Solidification and Melting of PCM on a Corrugated Tube

$100.00 Student Discount

- The problem numerically simulates the Solidification and Melting of PCM around a Corrugated Tube using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 115362.

- We perform this simulation as unsteady (Transient).

- We use the Solidification and Melting model to define phase change materials.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Solidification and Melting of PCM around a Corrugated Tube, CFD Simulation Training by ANSYS Fluent

This simulation is about the solidification and melting of PCM around a corrugated tube via ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

The present problem investigates the solidification and melting of a phase change material (PCM) inside a tube with a wavy inner surface. In general, phase change materials are materials with organic compounds that can absorb and store large amounts of latent thermal energy.

Thermal energy storage in these materials is achieved during the phase change process (solid phase to liquid or vice versa); So that when changing phase from solid to liquid, it absorbs heat from its surroundings (causes cooling of surrounding space) and when changing phase from liquid to solid, returns heat to its surroundings (causes surrounding space heating).

The phase change material studied in this simulation is paraffin. It has a density equal to 150 kg/m3, a specific heat capacity equal to 2000 j/kg.K, a thermal conductivity equal to 0.2 W/m.K, and a viscosity equal to 0.03499 kg/m.s.

The geometry of the present model is drawn by Spaceclaim software. The model is then meshed by ANSYS Meshing software. The model mesh is structured, and 135,939 cells have been created.

CFD Method

In this simulation, the solidification and melting model is used to define PCM.

To define paraffin as a phase change agent, the maximum temperature at which the solid phase temperature is (solidus temperature) is 350.15 K, and the minimum temperature at which the liquid phase temperature is (liquidus temperature) is 358.15 K. And the pure solvent melting heat is defined as 176000 j/kg.

The transient solver performs the simulation with a time step equal to 1s.

Solidification and Melting Conclusion

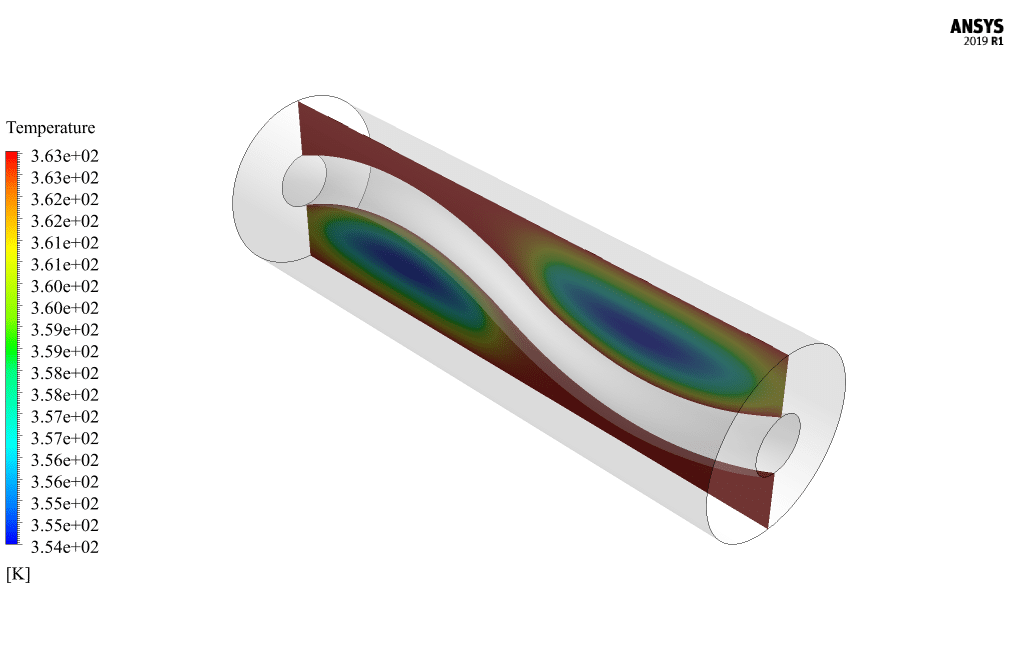

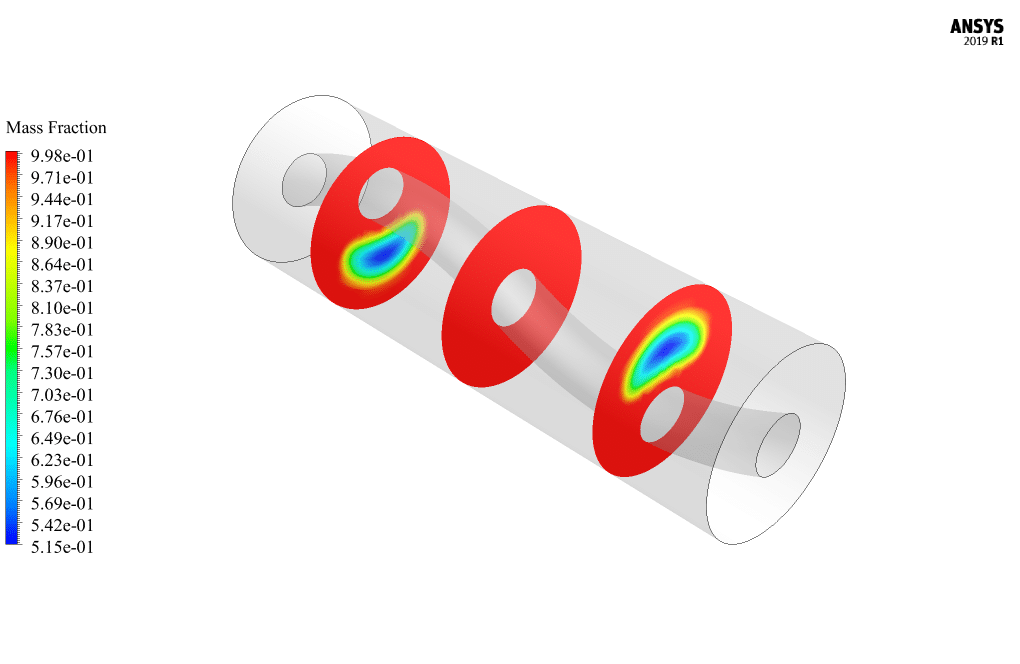

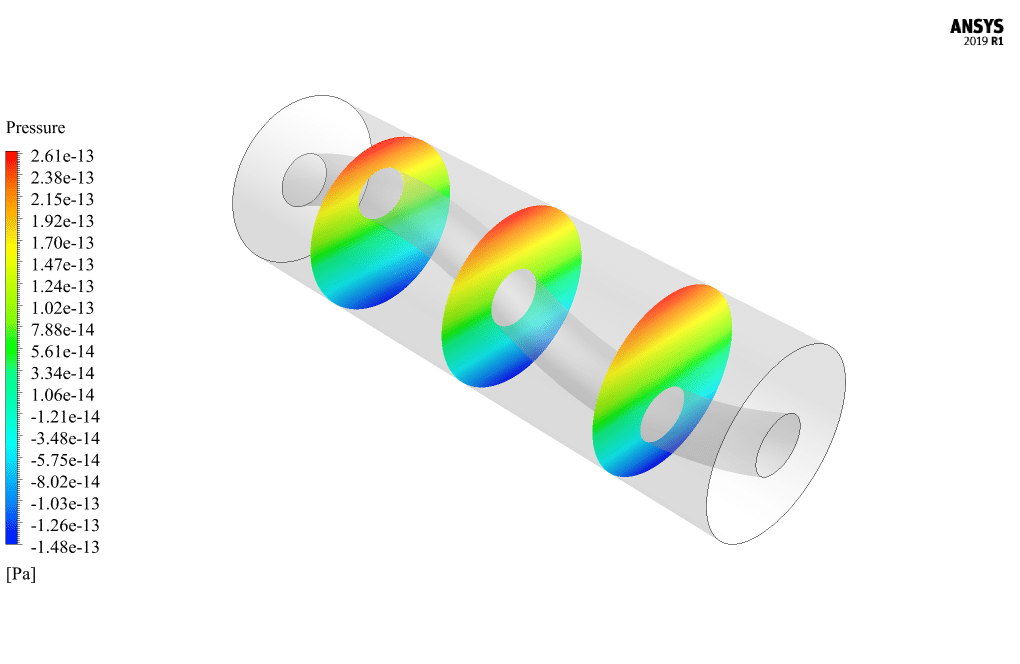

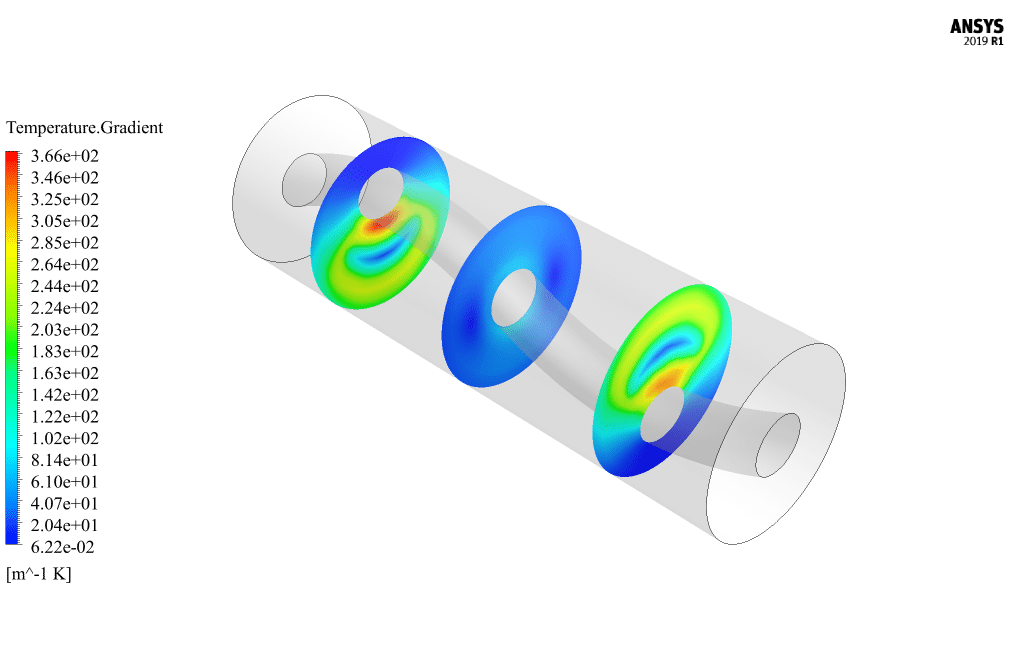

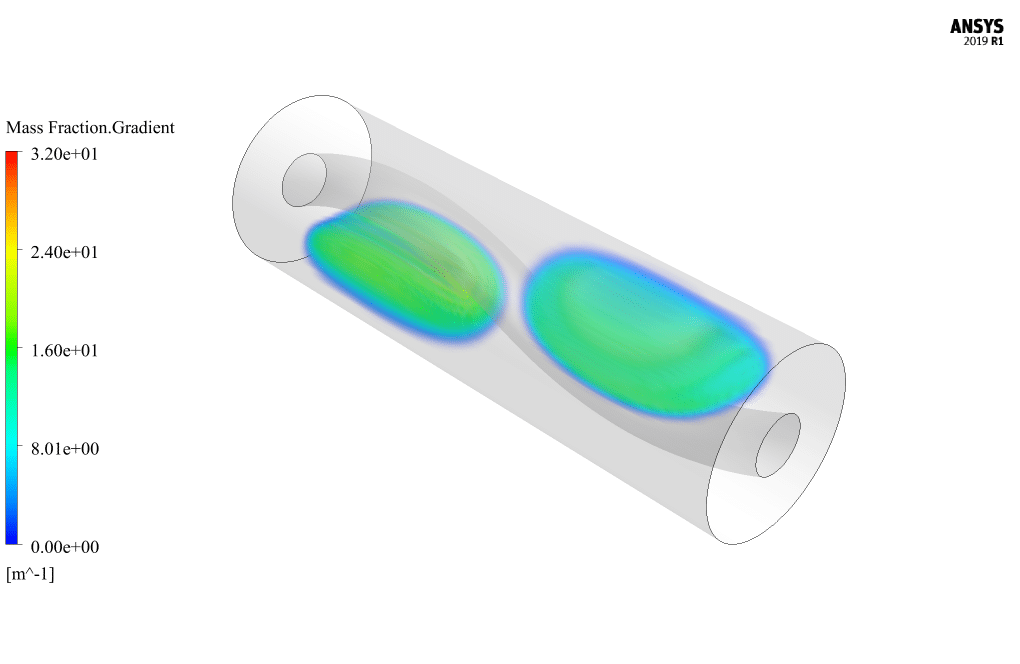

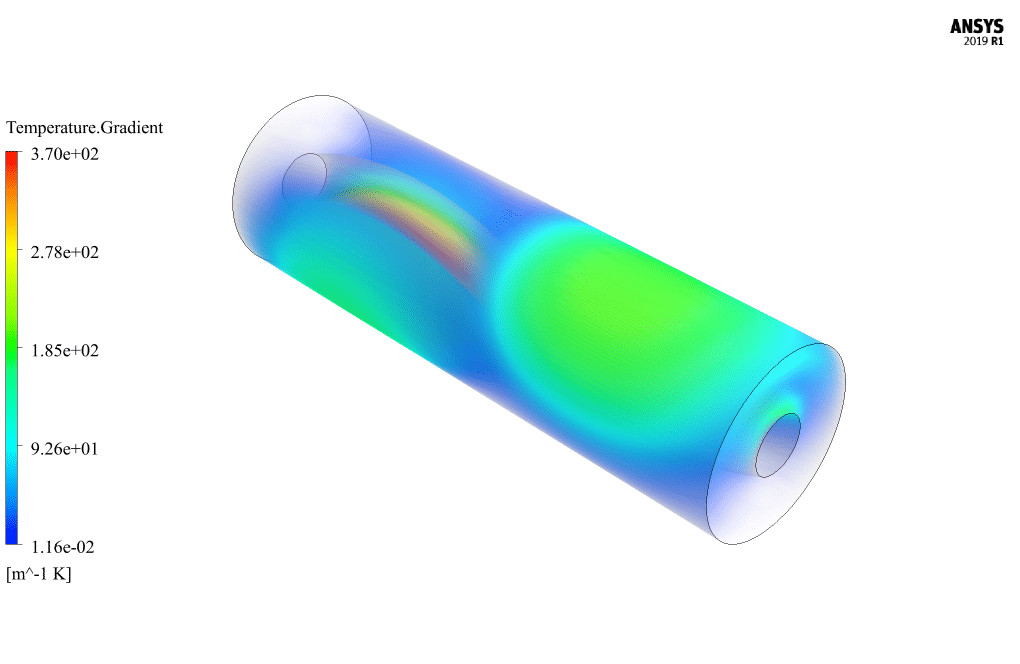

After simulation, the contours of temperature, temperature gradient, pressure, and liquid fraction are obtained. Since the simulation is performed unsteadily, the present results are related to the 7000s of the simulation process.

The results correctly show that the behavior of PCM corresponds to its temperature. The PCM’s temperature increases by receiving the heat of the inner tube; as a result, it undergoes a phase change by releasing its latent heat. In the zones of increased temperature, PCM changes from solid to liquid.

Bettie Larkin –

Can this simulation be modified to model different types of PCM or different system configurations?

MR CFD Support –

Yes, we can customize the simulation to your specific needs. Please provide more information about your particular requirements.

Chanelle Windler –

Can this simulation be used to optimize the design of thermal energy storage systems?

MR CFD Support –

Absolutely! The insights gained from this simulation can be instrumental in optimizing the design of thermal energy storage systems, improving their energy efficiency and performance

Kylee Boyer –

The details on the PCM properties are nicely laid out. What are some applications of this CFD simulation in real-world scenarios?

MR CFD Support –

In the real world, PCM simulations guide many innovative developments like enhancing the efficiency of energy storage systems, designing thermal regulation material in electronics, advancements in building materials for improved temperature control, and creating effective heat exchange systems in various industries.

Miss Dariana Kerluke DDS –

I’ve recently completed the simulation training on solidification and melting of PCM around a corrugated tube using ANSYS Fluent. The content was very informative, and I was impressed by the structured approach to the simulations. Not only did it enhance my understanding of phase change materials, but the challenge of working with PCMs and dynamic temperature conditions made it very engaging. Thank you for such a comprehensive training module!

MR CFD Support –

We appreciate your positive feedback and are thrilled to hear that our Solidification and Melting of PCM training has been beneficial to you. It’s great to know that you found it informative and engaging, and we hope it’ll be useful in your future endeavors. Thank you for choosing MR CFD Company’s learning products!

Mrs. Kylie Jakubowski DVM –

The training module was highly informative! Solidification and melting process was made easy to understand with this CFD Simulation. Great job.

MR CFD Support –

Thank you for your positive feedback! We’re glad the training on solidification and melting of PCM on a corrugated tube met your expectations and was informative. If you have further inquiries or need more assistance, feel free to reach out to us. Your success is our top priority!

Prof. Bryon Cormier Jr. –

The simulated phase change process seems very effective. Well done!

MR CFD Support –

Thank you for your positive feedback on our simulation of a PCM around a corrugated tube using ANSYS Fluent. We’re thrilled to hear that you’re impressed with the effectiveness of the phase change process as demonstrated in our simulation. Your satisfaction with our learning products is our top priority!

Delphia Wisozk MD –

The explanation of the simulation process is very informative. The results must be quite insightful, especially visualizing the phase change!

MR CFD Support –

Thank you for your words of appreciation! I’m glad you find the simulation process informative. Visualizing the phase changes is indeed one of the exciting parts of this simulation, and we made sure to provide detailed results. It’s great to hear positive feedback which encourages us to keep offering high-quality CFD training materials!

Tiffany Lebsack –

The explanation was illuminating. Kudos to the MR CFD team for such thorough insight into the complex physics of PCM and their effects on heating and cooling systems.

MR CFD Support –

Thank you for your kind words! We’re glad that you found the information provided to be thorough and helpful. Understanding the behavior of PCM in these systems is indeed complex, and we strive to make our simulations as detailed and informative as possible. If you have any further questions or need more insight, don’t hesitate to ask. We’re here to help!

Roderick Prosacco –

I was very impressed with how the PCM’s behavior was portrayed in the simulation during the phase changes. It was enlightening to see the effect of the corrugated tube during the entire process of absorption and release of the thermal energy.

MR CFD Support –

Thank you for your kind words! We are delighted to hear that our simulation provided you with a clear understanding of the PCM behavior and its interaction with a corrugated tube during thermal energy storage processes. If you have further interest in the subject or any more feedback, please feel free to reach out.

Mrs. Daisy Emard –

I’m amazed by how the PCM’s behavior can be simulated in the wavy inner surface of the tube. Could you please elaborate on why a corrugated tube is chosen for this application instead of a smooth tube?

MR CFD Support –

Admin Usage of a corrugated tube in applications like PCM solidification and melting enhances heat transfer due to the increased surface area and turbulence creation as fluid flows over the corrugations. This leads to a more efficient thermal exchange compared to a smooth tube. Additionally, the special geometry can affect the solidification/melting rate beneficially in thermal management systems.

Chadrick Rippin –

Was this CFD simulation set up to include gravity effects, especially since the PCM has different phases and densities that could be influenced by gravity?

MR CFD Support –

Yes, the CFD simulation was set up to include gravity effects to accurately simulate the behavior of the phase change material (PCM) in both its solid and liquid phases, as these phases have different densities and the influence of gravity is a key aspect in such thermal processes.

Jo Denesik –

This training provided an excellent explanation of PCM behavior around a corrugated tube. The insights into the thermal properties and the simulation process were very practical for my understanding!

MR CFD Support –

Thank you so much for your kind words! We’re delighted to hear that you found the simulation insightful and practical. If you have any more questions or require further assistance with your understanding, don’t hesitate to reach out!

Marcelle Hintz –

The results truly impressed me! How well did the CFD performance capture the phase change behavior during the solidification and melting processes?

MR CFD Support –

We are delighted to hear that you are impressed with the simulation results! Regarding the phase change behavior, our CFD simulation precisely demonstrated the solidification and melting processes of the PCM around the corrugated tube. The simulation used a transient solver along with the solidification and melting model in ANSYS Fluent to accurately predict how the PCM interacts with the varying temperatures. The phase change was evidenced by the temperature contours and liquid fraction results, highlighting the effective capture of thermal energy exchange and accurately depicting PCM’s transition from solid to liquid and vice versa over the simulation time.

Carli Fritsch –

The training module for the PCM solidification and melting seems detailed. Great work! I’m particularly interested in the real-world applicability of this analysis. Can it be utilized for designing efficient thermal storage systems?

MR CFD Support –

Absolutely! The principles covered in the solidification and melting of PCM around a corrugated tube simulation can be directly applied to the design of efficient thermal energy storage systems. By understanding the phase change behavior of PCM and its interaction with the corrugated surface, engineers can optimize these materials for better thermal management and energy conservation in various applications.

Marcella Zemlak Jr. –

Is there a way for me to contribute to this simulation?

MR CFD Support –

We welcome contributions! Feel free to share your ideas or suggestions