Passive Ventilation by PCM, ANSYS Fluent CFD Simulation Tutorial

$140.00 Student Discount

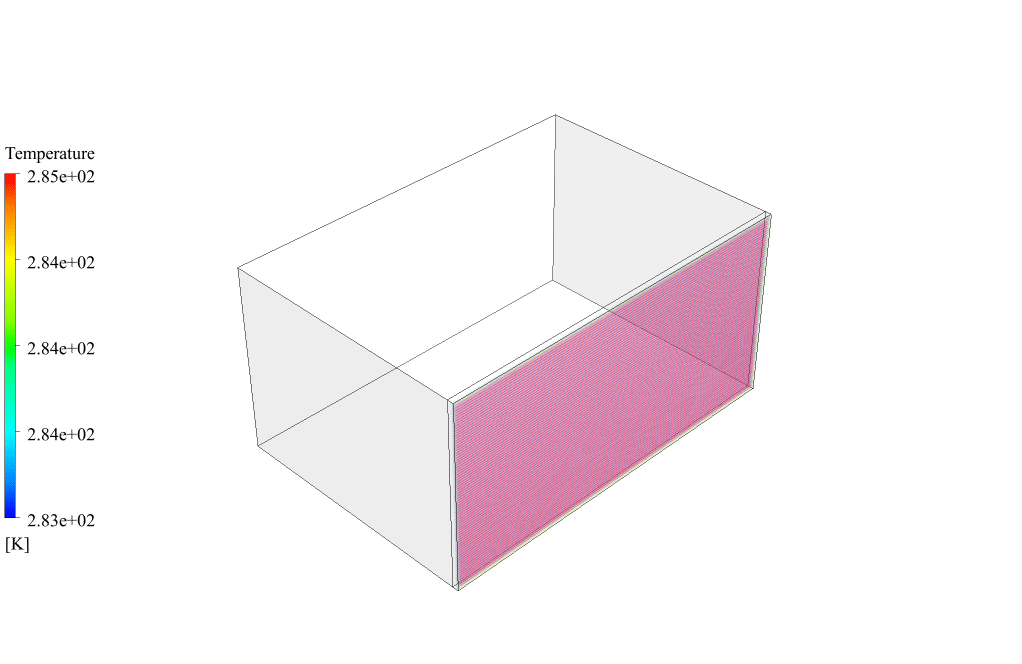

- The present CFD Project simulates PCM for Passive Ventilation via ANSYS Fluent software.

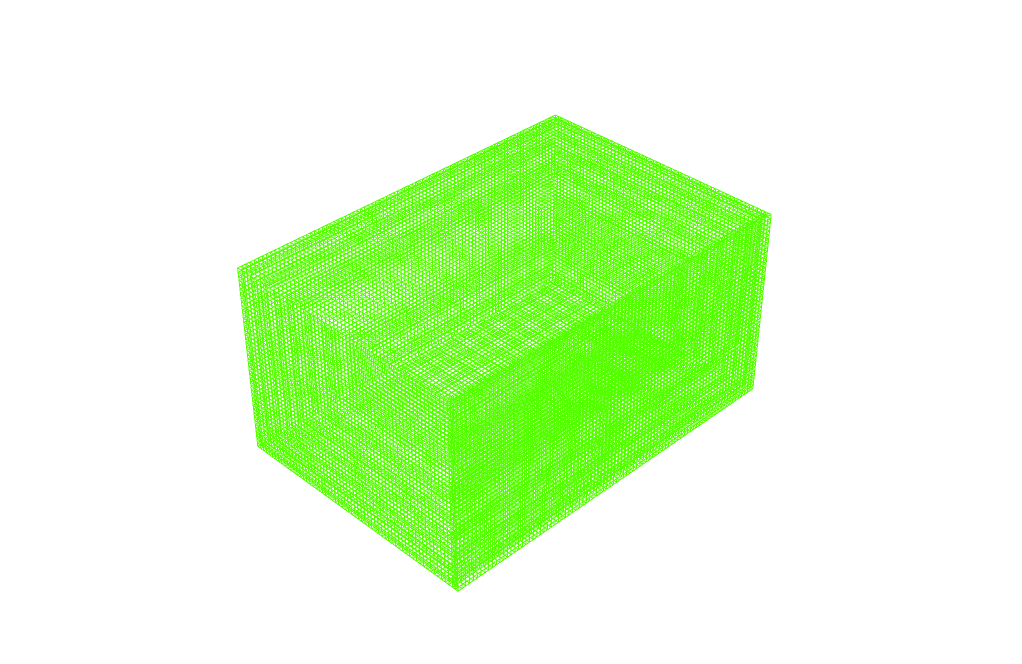

- We modeled the geometry using ANSYS Design modeler software and created the mesh using ANSYS meshing software.

- The meshing is structured, and the number of cells for the first and second models is 228448 and 241560, respectively.

- The solidification and Melting Model has been used to define PCMs.

- Incompressible Ideal Gas has been used to define density changes.

- The problem is dependent on time and unsteady.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Introduction

This project is related to a simulation of PCM for passive ventilation using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

Phase change materials can store energy and give it back to the environment when necessary.

So, PCMs can cause cooling and heating and also thermal storage in the environment by changing the phase between solid and liquid.

If the ambient temperature is high, the phase change from solid to liquid occurs. The resulting liquid stores the latent energy of melting.

Meanwhile, the phase change from liquid to solid happens if the ambient temperature decreases. The resulting solid releases the latent energy of solidification.

So PCMs cause heat transfer without using any mechanical device. Therefore, these systems are included in the passive ventilation group.

This passive ventilation system works based on the buoyancy effect. The difference in density caused by temperature changes leads to natural convection.

In this project, we have modeled a passive ventilation system. We performed this project in two steps.

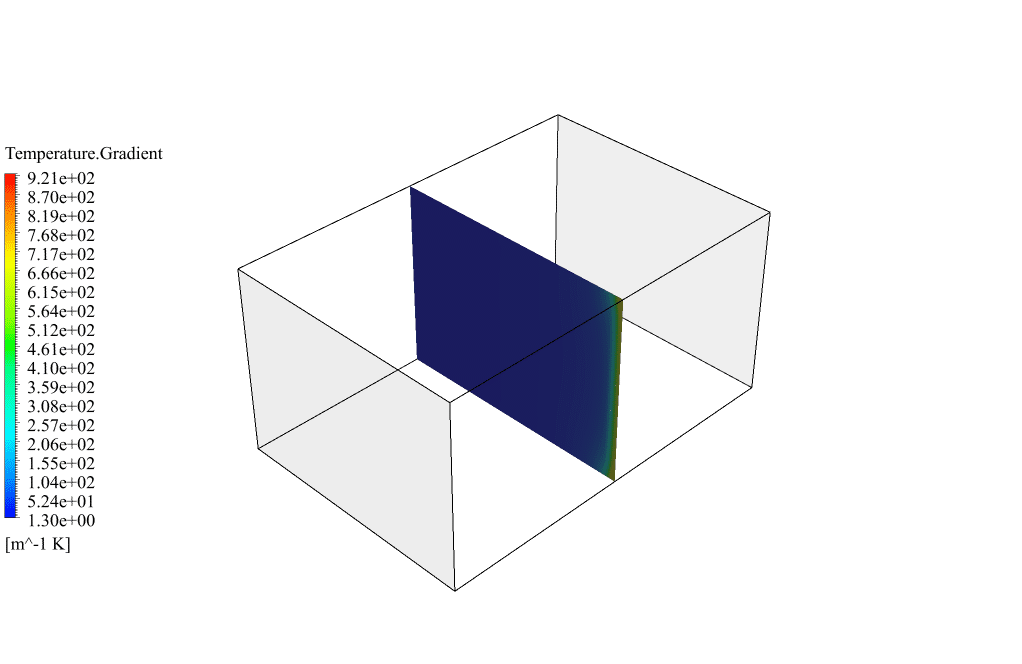

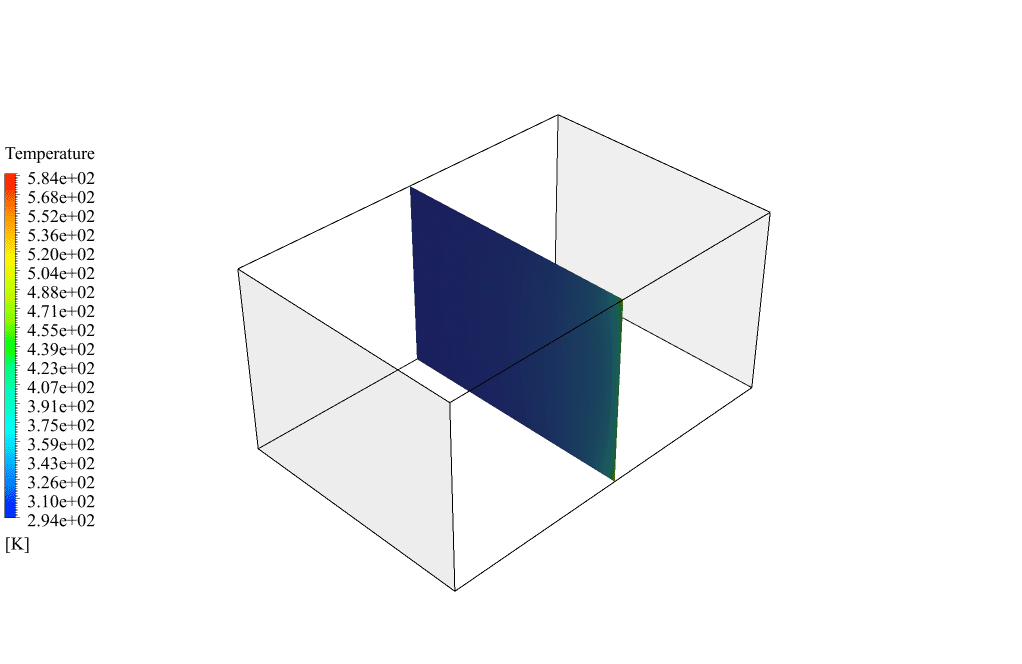

- We only investigated a room’s natural convection heat transfer in the first step. We assumed that one of the walls had a constant heat flux. This heat is derived from the warm air of the surrounding environment and the radiation of solar rays.

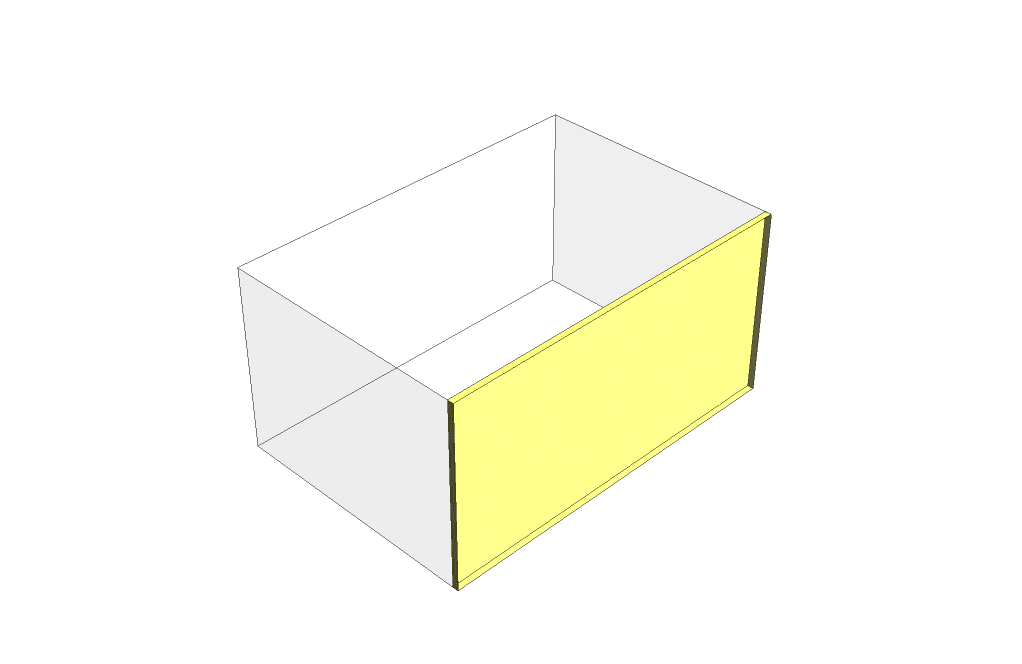

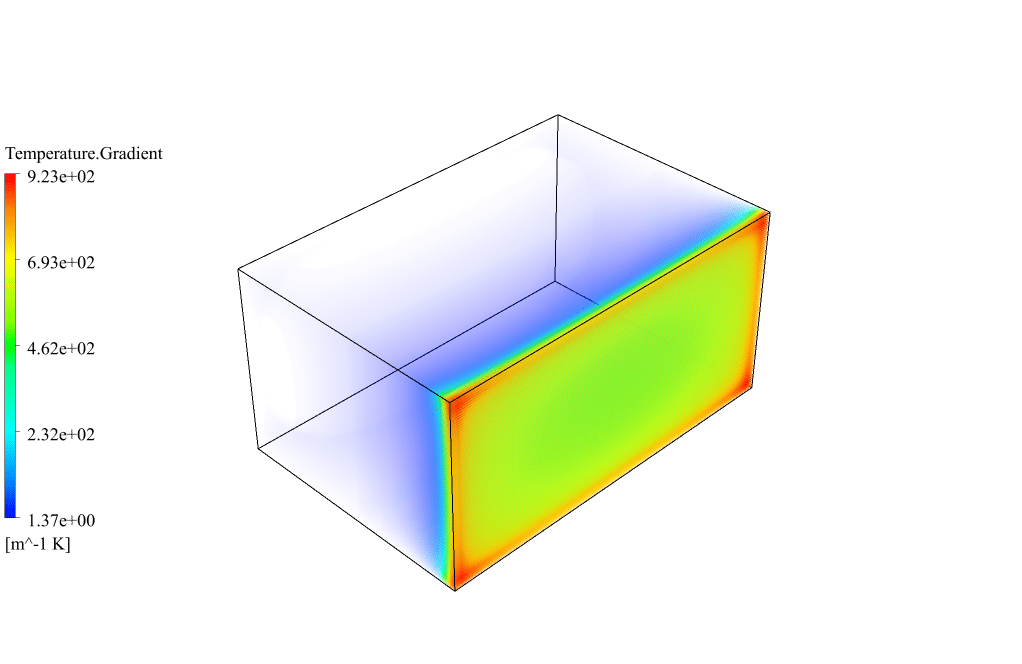

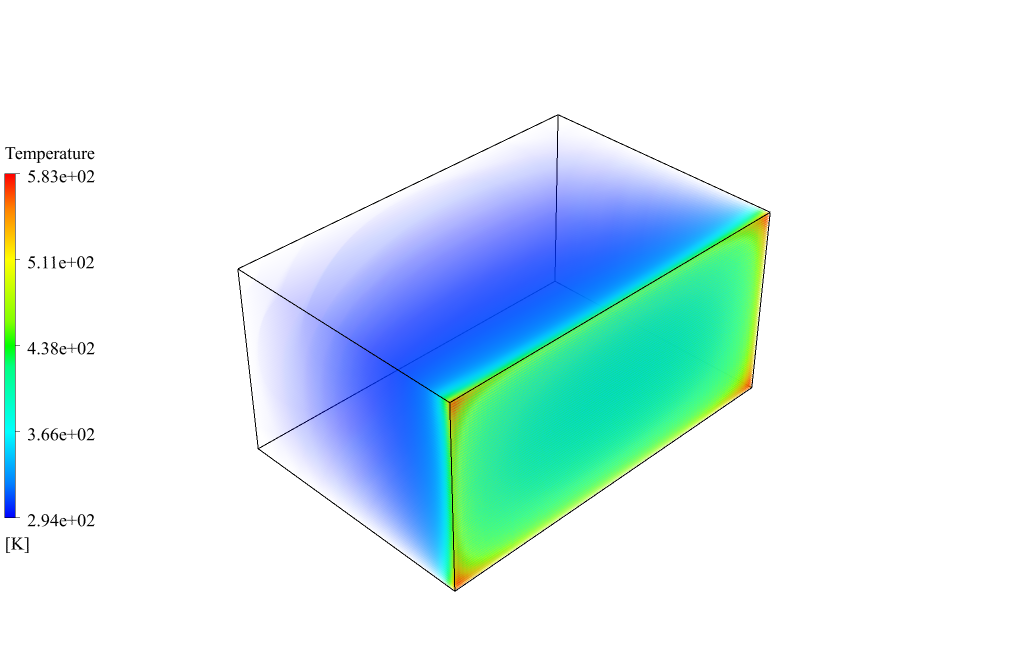

2. We used a PCM panel for the same heated wall in the second step. Our goal was to investigate the effect of PCMs on heat transfer.

We designed the geometry of the model using Design Modeler software. We modeled a simple room for the first step, and in the next step, we also applied a PCM panel.

Then we meshed the model using ANSYS Meshing software. The meshing is structured, and the number of cells for the first and second models is 228448 and 241560, respectively.

Passive Ventilation Methodology

Using ANSYS Fluent software, we numerically simulated this model according to computational fluid dynamics (CFD). This problem is dependent on time and unsteady state, and the solution is based on the pressure-based solver.

In this project, we need to define the phase change process between solid and liquid. The operating mechanism of phase change materials is based on continuous phase changes.

Then we use the solidification and melting model. When we use this model, we need to determine three parameters for our PCM.

The maximum temperature at which the solid phase prevails is equivalent to the solidus temperature. The minimum temperature at which the liquid phase prevails is equivalent to the liquidus temperature. Another parameter is equivalent to pure solvent melting heat.

As we said, natural convection heat transfer also happens in this problem. Natural convection is created based on the buoyancy effect. This means that changes in temperature cause changes in density.

Therefore, we do not consider the air density constant to apply the buoyancy effect. Then we use the incompressible ideal gas option to change the air density.

The relation between density, pressure, and temperature according to the ideal gas law is used in the incompressible ideal gas model. Note that the density is dependent on the operating pressure and is independent of the local relative pressure. So assuming constant pressure, density becomes a function of temperature.

Passive Ventilation Conclusion

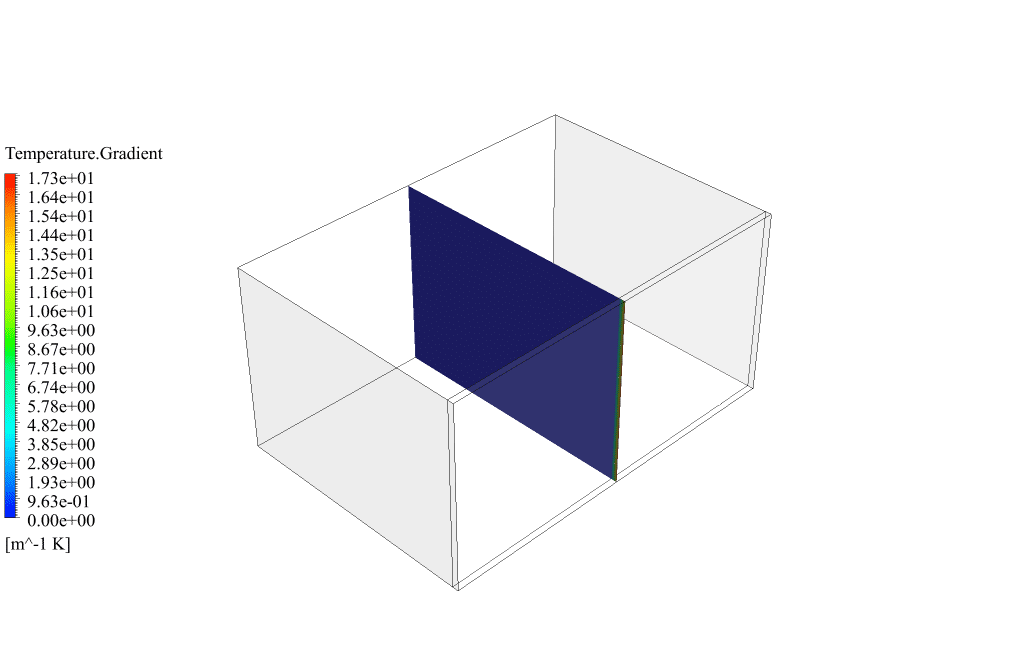

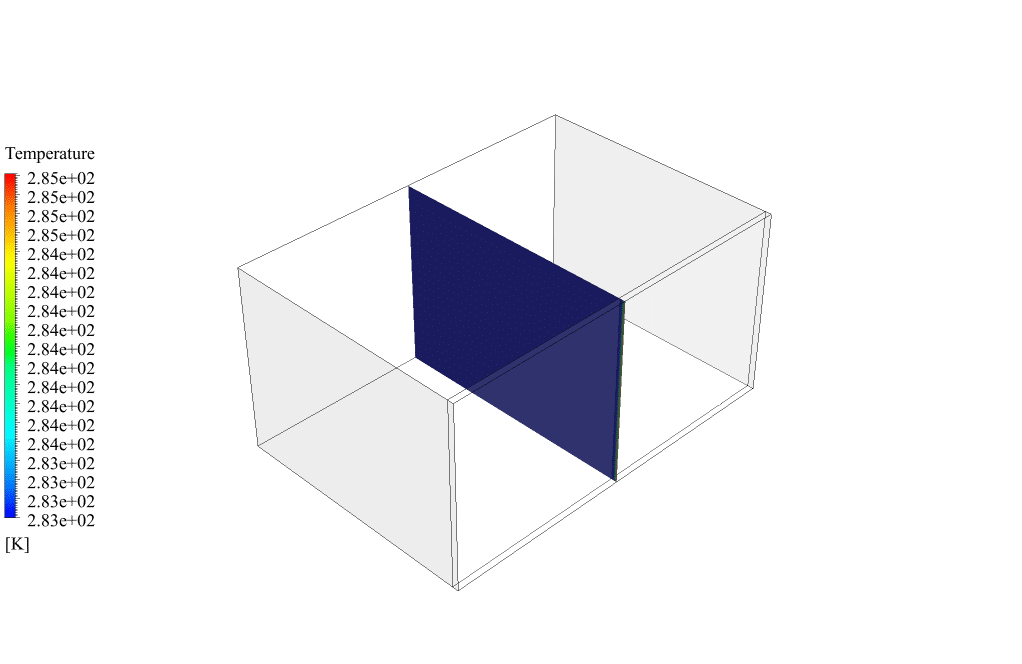

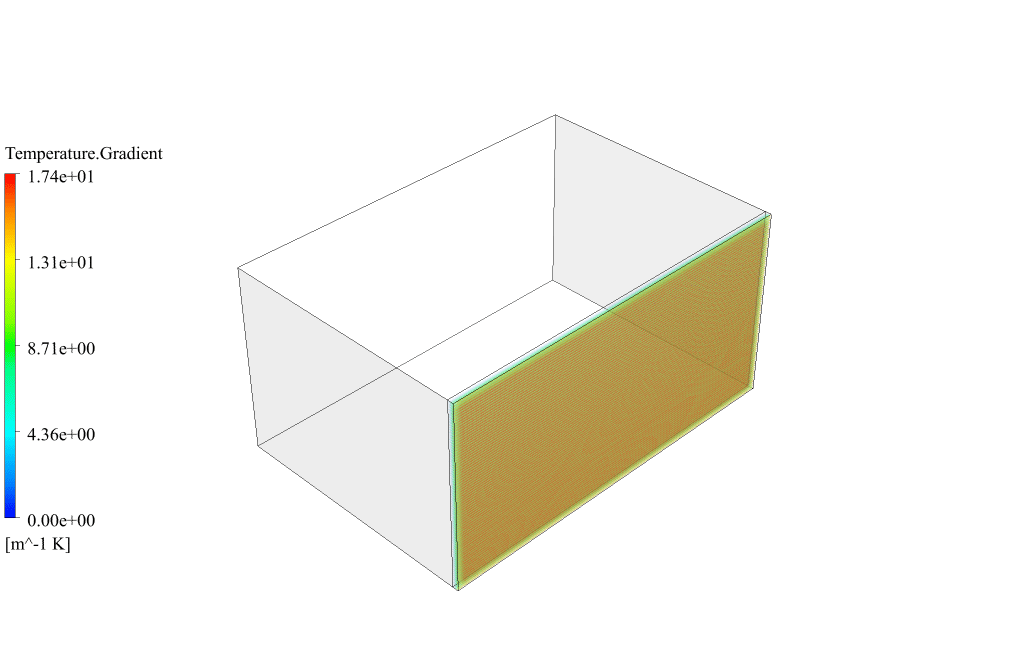

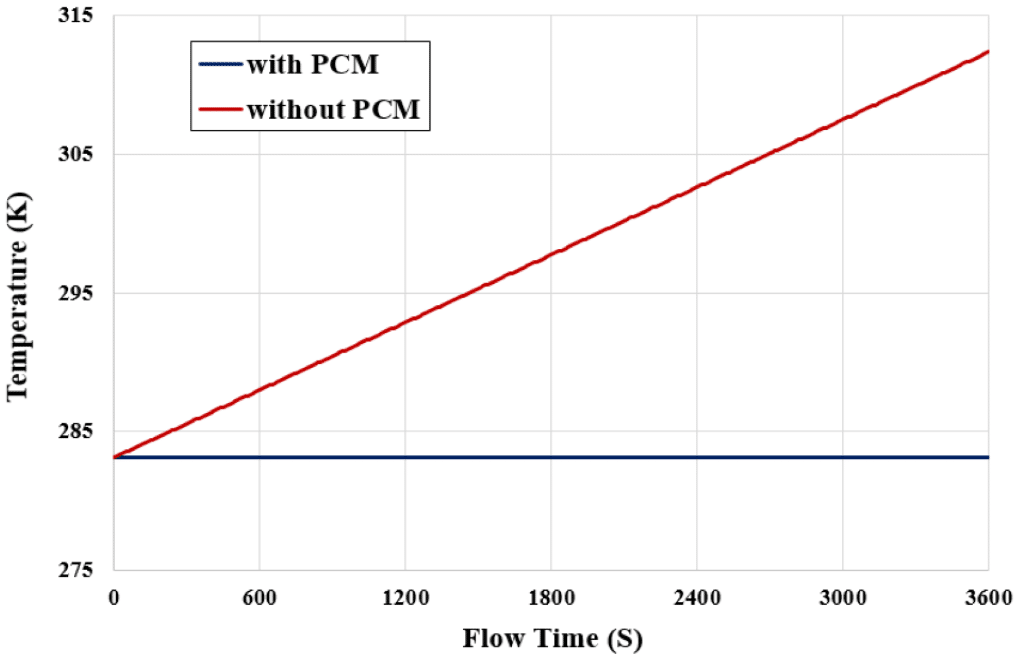

After the simulation, we obtained the plot of the average temperature inside the room over time. This plot compares two modes (with PCM and without PCM).

Also, we obtained 2D and 3D temperature contours and velocity vectors.

We want to analyze the effect of using PCM in passive ventilation.

The results show that the temperature increases over time in the first simulation. The heat flux of the wall and heat transfer inside the room lead to an increase in temperature.

Meanwhile, the temperature increases with the minimum slope in the second simulation.

Although the heat flux is applied, the presence of the PCM layer between the heat flux and the room space is effective. So these phase change materials receive heat in the form of latent heat. As a result, low heat penetrates the room.

Dr. Jaqueline O’Conner DVM –

The tutorial was so informative! The visuals for the temperature and velocity distributions were especially helpful for me to understand the PCM effects on passive ventilation.

MR CFD Support –

Thank you for your kind words! We’re really glad to hear that our tutorial was informative and the visual aids enhanced your understanding of the impact of PCM on passive ventilation. If you have any more feedback or need further information on our products, feel free to reach out.

Dr. Dulce Schultz –

The use of PCM seems intriguing for passive temperature regulation. Is there a particular type of PCM that is best suited for this application, or can various materials be used effectively? Could you please give examples of materials used for this purpose?

MR CFD Support –

Phase Change Materials (PCM) come in various forms, including paraffin waxes, fatty acids, and salt hydrates, each with different melting points and thermal storage capacities, making some better suited for passive temperature regulation in buildings than others. The selection of PCM is based on factors like the ambient temperature range, desired thermal comfort, and cost-effectiveness. For example, paraffin is commonly used in buildings for its moderate temperature range and high latent heat capacity.

Janessa Luettgen Sr. –

This tutorial for passive ventilation using PCM sounds great! I saw how PCM contributes to temperature management; could you explain how the ventilation effect is enhanced with PCM in comparison to traditional materials?

MR CFD Support –

The key enhancement of the PCM in passive ventilation comes from its ability to absorb significant amounts of latent heat during phase transitions. Traditional materials only absorb sensible heat and therefore require additional cooling to handle peak temperatures. PCMs can absorb and release heat while maintaining a nearly constant temperature, significantly reducing temperature fluctuations and the load on ventilation systems. This stabilizes the indoor environment and reduces the need for active cooling or heating.

Woodrow Boehm PhD –

The tutorial helped me understand how PCMs work in passive ventilation. Fantastic explanation on natural convection and phase changes!

MR CFD Support –

Thank you for your kind feedback! We’re thrilled to hear our tutorial on PCM for passive ventilation in ANSYS Fluent was helpful to you. It’s great that you found the explanation of natural convection and phase changes clear and informative. If there’s anything else you’d like to learn about, let us know!

Elizabeth White –

The tutorial thoroughly explains passive ventilation with PCM, and I can see how PCMs efficiently manage the heat. Just a quick query to understand better: What materials are commonly used as PCMs for these types of projects?

MR CFD Support –

Phase Change Materials (PCM) used in these types of thermal management projects are typically substances with a high latent heat of fusion that can absorb and release heat at a specific temperature. Commonly used PCMs include paraffin wax, fatty acids, salt hydrates, and polyethylene glycol. These materials are popular due to their desirable properties such as high thermal storage capacity, stability, and reliability during phase transition.

Naomie Hirthe II –

I am fascinated by the functionality of PCMs in this simulation. Can you explain how much of a temperature difference I could expect in a typical room using PCM compared to a room without it for passive cooling?

MR CFD Support –

The temperature difference resulting from using a PCM for passive cooling compared to a room without it depends on several variables, including the type and amount of PCM used, the heat gain, the ambient conditions, and the insulation of the room. The simulation results typically show a lesser increase in temperature over time when a PCM is used, as it absorbs heat during its phase change from solid to liquid, delaying the heat penetration into the room. The specific temperature difference for your scenario would require a detailed examination of the simulation data.