Tower Aerodynamic Behavior: A CFD Investigation of Burj Khalifa and Jeddah Tower

Free

- Tower aerodynamic project presents a CFD analysis of the Burj Khalifa (828 m) and Jeddah Tower (1000 m) under a steady 10 m/s wind using ANSYS Fluent.

- Geometries were built in SpaceClaim/Design Modeler and meshed in ANSYS Meshing, later converted into polyhedral elements for efficiency.

- A pressure-based steady solver with the Realizable k-ε turbulence model was applied, with velocity-inlet and pressure-outlet boundary conditions.

- Results show pressure drag dominates in both towers, while torque due to height is a critical factor, influenced strongly by tower geometry.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Tower Aerodynamic Behavior: A CFD Investigation of Burj Khalifa and Jeddah Tower

Problem Description:

In tower aerodynamic project, the 828-meter-high Khalifa Tower and the 1,000-meter-high Jeddah Tower are simulated to investigate the aerodynamic behavior of the air flow around the two structures, which are exposed to a wind flow of 10 meters per second.

Geometry and Meshing:

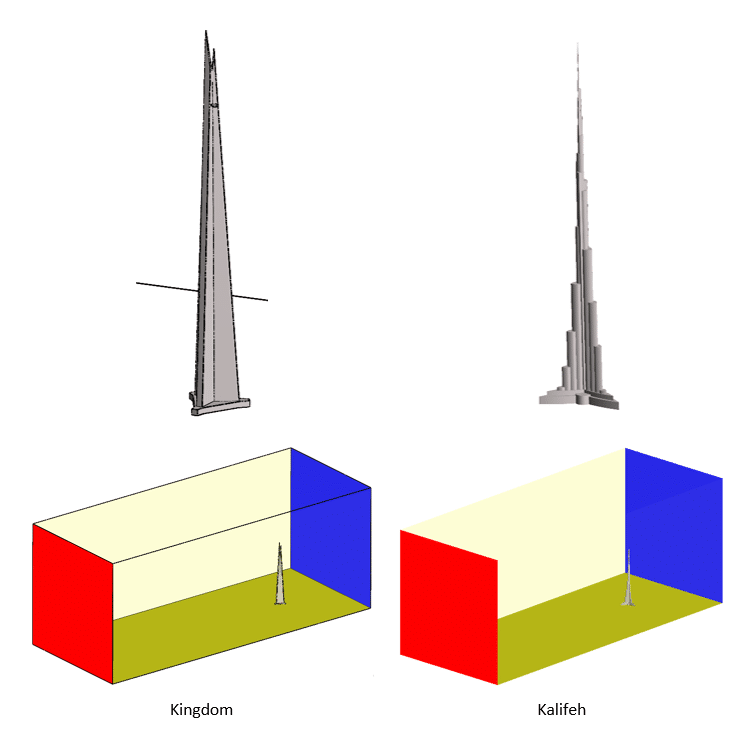

Two software programs used for tower aerodynamic project, ANSYS Design Modeler and SpaceClaim, were used to create the geometries of both problems. The domain is considered a rectangular cube with a length, width, and height of 2h*2h*5h (h is the tower’s height). Also, the tower’s distance from the entrance area is one h, as shown in Figure 1.

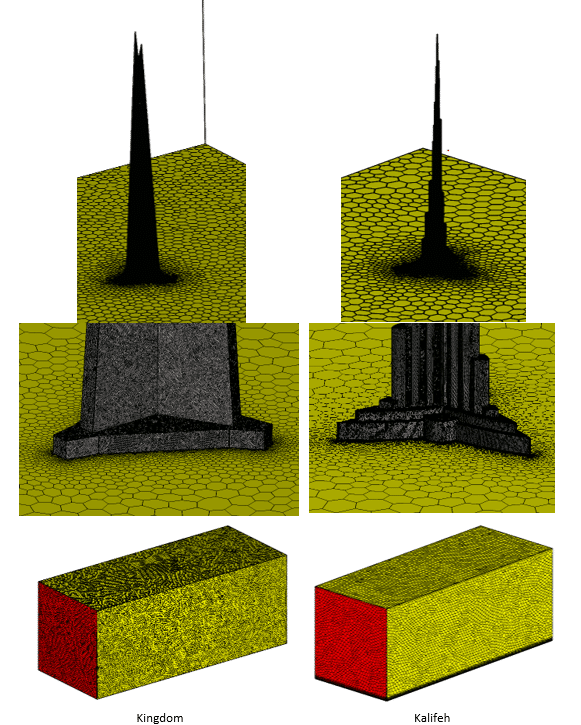

Ansys Meshing software was used to mesh the tower aerodynamic problem. The tower aerodynamic mesh was generated in an unstructured manner with triangular elements at first, and considering the sensitivity and complexity of the fluid behavior near the tower walls, we used a boundary layer mesh with a first layer thickness of 2 cm (Figure 2). The number of initial elements for the Khalifa tower problem is 14,668,281, and for the other problem, 31,299,717. However, after using the capabilities of Ansys software and converting the elements to Polyhedral, without reducing the mesh quality, we achieve a smaller number of elements, significantly reducing the computational load. It is worth noting that the mesh quality control parameters report very high quality.

Simulation:

For simulation of tower aerodynamic in Fluent, the Pressure-based solver has been used with respect to the working fluid, which is air and can be assumed to be incompressible. The solution has also been solved Steady, so that the variables do not change with time; in other words, the solution is independent of time. In addition, the boundary conditions at the inlet are defined as velocity-inlet with a velocity of 10 m/s, and at the outlet as pressure-outlet with a relative pressure of 0, to consider the environmental conditions properly. Specifically, the ground surface is defined as a wall to have its effect on the flow, and the walls of the three-dimensional domain are symmetry boundary conditions. It is worth noting that the k-e Realizable turbulence model has been used to model the flow.

Results:

In civil structures and tower aerodynamic analyses, the most crucial parameter to be examined is the forces acting on the structure, which directly affect the design, the type of materials used, etc. In non-moving structures, the force in the direction of the fluid flow, known as the drag force, has the most significant effect because it creates a torque relative to the support (ground), making many critical points that must be carefully examined during design. It should be noted that the drag force created according to fluid mechanics exists in two forms. Pressure drag, which is caused by the pressure difference and is usually seen in structures with a large cross-sectional area relative to the direction of the fluid flow and accounts for the majority of the force, and viscous drag, which is caused by surface forces such as shear stress on the surface of the structure, which is very effective in structures with a large surface to volume ratio. The results from both cases are examined below.

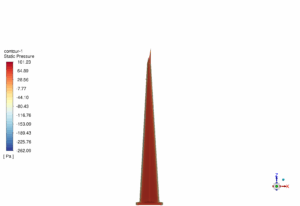

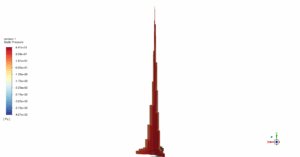

Case 1: Jeddah Tower

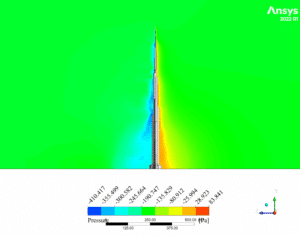

As can be seen in Figure 3, the drag force values are reported separately in the Fluent software. Given the large dimensions of the tower, we expect the compression drag to dominate in this problem. The viscous drag force is 1545 Newtons, and the compression drag is 6002140 in this case. In other words, the contribution of compression drag is 0.025% of the total applied force and can be ignored in the calculations. On the other hand, due to the very high height of the tower, the torque generated can be very impressive, which, according to the software report, is 2e+9 N · m. We know that the torque is the product of the force multiplied by the perpendicular distance from the fulcrum. So, with increasing distance from the ground, the moment applied to the building increases greatly. For this reason, the tower is designed to decrease its cross-sectional area with increasing height, and sharp points are used. To better understand the pressure drag force at each point, the pressure-distance diagram is plotted on the centerline on the surface exposed to the wind flow and the corresponding back surface (Figure 4).

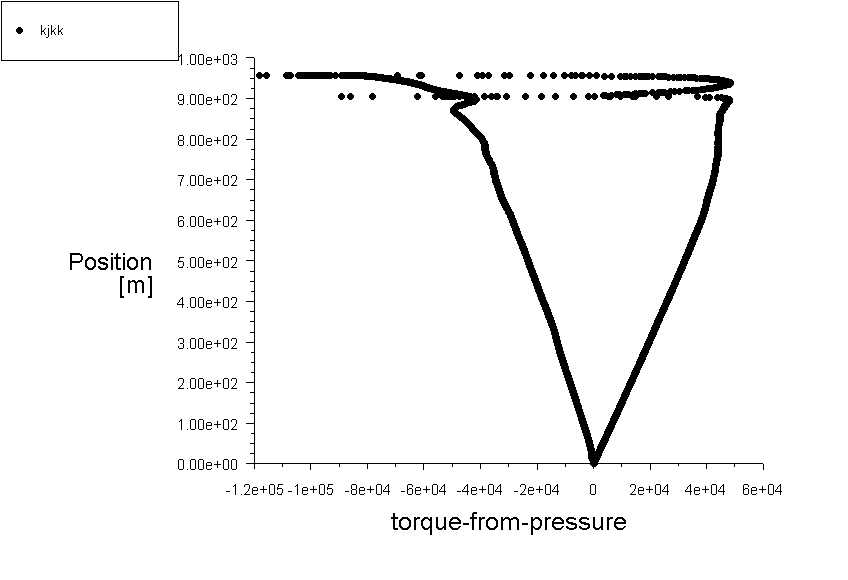

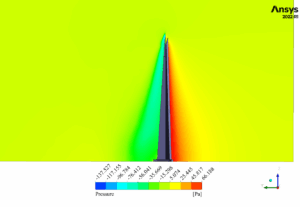

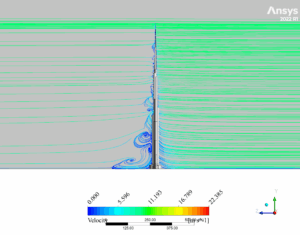

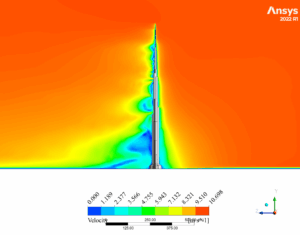

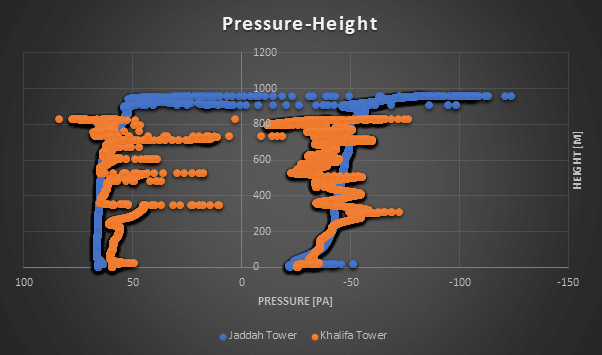

As can be seen in the diagram, the positive values are related to the front of the tower, where the pressure increases as the flow hits the tower wall and its velocity becomes zero (stagnation point). The negative values are related to the back of the tower. This extreme pressure difference in front and back of the tower is the cause of pressure drag. In the contours below, this pressure gradient and the flow and velocity lines can be clearly seen. (Figure 5 – 6)

Figure 5 – Pressure contour from, back, front, and top of the tower

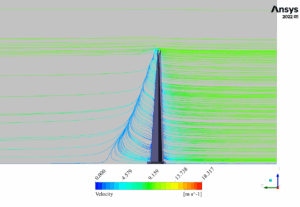

Figure 6 – Two-dimensional velocity and pressure streamlines

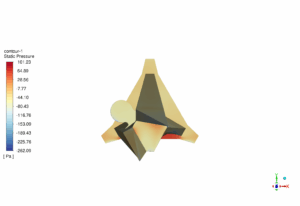

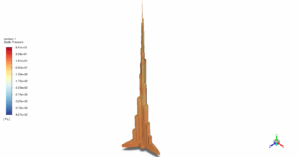

Case 2: Khalifa tower

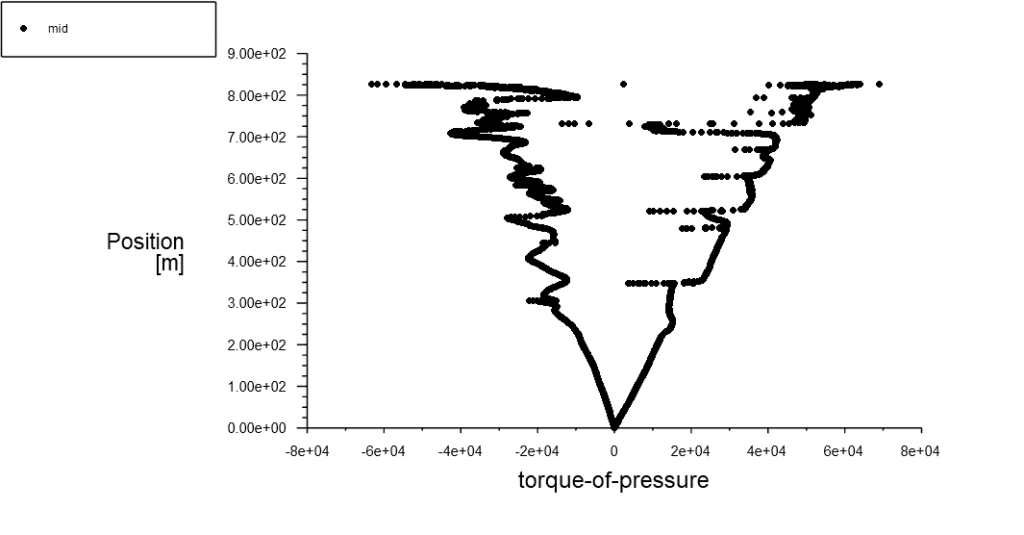

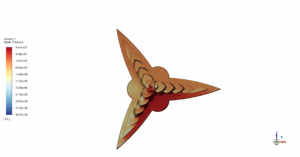

As can be seen in Figure 7, the drag force values are reported separately in Fluent software. Given the large dimensions of the tower, we expect the pressure drag to dominate in this case as well. The viscous drag force is 2502 Newtons, and the pressure drag is 2012954 N in this case. In other words, the pressure drag contribution is 0.12% of the total applied force and can be ignored in the calculations. On the other hand, given the 828-meter height of the tower, the torque generated can be very impressive, which, according to the software report, is 4e+8 N · m! We know that the torque is the product of the force multiplied by the perpendicular distance from the fulcrum. So, with increasing distance from the ground, the moment applied to the building increases greatly. For this reason, the tower is designed so that its cross-sectional area decreases with increasing height, and the curvature of the walls is directed towards the same. To better understand the pressure drag force at each point, the pressure-distance diagram is plotted on the centerline on the surface exposed to the wind flow and the corresponding back surface (Figure 7).

Figure 7 – Torque of pressure drag as a function of height

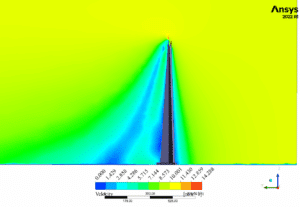

As can be seen in the diagram, the positive values are related to the front of the tower, where the pressure increases as the flow hits the tower wall and its velocity becomes zero (stagnation point). The negative values are related to the back of the tower. This extreme pressure difference in front and back of the tower is the cause of pressure drag. In the contours below, this pressure gradient and also the vortices formed behind the tower can be clearly seen using the contours of the streamlines and velocity lines. (Figures 8 – 9).

Figure 8 – Pressure contour from back, front, and top of the tower

Figure 9: Two-dimensional velocity and pressure streamlines

Comparison of the two towers:

To compare the two towers, we must first pay attention to the geometry of each. The Jeddah Tower has sharp edges along its entire length, and on the other hand, the Burj Khalifa has multiple floors that decrease in area as it moves away from the ground. Another critical point is the Burj Khalifa’s symmetry and the Jeddah structure’s asymmetry. The large curvatures of the Burj Khalifa also significantly impact the results obtained.

In the results of tower aerodynamic project, we saw that the compressive drag on the Burj Khalifa is about 2 meganewtons, and the compressive drag of the Jeddah Tower is 6 meganewtons. At the same time, the height of the Jeddah Tower is only 180 meters higher than the Khalifa. In the graph below, the pressure changes with height on the tower’s two front and back surfaces (relative to the direction of the wind), which are plotted for both towers. The blue graph for the Jeddah Tower shows pressure variations with a nearly constant gradient up to a height of 900 meters. This behavior is very similar at the front and back of the tower. For this reason, at any height, the pressure difference between the front and back of the tower is at its maximum. In contrast, the pressure distribution in the Burj Khalifa is entirely variable. This is related to the curvature of the sides and the change in cross-sectional areas at each floor, which has reduced this pressure difference.

You must be logged in to post a review.

Reviews

There are no reviews yet.