Savonius VAWT CFD Simulation with Mesh Motion in ANSYS Fluent

$140.00 $56.00 HPC

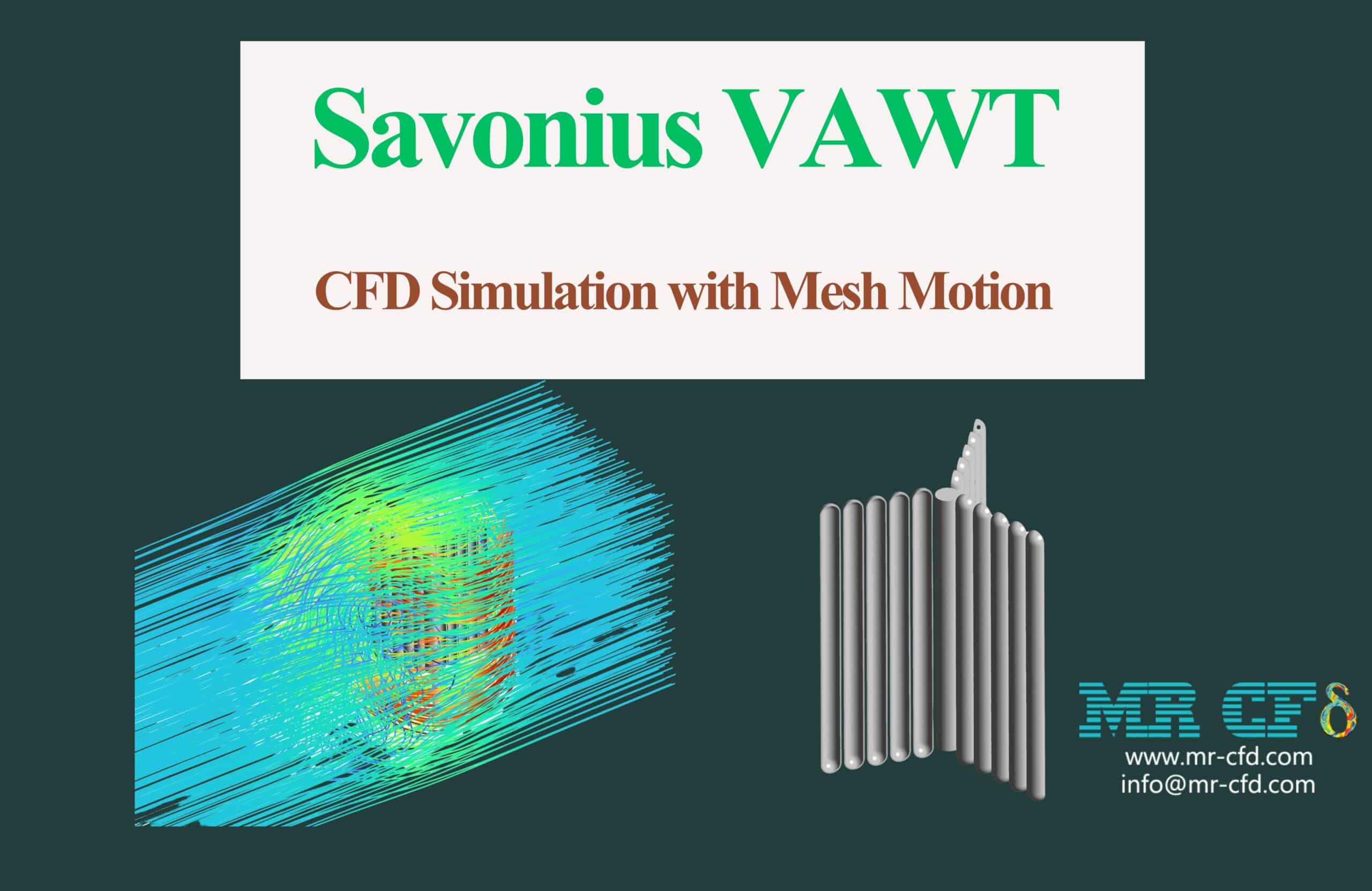

- This study presents a CFD analysis of a Savonius VAWT using mesh motion in ANSYS Fluent to examine aerodynamic performance and flow characteristics.

- The rotor geometry was modeled in DesignModeler and meshed with a non-conformal, unstructured grid containing about 5.5 million cells for accurate flow resolution.

- A transient, pressure-based solver with the RNG k-ε turbulence model was applied; air was used as the working fluid, with rotating and stationary flow zones defined.

- The simulation revealed pressure variations, wake formation, and vortex structures around the blades, highlighting key aerodynamic behaviors of the Savonius VAWT.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

CFD Simulation of Savonius VAWT (Vertical Axis Wind Turbine) with Mesh Motion by ANSYS Fluent

Description

This study investigates the airflow behavior and aerodynamic performance of a Savonius vertical axis wind turbine (VAWT) using computational fluid dynamics (CFD) analysis in ANSYS Fluent. The aim of the simulation is to evaluate pressure and velocity distribution around the rotor blades and analyze the flow patterns that develop during turbine operation. The simulation is performed using transient conditions to capture the dynamic nature of the rotating blades and the unsteady flow separation and vortex formation characteristic of Savonius VAWT rotors. The computational domain includes a rotating rotor region and a stationary flow domain to simulate the incoming airflow interaction accurately.

Geometry and Mesh

The geometry of the model was designed in ANSYS DesignModeler and represents a three-bladed Savonius VAWT rotor enclosed within a computational domain that allows sufficient clearance for airflow around the turbine. The meshing process was conducted in ANSYS Meshing, where a non-conformal, unstructured mesh was generated to accommodate the complex blade geometry and ensure accurate resolution of boundary layers. The total number of cells in the model is approximately 5.5 million, providing an adequate balance between computational cost and accuracy. The mesh shows refined regions near the rotor surfaces to better capture velocity gradients and flow separation effects.

Model and Solver Settings

The CFD analysis was carried out in ANSYS Fluent using a pressure-based transient solver, suitable for incompressible flow conditions. The working fluid was air, modeled as a Newtonian, incompressible fluid. To account for turbulence effects, the RNG k-ε turbulence model was employed, known for its improved performance in swirling and recirculating flows, common in Savonius VAWT simulations. The computational domain was divided into two zones: a rotor zone (rotating) and a flow zone (stationary). The rotor zone was assigned a mesh motion corresponding to a rotational speed of 144 RPM, representing the turbine rotation. Boundary conditions included a velocity inlet with a magnitude of 12 m/s, a pressure outlet at the downstream side, and no-slip walls on the turbine surfaces. The SIMPLE algorithm was applied for pressure-velocity coupling, while second-order discretization schemes were used to enhance accuracy for momentum and turbulence equations.

Results

The simulation results provide insights into the pressure, velocity, and flow behavior around the Savonius VAWT rotor. Pressure contours show high-pressure regions at the windward side of the blades and low-pressure regions at the leeward side, confirming the generation of torque due to differential pressure forces. The velocity contour plots and streamlines reveal complex vortex structures and recirculation zones behind the rotor, illustrating the unsteady wake dynamics typical of drag-based turbines. The velocity vectors indicate how airflow is deflected and accelerated around the blades, while the streamlines visualize the rotational flow entrainment near the rotor arms. The overall flow pattern suggests a consistent power extraction process, although some regions of flow separation and turbulence intensity may reduce efficiency. These results validate the aerodynamic characteristics of the Savonius VAWT design and demonstrate the effectiveness of CFD simulation for performance evaluation.

You must be logged in to post a review.

Reviews

There are no reviews yet.