PCM Melting Rate Via Internal Fin and Nanoparticles

$100.00 $40.00 HPC

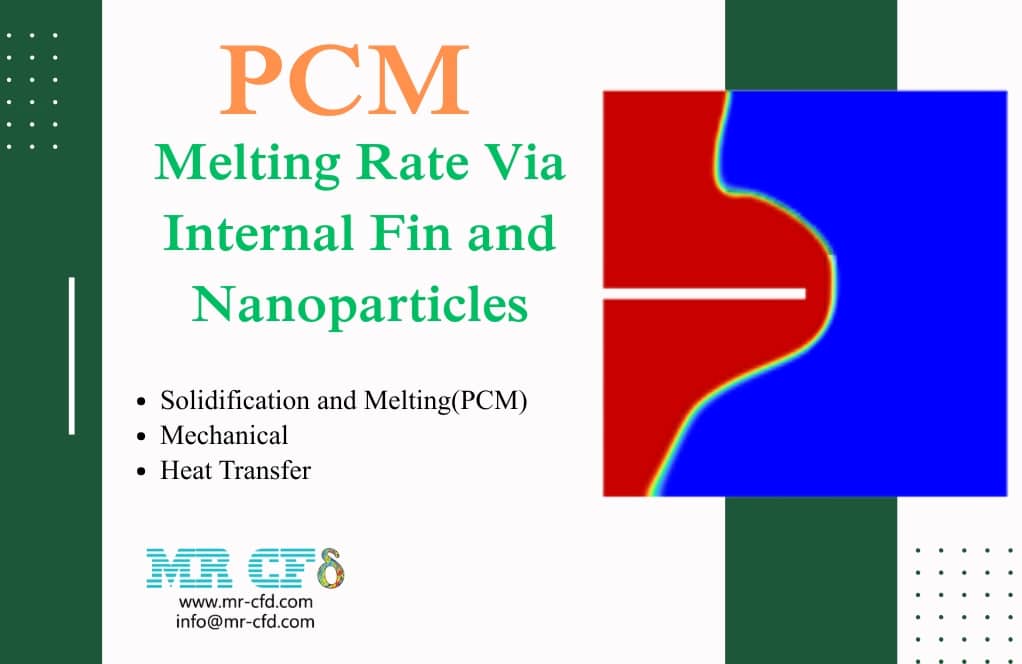

- This project explores the simulation of phase change material (PCM) melting within a 2D cavity, utilizing internal fins and nanoparticles to enhance thermal performance.

- The cavity, measuring 20mm in width and filled with paraffin wax, features a left wall and fin maintained at a constant temperature of 350K, while the right wall is kept at 300K, with other walls insulated.

- Simulations conducted over 375 seconds revealed that heat transfer occurs due to a temperature gradient, initiating phase change once the PCM reaches its melting temperature.

- Results indicated that 35.65% of the material was melted by the end of the simulation, providing critical insights into heat transfer efficiency and the influence of design parameters on PCM behavior in thermal systems.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

PCM Melting Rate Via Internal Fin and Nanoparticles CFD Simulation by ANSYS Fluent

Project Description:

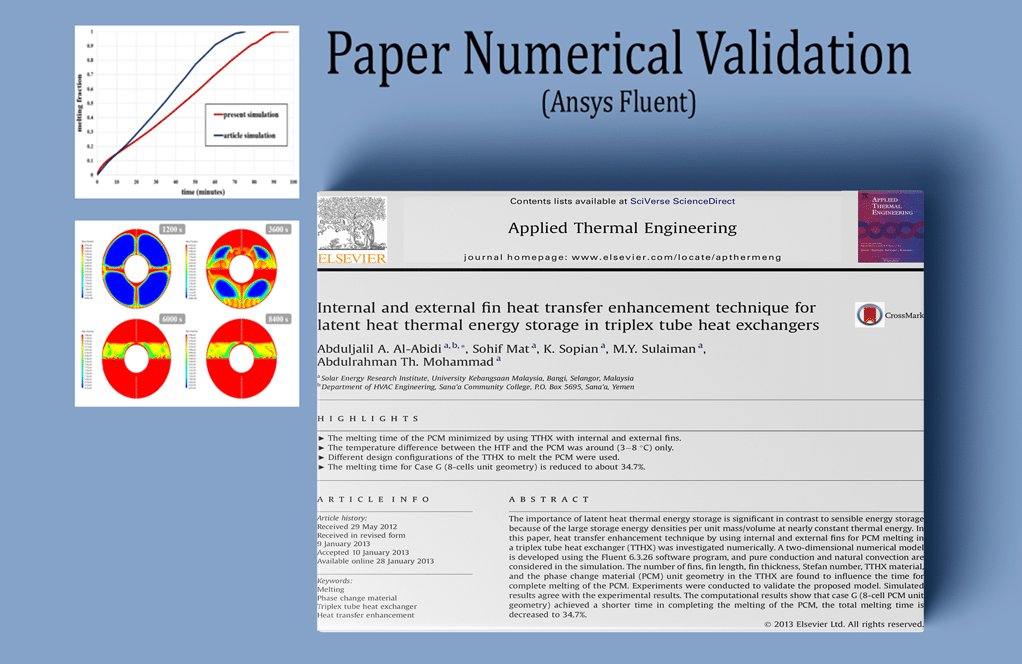

In this project, we aim to simulate the PCM melting inside a 2D cavity using internal fin & nanoparticles, which setup uses” Enhancement of PCM melting rate via internal fin and nanoparticles “ paper.

Geometry and Mesh:

The geometry of the PCM project is created using Design Modeler software—the cavity, with a size of W = 20 mm, filled with paraffin wax. The geometry is inserted into the Ansys Meshing Software, and approximately 10,000 structure cells are generated.

Methodology:

First, the gravitational acceleration is taken into account. Moreover, in the paper, some of the thermo-physical properties of PCM were applied using user-defined functions (UDFs). Thus, we had to seek the properties in some key points and use a polynomial linear model instead. Note that the properties of the material, which is a mixture of paraffin-wax & CuO, were calculated. The left wall and the fin are maintained at a constant temperature of 350 K, while the right wall is maintained at 300 K. Additionally, the other walls are assumed to be insulated. We have selected the case with a w/W ratio of 0.5 specification.

Results:

After 375 seconds of simulation, the results were extracted. As illustrated in the figure below, heat is transferred from the left wall to the right wall due to a temperature gradient. As the temperature in a region gets to PCM melting temperature, it starts to change phase. After 375 seconds, just 35.65% of the material is melted.

You must be logged in to post a review.

Reviews

There are no reviews yet.