Sloshing of a Tanker Truck CFD Simulation, Ansys Fluent Training

$120.00 Student Discount

In this project, the sloshing of a tanker truck has been simulated, and the results have been investigated.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Sloshing of a Tanker Project Description

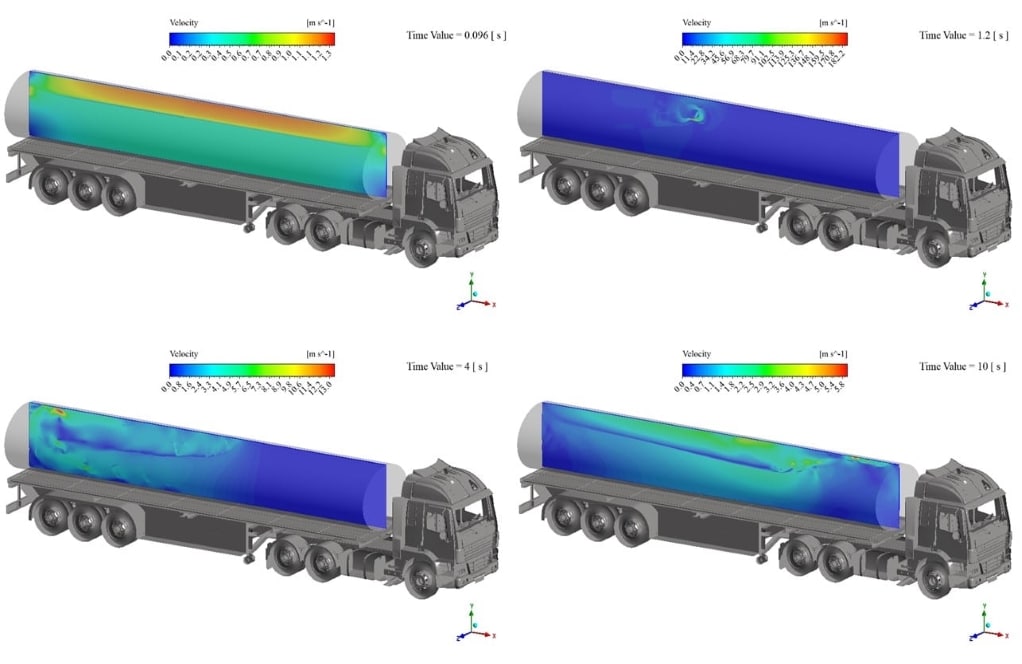

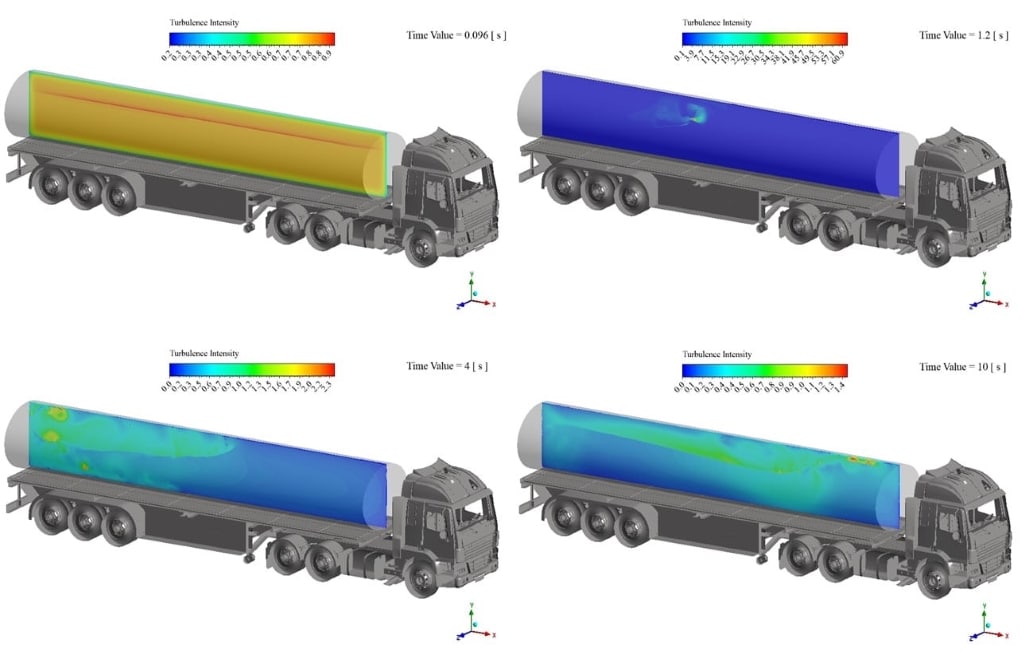

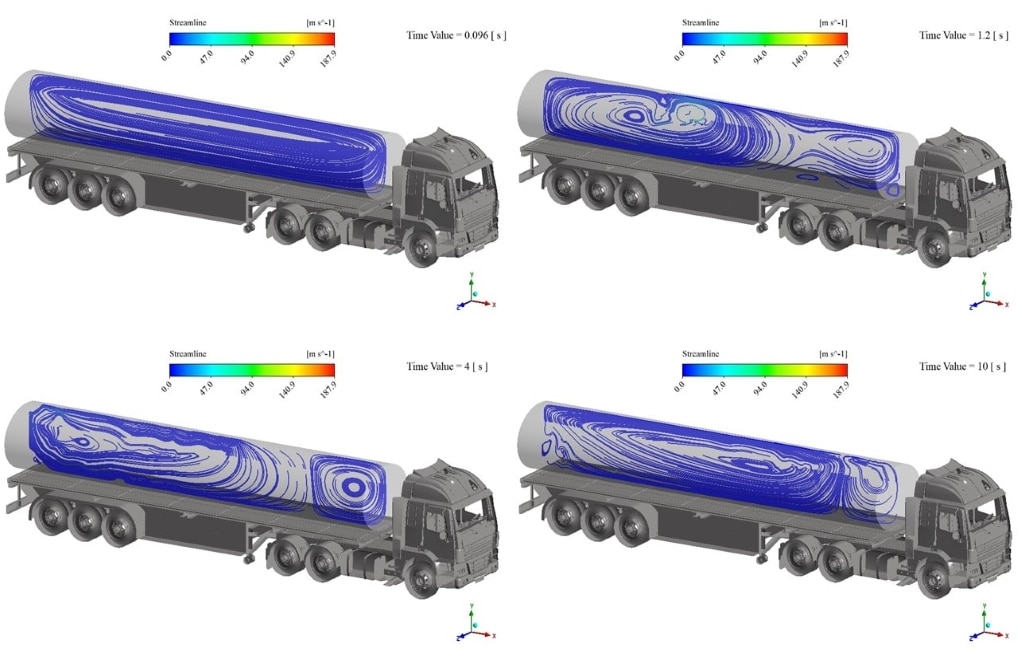

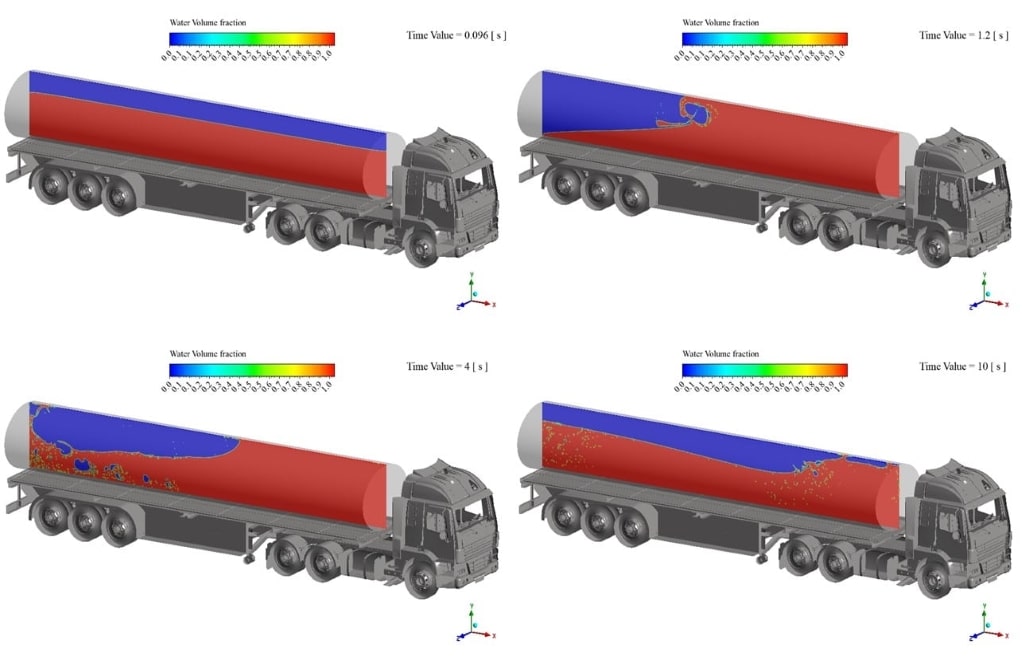

In this project, Ansys Fluent software has been used to simulate the sloshing of a tanker truck. The Volume of Fluid (VOF) model has been used to simulate and solve the two-phase flow field equations. The primary phase is air and, the secondary phase is water. The truck brakes at the speed of 15 m/s, and after 3 seconds, it stops. This means that in addition to gravity acceleration, the water inside the tanker feels the brake deceleration.

Geometry & Mesh

The geometry of the present model is generated using SpaceClaim software. The tanker dimension is 12300* 1900.1867 mm.

The meshing of the present model has been done using Ansys Meshing software. The mesh type is structured in all of the computational domains, and the cell number is equal to 233,700.

Sloshing of a Tanker CFD Simulation Settings:

We consider several assumptions to simulate the present model:

- Due to the incompressibility of the flow, the pressure-based solver method has been selected.

- The simulation is transient.

- The gravity effect is considered equal to -9.81 m.s-2 on Y-axis

- The brake deceleration is considered at the first 3 seconds equal to 5 m.s-2 on X-axis

The K-epsilon Realizable viscous model with Scalable wall function has been used to solve the turbulent flow equations. The pressure-velocity coupling scheme is SIMPLE. The second-order upwind discretization method has been used for Momentum, Turbulent kinetic energy, and Turbulent dissipation rate.

The following table represents a summary of the defining steps of the problem in this project and its solution:

| General | ||

| Solver | Type | Pressure-based |

| Time | Transient | |

| Gravity | X | IF(t<=3[s],5[m/s^2],0[m/s^2]) |

| Y | -9.81 [m/s^2] | |

| Z | 0 | |

| Models | ||

| Multiphase | ||

| Model | Volume of Fluid | |

| Number of Eulerian phases | 2(air & water) | |

| Interface modeling | Sharp | |

| Formulation | Explicit | |

| Primary phase | air | |

| Secondary phase | water | |

| Phase interaction | ||

| Surface Tension coefficient[N/m] | Constant = 0.072 | |

| Viscous | ||

| k-epsilon | Realizable | |

| Near wall treatment | Scalable wall functions | |

| Material Properties | ||

| Air | ||

| Density | 1.225 | |

| viscosity | 1.7894e-05 | |

| water-liquid | ||

| Density | 998.2 | |

| viscosity | 0.001003 | |

| Methods | ||

| Pressure-Velocity Coupling | SIMPLE | |

| Pressure | PRESTO | |

| Momentum | Second-order upwind | |

| Turbulent kinetic energy | Second-order upwind | |

| Turbulent dissipation rate | Second-order upwind | |

| Volume fraction | Compressive | |

| Initialization | ||

| Initialization methods | Standard | |

| Patch | Phase | water |

| Variable | Volume Fraction | |

| Zones to patch | Water_mesh_ | |

| Value | 1 | |

| Run calculation | ||

| Time step size | 0.002 | |

| Max iterations/time step | 20 | |

| Number of time steps | 5000 | |

Sloshing of a Tanker Results

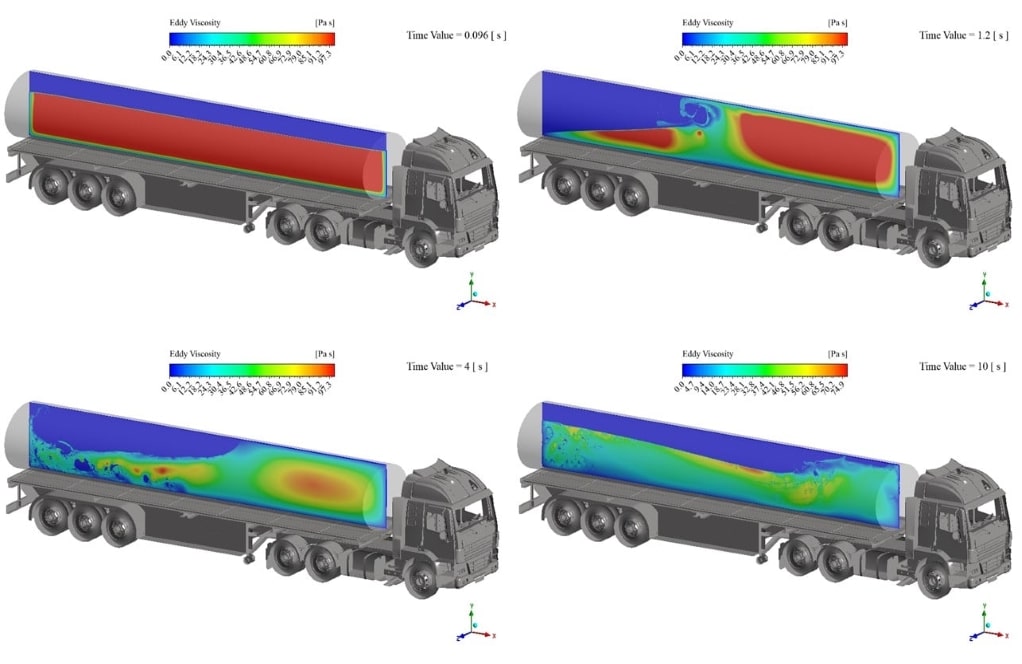

After the solution process is completed, contours of velocity, Pressure, Water volume fraction, Eddy viscosity, Streamline, and Turbulence intensity are extracted. As can be seen, under the influence of gravity and deceleration, the water inside the truck tanker moves and hits the front wall of the tanker. After 3 seconds, the truck stops, and, since that time, only gravity affects the water.

Mr. Raymundo Powlowski –

The detailed explanation was incredibly helpful. I was particularly impressed with how thorough the description was on sloshing dynamics due to braking, which gives crucial insights into the problem’s practical implications. Great work on the CFD model. The results must be fascinating, especially seeing how the water impact changes over that 3-second time frame. Compliments to the MR CFD team for a well-executed simulation study!

MR CFD Support –

Thank you for your kind words and appreciation. We are thrilled to hear that you found our CFD simulation of a tanker truck’s sloshing dynamics informative and helpful. At MR CFD, we strive to provide realistic and thorough analyses, and your feedback validates our efforts. Don’t hesitate to reach out if you have further interest in our studies or need assistance with similar CFD challenges.

Prof. Desiree Heaney IV –

I really appreciate the detailed breakdown for setting up the CFD simulation of a Tanker Truck sloshing provided in the training. It covered essential factors affecting the simulation, such as gravity and braking deceleration, with utmost precision!

MR CFD Support –

We’re thrilled to hear that our training on the CFD simulation of a Tanker Truck sloshing was helpful to you. It’s great to know that the detailed information and step-by-step setup were clear and precise. If you have further questions or need additional support, feel free to reach out. Thank you for choosing our training materials!

Alexane Stanton DDS –

I found the section on VOF model configuration intriguing! Can you tell me if different models might be needed for more viscous fluids or those with more complex properties than water-air interactions?

MR CFD Support –

For fluids with a greater viscosity or more complex properties than the water-air interactions, you would typically consider using different turbulence models or multiphase approaches, such as the mixture model or the Eulerian model, depending on the flow regime and the interactions between the phases. Special attention must be paid to accommodate increased computational complexity and provide additional precision where required, like with non-Newtonian fluid characteristics or significant phase coupling scenarios.

Myriam Ruecker –

Does the presented model consider thermal effects on the fluid properties or is it a purely mechanical simulation?

MR CFD Support –

In the given CFD simulation of the tanker truck sloshing, the focus is on the mechanical aspects of sloshing due to braking and gravitational forces. Thermal effects on the fluid properties are not considered in this model, which uses a Volume of Fluid (VOF) method for simulating the two-phase flow of air and water.

Curt Swaniawski –

The training assets for the Sloshing of a Tanker Truck CFD Simulation in ANSYS Fluent look very comprehensive. How effectively do you feel the course prepares someone for conducting similar CFD simulations on their own?

MR CFD Support –

We’ve designed the course with the practical know-how and industry nuances in mind to prepare participants for real-world challenges. The Sloshing of a Tanker Truck is particularly focused on equipping learners with hands-on experience using the VOF model, managing dynamic boundary conditions, and understanding the physical behavior of different fluid phases – giving them confidence to tackle similar complex simulations independently after completion of the course.

Tara Ullrich –

I was really impressed by the comprehensive settings and detailed modeling of the tanker truck sloshing simulation. The careful attention to dynamics in the initial braking phase and then the shift to gravity impact was enlightening. The use of a structured mesh to assist with such calculations seems very efficient. Seeing the impact on the front wall portrays a realistic picture of what occurs in such scenarios. Great use of Ansys Fluent!

MR CFD Support –

We appreciate your positive feedback! It’s fantastic to hear that our detailed tanker truck sloshing simulation has provided valuable insights. Our aim is always to model and simulate as close to real-world scenarios as possible, offering a deep understanding of physical phenomena. Thank you for your review, and we are glad that the training material met your expectations!

Ernestina Hilpert –

I’m impressed with the detailed setup explained in this CFD project. Quick question though: how is the effect of air on the water accounted for in the simulation?

MR CFD Support –

The interaction between the air and water phases in the simulation is accounted for through the Volume of Fluid (VOF) model, which allows tracking of the phase interface. Air is set as the primary phase, and water as the secondary phase. Furthermore, a Sharp Interface model along with a surface tension coefficient is used to capture the interaction between the two fluids accurately.

Freddy Hill –

The training provided clear visualizations and step by step settings, which immensely helped grasp the concept of fluid dynamics in transportation applications. The transition between acceleration and gravity impact was elucidated with precision.

MR CFD Support –

Thank you for your kind words! We’re glad that our Ansys Fluent training for sloshing of a tanker truck met your expectations and provided you with a solid understanding of the dynamics at play. If there’s anything else you’d like to explore or any questions you might have, please let us know. We are always here to help enhance your learning experience!

Johann Skiles –

Fantastic resource! The detailed step-by-step explanation provided a great insight into the sloshing simulation process for a tanker truck. I was able to understand the setup and the effects of gravity and deceleration on the water movement inside the tank. Really impressed with the visualization of results provided.

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that you found our step-by-step explanation helpful and that the visualizations brought the concept to life. It’s gratifying to know that our product met your expectations and was instrumental in enhancing your understanding of the sloshing simulation process.

Jalen Rowe PhD –

This CFD project has provided remarkable results demonstrating the effects of braking and gravity on the fluid inside the tanker. The details presented on the VOF method and specific settings for the simulation give valuable insight into the complexities of such analyses. Truly a testament to the importance of precise simulation settings.

MR CFD Support –

We’re really glad you found the project insight valuable and appreciative of the simulation’s comprehensiveness. Your positive feedback encourages us to continue delivering high-quality CFD training. Thank you for taking the time to review our product!

Scarlett Kling –

The training material was incredibly comprehensive, walking me through the steps realistically step by step. Everything from setting the geometry with SpaceClaim to detailing the mesh in Ansys and using the VOF model for the two-phase flow equations. I feel like I now understand the complexities of tanker truck sloshing at speed!

MR CFD Support –

Thank you for your kind words. We are delighted to hear that our training material on tanker truck sloshing simulation in ANSYS Fluent has provided you with a clear understanding of the process. Your recognition of the effort put into making the material realistic and comprehensive is much appreciated. We hope it will be beneficial for your future simulations!

Dr. Charity Collins –

I particularly like how the brake deceleration aspect was simulated. Can you tell me what impacts the sloshing has on the tanker’s stability and how is it mitigated?

MR CFD Support –

In real-world applications, liquid sloshing inside tanker trucks potentially impacts stability by creating dynamic forces, which can alter the balance of the vehicle especially during rapid speed changes or turns. Maneuvers such as breaking directly translate into fluid momentum shifts, which may induce vehicle rollover or jack-knifing. This effect is mitigated in simulations and in practice by designing baffles within the tank to disrupt the flow and reduce the amplitude of sloshing, ensuring proper tank volume and liquid fill levels, and considering dynamic behavior during the design of the vehicle’s stabilization systems. In our simulation, the effect of sloshing is primarily assessed in terms of pressure and force distribution against the tanker walls post-braking.