Porous Jump in a Perforated Plate CFD Simulation

$80.00 Student Discount

In this project, a Porous Jump, Perforated Plate has been simulated and the results of this simulation have been investigated.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Porous Jump in a Perforated Plate CFD Simulation, Ansys Fluent Training

Perforated plates have patterns of holes, slots, or decorative shapes. They have a wide area of usage in industrial applications, such as filters, silencers, radiator grilles, ventilation, or separator plates. Porous jump conditions are used to model a thin “membrane” with known velocity (pressure-drop) characteristics. Examples of uses for the porous jump condition include modeling pressure drops through screens and filters and modeling radiators when you are not concerned with heat transfer. Perforated louvers are generally used indoors to permit air movement from one area to another. Perforated louvers are generally used indoors to permit air movement from one area to another.

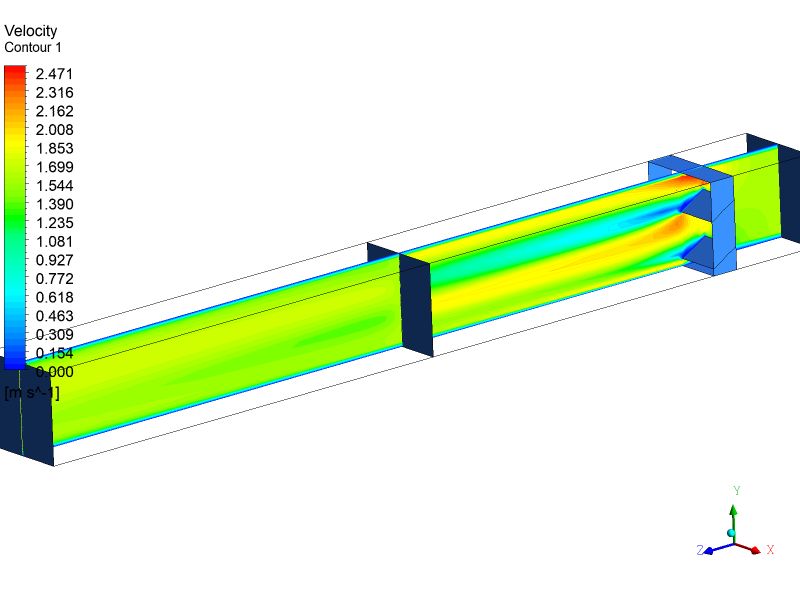

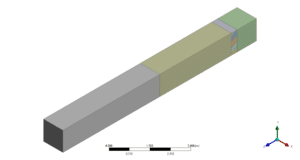

In this project, We used the Ansys Fluent software to simulate the Porous jump, perforated plated louver. The inlet and outlet boundary conditions are velocity inlet and pressure outlet, respectively. The velocity magnitude is 1.5 meters per second. We have introduced a series of fluid flows into a rectangular cube duct and created a porous series to study the flow behavior and heat transfer. The dimensions of this cube are 1*1*10 cubic meters.

Geometry & Mesh

The 3-D geometry of the present model is generated using Design Modeler software.

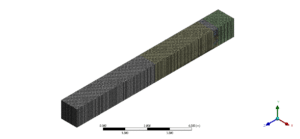

The meshing of the present model has been done using Ansys Meshing software. The mesh type is structured in all of the computational domains, and the element number is equal to 85760.

Porous Jump CFD Simulation

To simulate the present model, we consider several assumptions:

- The solver is pressure-based.

- The current simulation is steady.

- We ignored the gravity effect.

Here is a summary of the steps for defining the problem and its solution in the following table:

| Models | |||

|

Viscous model

|

k-epsilon |

||

|

Material Properties

|

|||

|

Air

|

|||

|

|

Density |

1.225 |

|

|

viscosity |

1.7894e-05 |

||

|

anthracite

|

|||

|

Density |

1550 |

||

| Solution Methods | |||

| Pressure-velocity coupling |

coupled |

||

| Spatial discretization | pressure | Standard | |

| momentum | first-order upwind

|

||

|

|

Volume fraction

|

Geo reconstruct | |

|

|

Turbulent kinetic energy | First-order upwind | |

|

|

Turbulent dissipation rate

|

First-order upwind | |

| Initialization | |||

| Initialization method | Standard (computed from inlet) | ||

| Run calculation | |||

| Number of time steps | 400 | ||

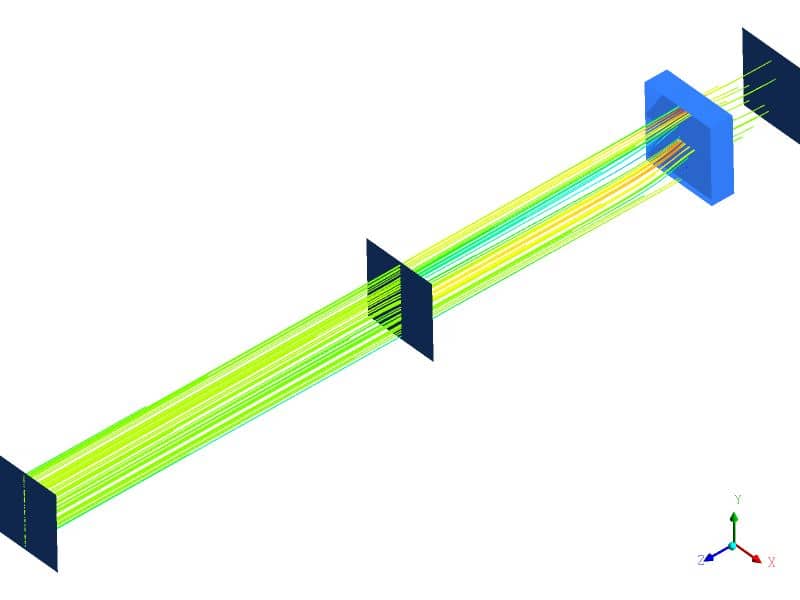

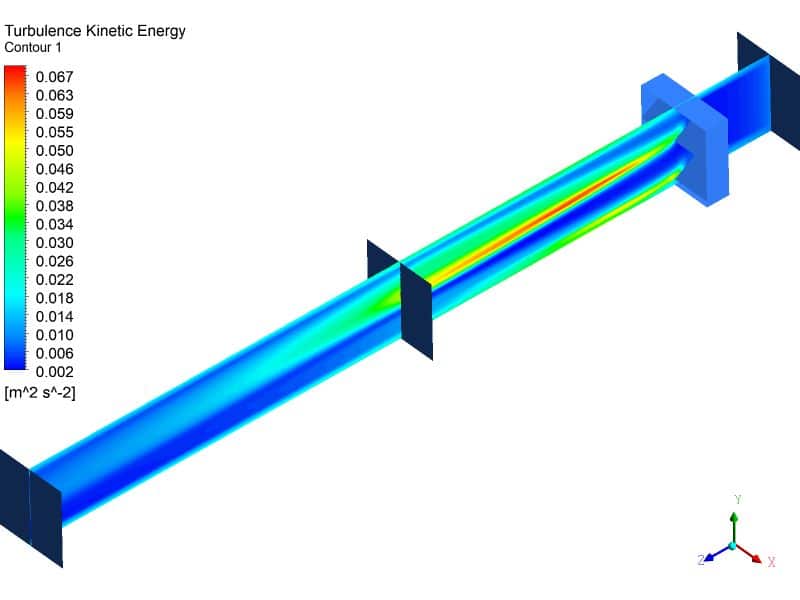

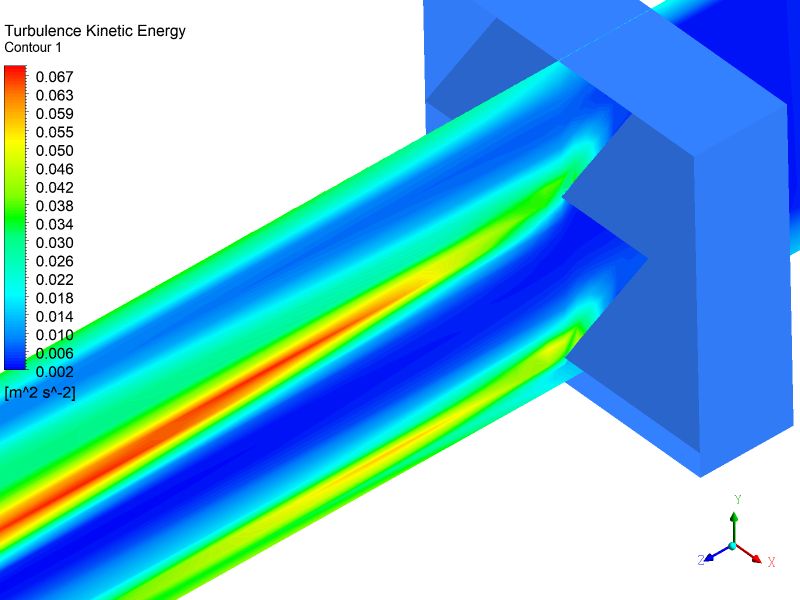

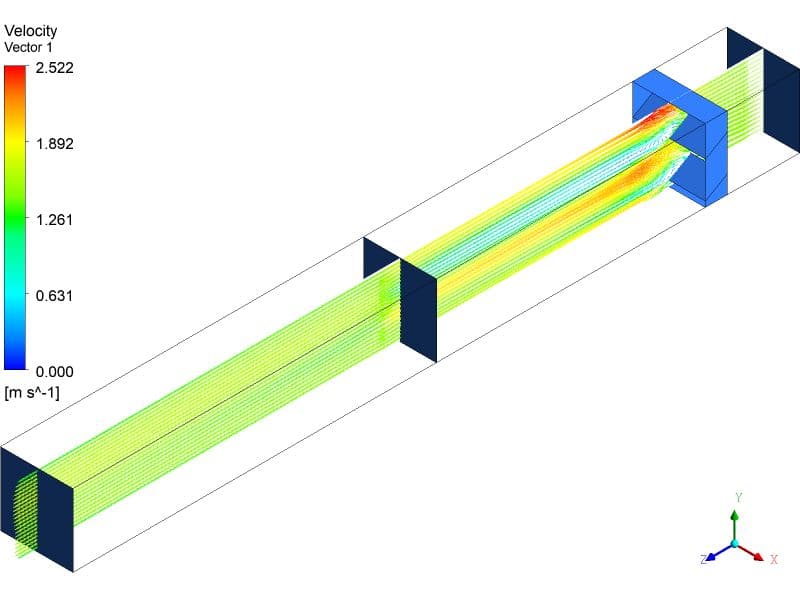

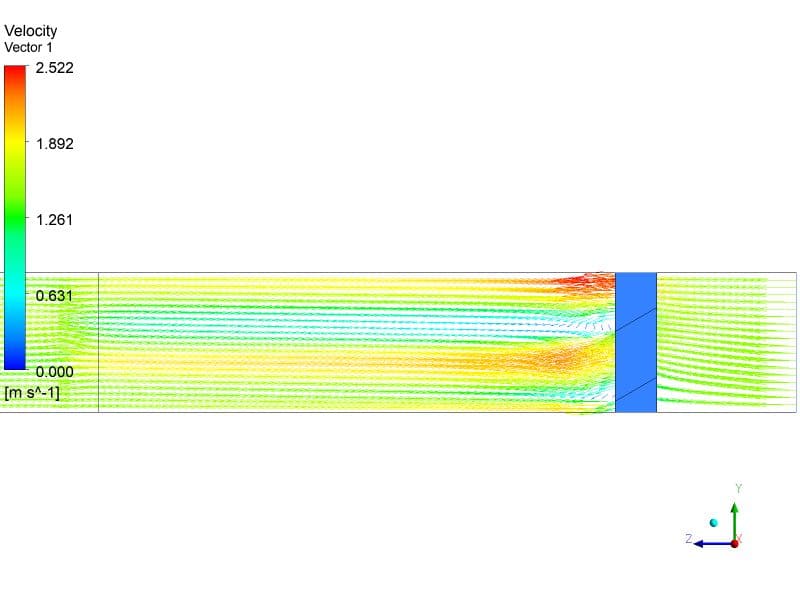

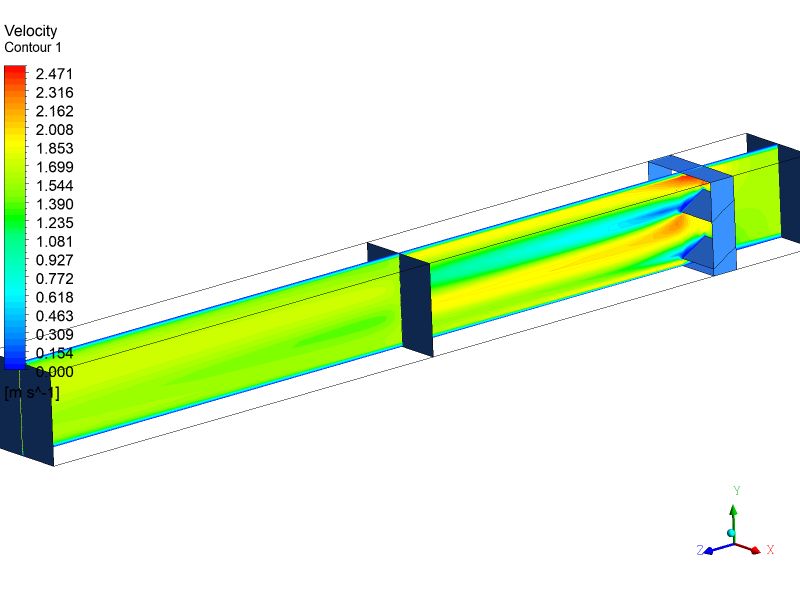

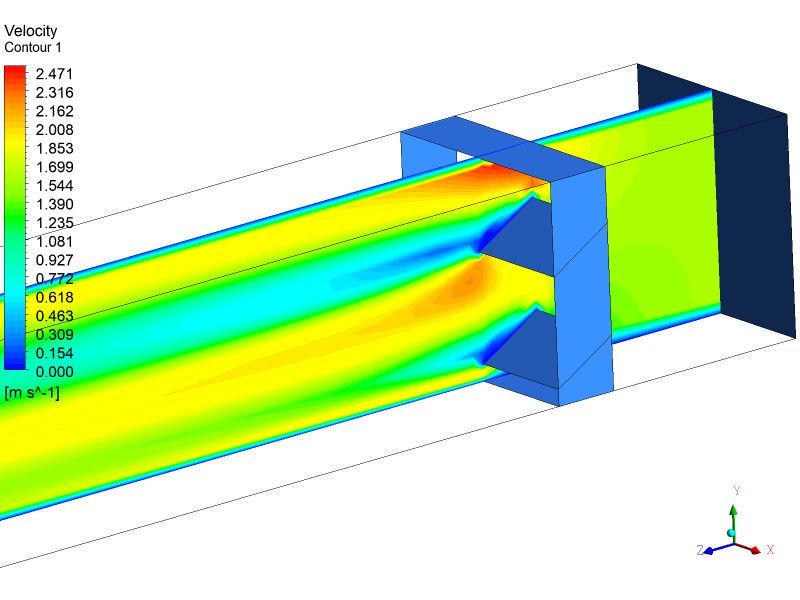

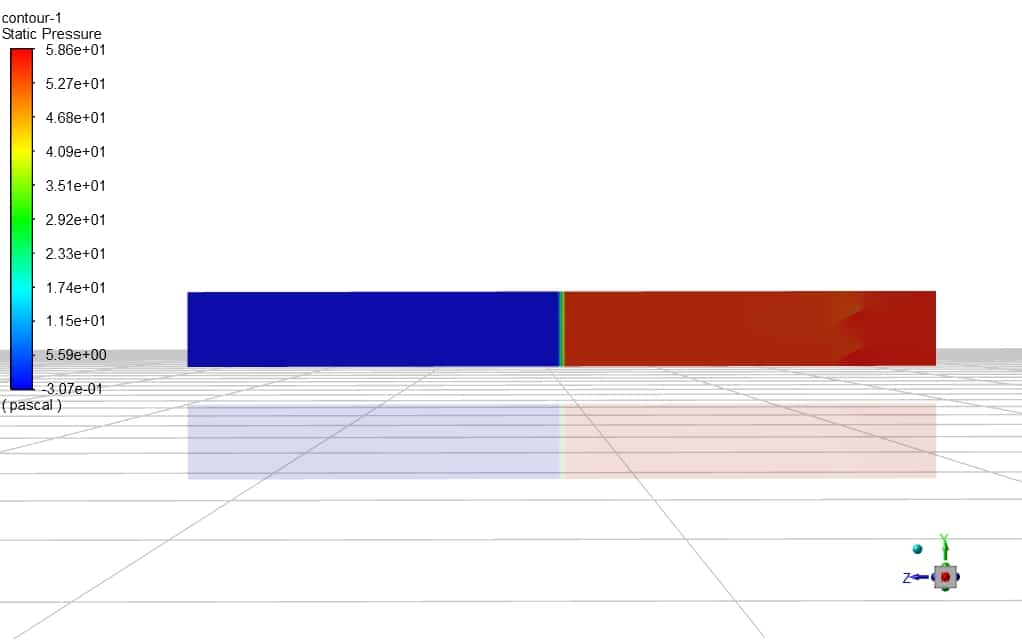

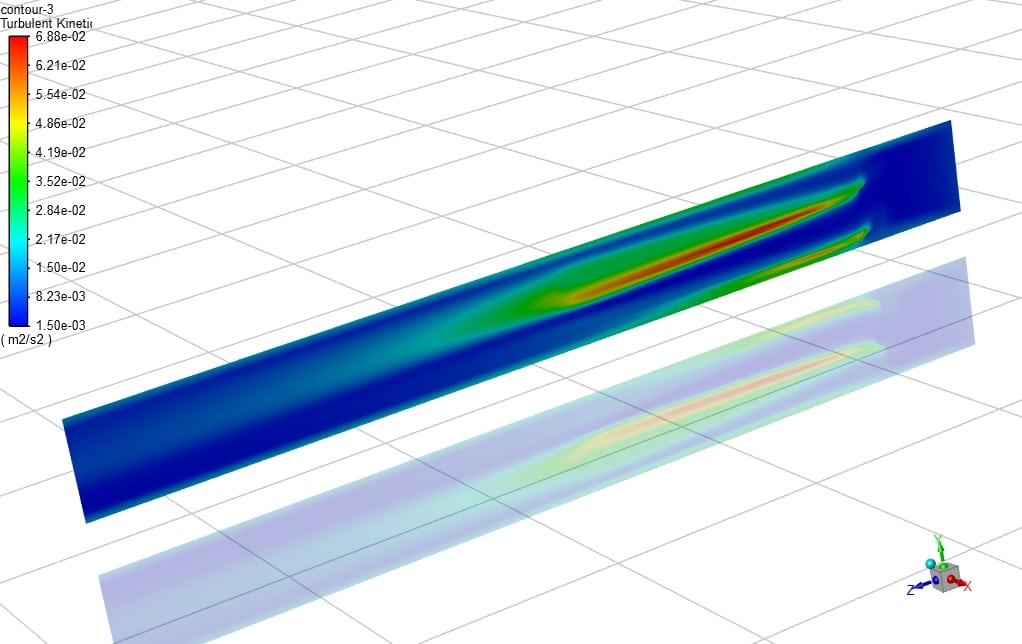

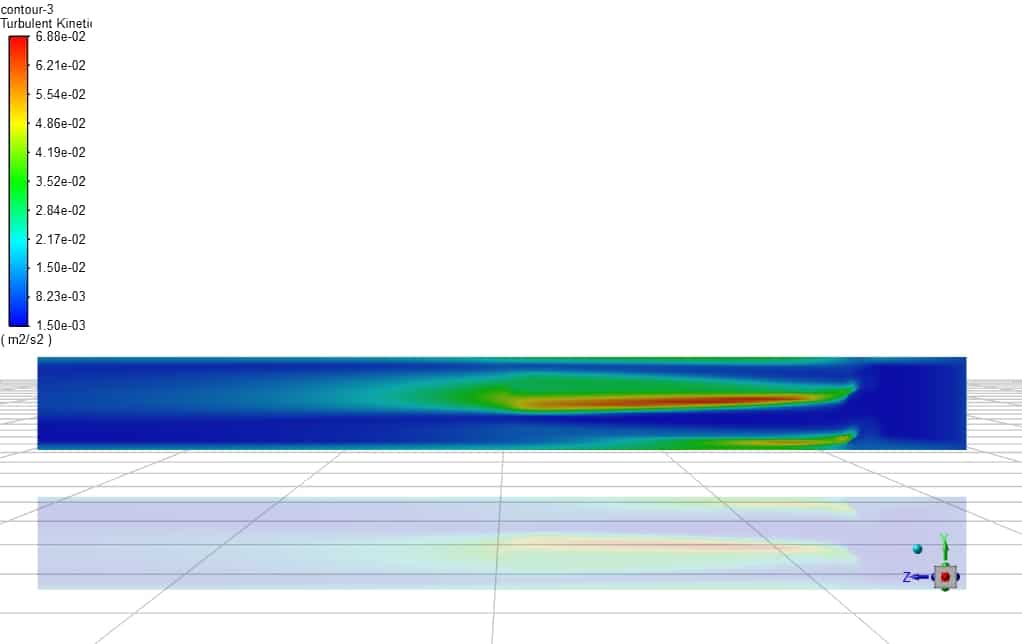

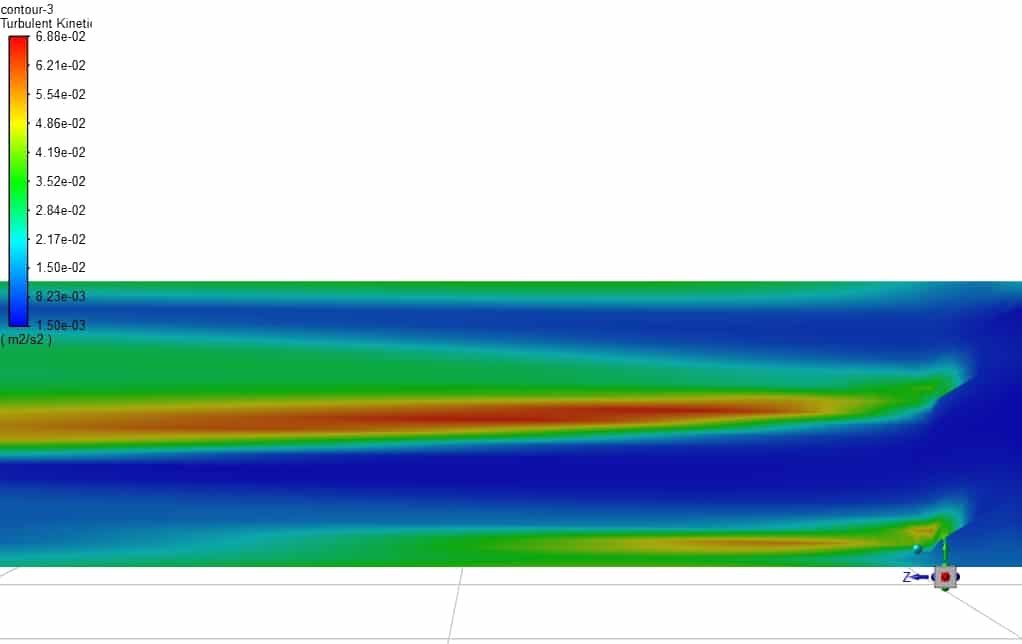

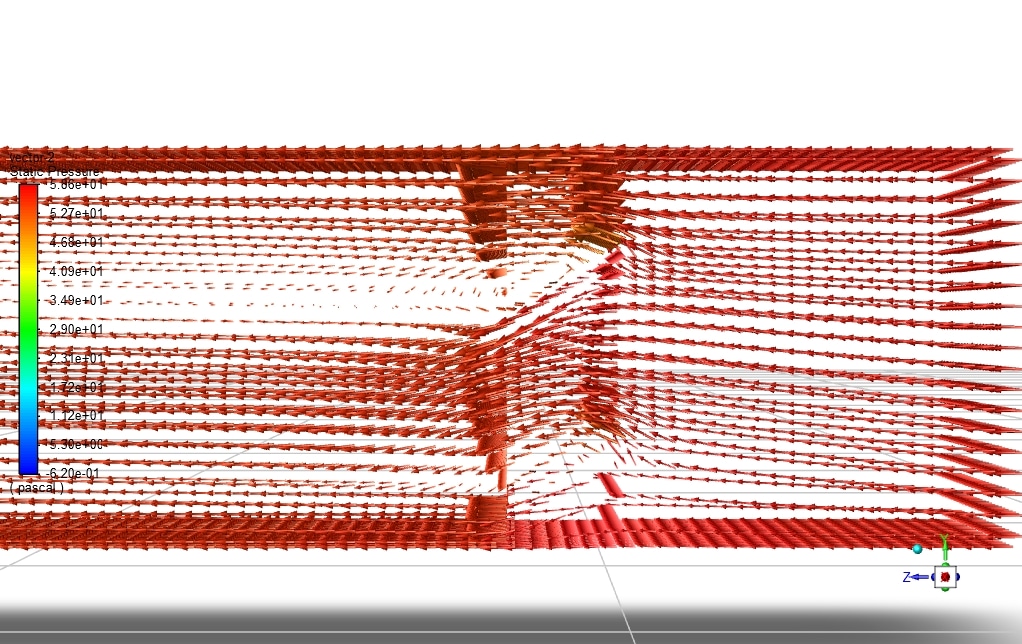

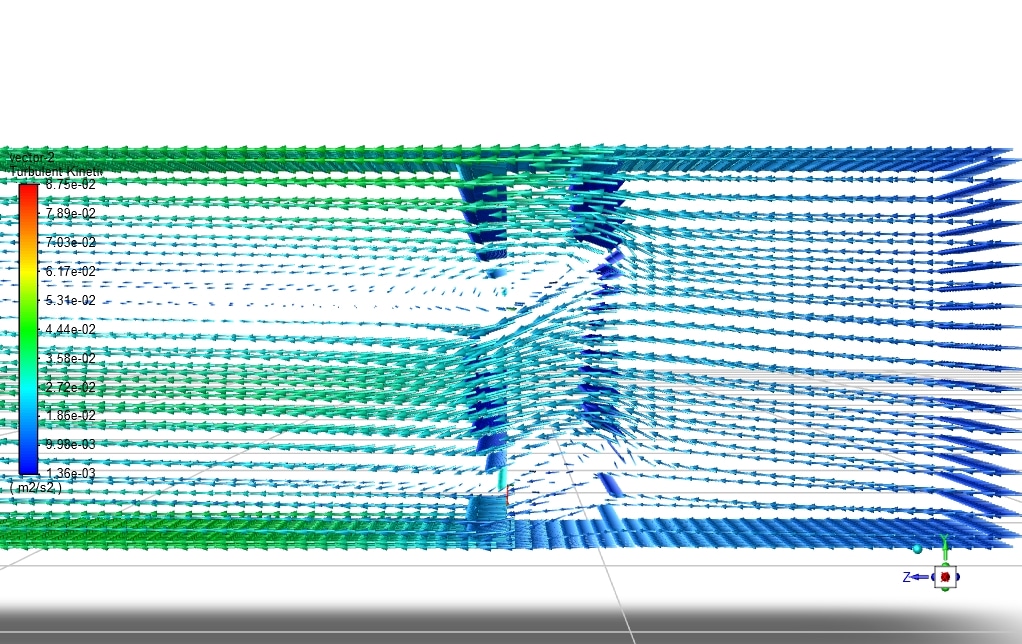

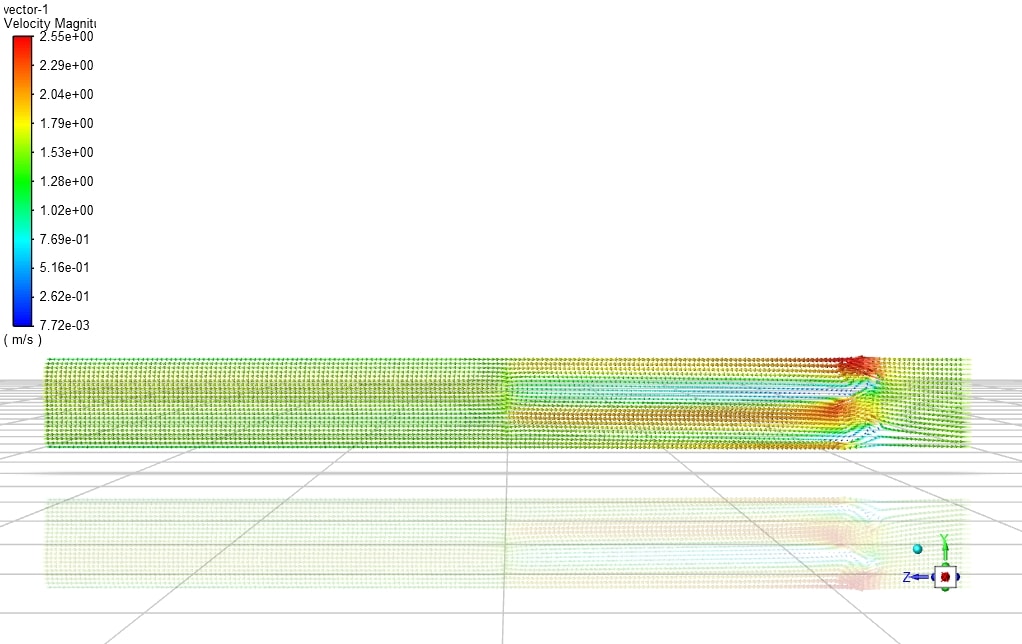

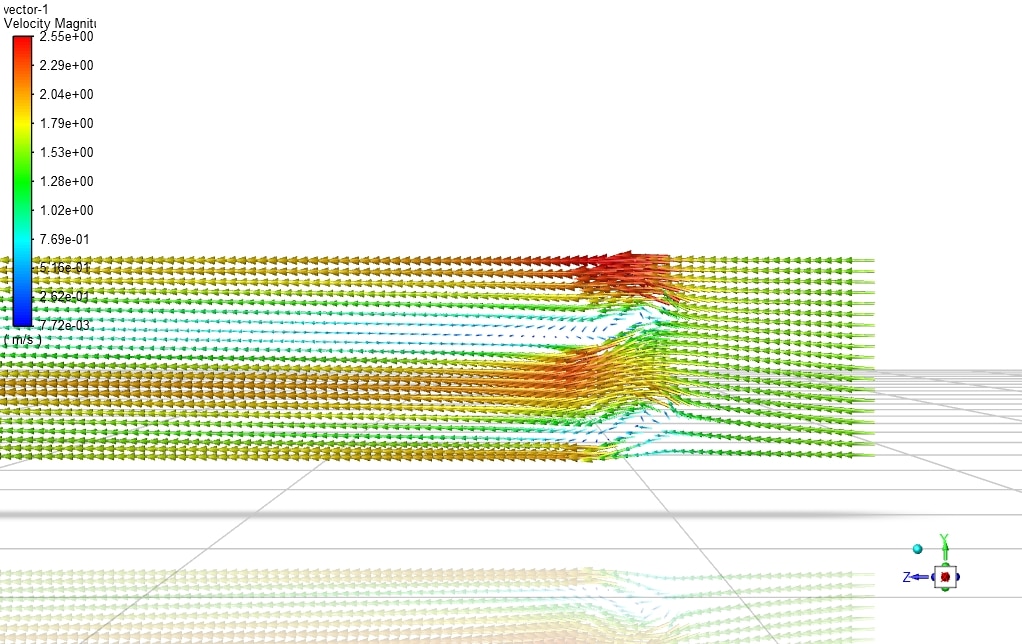

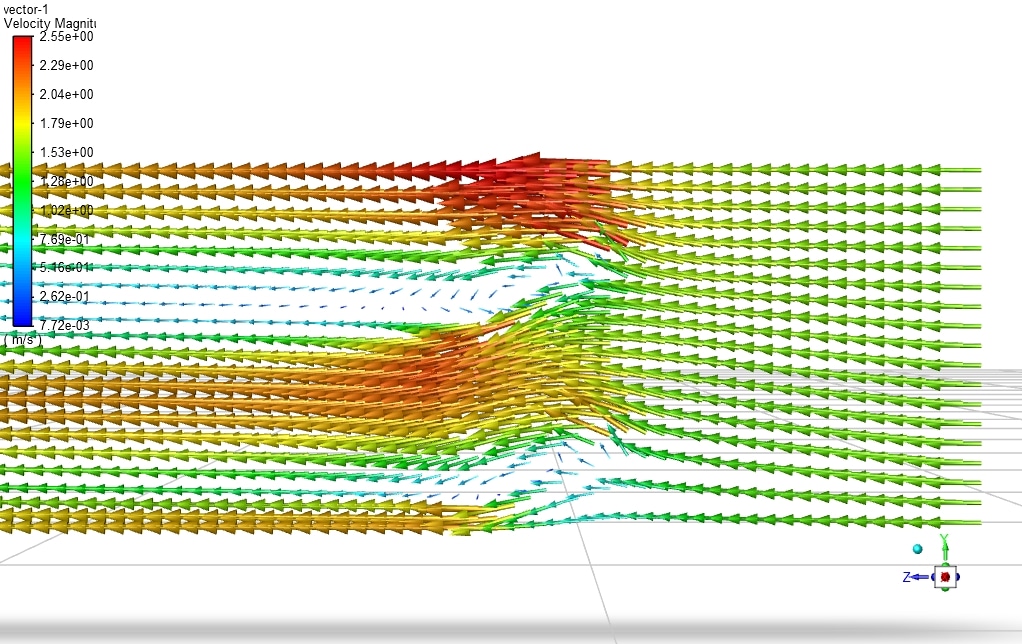

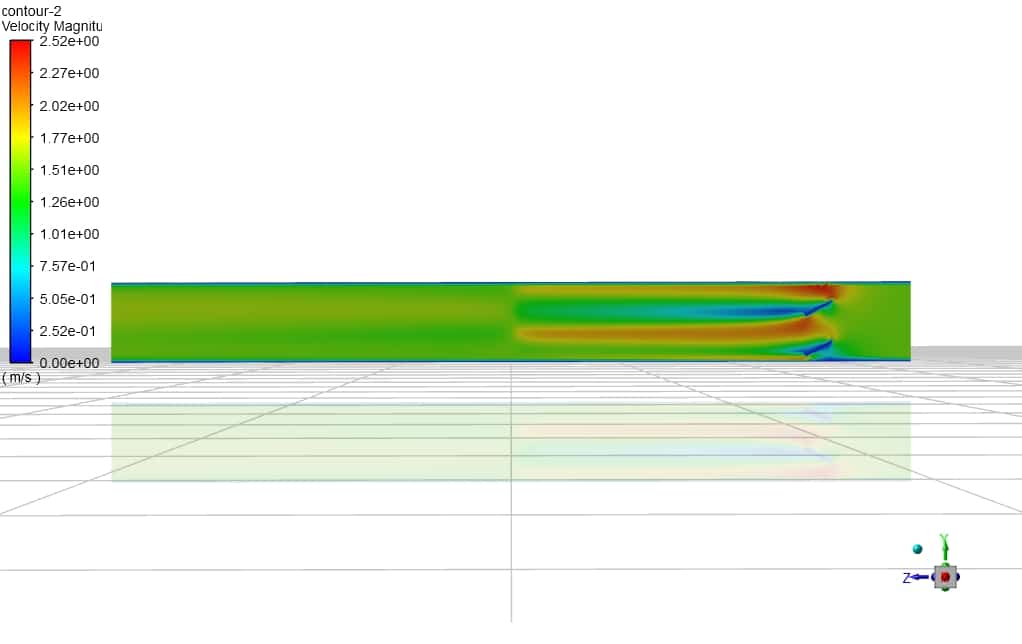

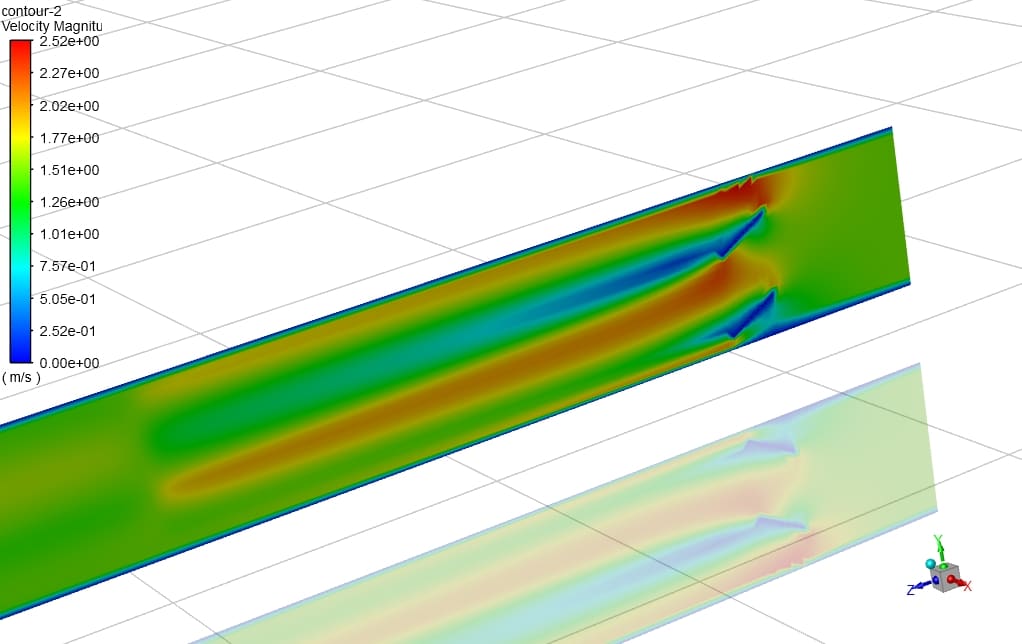

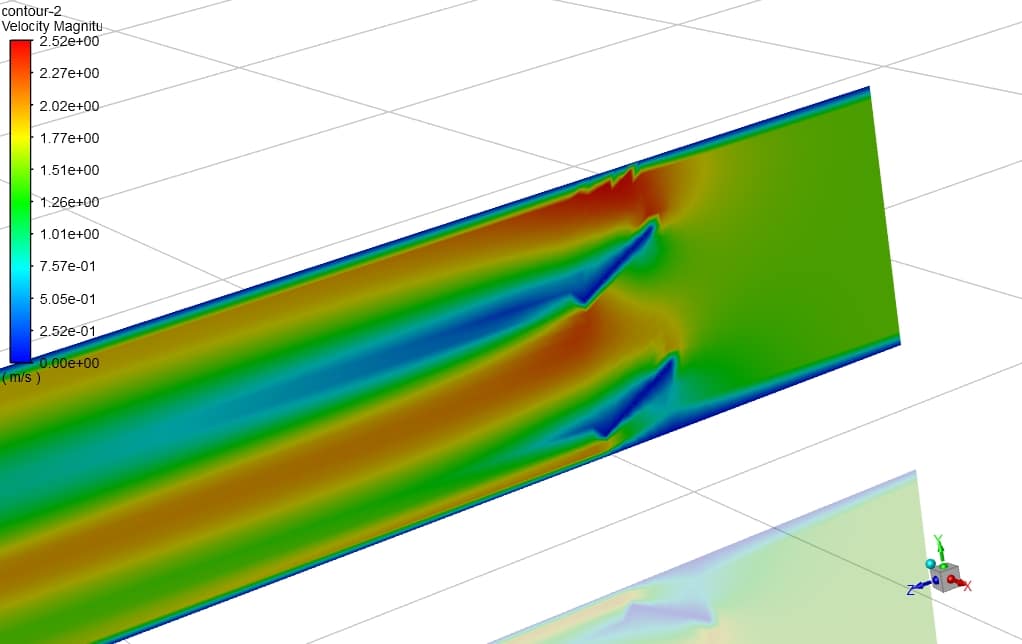

In this simulation, two-dimensional contours related to vectors, velocity, pressure, and contour are fluent and CFD-post software.

Velocity vectors show how the flow is aligned through the perforated plate.

Piping systems often include numerous fittings such as bends (elbows), valves, tees, enlargements and contractions, and many others. Fluids passing through such fittings inevitably emerge as maldistributed flows, which may be undesirable. Consequently, there is a clear need to incorporate fixtures in pipelines to improve flow maldistribution. Perforated plates are a frequently used means of flow homogenization in addition to other flow control applications.

Lia Cassin –

The training on porous jump in a perforated plate, particularly when applied to louvered vents for indoor air movement, really expanded my understanding. It clarified how to properly use boundary conditions and the importance of element number for structural mesh.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that the training provided you with clear insights into how to work with perforated plate simulations and employ appropriate boundary conditions. If you have any more questions or need further clarification on any aspect of the simulation, feel free to reach out. We appreciate the recognition of the importance of precise mesh structuring in CFD analysis.

Dr. Marisa Littel –

I was truly impressed by the detailed approach to incorporating porous jump conditions for a perforated plate using Ansys Fluent. The mesh generation is meticulous, and the simulation’s assumptions, along with the clear step-by-step summary, made the learning experience very comprehensive. Great job!

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that you found our training informative and comprehensive. It’s wonderful to know that our detailed instructions and mesh generation for the Porous Jump in a Perforated Plate CFD Simulation added value to your learning. If there’s anything else you’d like to learn or need further assistance with, we’re always here to help!

Dr. Mittie Huels III –

Fantastic educational content! The section detailing boundary conditions and the meticulous setup for the ‘Porous Jump in a Perforated Plate’s simulation was incredibly insightful. I particularly appreciated learning how the velocity inlet and pressure outlet were configured, and the explanation regarding the various utilities of porous plates in industrial applications was invaluable. These practical examples help solidify theoretical concepts into relatable use cases. Well done MR CFD for an exceptional learning module on Ansys Fluent.

MR CFD Support –

Thank you for your kind words! We are delighted to hear that the ‘Porous Jump in a Perforated Plate’ CFD Simulation course was both informative and helpful in understanding the application of porous jump conditions. It’s great to know that the course content has succeeded in bridging the gap between theory and practical industry applications. We strive to provide comprehensive training and appreciate your acknowledgment. Stay tuned for more insightful learning experiences!

Damaris Brown –

The Ansys Fluent training for the Porous Jump in a Perforated Plate simulation sounds comprehensive. It’s great how you’ve included the steps and considerations for setting up this simulation. The details on boundary conditions and solver settings illustrate a well-thought-out process to examine flow behavior through perforations, which appear vital in various industrial applications.

MR CFD Support –

Thank you for recognizing the effort to provide an elaborate training module on the Porous Jump in a Perforated Plate CFD Simulation. We strive to present detailed and practical simulations to enhance learning and application in real-world scenarios. Your positive feedback is much appreciated, and we’re glad you found the content admirable and helpful!

Prof. Lyric Lowe Sr. –

The provided CFD analysis of the porous jump sounds incredibly detailed! It’s impressive to see the extensive work on meshing and simulation setup aligning with such practical applications in industrial fields. The velocity vectors, in particular, must have visually illustrated the effectiveness of the perforated plate in homogenizing the flow. Great to have this clarity and applicability in a computational study!

MR CFD Support –

Thank you for your enthusiastic review! We’re thrilled to hear that you appreciate the meticulous effort put into our simulation and find the velocity vectors helpful in visualizing flow patterns. It’s heartening to know our products are proving valuable and insightful in understanding such complex dynamics. Your support inspires us to continue delivering high-quality simulations that serve both educational and industrial needs!

Nola Kautzer –

The training on porous jump in a perforated plate was very thorough. The way you simulated the pressure drops and airflow was insightful. I appreciate how the course also went beyond just the simulation part and also touched on the practical uses of perforated plates in industry like for flow homogenization. Great job!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you found the training thorough and insightful. It’s great to know the practical applications of perforated plates were well covered and useful. If you have any further questions or need further assistance, feel free to reach out to us. Your success is our priority!

Monty Labadie DVM –

I thoroughly enjoyed learning how to set up and analyze a ‘Porous Jump in a Perforated Plate’ using ANSYS Fluent. The course provided a thorough understanding of perforated plates and how they influence flow behaviors in various industries. The detailed explanation of setting up the problem, the step-by-step approach to simulation, and the clear interpretation of the resultant velocity and pressure contours were excellent. I particularly appreciated the structured mesh approach and the finalized post-processing CFD visualization which very clearly depicted the flow passage across the perforated plate.

MR CFD Support –

We’re thrilled to hear that you found the ‘Porous Jump in a Perforated Plate’ CFD Simulation course helpful and clear! It’s fantastic that you could appreciate how the course content reflects real-world applications using ANSYS Fluent. Your kind words are incredibly motivating for our team. We look forward to providing you with more engaging learning experiences. Thank you for the wonderful feedback!

Jaida Miller –

I found the details on modeling the porous jump in Ansys Fluent extremely useful for understanding the overall flow behavior through perforated plates. The step-by-step setup and the structured approach to simulation are commendable.

MR CFD Support –

Thank you for the positive feedback! We’re delighted to hear that the structured approach and the detailed setup description in our Ansys Fluent training for the Porous Jump in a Perforated Plate simulation was helpful for you. It’s our goal to provide comprehensive guidance to help our customers understand and implement CFD simulations effectively. Your acknowledgment means a lot to us!

Anika Quitzon –

What assumptions were made in the simulation regarding the effect of gravity and the state of the flow?

MR CFD Support –

In this simulation, the effect of gravity was ignored, and the flow was considered steady, meaning it does not change over time.

Austyn Yost –

This was my first dive into using porous jump conditions in CFD analysis, and the training product you offer made it an easy and comprehensive learning experience! The step-by-step guidance on how to handle pressure drops in perforated plates and create realistic simulation conditions in Ansys Fluent was invaluable. It’s great to have detailed tutorials that help understand both the theoretical and practical applications of perforated objects in flow systems. Thank you for an excellent training session.

MR CFD Support –

We’re thrilled to hear you found our training helpful and comprehensive. It’s fantastic that you were able to apply the concepts of porous jump conditions in CFD and simulate pressure drops effectively. We appreciate your kind words and hope that you continue to find success in your simulations. If you have any more questions or require further assistance in the future, don’t hesitate to reach out. Thank you for choosing our training products!

Prof. Mauricio Conroy III –

The product has helped me enhance my understanding of flow through perforated plates. The structured format and step-by-step solution process simplified a very complex topic. Thank you for the meaningful learning experience!

MR CFD Support –

We are delighted to hear that our product has provided you with a comprehensive understanding of flow through perforated plates. Your positive feedback is greatly appreciated, and we thank you for choosing our training for your learning journey. We look forward to providing you with many more enriching learning experiences in the future!

Alicia Muller MD –

This CFD simulation product was so enlightening. I never realized how perforated plates could affect airflow. Thanks for a well-explained process and the detailed summary!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear you found the CFD simulation on the porous jump in a perforated plate insightful and informative. We’re always here to provide comprehensive education on such complex processes!

Elna Koepp III –

This CFD simulation of a porous jump in a perforated plate was extremely informative. It provided clear insights into how perforated plates can be used to manage air flow in various industrial applications. The detailed steps involved in setting up and running the simulation are well-explained, making it easy to follow and understand the process for someone learning about CFD applications in flow control. Great job!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that the CFD simulation met your expectations and was able to provide you with the clarity needed to understand the flow control applications of perforated plates. If you have any more questions or need further assistance, feel free to reach out. We are always here to help with your learning journey!

Mavis Botsford PhD –

I had a great experience simulating the porous jump in a perforated plate using Ansys Fluent. The step-by-step instructions made setup easy, and the results were clear and insightful. Truly a testament to how powerful and user-friendly Ansys software is!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our training materials provided a smooth simulation experience and that you found Ansys Fluent software both powerful and approachable. Your insights are valuable to us, and we strive to continue producing high-quality content that meets your learning needs. If there’s anything else we can assist with in your CFD journey, please let us know!

Abraham Rice –

This course seems quite comprehensive, but could you please tell me if it also includes tutorials on calculating and specifying the porous media properties in ANSYS Fluent?

MR CFD Support –

Yes, the course covers the determination of porous media properties. It includes how to define these properties within ANSYS Fluent to ensure accurate simulation of flow through porous materials such as perforated plates.

Grace Luettgen –

I am impressed with the level of detail in the Porous Jump perforated plate simulation. The results must provide significant insight into airflow dynamics. Could you share if the simulation accounts for acoustic analysis, considering perforated plates are often used in silencer applications?

MR CFD Support –

We are glad that you appreciate the depth of the simulation. The primary focus of this CFD simulation is to analyze flow behavior and heat transfer using ANSYS Fluent. Acoustic analysis is typically a separate study that evaluates sound transmission and reduction; it isn’t factored into this particular simulation. For silencer applications, an additional acoustic module in ANSYS or other dedicated software would be required to perform such analysis.

Conrad Hermann V –

I am really impressed by how the porous jump in a perforated plate was simulated. It provided clear visuals that helped me understand the flow distribution better. Great job on this project!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our simulation was informative and provided clear visuals to understand the flow distribution through a perforated plate. Your satisfaction is our top priority, and we take great pride in offering detailed and accurate simulations.

Dr. Andre Sawayn IV –

The training and simulation on Porous Jump in a Perforated Plate are incredible! The velocity fields and pressure drops through the porous medium appeared realistic, mirroring industrial scenarios.

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that our simulation met your expectations and accurately reflected real-world applications.