Solar Heater of Water Tank with PCM CFD Simulation

$120.00 Student Discount

- The problem numerically simulates the Solar Heater of a Water Tank and the Effect of PCM using ANSYS Fluent software.

- We design the 2-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 5803.

- We perform this simulation as unsteady (Transient).

- We use the Solidification and Melting model to define phase change materials.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Solar Heater of a Water Tank and the Effect of PCM, ANSYS Fluent CFD Simulation Training

This simulation is about the solar heater of a water tank and the effect of PCM via ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

Phase change materials can change phase (from solid to liquid and vice versa) over an almost constant temperature range. The phase change process in such materials is usually accompanied by the exchange of a large volume of energy, referred to as latent phase change heat.

This high volume of heat is exchanged in harmony with nature and automatically and intelligently through ambient temperature changes. These materials have become one of the special energy storage capacities in various uses, like solar heaters.

Due to the increasing need for energy and the limitation of fossil fuels, which are a depleting source and polluting the environment, the need to use new energy sources is felt more than ever. One of the most widely used energies is solar energy.

PCM phase-changing materials with high latent heat are suitable for storing thermal energy, especially solar energy, which has been very popular recently. Meanwhile, phase change materials in the water tank related to solar water heaters are a new method recently being considered.

In this project, using PCM encapsulated in a water tank solar heater has been investigated with different considerations, including the effect of melting and freezing temperature of PCM material, the effect of PCM material volume, and a comparison with no PCM material.

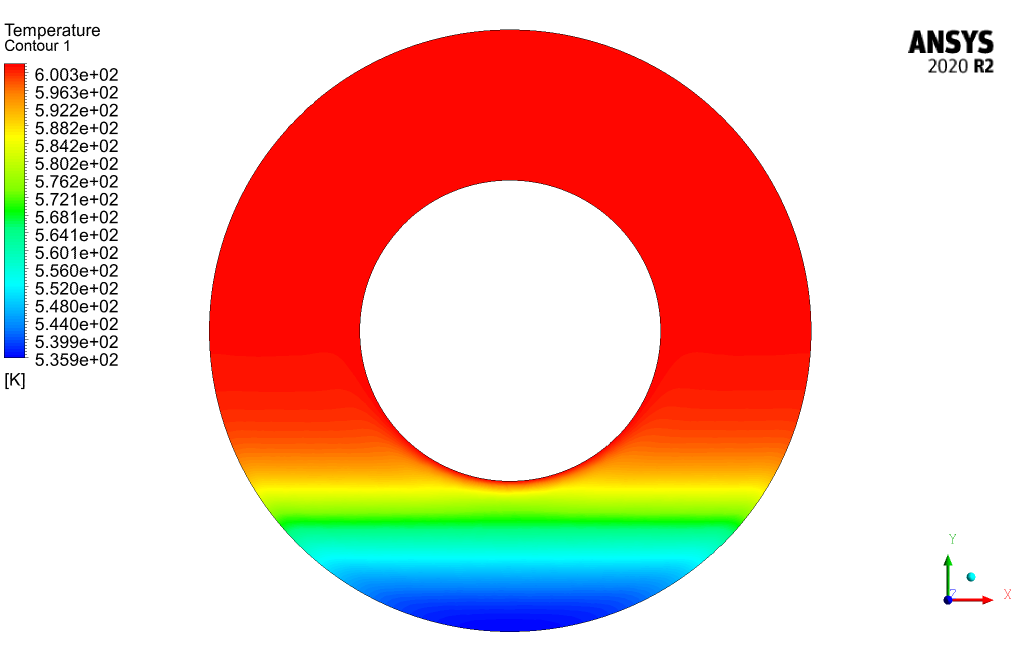

The PCM space’s inner wall is considered a wall with a temperature condition of 603.3 K and a thickness of 0.0015 m. The wall boundary condition with the Adiabatic condition is used for the outer wall of this space.

The geometry of the present model is drawn by Design Modeler software. This geometry is related to a chamber that is a space between two coaxial tubes, and we fill the space between these two coaxial tubes with PCM. The model is then meshed by ANSYS Meshing software. The model mesh is unstructured, and 5803 cells have been created.

Method

The energy equation is activated in this simulation to obtain temperature distribution inside the computational domain.

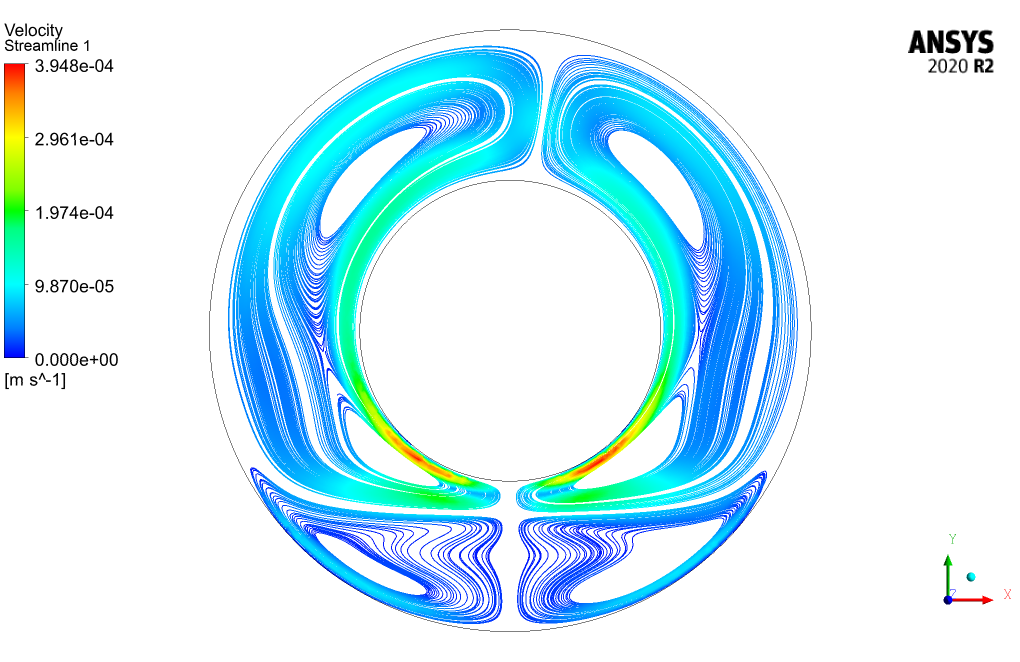

The solidification and Melting model has been used to analyze the phase change of PCM material from solid to liquid and vice versa due to temperature changes inside the water storage area. We should apply the Boussinesq model to determine the density changes in proportion to temperature.

Also, when we use the solidification and melting model, we should define solidus temperature, liquidus temperature, and latent heat of melting of the pure solvent melting.

Conclusion

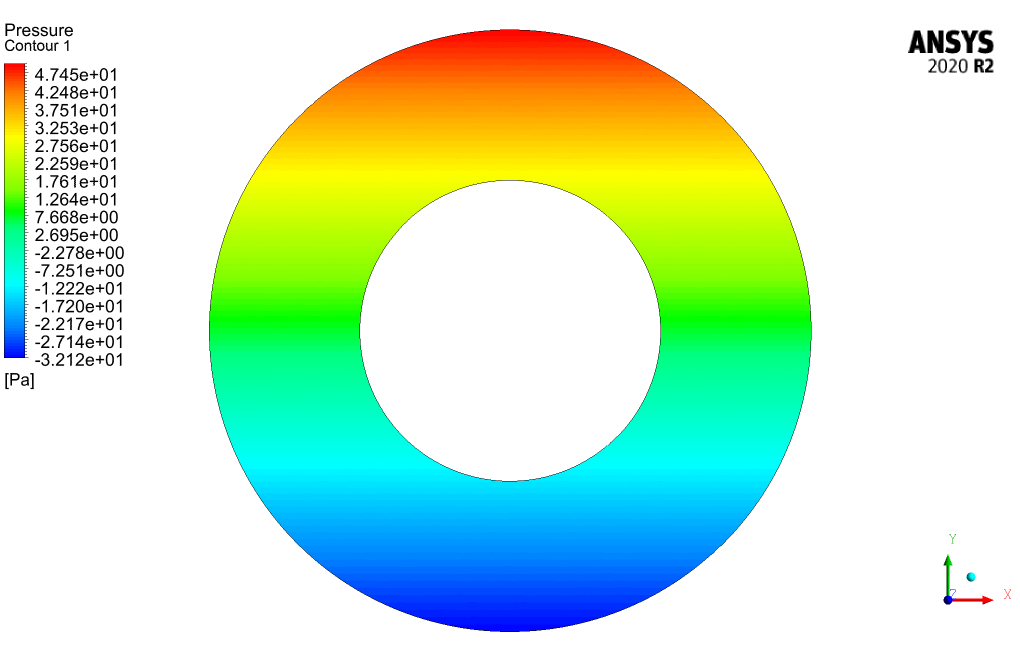

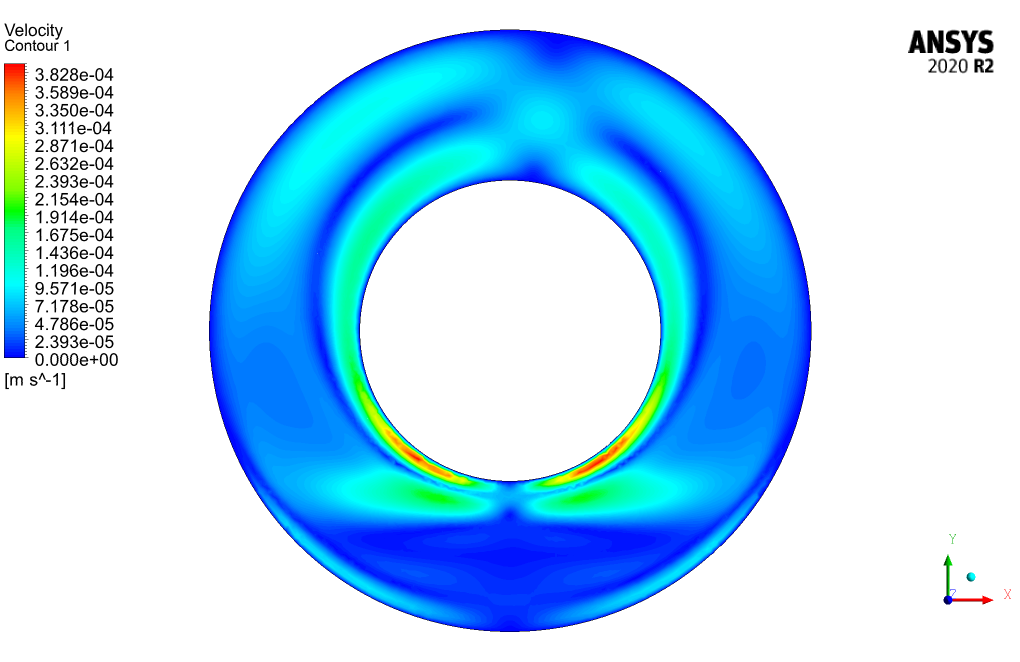

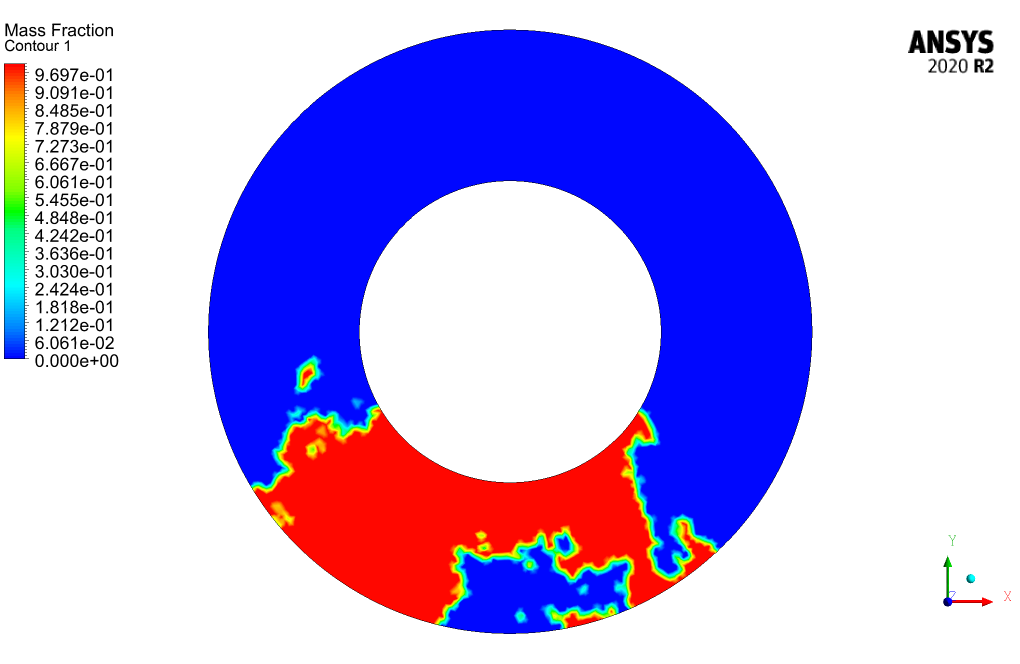

After simulation, the contours of temperature, velocity, pressure, and liquid volume fraction are obtained. The results completely confirm that the temperature and liquid fraction are consistent.

As the temperature of the PCM increases under the influence of the inner wall’s thermal boundary condition, the PCM’s liquid fraction also decreases. Because with decreasing temperature, the phase change from liquid to solid occurs, and the solidifying process occurs.

Genoveva Ryan –

The training was fantastic! I’ve always wanted to enhance thermal storage with PCMs in solar heaters. Seeing how PCM incorporation affects the whole system was fascinating. Great work on this simulation and training!

MR CFD Support –

We’re thrilled to hear that you found the simulation and training on solar heaters using PCMs enlightening and beneficial. It’s always rewarding when customers appreciate the hard work and detailed analysis we put into our training materials. Thank you for your positive feedback, and we’re here if ever you have more questions or need further assistance!

Morgan Kunde –

Just wanted to say that this product and your clear description of the simulation process have deeply impressed me! The focus on energy efficiency and detailed analysis of PCM performance in a solar water heater is exactly what I’m looking for. Great job incorporating environmental considerations into your product design!

MR CFD Support –

Thank you for the positive feedback! We are thrilled to hear that our Solar Heater of Water Tank with PCM CFD Simulation training met your expectations and provided the valuable insights you were looking for. We always strive to deliver high-quality products that emphasize ecological benefits and innovation. If you need any further assistance or have more questions in the future, please don’t hesitate to reach out.

Amparo Haag –

I’m really impressed with the comprehensive analysis of the solar heater project utilizing PCM in ANSYS Fluent. The approach in understanding phase-change materials and their role in energy efficiency is quite innovative. It seems to be a very effective solution for solar energy storage.

MR CFD Support –

Thank you for your kind words! We are delighted to see that our product has positively impacted your understanding of phase-change materials in solar energy applications. We are always striving to provide the best learning experience with our CFD simulations. Your satisfaction is our biggest motivation!

Nella Spinka –

As a customer who enjoyed learning from the product, I found the application of PCM in solar water heaters fascinating. It’s exciting to see how this innovative method optimizes energy usage—great work on exploring this in the simulation.

MR CFD Support –

Thank you for your kind words and for taking the time to review our ‘Solar Heater of Water Tank with PCM CFD Simulation’ training product. We’re thrilled to hear you found the application of phase change materials in solar water heating systems both engaging and educational. If you ever have any more questions or need further clarifications, we’re here to help!

Prof. Zoey Upton PhD –

I’m impressed with the thoroughness of your computational analysis for the solar water heater using PCM in ANSYS Fluent. It’s a brilliant way to optimize energy storage using solar energy. Thanks for your consistent innovation in using materials like PCM for sustainability and efficiency in energy systems!

MR CFD Support –

Thank you for your kind words and for recognizing our efforts to push the boundaries of energy efficiency and sustainability using innovative CFD simulation solutions. Your appreciation motivates us to continue developing and providing top-notch analyses in the field.

Mr. Bertram Torphy –

I appreciated learning about the practical application of PCM in solar heaters through your simulation. The detailed breakdown of the model configuration, including the specific temperature and phase change properties, was enlightening.

MR CFD Support –

Thank you for taking the time to provide feedback on our Solar Heater of Water Tank with PCM CFD Simulation product. We are pleased to hear that you found the simulation information enlightening and of practical use. It’s great to know that the details on phase change materials contributed positively to your understanding. We look forward to providing you with more valuable insights in the future.

Dr. Harmony Koepp –

I am amazed by the real-world applications of PCM that this simulation displays. Well done on a comprehensive and insightful module!

MR CFD Support –

We’re thrilled to hear that you found the PCM simulation and its applications valuable! Thank you for taking the time to review our course, and we hope it has enriched your understanding of solar energy storage and CFD analysis.

Eileen Gulgowski MD –

This review covers a fantastic simulation project using PCM in a solar heater. It’s engaging to see how phase change materials can be utilized to store thermal energy, specifically solar energy. The methodology in investigating various effects like PCM material volume and melting/freezing temperatures provides a thorough efficiency analysis. The implicit inclusion of the Boussinesq model for dealing with temperature-induced density changes is a highlight, ensuring accuracy in the simulation. Great job on incorporating the Solidification and Melting model for phase change representation and the well-crafted geometry and meshing process that results in conclusive temperature and liquid fraction data. Superb analysis!

MR CFD Support –

Thank you for recognizing the strengths of our Solar Heater of Water Tank with PCM CFD Simulation Project. We’re glad you appreciate the thoroughness of our methodologies and the application of the Boussinesq model and Solidification and Melting model in our analysis. It’s great to see such positive feedback on our efforts to accurately replicate and analyze the effects of using PCMs in solar energy storage. We look forward to continuing to provide you with high-quality CFD training and analysis. Thank you again for your support!

Prof. Dorothea Gleichner –

I am really impressed with how the simulation captures the phase change process and intelligently manages energy exchange through ambient temperature changes. It ensures effective thermal energy storage using PCM, which seems like an innovation in solar heater designs. Well done!

MR CFD Support –

Thank you for your kind words! We are delighted to hear that you appreciate the effectiveness of using Phase Change Materials in promoting sustainable energy storage in our solar heater simulation. It’s great to know that the innovation resonates with you. We remain committed to providing valuable insights through our CFD simulations and analyses.

Trevion Purdy DVM –

Absolutely fascinating results! I was particularly impressed by how the simulation accurately depicted the phase changes and heat exchange in PCM. It presents a viable solution for thermal energy storage, especially using solar energy.

MR CFD Support –

We’re thrilled to hear that our simulation provided you with valuable insights into PCM behavior and thermal storage using solar energy. Thank you for recognizing the potential behind this technology, and we’re glad our product surpassed your expectations!

Sigrid Donnelly –

I can really feel the practical benefits of this advanced CFD training in my studies on thermal energy storage. The comprehensive way it dealt with solar energy and PCM utilization helped me a lot. Amazing work in detailing the process and visualization of the simulations!

MR CFD Support –

Thank you very much for your kind words! We’re thrilled to hear that our simulation training on ‘Solar Heater of Water Tank with PCM’ has positively impacted your studies on thermal energy storage. It’s our pleasure to provide tools and knowledge that help someone grasp complex concepts more effectively. We appreciate you taking the time to provide feedback and are glad you found the detailed process and visualizations beneficial. Don’t hesitate to reach out if you need further support or more training materials!

Clifford Watsica –

This CFD simulation package impresses me with the detailed analysis of thermal energy storage in PCM. I’m intrigued by the effects of varying PCM volumes. It’s truly a comprehensive piece.

MR CFD Support –

Thank you for your kind words! We are glad to hear that our simulation package on the Solar Heater of a Water Tank with PCM has met your expectations and provided comprehensive insights. Your interest in the effects of PCM volumes motivates us to continue delivering high-quality simulation studies.

Dr. Joesph Yost III –

Fantastic learning experience! This CFD simulation about the solar heater water tank using PCM in ANSYS Fluent opened my eyes to new and efficient ways to store thermal energy. I could follow along with the project and understand the impressive impacts of PCM in solar energy storage. The detailed result analysis was especially helpful in grasping the concepts. Well done!

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that you found the ANSYS Fluent solar heater and PCM CFD simulation training insightful and educational. It’s great that the project helped you understand the important role of PCM in thermal energy storage and that you found the result analysis to contribute to your learning. We appreciate your commendation and hope to continue providing valuable learning experiences.

Prof. Loyce Jast Jr. –

I learned a lot about solar energy and the use of PCM in this course. It gave great insight on how energy storage can be optimized using PCM in water tanks. Fantastic simulation visuals helped solidify my understanding!

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear that our course provided valuable insights and that the simulation visualizations enhanced your learning experience. Your understanding and appreciation motivate us to continue delivering high-quality educational materials.

Romaine Durgan I –

The improvement of heat storage with PCM in this solar heater simulation is impressive! Capturing both melting and solidification dynamically offers a comprehensive view of energy management within the system.

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that you found the simulation, especially regarding the integration of phase change materials (PCM), to be thorough and insightful. Effective heat storage is crucial for maximizing the utilities of solar heaters, and we are glad our product could portray that effectively.

Zakary Moen MD –

I’m thoroughly impressed with how efficiently the PCM in the solar heater works in the simulation! What a great use of energy storage.

MR CFD Support –

Thank you for your positive feedback! We’re glad that you’re impressed with the simulation regarding the efficient energy storage using PCM in the solar water heater. Harnessing solar energy is indeed a sustainable solution, and we’re proud to showcase such innovative applications in our training products. If you need any further insights or have any more thoughts to share, please feel free to reach out.

Jordane Huel –

Great product! The incorporation of PCMs for thermal energy storage is ingenious, providing an efficient solution for utilizing solar energy in water heating systems.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you appreciate the innovative application of phase change materials (PCMs) in our solar water heater simulation product. It’s wonderful to see our customers recognize the efficiency of integrating renewable energy solutions.

Douglas Bode DVM –

The PCM simulation seems detailed and important. What are the advantages of using PCM in solar water heaters?

MR CFD Support –

Phase Change Materials (PCM) in solar water heaters provide efficient thermal energy storage, allowing the system to retain heat when solar energy is plentiful and release it as needed. This results in more consistent water temperatures, reduced reliance on auxiliary heating sources, and overall improved energy efficiency, especially in fluctuating climate conditions.