Thermal Effects on the Mixing Behavior of Glycerin and Water by ANSYS Fluent

$120.00 $48.00 HPC

- In the thermal effects on mixing in pipesCFD study investigates the thermal effect on the mixing of glycerin and water in a Y-shaped pipe using ANSYS Fluent.

- The geometry is created in ANSYS Design Modeler and meshed in ANSYS Meshing to generate a high-quality computational grid.

- The Volume of Fluid (VOF) method with an implicit formulation is applied, and the realizable k–epsilon model is used for turbulence modeling.

- A mass flow inlet of 0.15 kg/s is set for both phases, and simulations are carried out without heat flux and with a 30,000 W heat flux.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Thermal Effects on the Mixing Behavior of Glycerin and Water by ANSYS Fluent

Problem Description

This project investigates the thermal effect on the mixing of Glycerin & Water-liquid. The study aims to determine the impact of applying heat flux to a Y-shaped pipe. First, the problem is solved without any heat flux, and then a different heat flux is used.

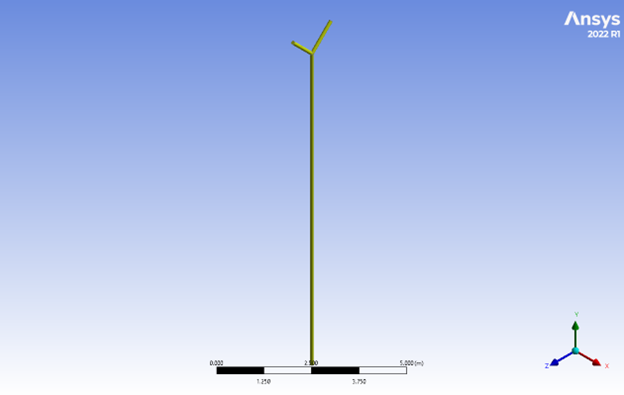

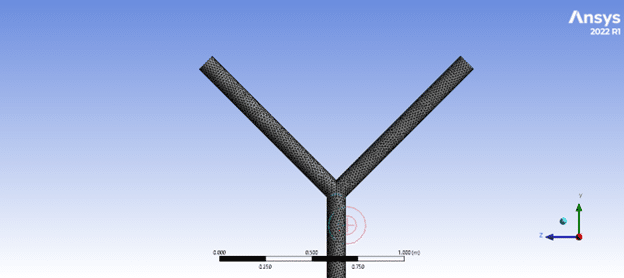

Geometry & Mesh

The 3D geometry of thermal effects on mixing in pipes is designed in Ansys Design Modeler (Fig.1). There are two inlets for water-liquid and glycerin. After getting in contact, they interact in a 10-meter-long pipe. In addition, the mesh grid is carried out using Ansys Meshing software (Fig.2).

Figure 1: Geometry of thermal effects on mixing in pipes

Figure 2: Mesh of thermal effects on mixing in pipes

CFD Simulation

In the Thermal effects on mixing in pipes study, several assumptions have been considered, including:

- The simulation is Steady to capture fluid behavior in a steady-state manner.

- The pressure-based solver type was used due to the incompressibility of the working fluid.

- Gravitational acceleration effects were ignored.

This study on multiphase models used the Volume of Fluid (VOF) method with an implicit formulation. The realizable k–epsilon model was employed for the viscous model. The Coupled algorithm was also used to couple the velocity and pressure equations. A mass flow inlet boundary condition of 0.15 kg/s was applied for glycerin and liquid water.

Results

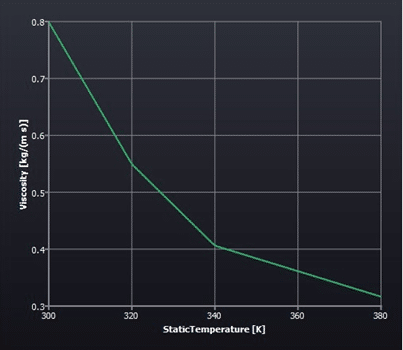

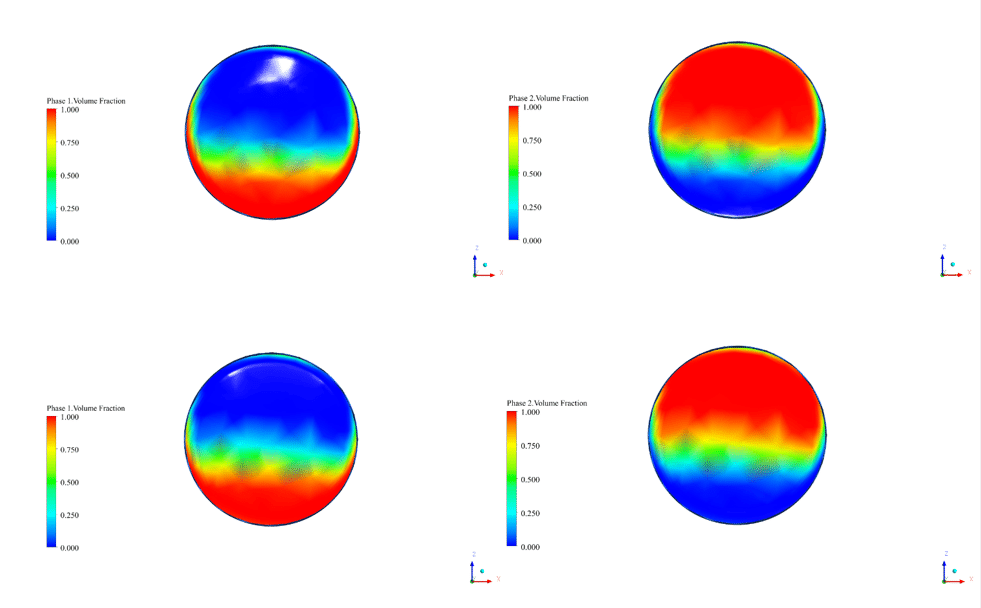

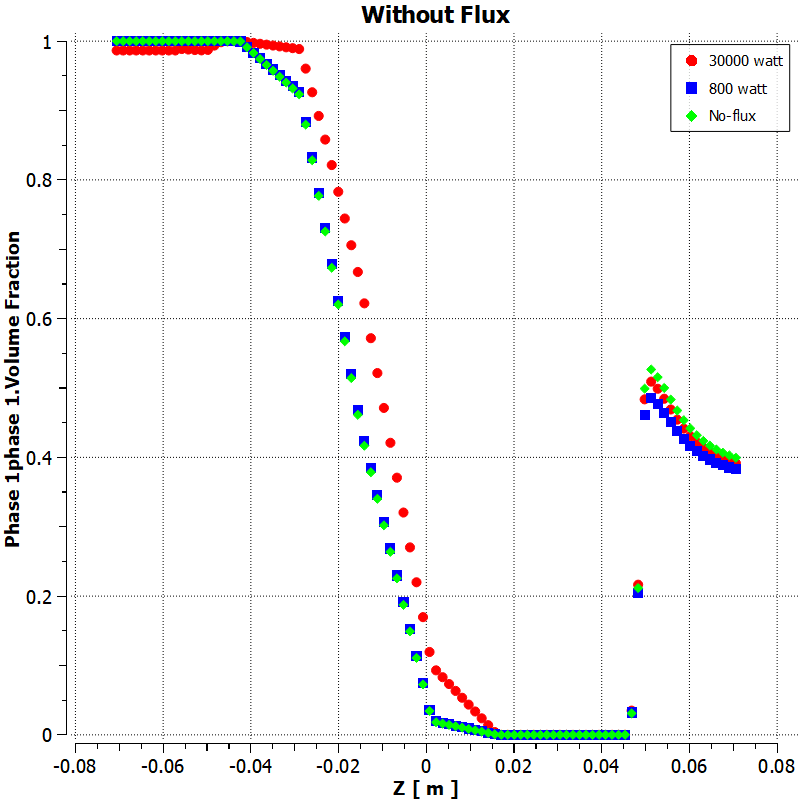

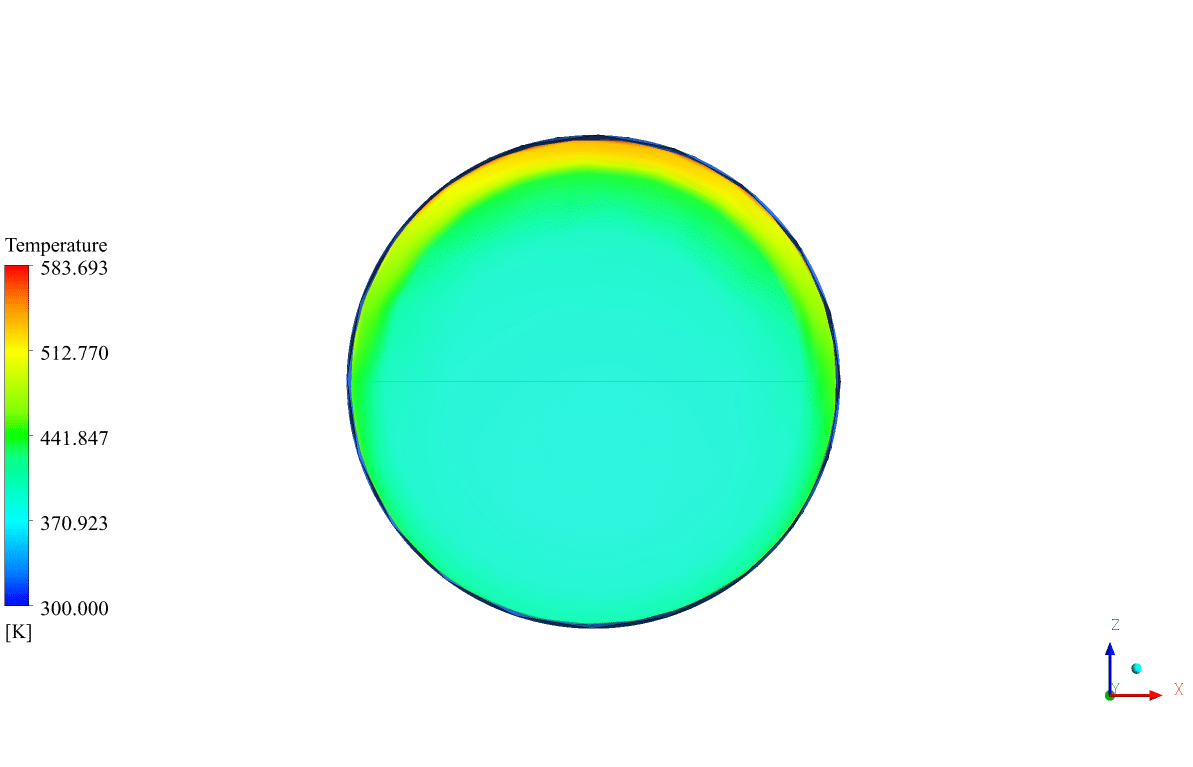

After the simulation of thermal effects on mixing in pipes, 2-dimensional contours of both volume fractions are extracted. Plus, a plot indicating the volume fraction of phase 1, which is water-liquid, through the centerline of the outlet, is shown below. Indeed, the viscosity of glycerin is highly dependent on temperature, as illustrated in Fig.3. Applying a heat flux to the pipe walls increases the temperature and decreases the glycerin viscosity. As a result, it has less surface interaction (viscous forces) and resistance through water-liquid and causes better mixing (see Fig.4). The plot shows that by applying 30000-watt heat flux, the volume fraction of water liquid gets higher at each point, which illustrates the presence of water where it was not before. Moreover, the contours show that, due to glycerin’s low thermal conductivity, the central points’ temperature remains approximately constant. In other words, the impact of thermal conditions on mixing would be more impressive when using a highly conductive fluid.

Figure 4 – Volume fraction of water through the centerline at the outlet

Figure 6 – Temperature contour of cross-section at the outlet

You must be logged in to post a review.

Reviews

There are no reviews yet.