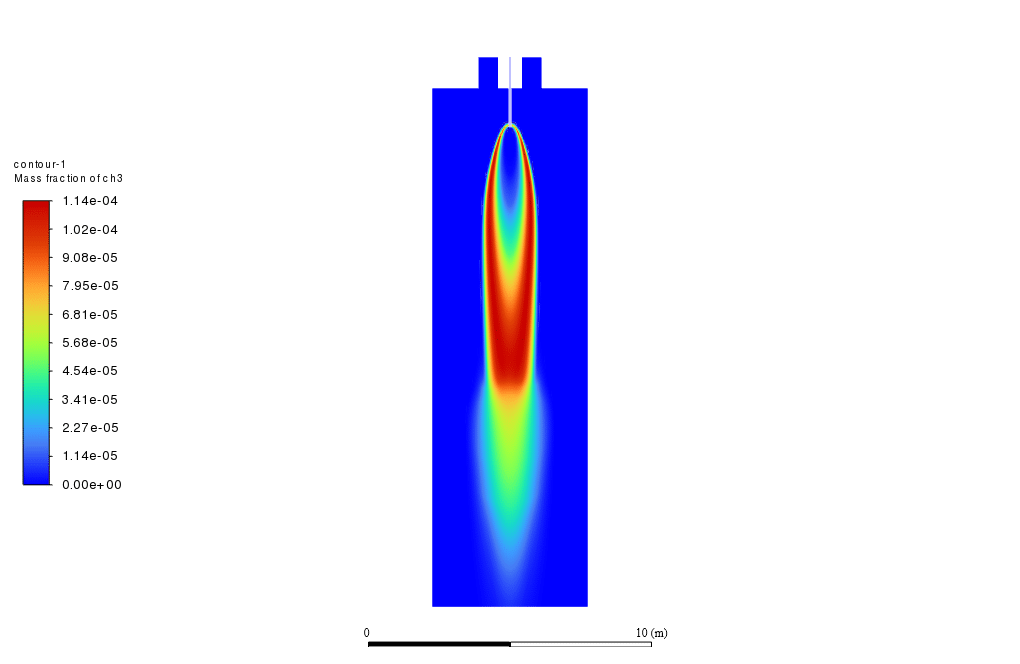

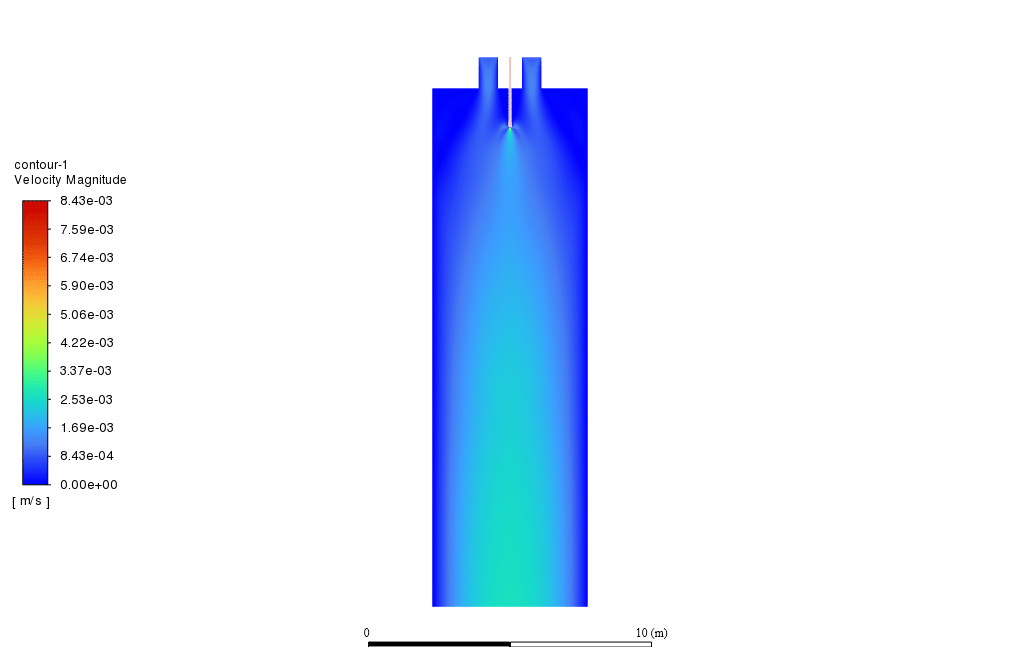

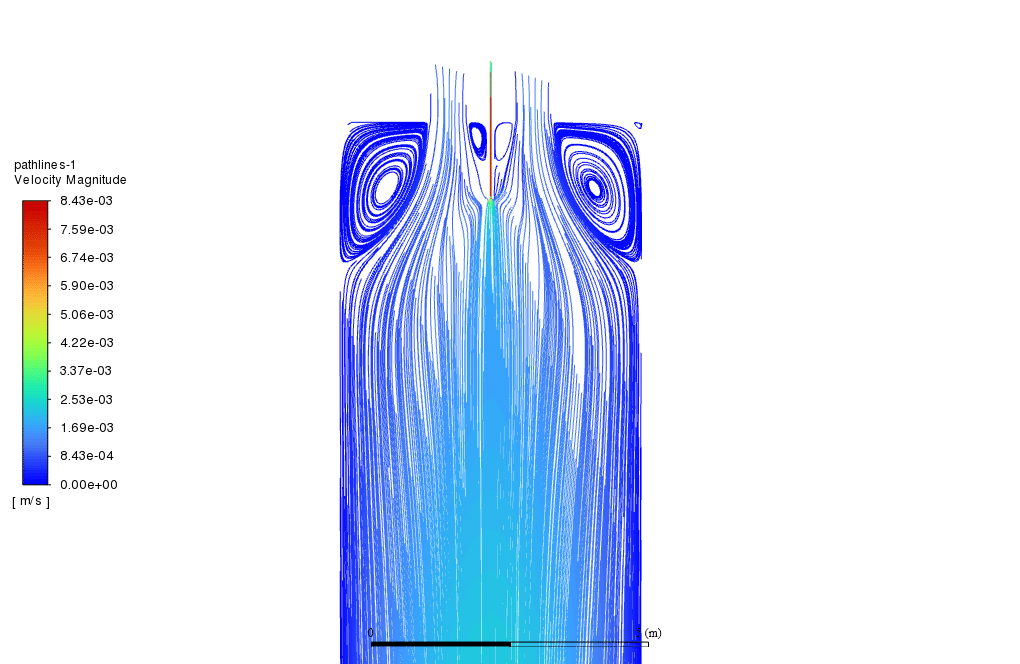

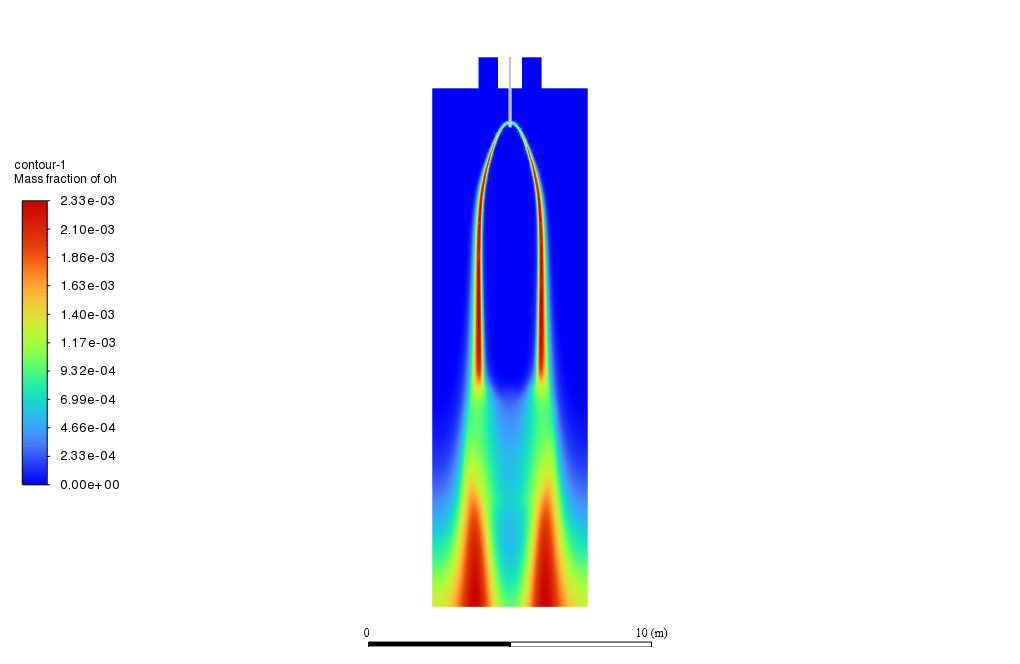

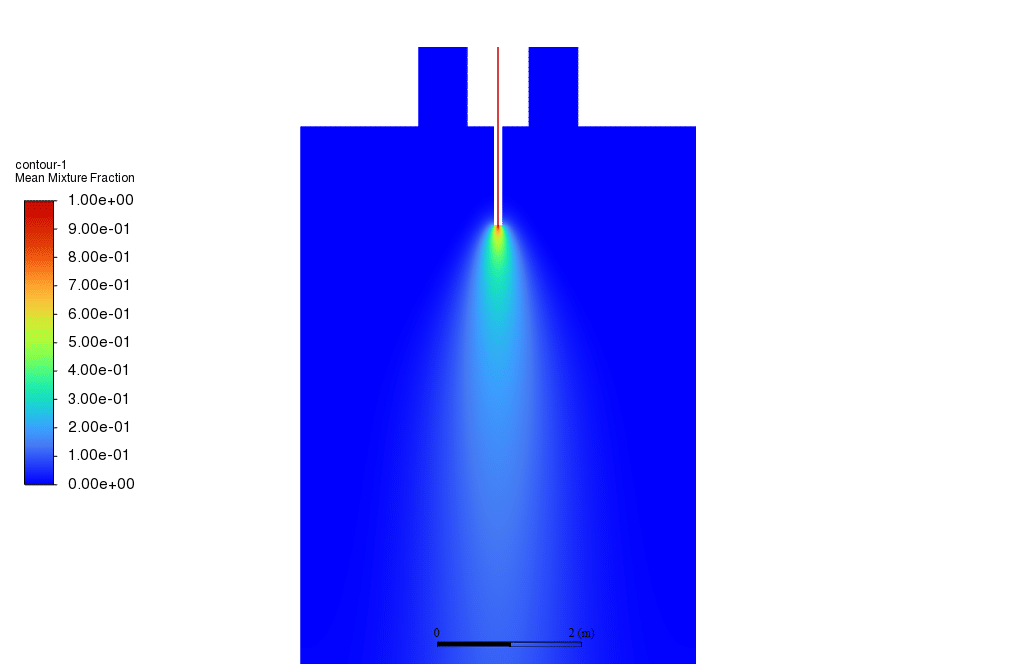

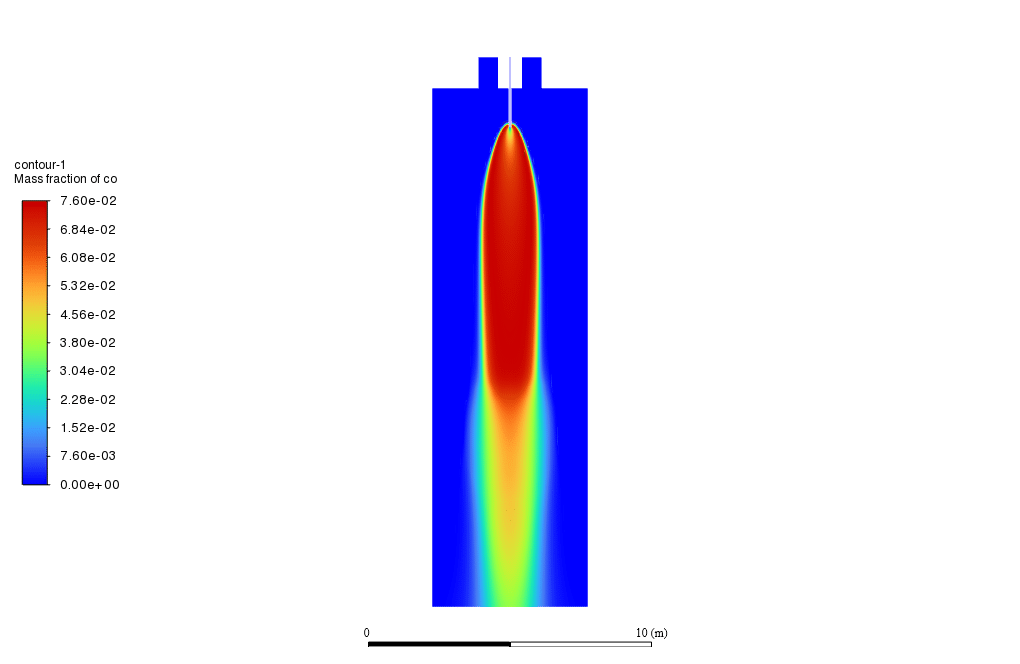

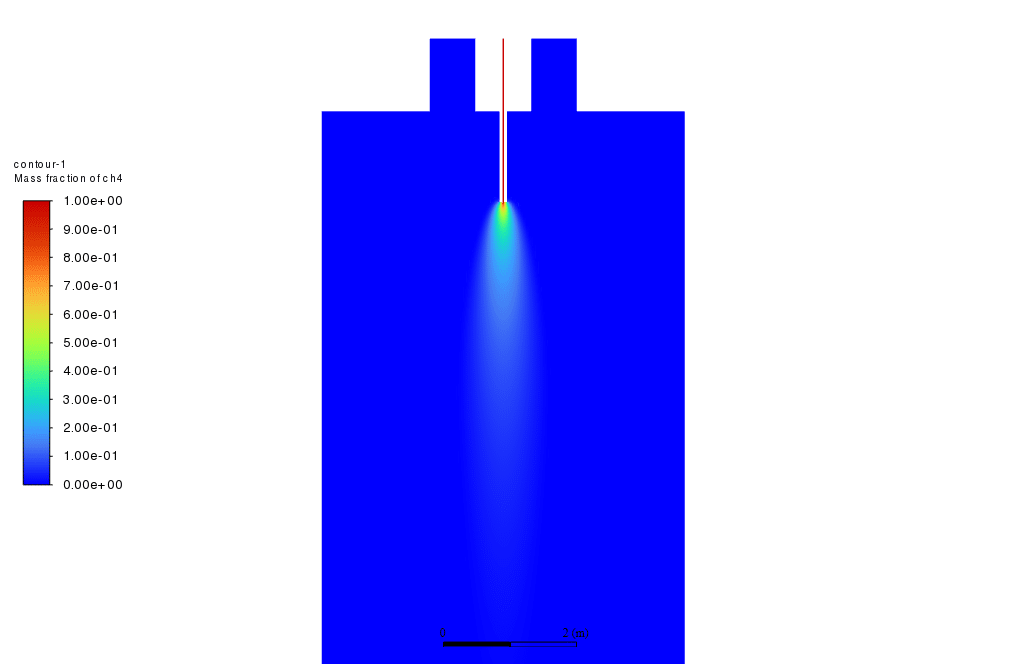

After the simulation process was finished, contours such as temperature, velocity, different species’ mass fractions, and streamlines were obtained. As shown in the temperature contour, the temperature has increased in the chamber, indicating that the combustion has taken place.

Also, the formed secondary flows in the chamber are shown in the streamlines. These secondary flows have the role of increasing the mixing process between fuel and air and hence enhancing the combustion process.

Naomi Sawayn –

I’m amazed by the detail in the combustion simulation! Could you clarify if the PDF table affects the computation speed or accuracy in this simulation?

MR CFD Support –

Thank you for your kind words! The use of the PDF table actually makes the simulation more efficient and accurate. It allows the pre-computation of complex chemistry and thermochemical properties, which can be quickly accessed during the simulation. This leads to reduced computation times while maintaining a high level of accuracy for non-premixed combustion scenarios.

Dr. Amparo Sanford III –

I was delighted with the attention to detail in setting up the steady diffusion flamelet model for the non-premixed combustion simulation. Fantastic work!

MR CFD Support –

Thank you for your kind words! We take pride in delivering detailed and accurate simulations for complex processes like combustion. We’re thrilled to hear that you appreciated our efforts in the steady diffusion flamelet model setup.

Mrs. Raquel Ziemann I –

I’m impressed with the fluent explanation and clear presentation of the results for non-premixed combustion simulation. Learning from this training gave me insights into complex combustion dynamics that I can apply in real-world scenarios.

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that our Non-premixed Combustion simulation training helped deepen your understanding of combustion processes. We strive to create detailed and intuitive educational content for our users. Your feedback is greatly appreciated, and it motivates us to keep delivering high-quality CFD training materials.

Ms. Zetta Reichel Jr. –

How does the steady diffusion flamelet model differ from other combustion models, and why was it chosen for this scenario?

MR CFD Support –

The steady diffusion flamelet model is designed to simulate combustion processes where fuel and oxidizer are not premixed. It simplifies the chemistry by assuming that turbulence affects the mixing process but does not affect the chemistry directly. This is different from other models, like the Eddy Dissipation Concept or the Laminar Finite-Rate model, which might account for turbulence-chemistry interaction more directly. It was likely chosen for this scenario as it’s computationally efficient for modeling the mixing and combustion of distinct streams of fuel and air, which is the case in non-premixed combustors.

Dr. Sam Herzog –

The level of detail provided in the results for non-premixed combustion simulation was excellent. I was able to understand the combustion process and its effects clearly through the illustrations and explanations given.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to know that our training materials on non-premixed combustion in ANSYS Fluent have provided you with a clear understanding of such complex phenomena. Ensuring our customers can utilize our CFD training to full potential is vital to us, and your comment reinforces our commitment to quality content.

Dr. Edwin Keeling –

I just finished the Non-premixed Combustion course with the Steady Diffusion Flamelet model and I was blown away by the quality of the content! The visualization of temperature and streamlines was particularly insightful for understanding the combustion process. The delivery of the course material made complex topics very accessible.

MR CFD Support –

Thank you for your enthusiastic review! We are thrilled to hear that you found our Non-premixed Combustion course insightful and the content on temperature and streamlines informative. It’s great to know that we were able to make complex topics accessible for you. We appreciate your feedback and look forward to possibly assisting you with more learning experiences in the future!