Revolving Rice Dryer Using DPM CFD Simulation

$240.00 Student Discount

In this project, a revolving rice dryer using one-way DPM has been simulated and the results of this simulation have been investigated.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Rice Dryer Using DPM (Revolving ), CFD Simulation Ansys Fluent Training

In this project, a revolving rice dryer device was simulated using Evaporating droplets with a one-way DPM model in Ansys Fluent software, and then the results were investigated. Hot air enters the rice dryer through the holes in a porous tube located at the center of the enormous chamber. About three million rice particles are injected with 15% moisture droplets into a chamber revolving with 100rpm angular speed.

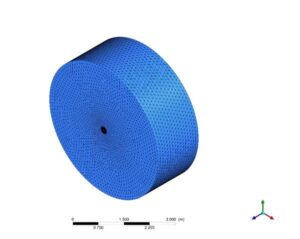

Geometry & Mesh

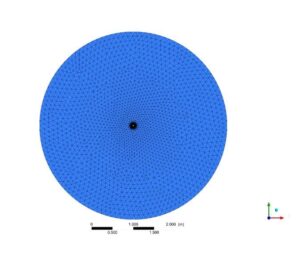

The 3D geometry was generated in Design Modeler software. A cylinder with a 4.5m diameter and 1.68m height.

In addition, an unstructured mesh grid was carried out using Ansys meshing software, and overall, 2703907 elements were generated.

CFD Simulation

Several assumptions have been considered to simulate Revolving rice dryer, including:

- The simulation is Transient(unsteady) in order to capture the behavior of fluid and particles over time.

- The pressure-based solver type was used due to the incompressibility of the working fluid(air).

- The One-way Discrete Phase Model(DPM) was utilized, so the grains of rice particles were injected with our desired condition into the fluid domain.

- Gravitational acceleration effects were considered 9.81m/s^2 in z-direction.

The following table represents a summary of the solution:

| Models(Viscous) | |||||||

| Energy | On | ||||||

| Viscous | k-epsilon Standard | Standard Wall Function | |||||

| Species | Species Transport | Mixture-template | |||||

| Discrete Phase Model | |||||||

| Interaction with continuous phase Unsteady particle tracking |

off

on |

||||||

| Injections | |||||||

| Injection Type

Number of streams |

Surface – wallinlet

|

||||||

| Particle Type | Droplet | ||||||

| Material

Evaporating species Diameter distribution |

Water-liquid

H2o Uniform |

||||||

| Diameter | 0.00214m | Stop Time | 8s | ||||

| Temperature | 300K | Velocity Magnitude | 1m/s | ||||

| Start Time | 0s | Total Flow Rate | 0.05kg/s | ||||

| Materials | |||||||

| Mixture-template | Definition method | Fluent database | |||||

| Material name | Air | ||||||

| Droplet Particle | Definition method | Fluent database | |||||

| Material name | Water-liquid

Volatile component fraction = 15% |

||||||

| Cell zone condition | |||||||

| Material name | Mixture-template | ||||||

| Frame Motion | Speed | 100rpm | |||||

| Boundary condition | |||||||

| Inlet | Type | Velocity inlet | |||||

| Velocity magnitude | 0.3m/s | ||||||

| Turbulent intensity | 10% | ||||||

| Hydraulic Diameter | 0.0254 | ||||||

| Temperature | 308K | ||||||

| DPM BC Type | escape | ||||||

| Outlet | Type | Wall | |||||

| DPM BC Type | reflect | ||||||

| Tube | Type | Wall | |||||

| Coupled | — | ||||||

| DPM BC Type | reflect | ||||||

| Solver configuration | |||||||

| Pressure-velocity coupling | Scheme | Coupled | |||||

| Spatial Discretization | Gradient | Least squares cell-based | |||||

| Pressure | Second-order | ||||||

| Momentum | Second-order upwind | ||||||

| Turbulent kinetic energy | First-order upwind | ||||||

| Turbulent dissipation rate | First-order upwind | ||||||

| H2o | Second-order upwind | ||||||

| Energy | Second-order upwind | ||||||

| Initialization | Initialization methods | Standard Initialization | |||||

| Run calculation | Time step size | 0.1 | |||||

| Number of time steps | 1600 | ||||||

| Max iterations per time step | 20 | ||||||

Results

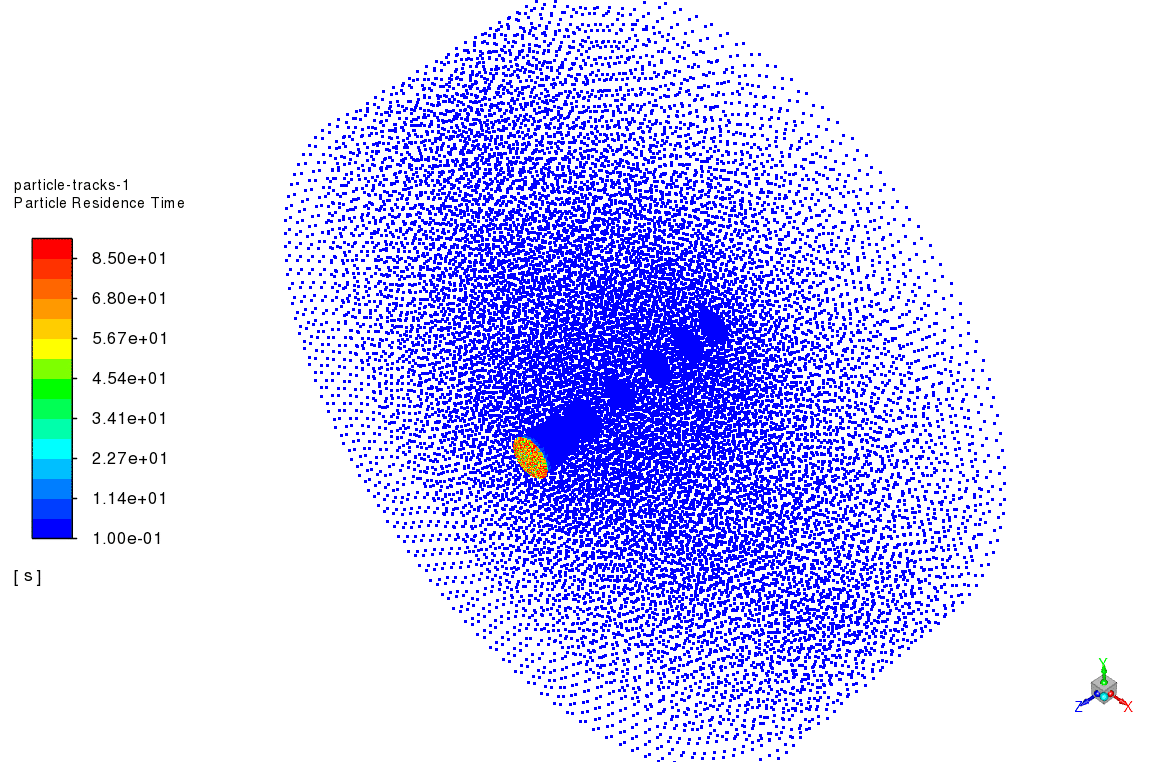

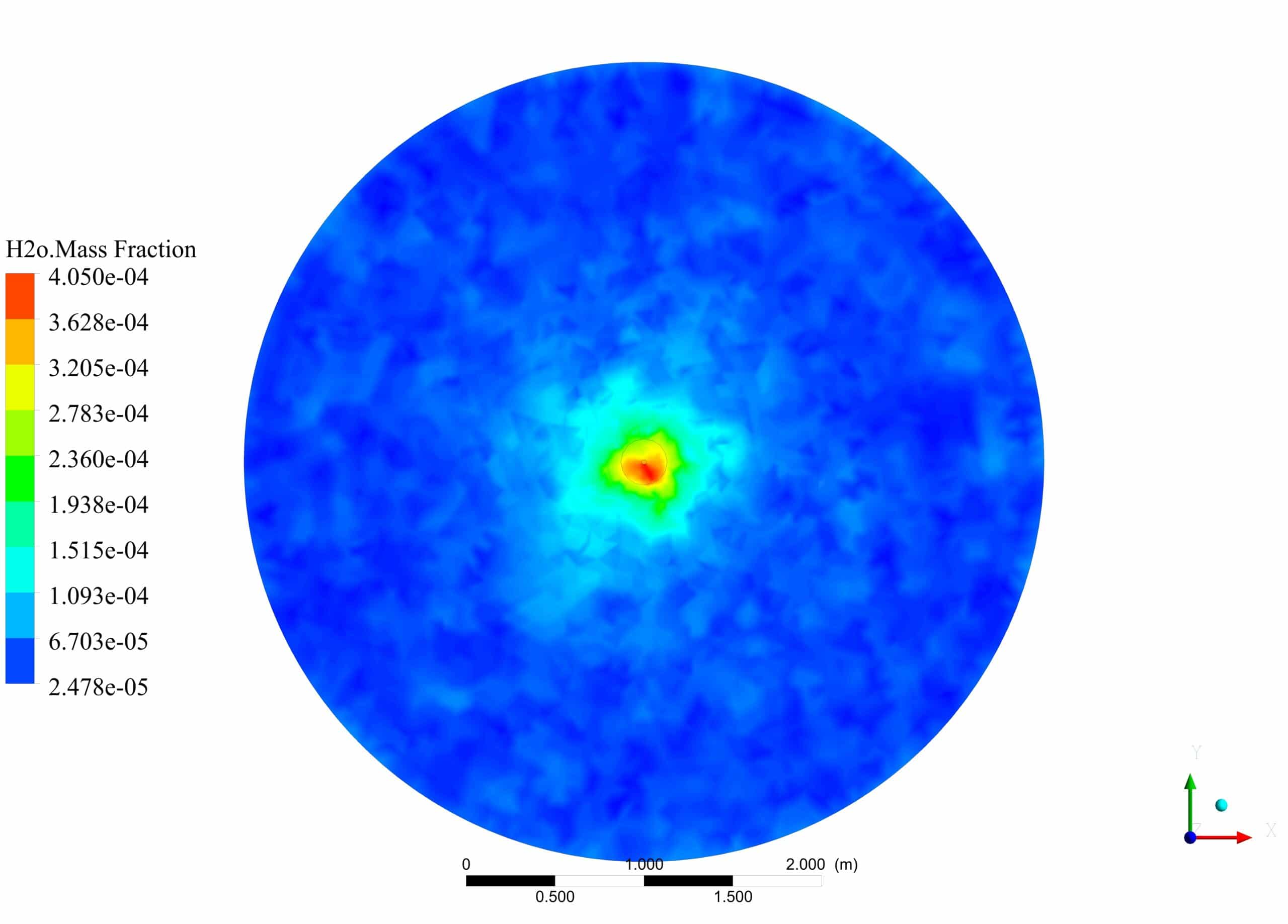

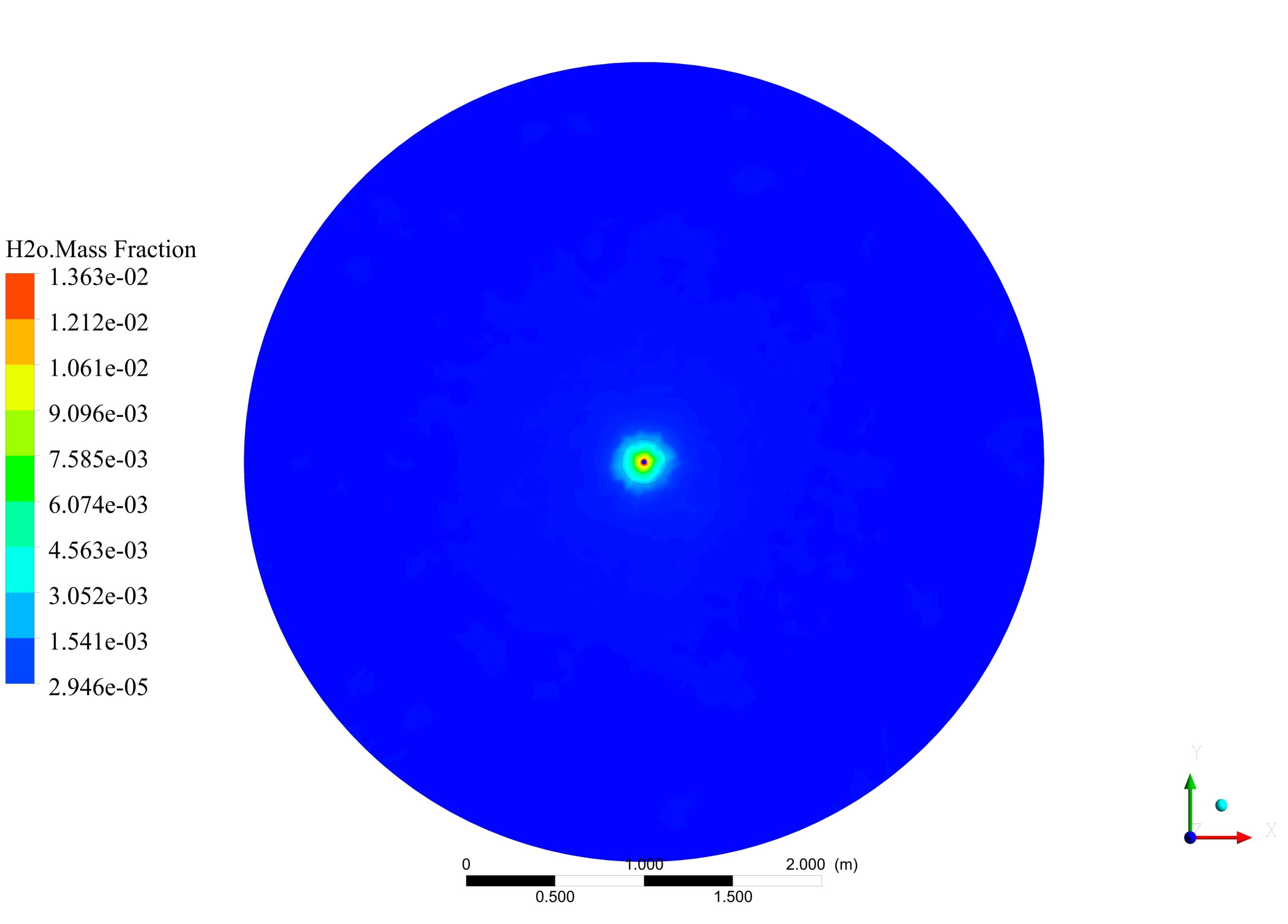

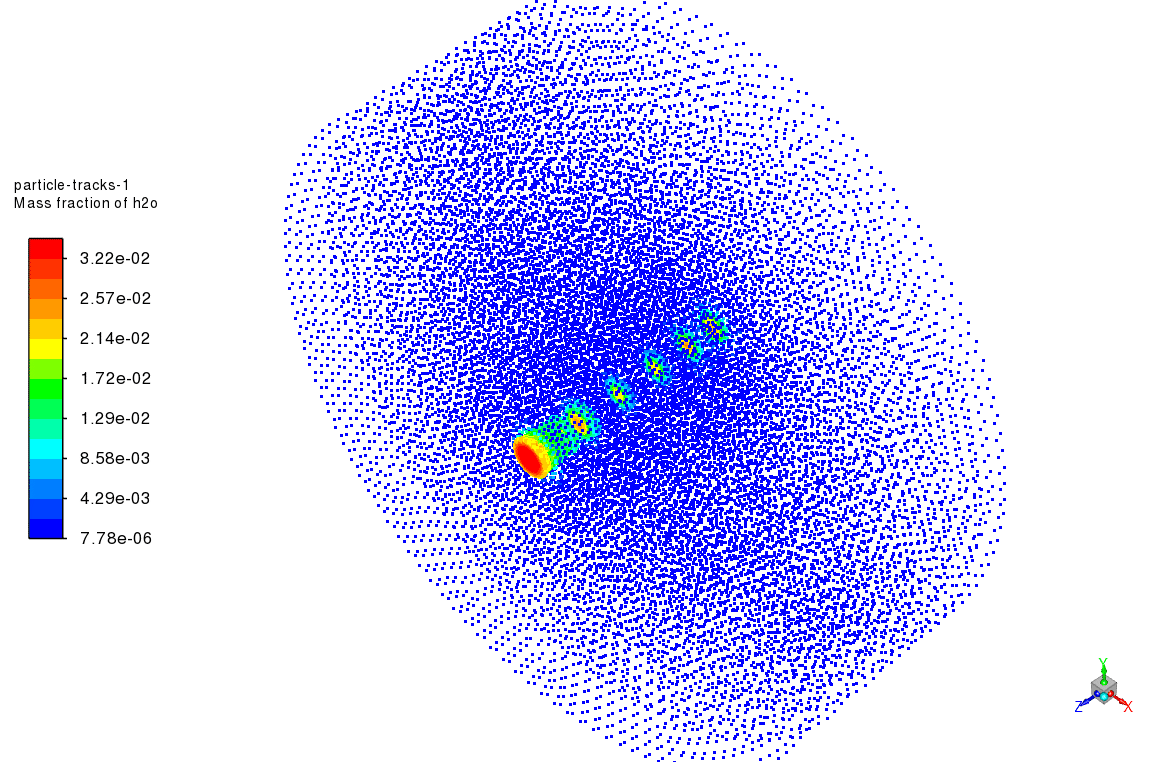

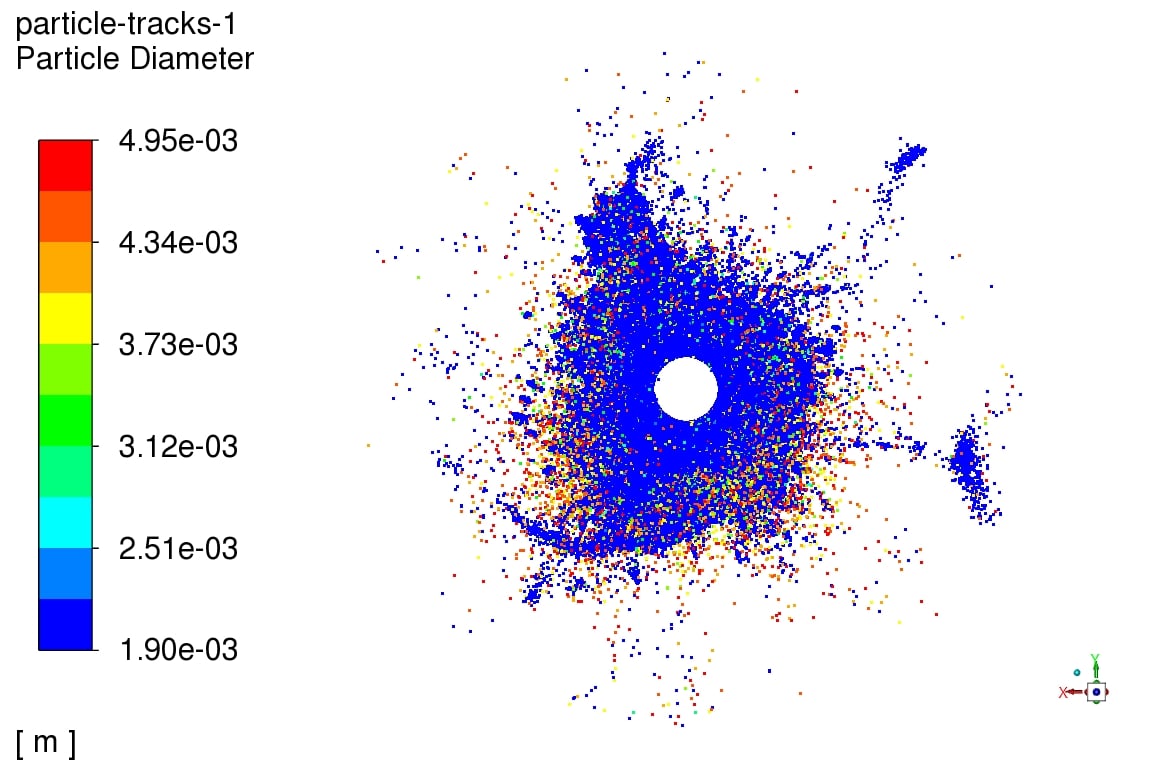

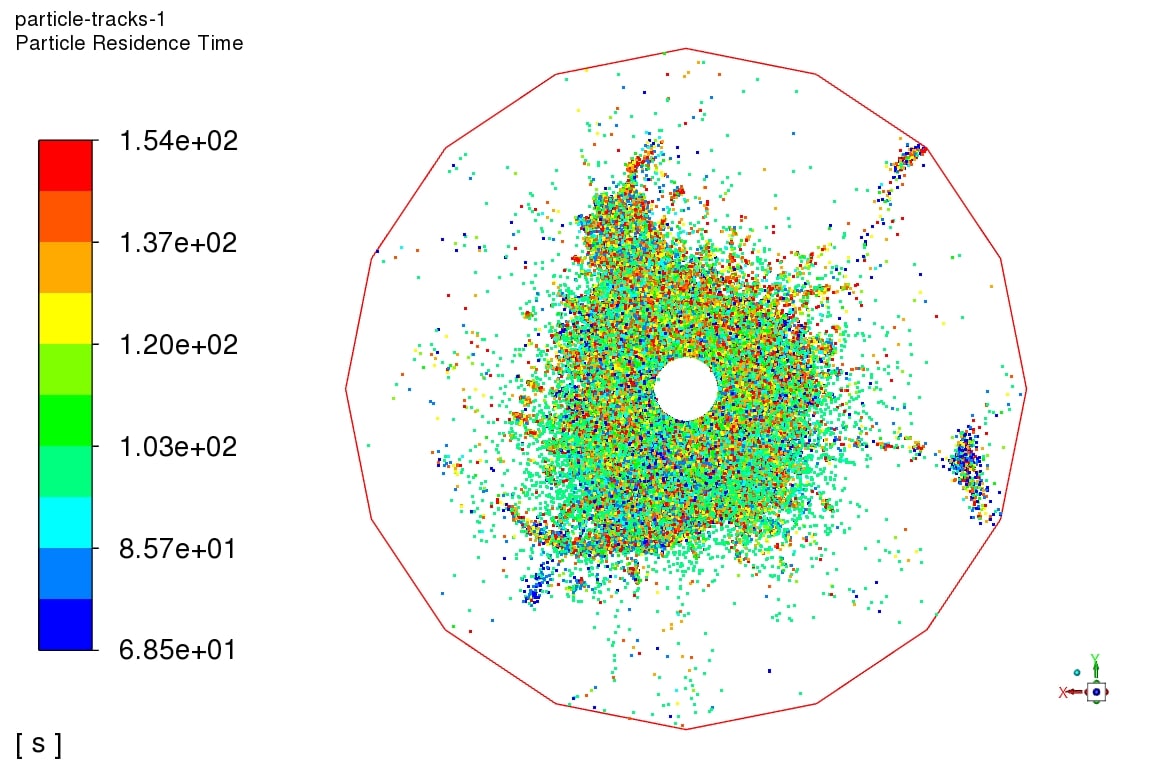

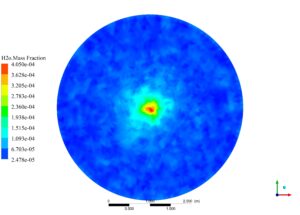

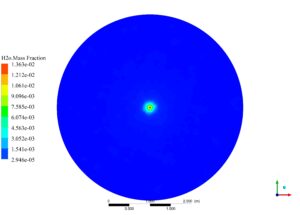

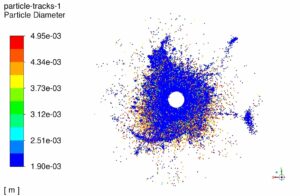

After injecting about three million rice particles through the inlet, they gather around the porous tube in the middle of the chamber. As shown in figure 1, H2o mass fraction concentrated around the tube at first, but after a while, due to the release of hot air from tube holes to the chamber, the evaporating process begins and causes vaporizing material(H2o) to disperse; This may reduce the moisture of rice particles which was 15% at the beginning and as a result, the diameter decrease that depicted in figure 2. In addition, the Rotational speed of the chamber accelerates the circulation of hot air.

Prof. Sage Boehm Jr. –

I’m impressed with the way the rotational speed of the chamber and the hot air worked together to decrease the moisture content in the rice particles. The detailed introduction of the phases and modeling process delivered straightforward insights into your simulation. It’s always quite fascinating to visualize the drying process and see the interaction between heat and the revolving particles. Outstanding work!

MR CFD Support –

Thank you for your review! We’re elated to hear that the simulation met your expectations and that you found the visualization and results enlightening. If you’re interested in learning more about CFD and our other simulations, we’re always here to assist with high-quality training and detailed explanations. Your positive feedback is immensely appreciated and motivates us to continue providing top-notch simulations. Thank you once again!

Twila Ward V –

The description of the dryer’s performance is quite comprehensive, but how exactly is the collision behavior of the rice particles with the chamber wall modeled in the simulation?

MR CFD Support –

In the simulation, the collision of rice particles with the chamber wall is captured using a Discrete Phase Model (DPM). The boundary condition set for the wall is reflective, meaning when particles hit the wall, they reflect off it rather than sticking to it or escaping. This ensures the simulation mirrors the physical behavior of rice particles inside a revolving dryer, successfully accounting for the interactions between particles and the revolving chamber wall.

Devante Baumbach –

What a thorough and data-rich simulation of the rice dryer. The intersection of CFD and practical applications like agriculture assures exciting progress in optimization! The details make for easy visualization of the process.

MR CFD Support –

Thank you for your compliment on the rice dryer simulation! At MR CFD, we value the practical application of CFD in various industries and strive to deliver comprehensive and detailed analyses to aid in optimization and development. We’re glad that you found the information useful and that it helped enhance your understanding of the process involved.

Dr. Humberto Jakubowski –

The explanation is quite detailed but I couldn’t find the information regarding how the outlet condition is defined for the rice dryer simulation. Could you provide some insights into that?

MR CFD Support –

In this simulation, the outlet boundary condition is typically defined as an ‘escape’ condition for the Discrete Phase Model (DPM) to allow particles to leave the computational domain without any restriction once they reach the outlet. The outlet for the continuous phase, the air, would generally be set up as a pressure outlet where the pressure is assumed to be atmospheric. However, this can vary depending on the specifics of the simulation setup and goals.

Paolo Mueller V –

This sounds like an extremely complex simulation with many variables. Can you clarify how the DPM model differentiates between evaporating and non-evaporating rice particles in the simulation?

MR CFD Support –

In this simulation, all rice particles start with 15% moisture content, which means they are capable of undergoing evaporation. The one-way Discrete Phase Model (DPM) accounts for the evaporation by calculating the change in mass of the water droplets as they lose moisture (evaporate) due to the hot air. The properties of particles that have undergone evaporation are automatically updated by the model based on the loss of moisture, which results in changes such as a reduction in their diameter. Non-evaporating particles would refer to particles that don’t experience significant moisture loss either due to shorter exposure times or conditions not conducive to evaporation.

Daphney Abernathy –

The training was highly informative, and I especially appreciated the detailed setup of the DPM conditions. The simulation seemed complex; were there any specific challenges in tracking the three million rice particles, given the high rotational speed and the potential for collisions among particles and with the dryer walls?

MR CFD Support –

The process of tracking a large number of particles, especially in a high-speed revolving environment, certainly poses challenges. However, ANSYS Fluent handles these using the one-way Discrete Phase Model, which simplifies the interactions by not considering feedback on the continuous phase from particles. Collisions and interactions with the walls are managed through defined boundary conditions, ensuring accurate simulation of particle behavior without significantly increasing the computational cost.