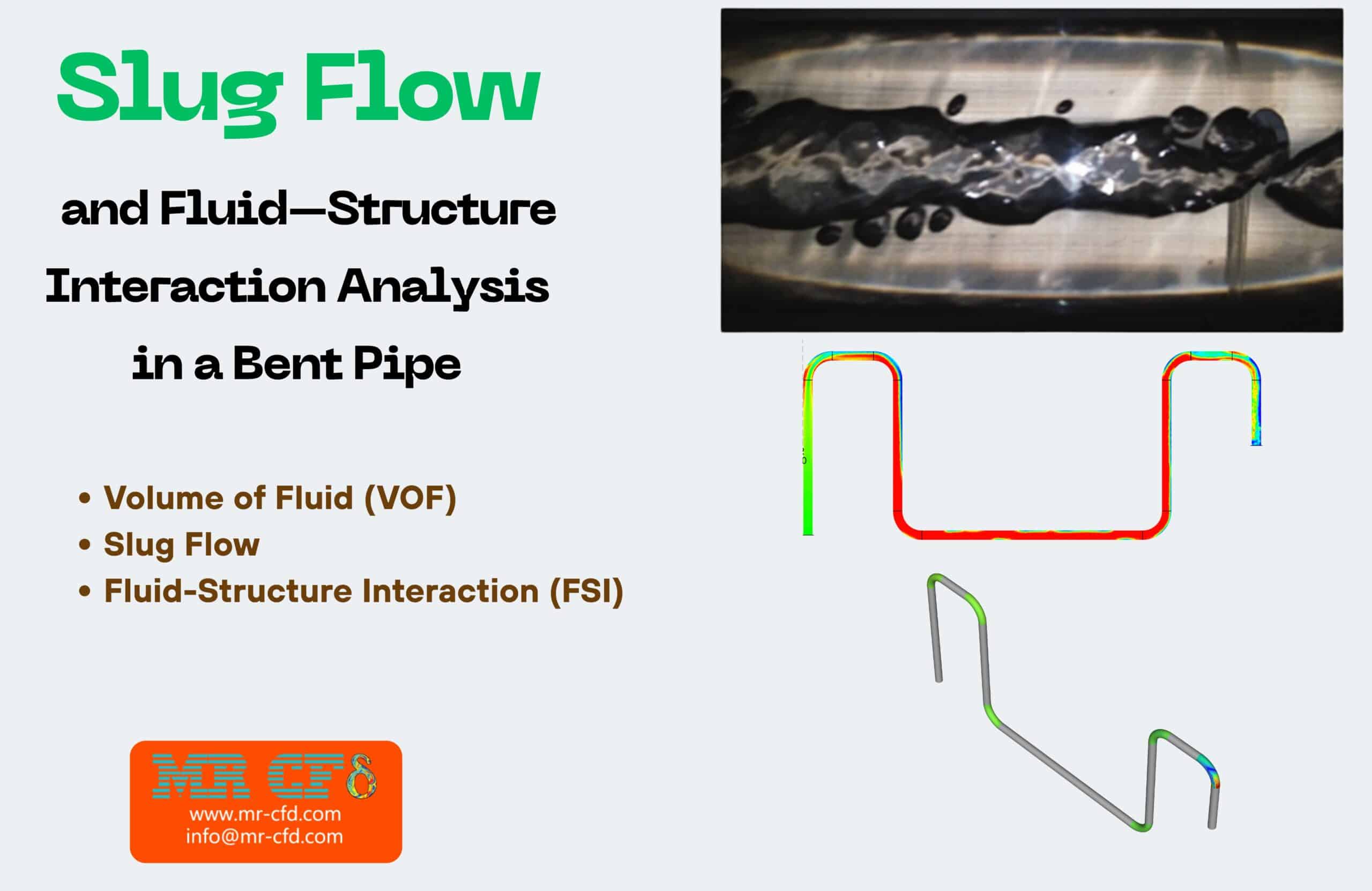

Slug Flow CFD Simulation and Fluid–Structure Interaction Analysis in a Bent Pipe

$210.00 $84.00 HPC

- This project simulates slug flow of gas–liquid mixture in a bent pipe using ANSYS.

- The VOF multiphase model is applied to capture slug formation, phase separation, and velocity distribution.

- Results show strong gas redistribution and velocity rise up to 48 m/s in pipe bends.

- The structural response is negligible, with displacements around 10⁻¹⁴ m near curved sections.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Slug Flow CFD Simulation and Fluid–Structure Interaction Analysis in a Bent Pipe Using ANSYS

Description

This project investigates the behavior of slug flow in a bent pipe system through a fluid, structure interaction (FSI) analysis using ANSYS Workbench. Slug flow, characterized by alternating liquid slugs and gas pockets, induces unsteady hydrodynamic forces that are especially critical in pipelines with bends. Such intermittent flow regimes cause significant fluctuations in pressure, velocity, and structural loading, which can contribute to long-term fatigue damage in industrial piping networks. The aim of this study was to replicate slug flow conditions in a multiphase simulation, examine the propagation of gas and liquid phases through the bends, and assess the resulting pipe wall deformation under these unsteady flow conditions.

Geometry and Mesh

The pipe geometry was created in DesignModeler and features six bends with straight segments in between, having an inner diameter of 0.21 m and an outer diameter of 0.27 m. This bent configuration was selected to highlight how slug dynamics interact with pipe curvature.

The computational mesh was generated in ANSYS Meshing using tetrahedral elements to properly capture the complex geometry. Approximately 500,000 cells were generated, with denser refinement along the curved sections and near the wall boundaries to ensure accurate resolution of slug propagation, velocity gradients, and pressure distribution. The structural mesh was also prepared for FSI coupling, enabling the evaluation of pipe deformation caused by unsteady fluid forces.

Physical Models and Solver Settings

The multiphase simulation was conducted in ANSYS Fluent using a pressure-based transient solver. The Volume of Fluid (VOF) model was employed to capture the interface between the primary phase (liquid water) and the secondary phase (gas), with the gas modeled as an ideal compressible medium. Gravitational effects were included to account for buoyancy, which plays a significant role in slug motion and separation. At the inlet, a velocity of 10 m/s was specified with a gas volume fraction of 0.5 to initiate slug formation, while the outlet was set as a pressure outlet at atmospheric conditions. The pipe walls were modeled as no-slip boundaries, and FSI coupling was activated at the wall-fluid interface. Pressure–velocity coupling was handled with the SIMPLE algorithm, and standard initialization was applied. A time step of 0.0005 s was chosen to ensure stable convergence while capturing the transient nature of slug dynamics.

Results

The simulation confirmed the presence of slug flow, with alternating liquid slugs and gas pockets propagating through the pipe. In straight sections, slugs remained relatively stable, whereas bends caused gas to shift toward the inner radius and liquid toward the outer wall, intensifying mixing and turbulence. Velocity increased sharply within bends, reaching nearly 48 m/s compared to the 10 m/s inlet. Gas volume fraction plots showed strong phase separation and redistribution after each bend, characteristic of slugging behavior. Structurally, the pipe experienced negligible deformation, with maximum displacements on the order of 10⁻¹⁴ m, concentrated mainly at the curved regions.

You must be logged in to post a review.

Reviews

There are no reviews yet.