Moving Train External Airflow CFD Simulation, ANSYS Fluent Training

Free

- The problem numerically simulates the Moving Train External Airflow using ANSYS Fluent software.

- We design the 3-D model by the Gambit software.

- We mesh the model with Gambit software, and the element number equals 1013277.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

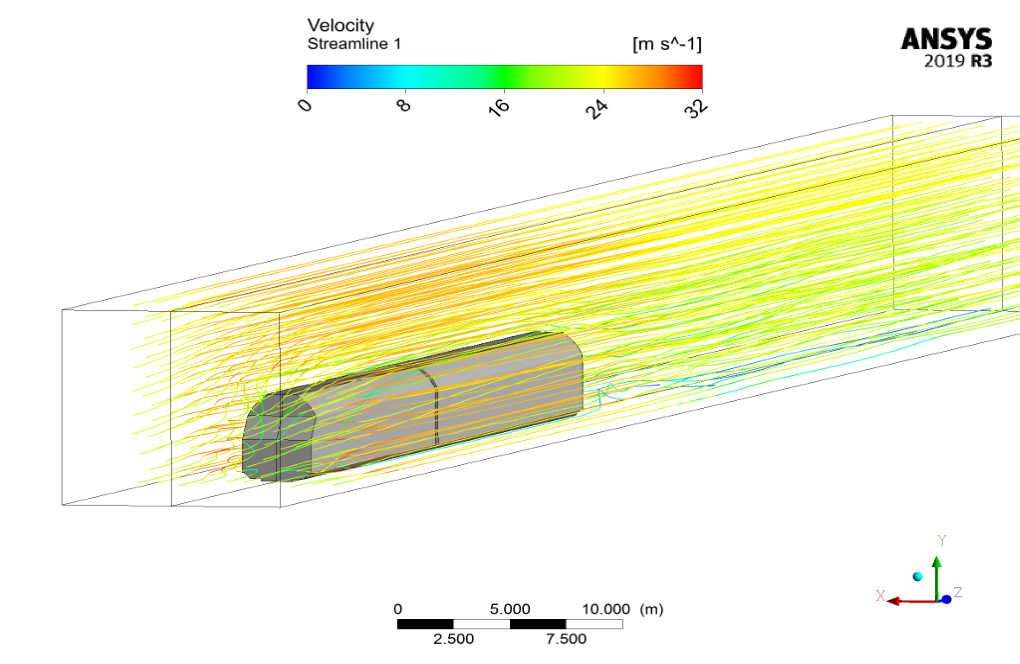

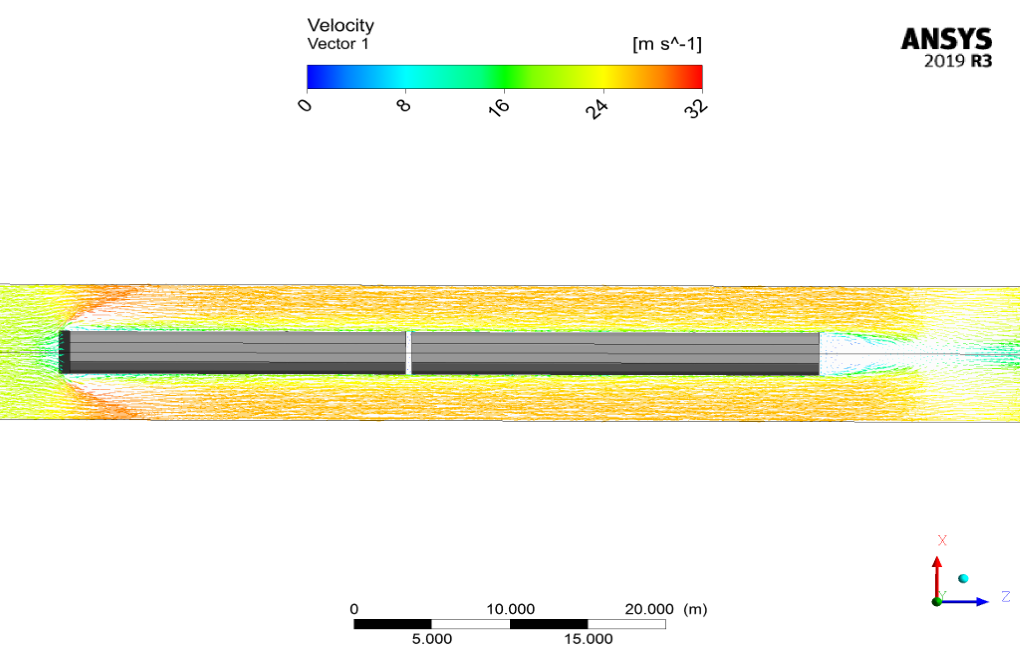

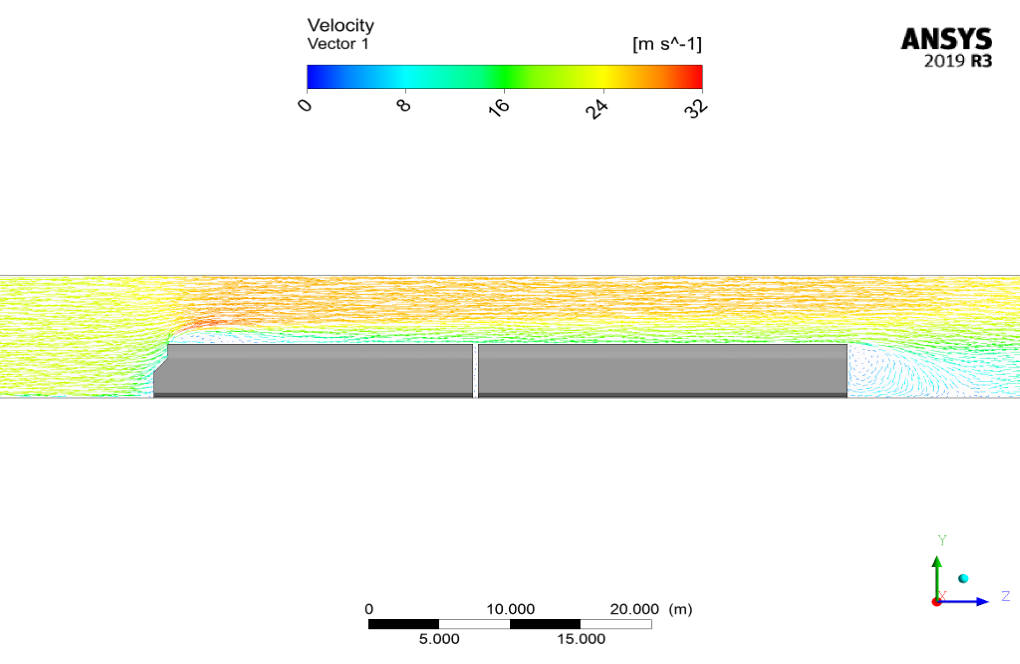

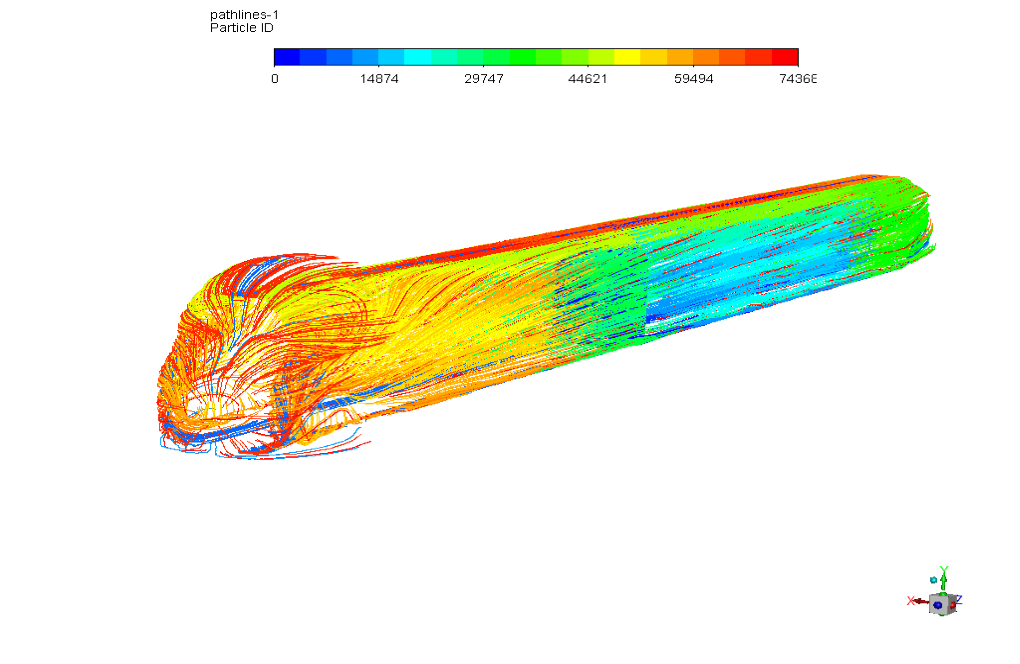

In this project, the airflow around a train is investigated and airflow parameters were extracted by ANSYS Fluent software. Due to the high speed of the train and the speed of airflow, phenomena such as separations or vortexes occur behind the train.

Advanced moving train aerodynamic design is an effective factor in reducing energy consumption. This reduction is possible when the drag force, exerted from the fluid is decreased. Therefore, aerodynamics plays an important role in the design of trains or any moving object that is exposed to airflow.

Computational fluid dynamics simulations have reduced the cost of building trains and locomotives, and have made it possible to check the efficiency of the new design before construction.

Train Methodology

This project aims to investigate turbulence flow around the train. The geometry of this project consists of a modeled train, and the fluid domain. The geometry is designed and meshed inside GAMBIT®. The mesh type used for this geometry is unstructured and the element number is 1013277.

Train Conclusion

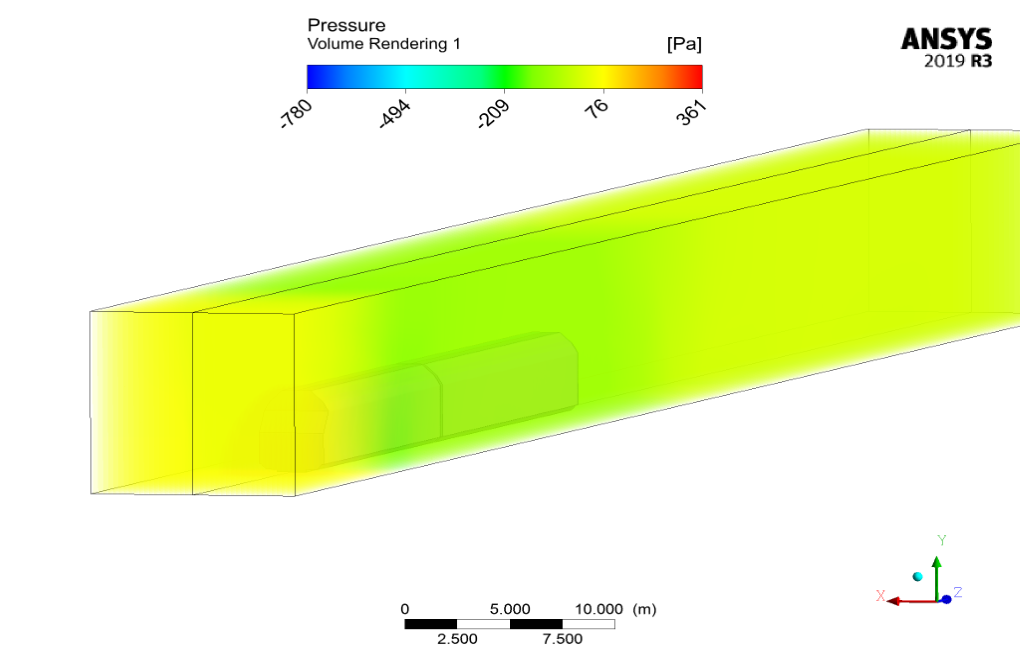

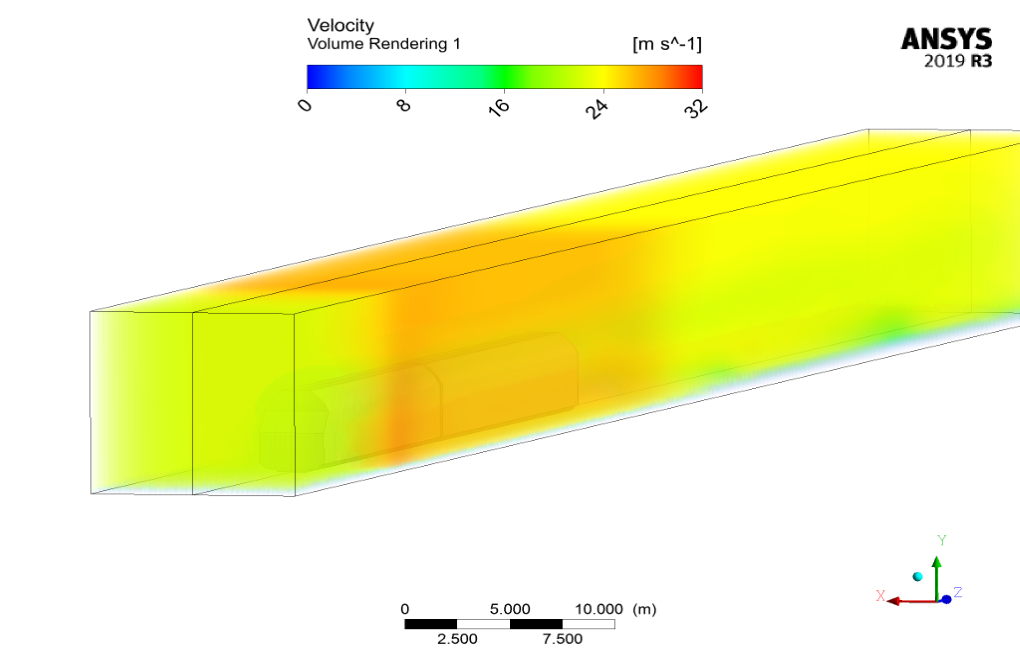

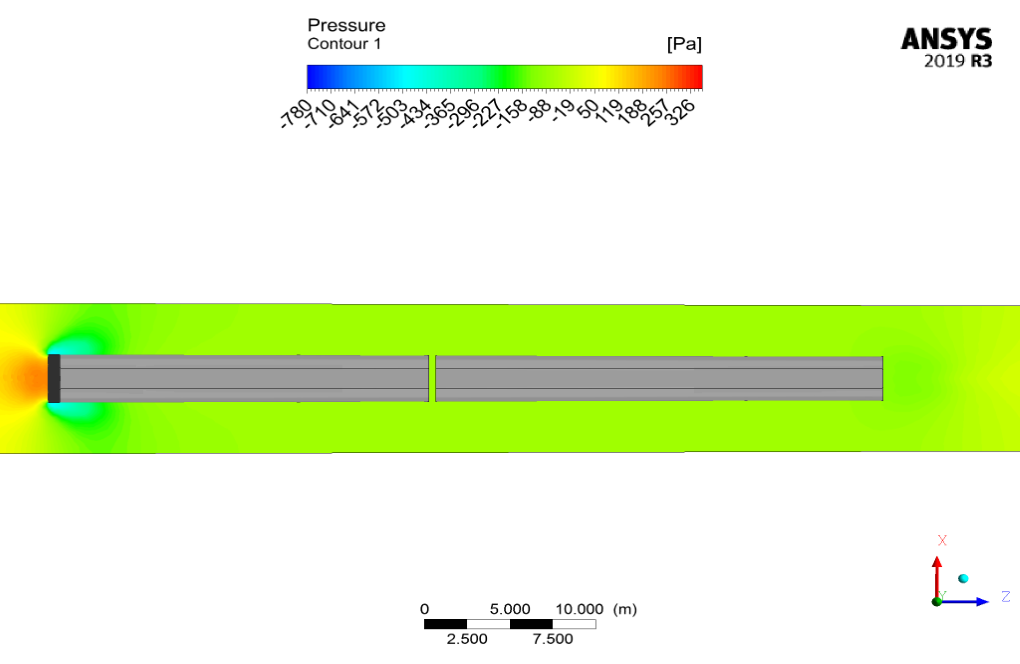

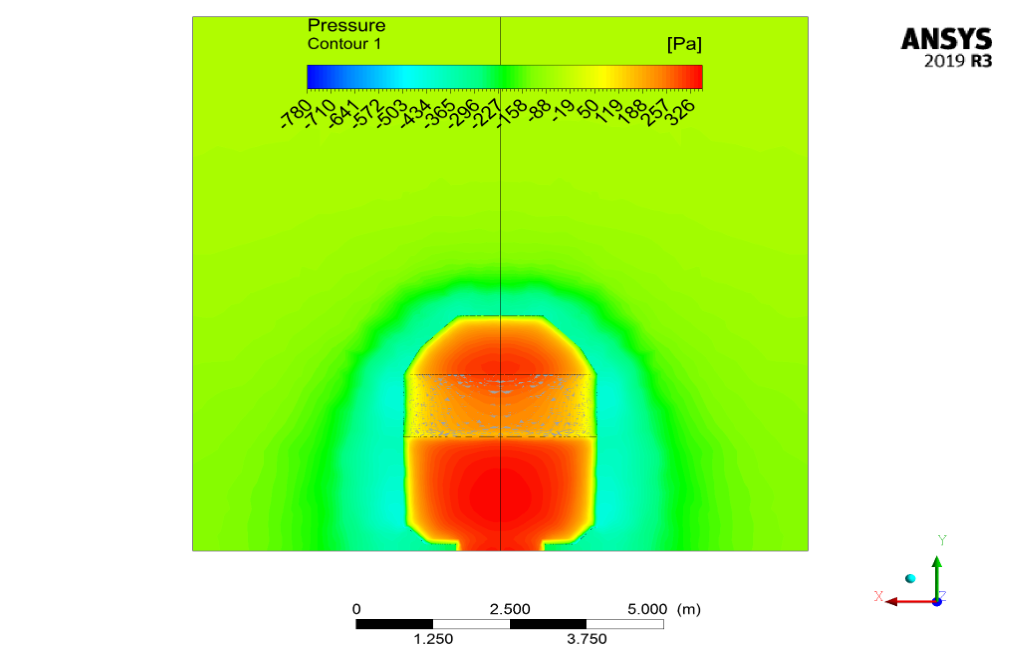

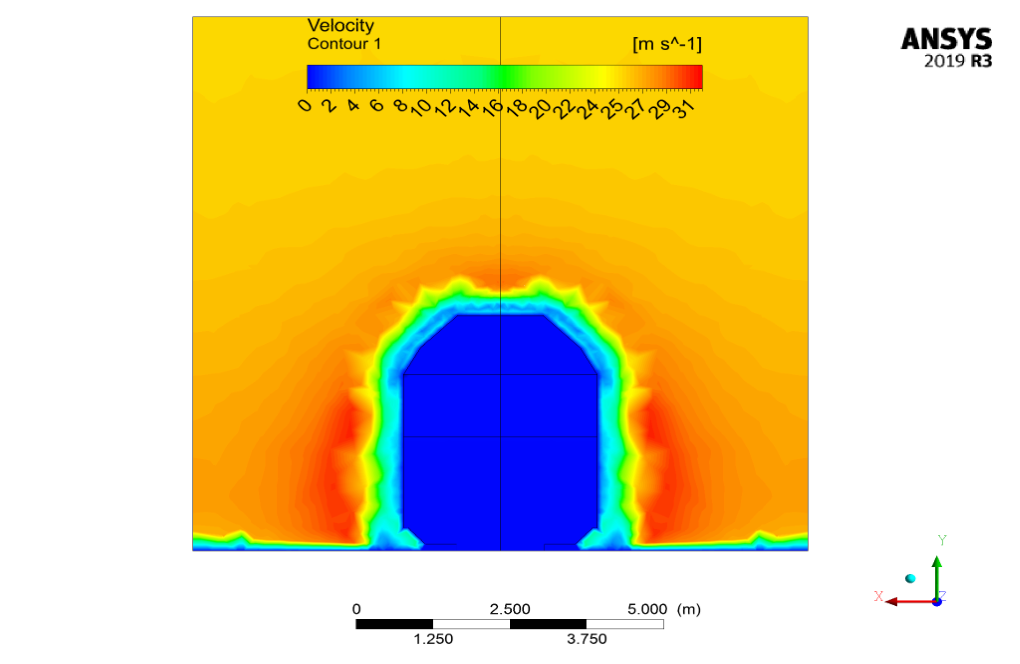

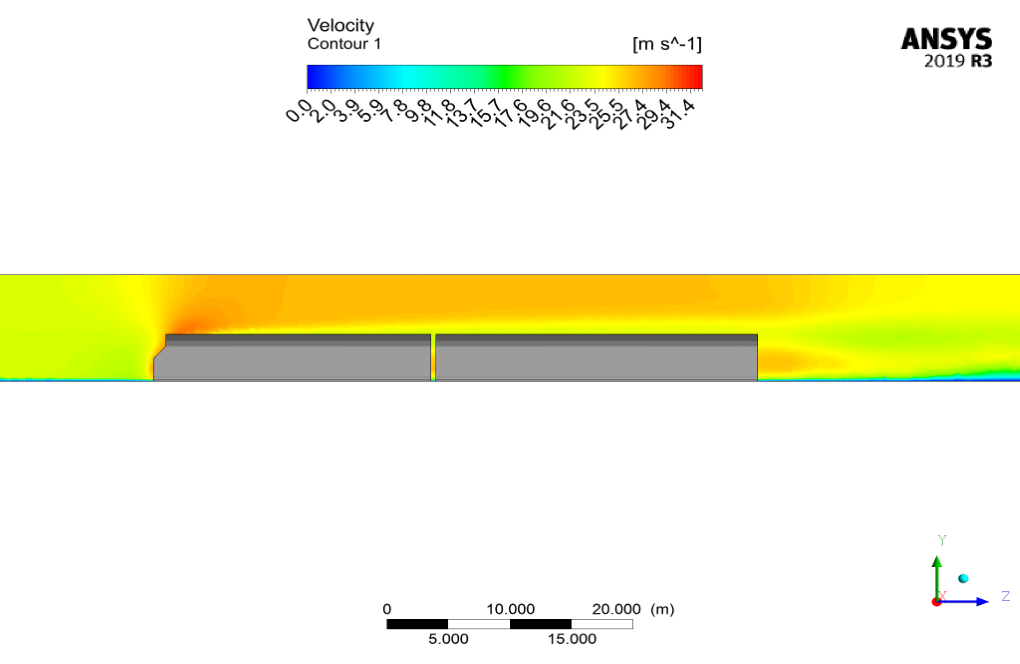

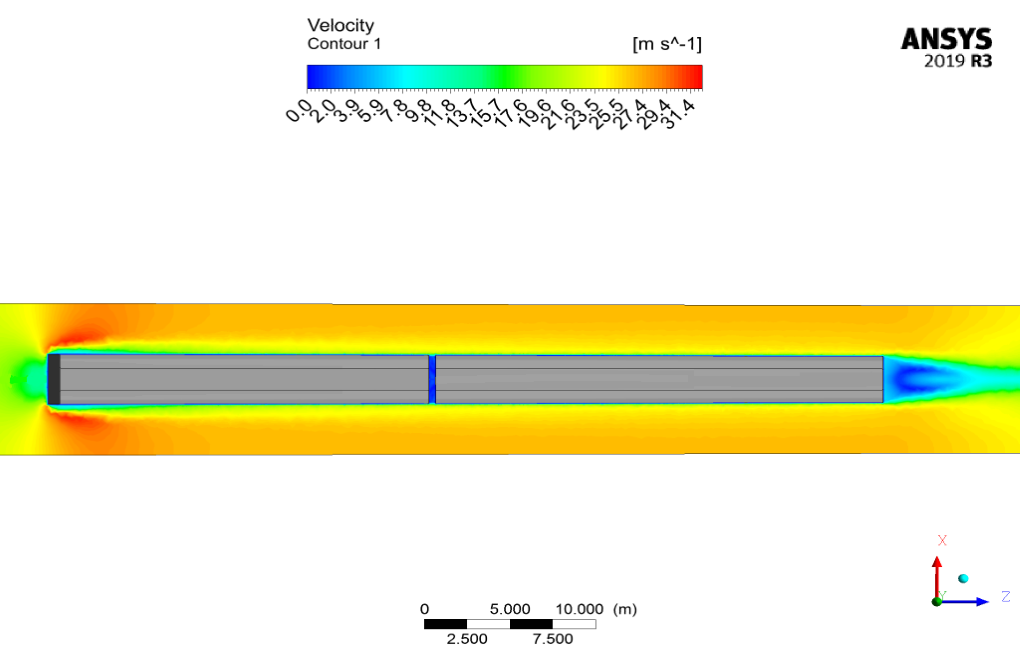

Contours were obtained at the end of the simulation. The pressure contour shows that the pressure initially has its maximum value on the front surface. However, with a slight distance from the wall, the aerodynamic suction pressure has increased while increasing the speed.

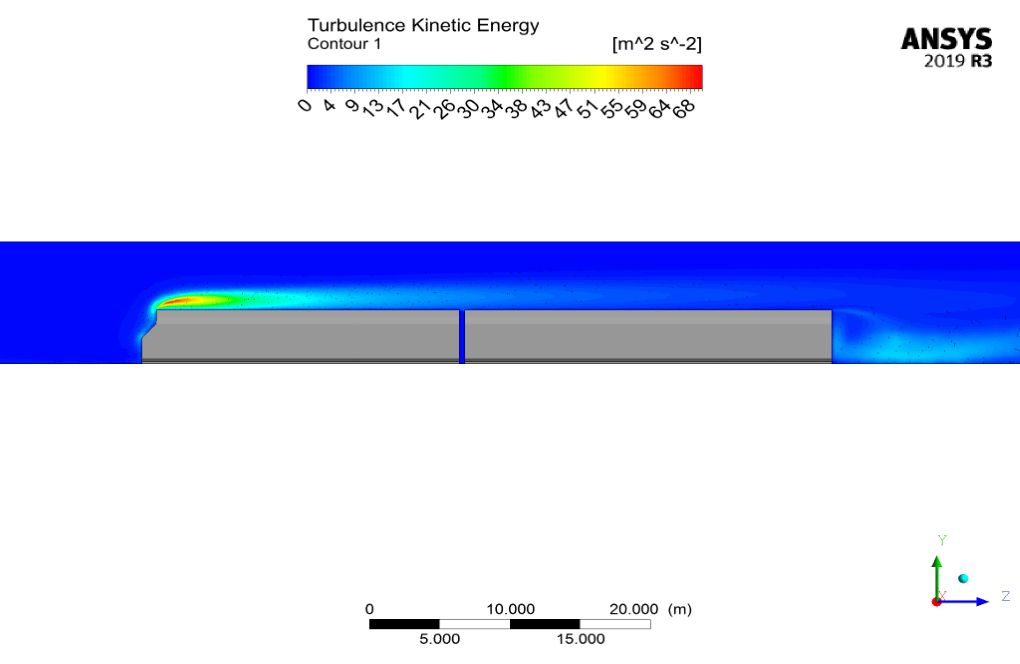

Also, the thickness of the boundary layer at the back of the train indicates that the flow’s turbulence has increased, which is due to the separation phenomenon behind the train. Due to the train’s movement and its exposure to airflow, the drag force enters the train body in the opposite direction of the flow.

In general, using methods to reduce vehicle drag can help control energy wastage. This video taught you how to simulate a train’s movement and draw the contours.

Sabina Rau –

I appreciate the dedication to accuracy and validation in this simulation.

Glenda Wilkinson –

Absolutely fantastic training module! I’ve learned so much about the influence of aerodynamics on train design. The utilization of CFD in train development truly reveals areas of optimization that can lead to significant energy savings. Well done MR CFD Company for such a comprehensive study!

MR CFD Support –

Thank you for your kind words! We are elated to hear that you found the training module on moving train external airflow simulation using ANSYS Fluent informative and useful. It’s gratifying to know that our efforts to teach the impact of aerodynamics on train design are appreciated. If you ever have any questions or need further assistance in future studies, please don’t hesitate to reach out!

Isobel Hermiston –

This training video was excellent! The step-by-step instructions made it easy to follow and understand how to simulate the exterior airflow of a moving train using ANSYS Fluent. I was able to see the impact of aerodynamic design in reducing drag, which is crucial for energy efficiency in high-speed trains. It’s fascinating to see the practical application of CFD in improving train designs.

MR CFD Support –

We’re thrilled to hear that you found our moving train external airflow CFD simulation training helpful and informative! It’s fantastic that you have deepened your understanding of aerodynamics in high-speed trains and their influence on energy efficiency. Thank you for sharing your positive experience, and we hope our training continues to support your learning and curiosity in the field of computational fluid dynamics.

Prof. Marcia Frami –

I’m impressed by the level of detail in the airflow analysis. This will greatly help in designing more efficient trains. Kudos to the training material for providing such thorough insights into drag reduction strategies.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you found our CFD simulation and training material on external airflow around a moving train so informative and helpful. Your appreciation truly motivates us to continue providing high-quality analysis and insights. If you require further details or have any more questions in the future, please don’t hesitate to reach out.

Trevor Steuber –

I’ve watched the video and seen the simulations of the train’s airflow patterns. The visuals were informative, and the explanations were clear. Understanding how the drag force works on the train at high velocities was particularly fascinating. The techniques discussed for reducing drag force will undoubtedly be invaluable for anyone involved in transport design!

MR CFD Support –

Thank you for your feedback! We’re glad the training on simulation of the train’s external airflow using ANSYS Fluent was insightful and helped deepen your understanding of the aerodynamic principles involved. It is encouraging to hear that the content was clear and beneficial for those interested in transportation design optimization. We appreciate your acknowledgment of the value provided in our training materials.

Jocelyn Lynch Sr. –

Is there a way for me to contribute to this simulation?

MR CFD Support –

We welcome contributions! Feel free to share your ideas or suggestions.

Miss Jolie Waelchi –

The simulation of the train in airflow was so thorough, I could clearly visualize the aerodynamic effects on energy consumption and identify where design improvements can be made. Excellent and insightful training material!

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that you found the training helpful for visualizing aerodynamic effects and identifying design improvements. We strive to provide comprehensive simulations for practical insights. Your feedback motivates us to continue delivering quality learning materials.

Ms. Nadia Botsford II –

I watched the tutorial video on how to simulate train movement in ANSYS Fluent and it was very informative. I particularly like the way the pressure and airflow contours were displayed and explained.

MR CFD Support –

Thank you for your kind words! We are thrilled to hear you found the tutorial video informative and that the explanation of pressure and airflow contours was clear. Understanding the aerodynamics around the train is crucial for design efficiency, and we’re glad our training could assist with that. If you have any more questions or need further insights, please do not hesitate to reach out.

Ricky Upton –

What advantages does using CFD offer in analyzing the external airflow around moving trains?

MR CFD Support –

CFD provides a detailed analysis of the airflow characteristics around moving trains, offering insights that are difficult to obtain through experimental tests.

Ms. Laisha Schmidt –

I’ve completed the Moving Train External Airflow CFD Simulation course and found the provided contour analyses incredible! It helped me understand how aerodynamics designs can influence energy consumption. Kudos to the team for such detailed work.

MR CFD Support –

Thank you very much for your kind words! We are thrilled to hear that our Moving Train External Airflow CFD Simulation course has contributed to your understanding of train aerodynamics and its effect on energy efficiency. It’s always great to receive feedback from satisfied customers. We aim to provide high-quality and detailed simulations to help our users make breakthroughs in their studies or work. Don’t hesitate to reach out if you need more information or further assistance. Thank you for choosing MR CFD!

Taurean Schmidt –

The training was absolutely enlightening! I’ve learned a lot about train aerodynamics and the factors that affect it through CFD analysis.

MR CFD Support –

We’re so glad to hear that our training was helpful to you! Understanding aerodynamics is crucial for efficient train design, and CFD is a powerful tool for this purpose. Thank you for your positive comments and we hope you continue to enjoy our products.

Dr. Christian Ryan PhD –

I’m amazed at how CFD simulations can help with designing trains with reduced energy consumption! Such detailed analysis before building actual models must save a lot of resources.

MR CFD Support –

Thank you for your positive feedback! We’re glad you find the impact of CFD simulations on train design impressive. It certainly helps in optimizing designs and reducing costs before the actual production. If you have any more thoughts or require further information about our simulation products, feel free to reach out to us.

Vernon Harber –

Which computational software is used for this simulation?

MR CFD Support –

This simulation is conducted using ANSYS Fluent, a leading computational fluid dynamics (CFD) software.

Dr. Everette Orn –

Couldn’t be more pleased with the Moving Train External Airflow CFD Simulation training! The instructional video made it easy to understand the process for simulating train movement and analyzing the airflow effects. The depiction of pressure contours and the explanation of airflow separation behind the train vividly illustrated how drag impact can be mitigated, shedding light on energy-saving methods. This completion of this course has significantly boosted my comprehension of aerodynamics in railway applications.

MR CFD Support –

We’re thrilled to hear that you found the Moving Train External Airflow CFD simulation training so beneficial! It’s fantastic to know that the video tutorials were clear and helped enhance your understanding of the aerodynamic principles involved in train design. Thank you for your positive feedback, and we’re here to support you if you decide to further your skills in CFD applications.

Dr. Jeramy Purdy II –

I’m astounded by the detail in the airflow simulation around the train! Would the drag reduction techniques explained in this training also work for similar high-speed vehicles?

MR CFD Support –

We’re delighted you enjoyed the training! Yes, many drag reduction techniques analyzed and explained in this particular training regarding train aerodynamics can be transferrable to other high-speed vehicles. Concepts such as streamlining the body, controlling boundary layer separation, and wake reduction are applicable across different vehicle types. This CFD simulation offers a foundation that can be built upon for various high-speed aerodynamic designs.

Adolphus Maggio –

The training video for the CFD simulation of train aerodynamics was clear and informative. I see how efficiently ANSYS Fluent can model the complex airflow around the train. The explanation of turbulence and observation of vortexes was especially fascinating. I appreciate the detailed visualization of the pressure contours and the grace with which the software tackled the separation phenomenon. It’s evident that your tutorials can be crucial in design optimization to reduce drag, hence saving energy and costs in train manufacture.

MR CFD Support –

Thank you for the positive feedback on our Moving Train External Airflow CFD Simulation training video. We are thrilled that you found it clear, informative, and beneficial for understanding the intricacies of train aerodynamics and the impact on energy consumption. We take pride in providing content that helps our clients optimize design processes and lead to real-world improvements. Your acknowledgement is highly appreciated and motivates us to continue delivering quality learning material. Should you require further assistance or have more interest in CFD simulations, feel free to reach out!