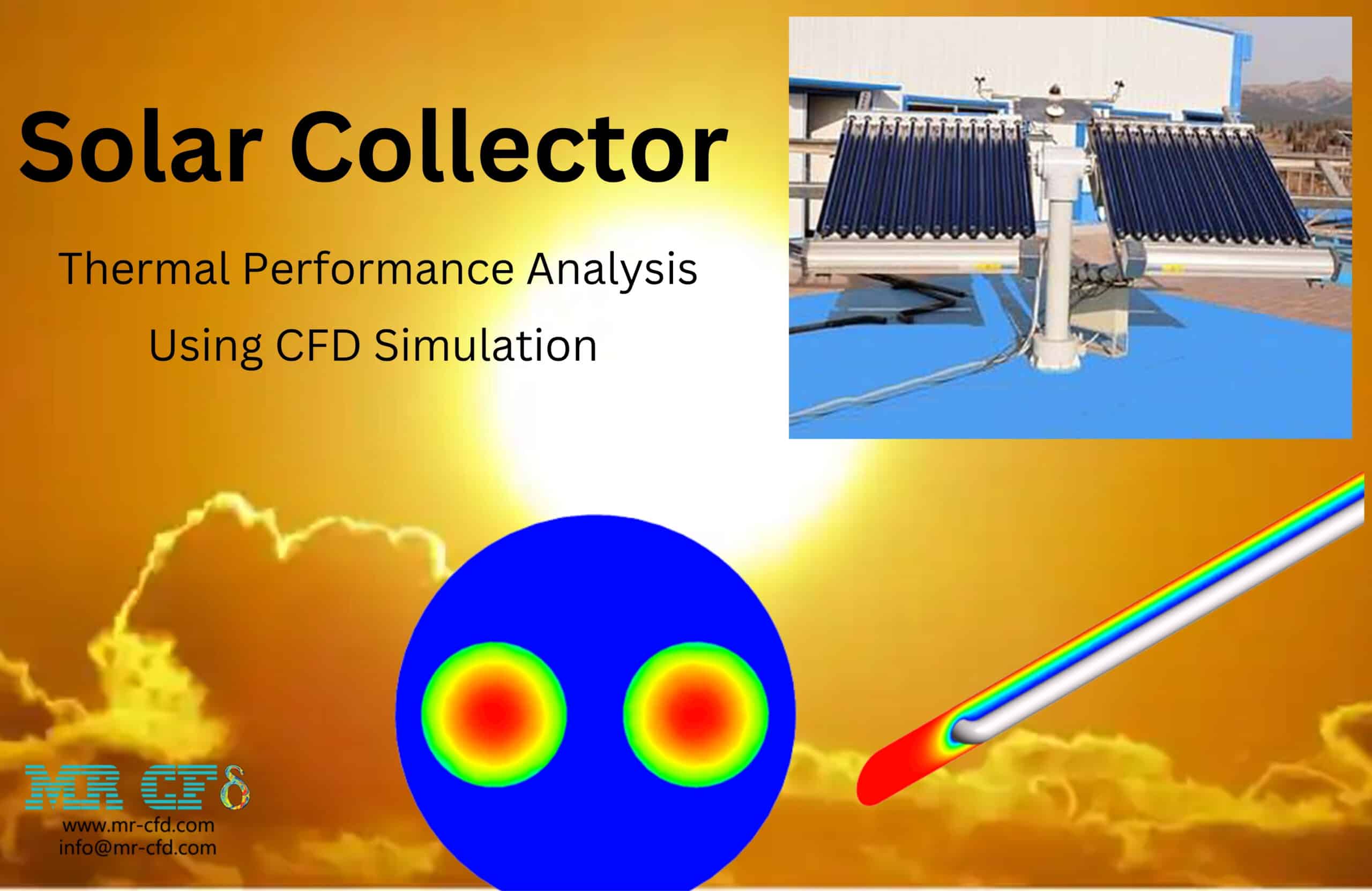

Solar Collector Thermal Performance Analysis Using CFD Simulation

$60.00 $24.00 HPC

- This project presents a CFD simulation of a solar collector designed to analyze heat transfer and fluid flow inside a U-shaped tube.

- The system uses water as the working fluid under steady-state conditions.

- The outer wall is maintained at a constant high temperature to simulate solar heating.

- Results show an effective temperature rise, confirming efficient thermal performance of the collector.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

CFD Simulation of Solar Collector and Thermal Performance

Description

This study investigates the thermal and flow performance of a solar collector using ANSYS Fluent. The collector includes a U-shaped tube designed to transfer heat from a heated wall to water flowing inside. The main goal is to analyze how the temperature and velocity of the fluid change as it passes through the collector under steady-state conditions. The simulation helps evaluate the system’s thermal efficiency and flow behavior, providing insights useful for improving solar thermal designs.

Geometry and Mesh

The solar collector geometry was modeled in Design Modeler, featuring a U-shaped tube connected to an inlet and outlet. The model was then imported into ANSYS Meshing to create an unstructured grid consisting of about 1.95 million elements. The mesh was refined near the walls and bends to accurately capture heat transfer and flow gradients. This setup ensures good computational accuracy while keeping the simulation efficient.

Model and Solver Settings

A steady-state simulation was performed using the standard k–ε turbulence model. Water entered the collector at a mass flow rate of 0.0332730006 kilograms per second and an inlet temperature of 295.15 Kelvin, while the wall was kept at 365 Kelvin. The outlet was defined as a pressure outlet, and the coupled algorithm was used for pressure–velocity coupling. These conditions allowed accurate prediction of heat transfer and fluid flow within the collector.

Results

The results show that the water temperature increased from 295.15 Kelvin at the inlet to 296.92 Kelvin at the outlet, indicating effective heat absorption from the collector wall. Velocity contours showed faster flow in the center and slower near the walls, typical of internal turbulent flow. The temperature field confirmed that heat was transferred efficiently through the pipe, demonstrating the collector’s good thermal performance and confirming the accuracy of the simulation setup.

You must be logged in to post a review.

Reviews

There are no reviews yet.