Venturi Scrubber, Numerical Study, Industrial Application

$540.00 Original price was: $540.00.$270.00Current price is: $270.00. Student Discount

- In this project, the performance of an industrial 720-2 series venturi scrubber is numerically investigated by ANSYS Fluent.

- Studying removal of sand particles

- Using two-way Discrete Phase Model (DPM) & VOF multiphase model

- The simulation is performed in Transient.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

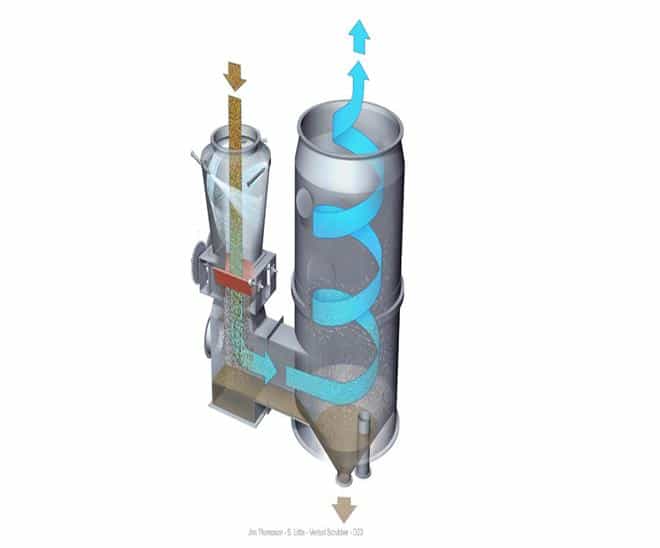

Venturi scrubber

Purpose:

Scrubbers have many applications in cement kilns, chemical and pharmaceutical industries, industrial boilers, gold factories, metallurgical industries, and incinerators. Therefore, this simulation aims to have the simulation settings of a sample scrubber. We can simulate all types of scrubbers in different sizes with these settings.

Introduction (Venturi Scrubber, Industrial Application):

The separation of particles from the gas flow is a significant challenge in the industry. One of the best tools to solve this challenge is a Venturi scrubber that removes gas particles. And compared to other scrubbers (wet scrubber, cyclone scrubber, etc.), it is more efficient.

Venturi scrubbers were designed to remove and collect particles for high efficiencies (over 99%). The high capability of Venturi in cases where the volume of incoming gas and its temperature are high has made them popular in various industries and consequently used to remove various particles in many industries.

This capability is especially desirable to reduce the emission of cement kilns and control the emission of simple oxygen kilns in the steel industry, where the inlet gas has a temperature of more than 350 c. Ventures are also used to control the emission of fly ash from incinerators and cement and sulfur dioxide furnaces in industries and boilers.

High liquid-to-gas ratio, liquid atomization, and open structure make it possible to purify highly polluted gases with high efficiency, minimal maintenance, and unlimited flow reversal capability. The ability of this system to remove toxic gases and particles simultaneously in different conditions makes Venturi one of the most flexible systems used.

Venturi is usually used in the first stage of multi-stage systems to control gas or air flow pollution, which is why this scrubber is used in various industries.

Abstract

In this project, ANSYS Fluent software stimulated an industrial Venturi scrubber. Venturi scrubbers collect particles and gas contaminants up to 0.1 micrometers. The amount of water in the device is very high, but it causes more water to contact particles and contaminants.

As a result, particles are trapped in the scrubber and removed from the fluid. After simulating the present Venturi Scrubber, it was observed that this device has the efficiency required for industrial applications.

How the Venturi Scrubber Works

The Venturi scrubber uses the inlet gas energy to atomize the gas flow scrubber.

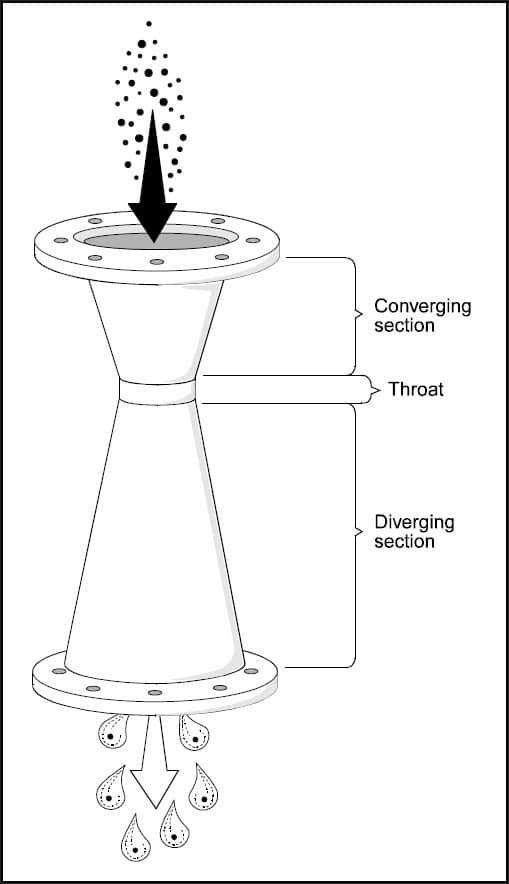

The Venturi scrubber consists of three parts: the convergent, the throat, and the divergent. The incoming gas stream enters the converging part and the gas flow rate increases as the area decrease. The fluid used is also added to the system at the throat or inlet of the converging part. The system inlet gas passes through the throat at high velocity, where the liquid is added, producing many droplets.

Removal of particles and contaminants from the gas stream is done in the throat. It is by colliding the incoming gas stream with fine liquid droplets. The inlet gas then moves towards the divergent part. It is where the flow will exit at a slow velocity and drown in water.

Advantages of Venturi scrubber

- low maintenance costs

- small space requirements

- cooling of hot gases and handling of corrosive flammable or explosive pollutants

Disadvantages of Venturi scrubber

- comparably high-pressure loss

- Requires much power

Simulation

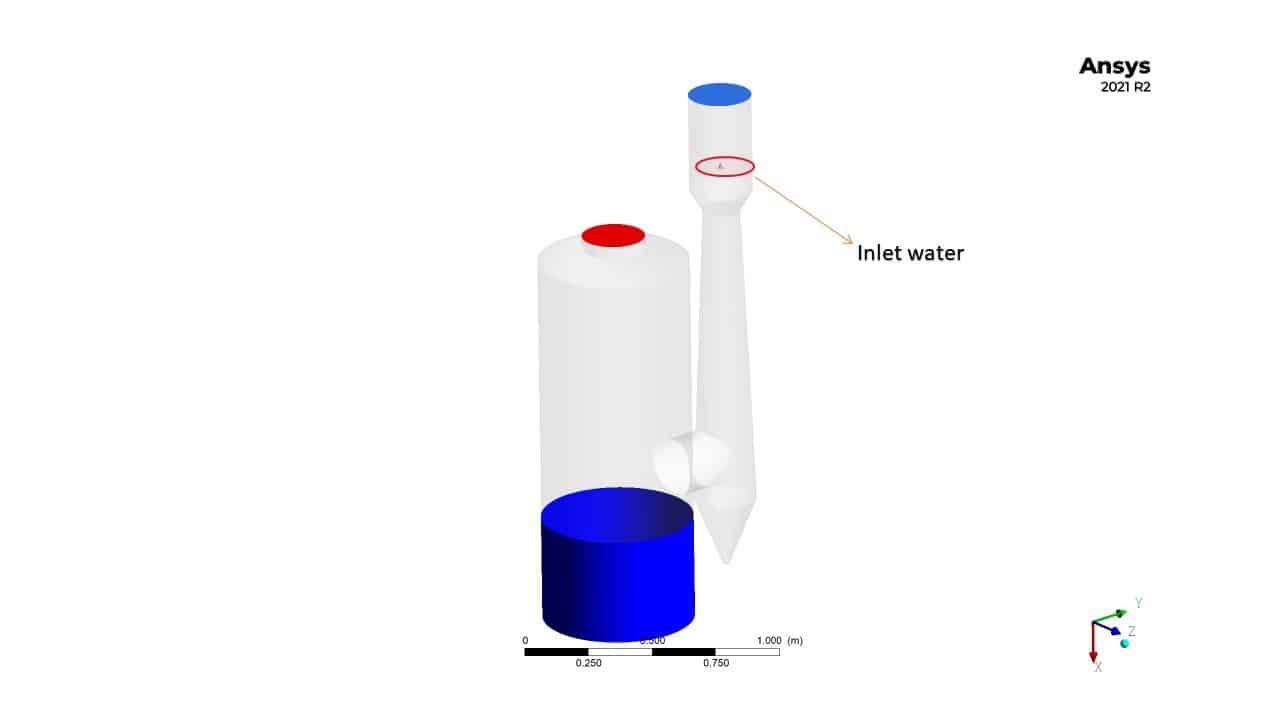

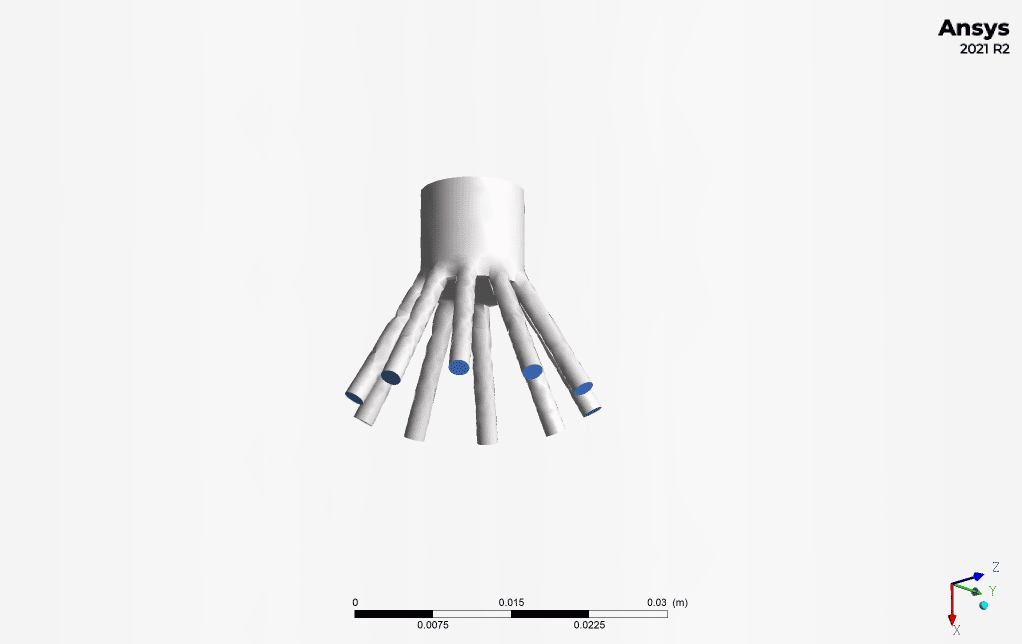

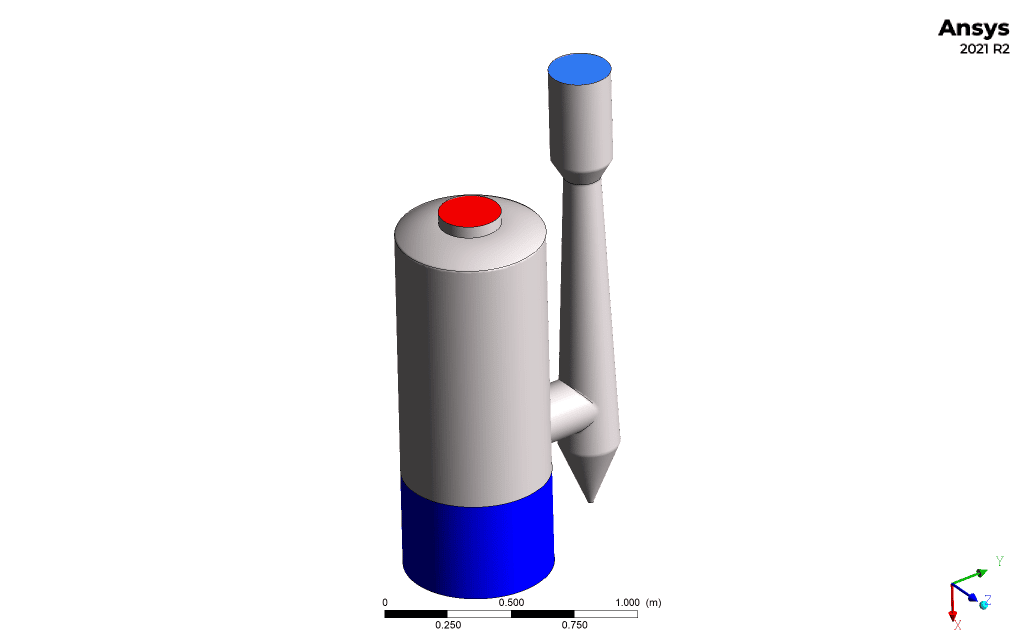

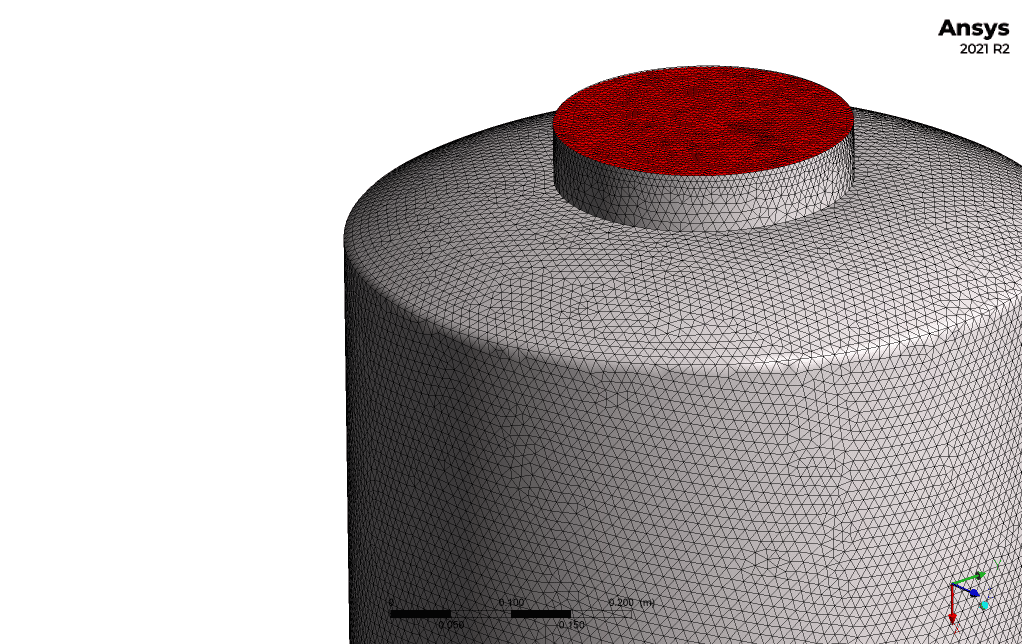

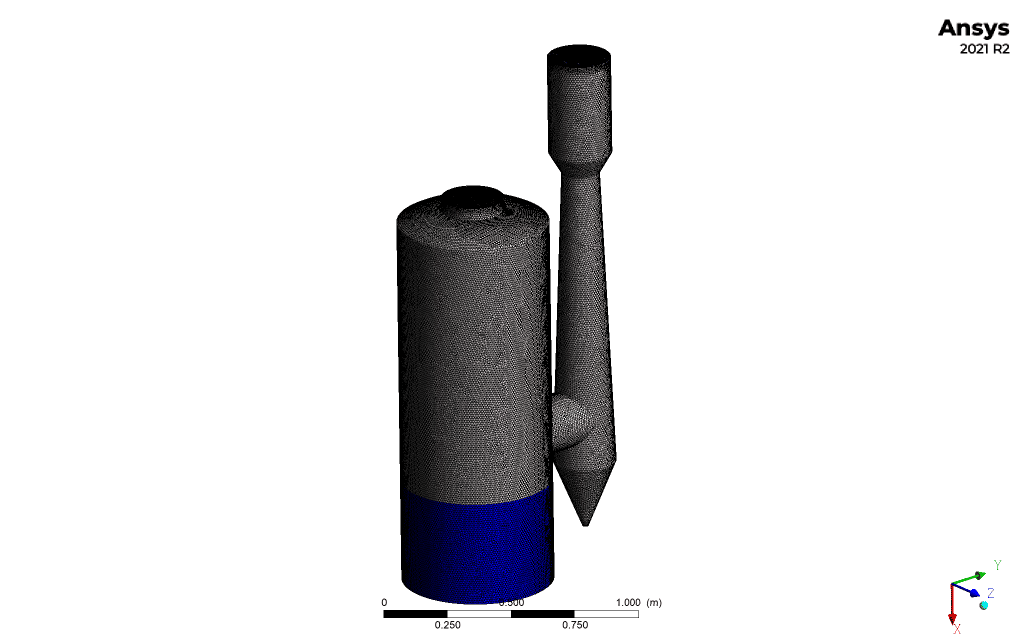

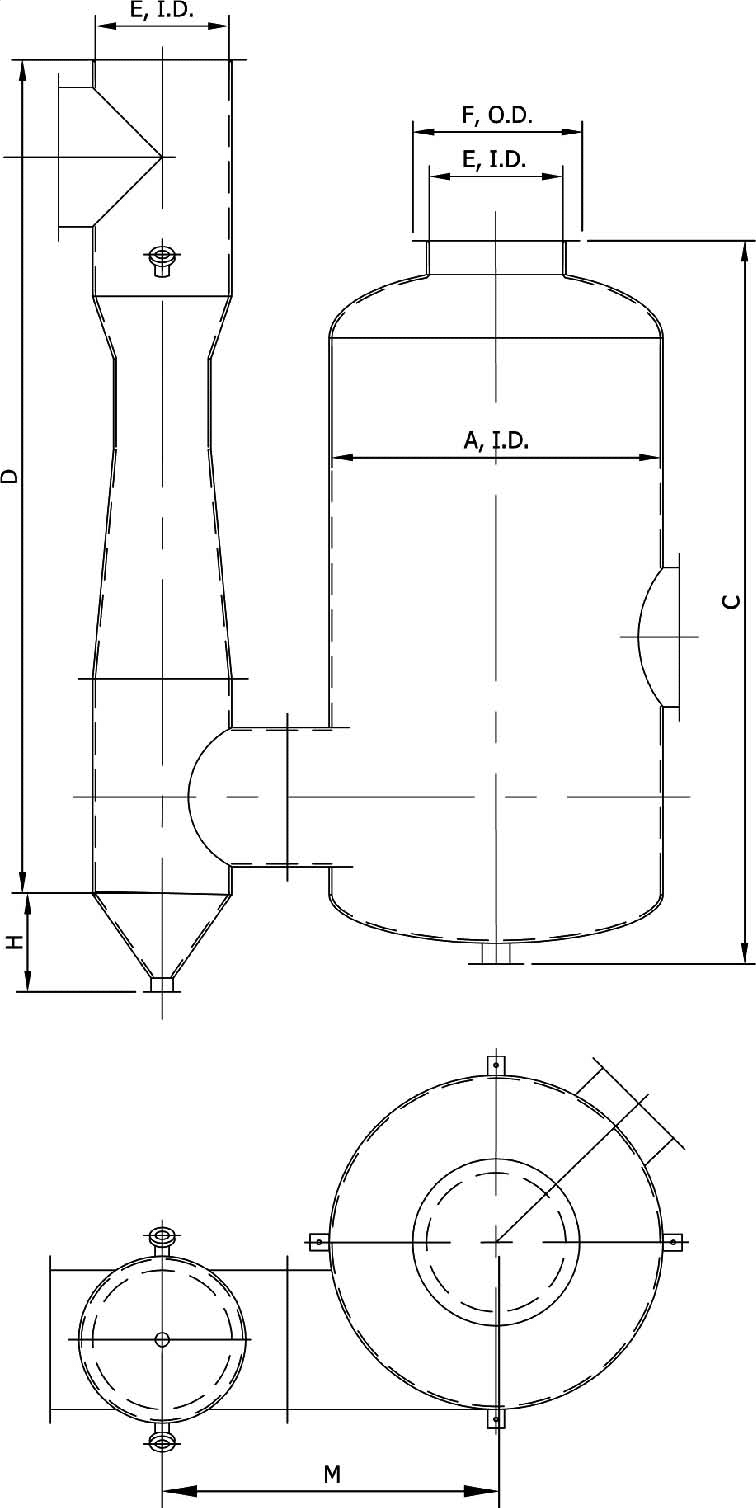

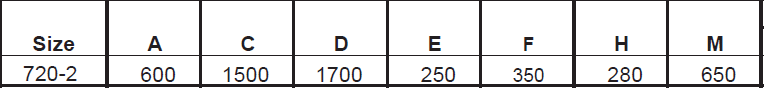

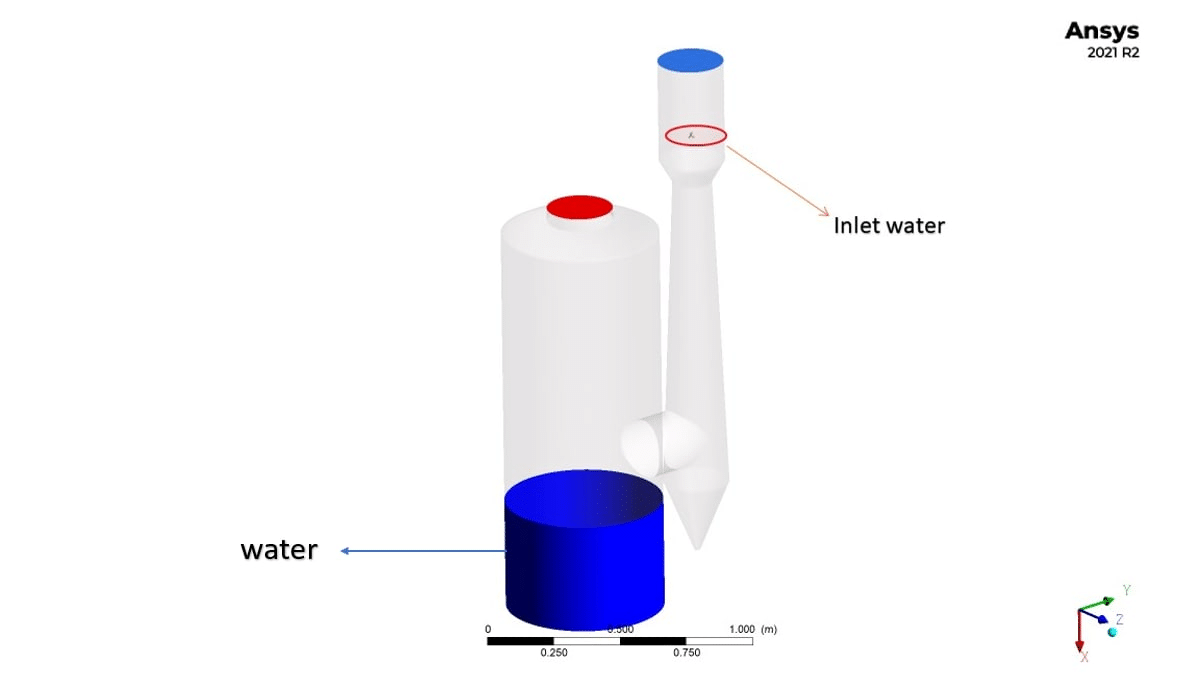

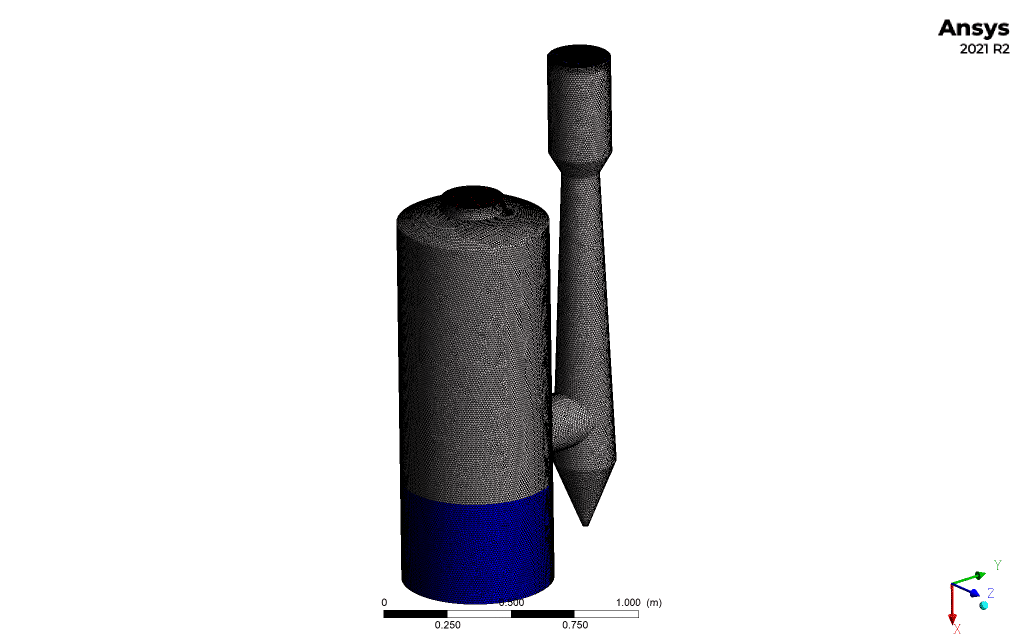

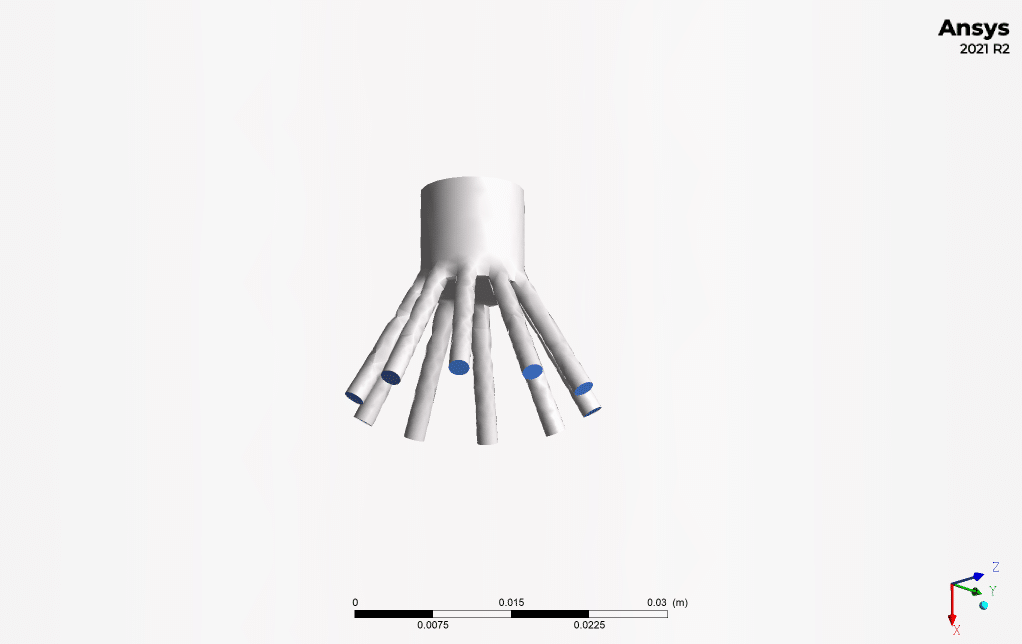

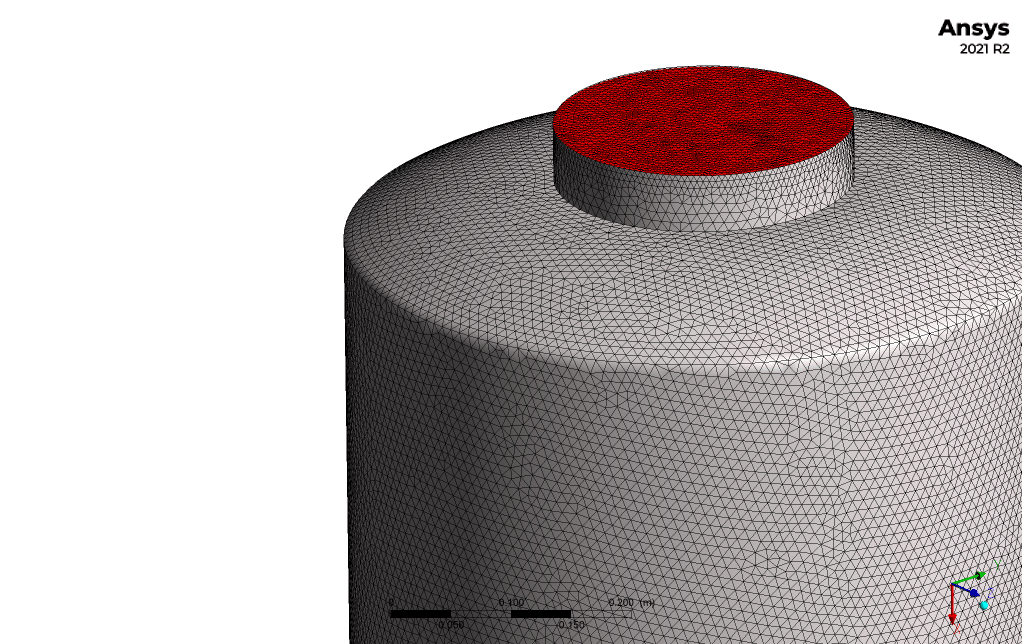

We designed the geometry of the present case study by Spaceclaim software, which has the exact dimensions as the Series 720 Venturi Scrubbers model. The meshing of this current model has been generated by Ansys Meshing software. The mesh grid is structured, and the total cell number is more than 4,600,000.

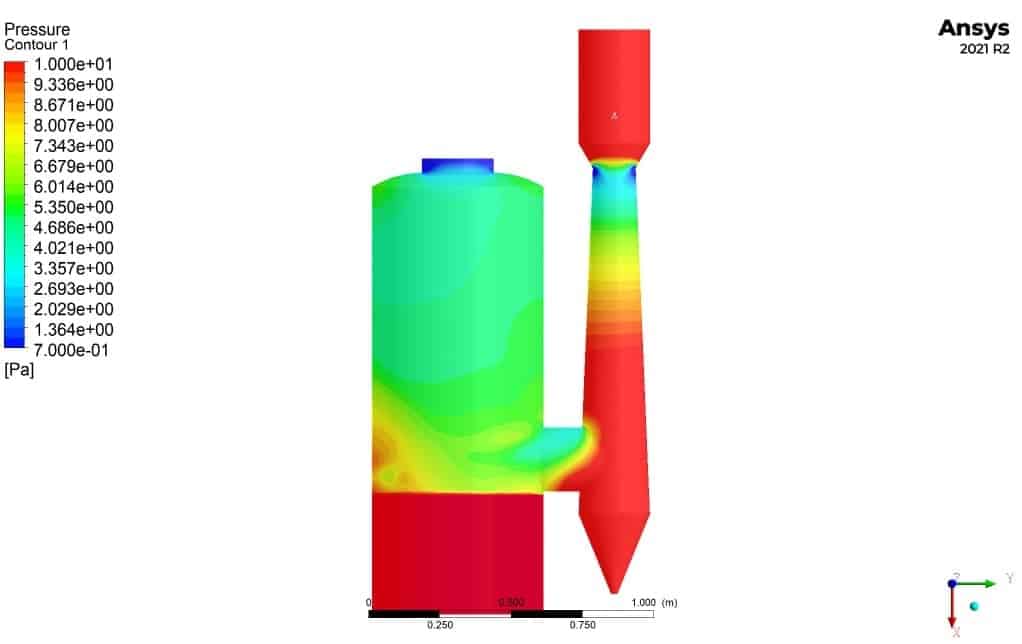

Venturi scrubber simulations are performed Transient with the energy equation, and the k-ε model is RNG as the turbulence model. In addition, multiphase and discrete phase equations are active. The fluids used in this simulation are water for the discrete phase and air for the continuous phase. Coupling of velocity and pressure equations is also performed using the SIMPLE algorithm.

Venturi scrubber Result:

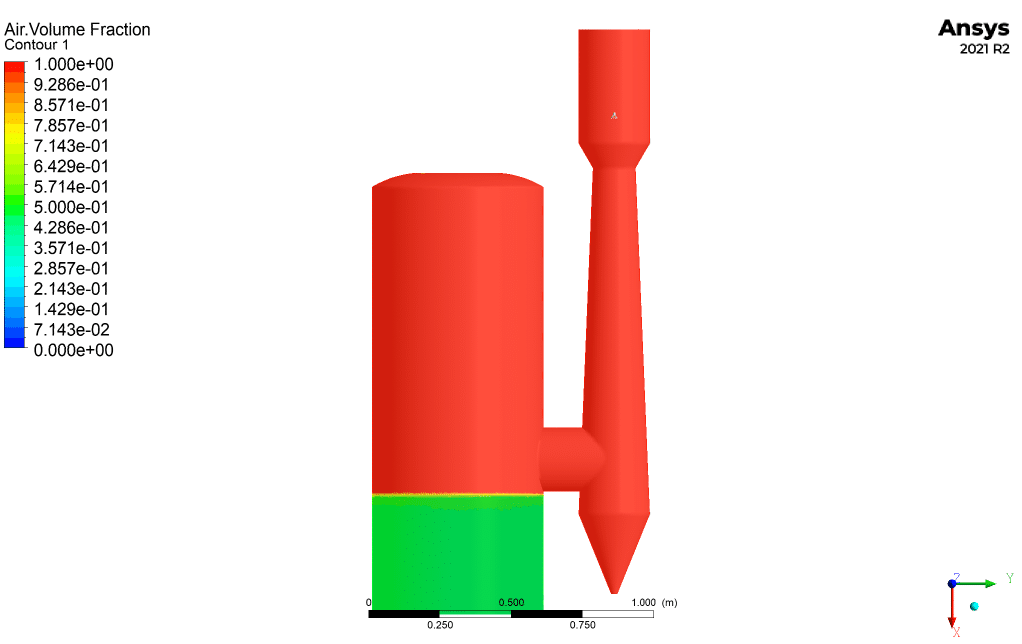

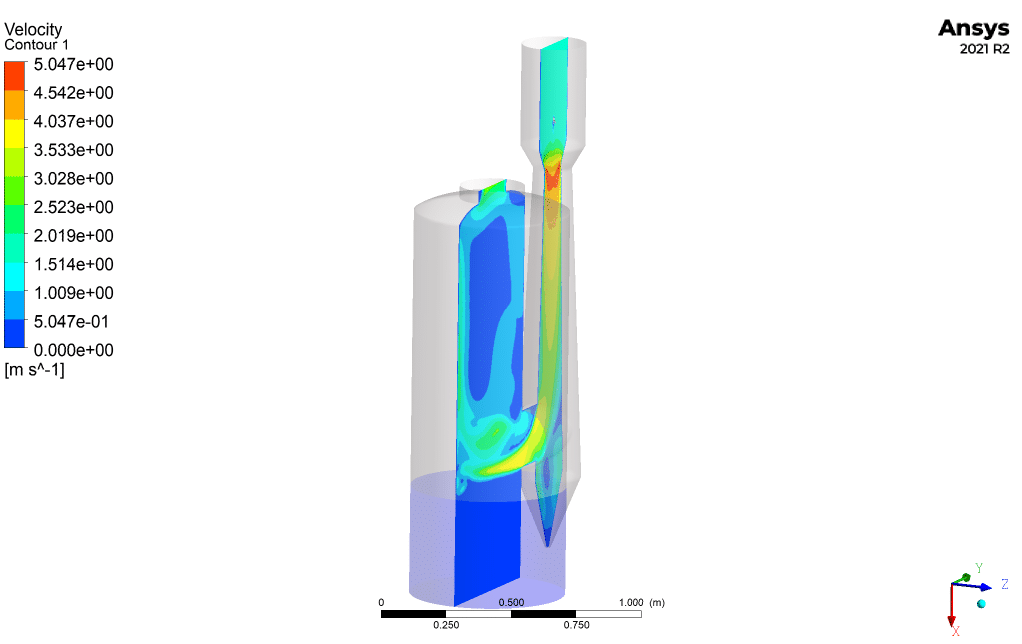

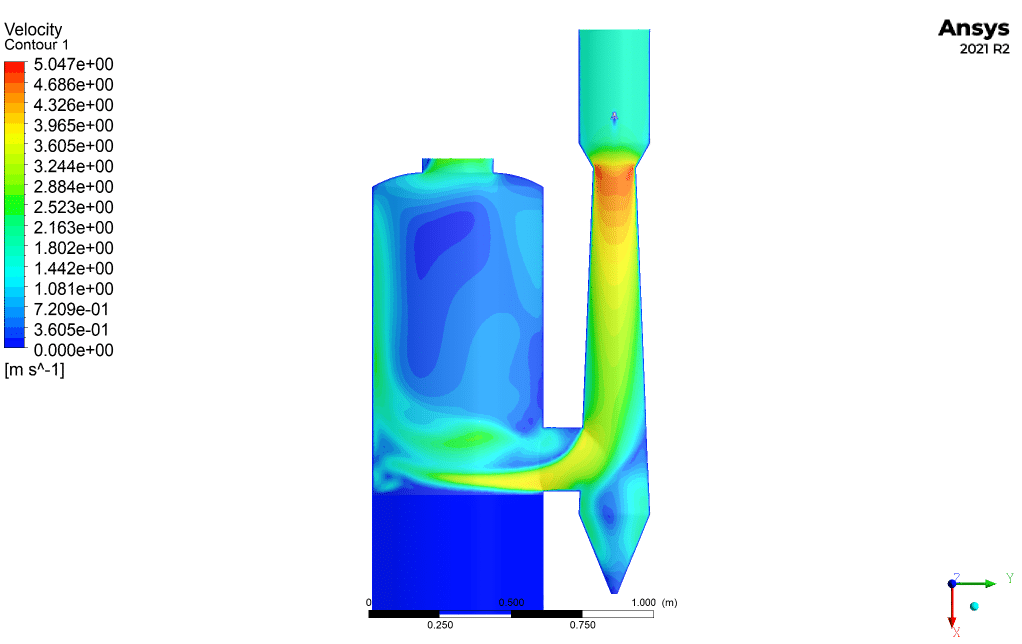

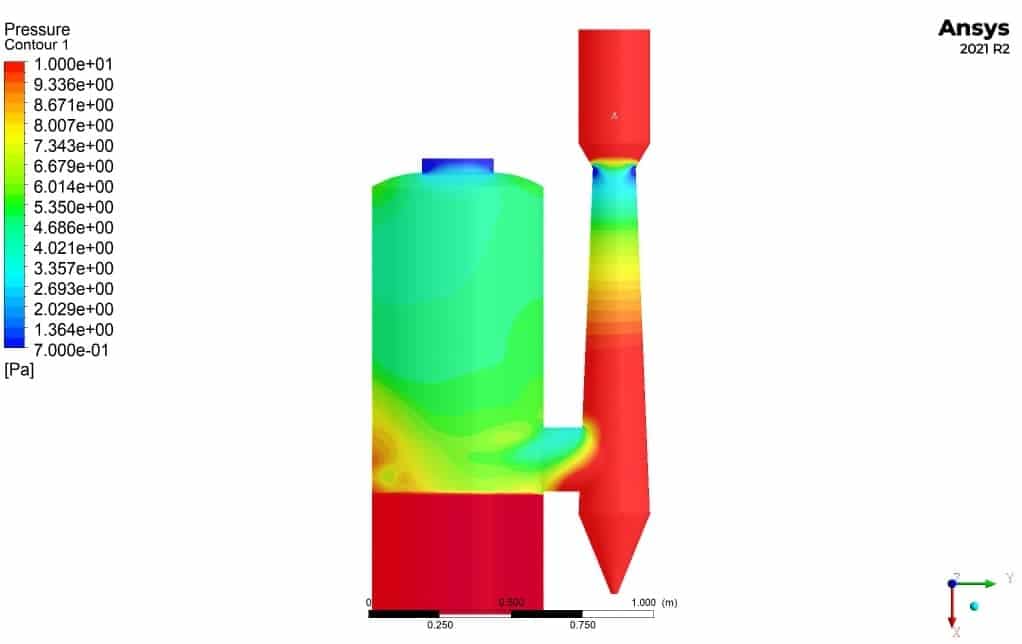

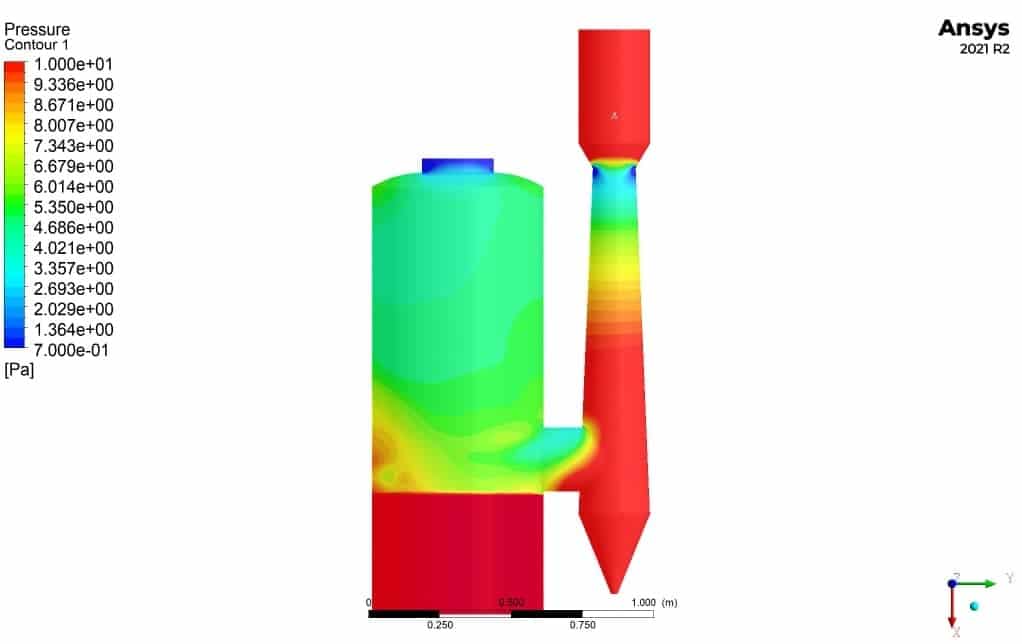

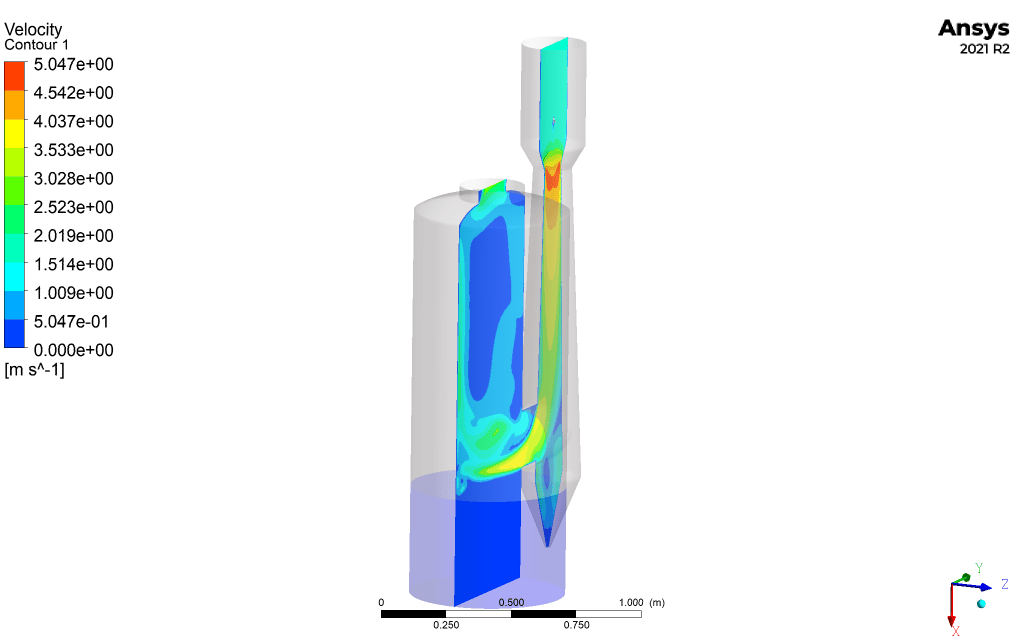

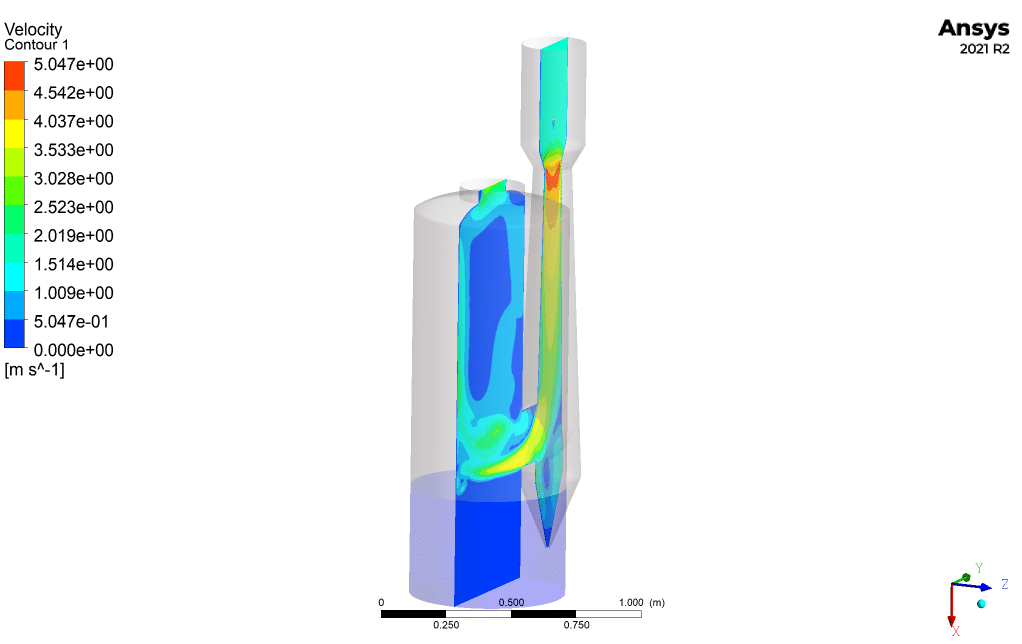

According to the simulation, it is observed that the pressure in Venturi decreases, which increases the velocity and turbulence, and water and particle disturbances are performed better, so the device is simulated correctly.

Suggestion:

A Venturi 720 series scrubber, size 720-2, has been simulated in this project. But if we want to use Venturi scrubber for other industries (with the different gas flow or particle flow). Due to the simulation settings of this size, the optimal state for the desired industry can be achieved with less time.

Attachment:

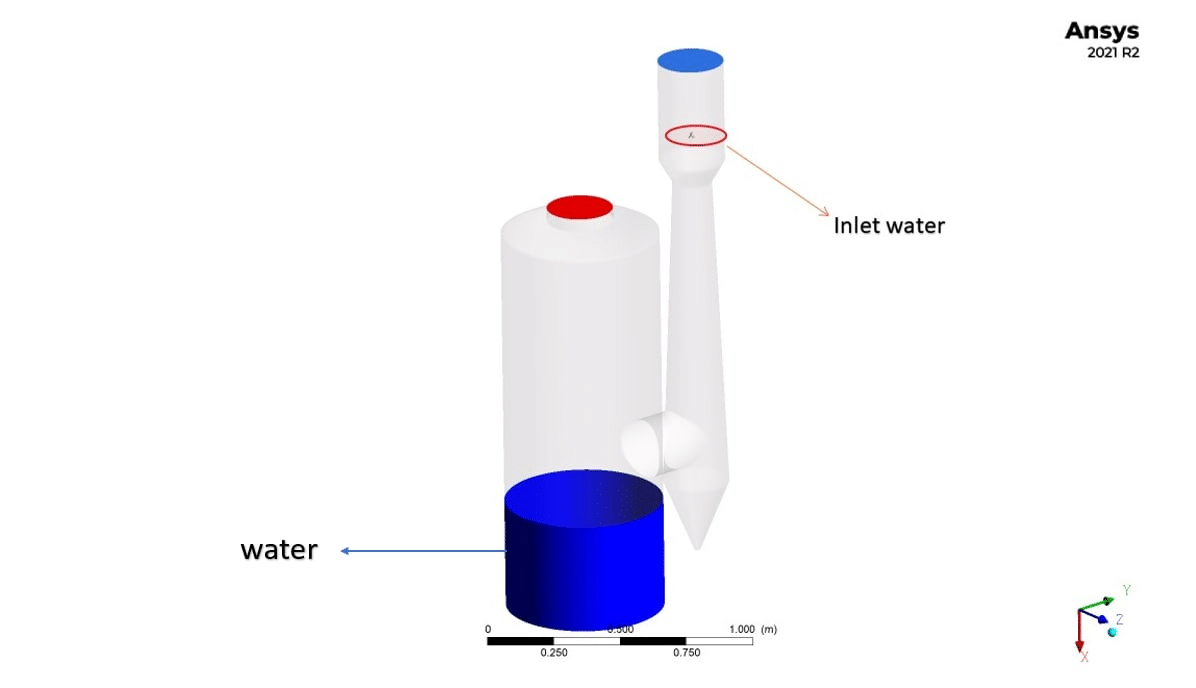

Geometry

Geometry

Mesh

Velocity Contour

Velocity Contour

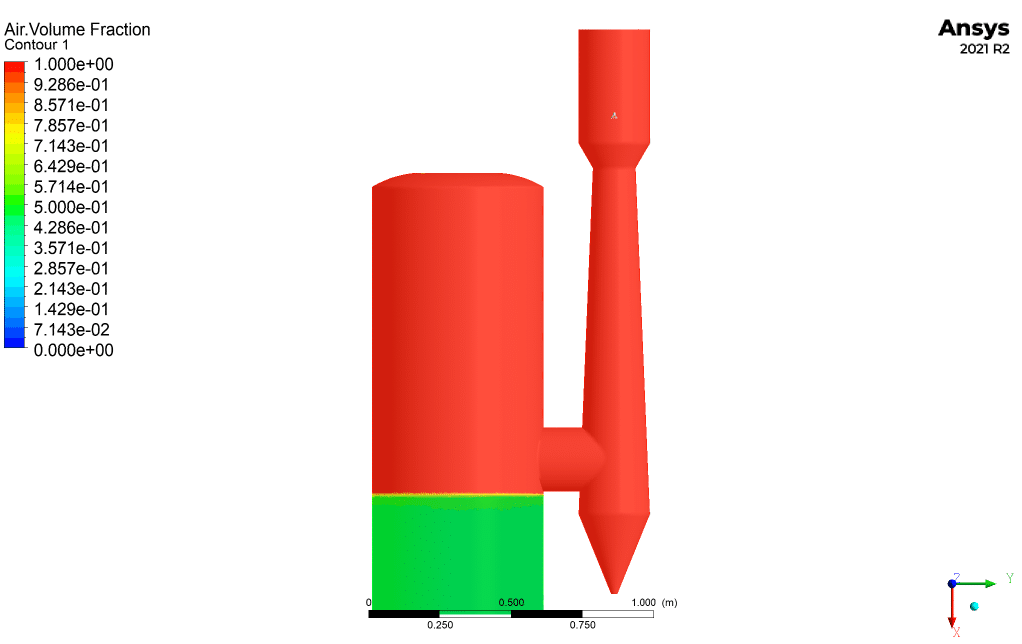

Air Volume Fraction

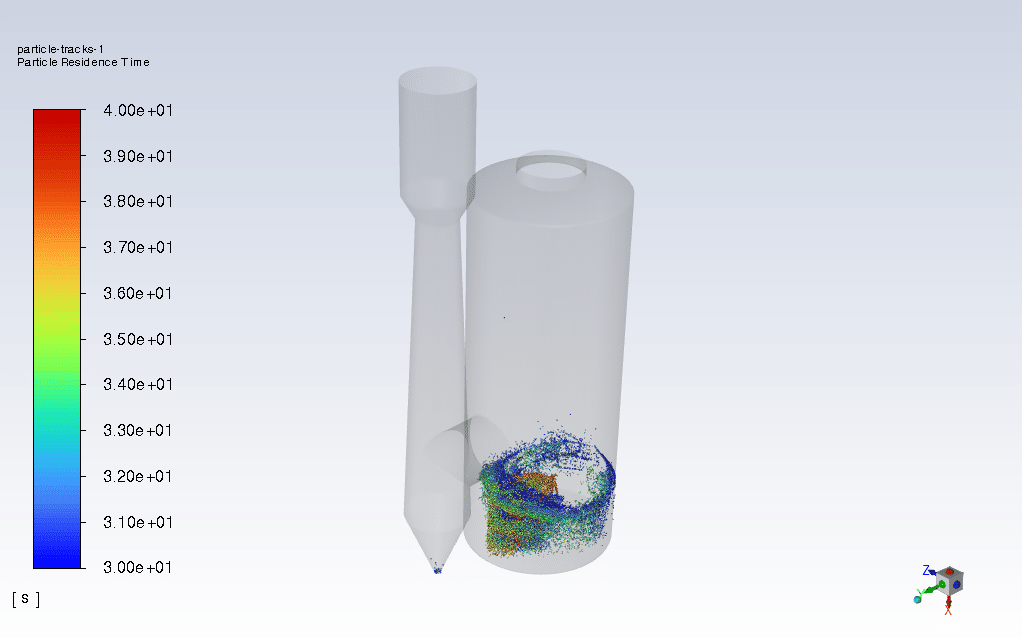

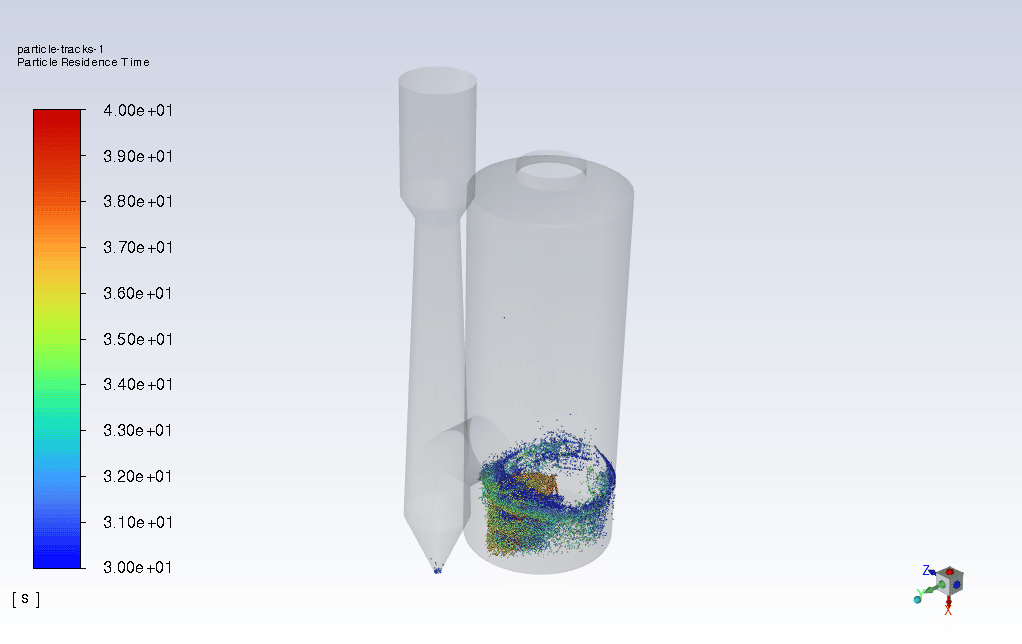

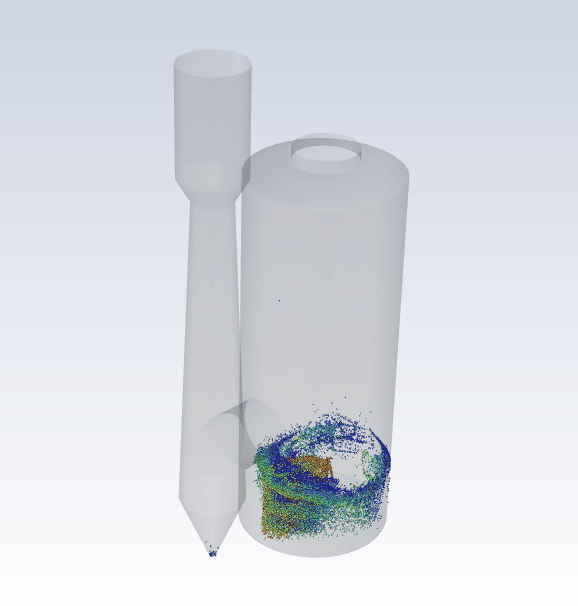

Particle Tracking

The figures above show the sand particles’ condition at different times. However, the animation of the whole 10 seconds of injecting process is extracted.

Annette Gulgowski –

I’ve recently completed my project using the Venturi Scrubber simulation and the results are impressive. The simulation’s capability to effectively trap and remove particles while handling hot, corrosive gases was especially beneficial in our industrial setting. Kudos to the team for a reliable product!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear how well the Venturi Scrubber simulation performed in your industrial project. It’s delightful that the product met your high-efficiency particle trapping requirements. We appreciate you taking the time to share your success, and we’re here to support any future simulation needs!

Linda Hansen –

The Venturi scrubber project is exceptional in demonstrating particle and gas separation, clearly an efficient design!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our Venturi scrubber simulation met your expectations and provided valuable insights. We’re committed to delivering high-quality CFD solutions, so your recognition is much appreciated.

Josiah Kuhic –

The review expresses satisfaction over the functionality and correct simulation of the Venturi scrubber system by emphasizing the high efficiency in trapping particles and confirming the design’s industry readiness. Further acknowledgment is given to the extensive detailing that accompanied the product, like geometry, mesh distribution, and particle tracking visuals.

MR CFD Support –

Thank you for the positive feedback! We are thrilled to hear that the product met your expectations and provided the necessary insights and results. It’s great to know that the detailed visualizations, such as geometry and particle tracking, added value to your experience. We appreciate you recommending our Venturi scrubber simulation for industrial applications.

Arno Kilback PhD –

I’m impressed by the quality of the simulation and the clearly detailed operation of the Venturi scrubber! Good job on building an illustrative system that exceeds efficiency requirements.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our simulation met your expectations and provided a clear understanding of the Venturi scrubber system. If you have any more questions or need further assistance, please don’t hesitate to reach out!

Leilani Hartmann –

The review provides a detailed explanation of the product, highlighting both advantages and disadvantages while offering insights into simulation outcomes. This holistic take will certainly assist prospective users in making an informed decision. Thank you for sharing your thorough experience with the Venturi Scrubber CFD simulation.

MR CFD Support –

Thank you for your kind words and for providing such a comprehensive review of our Venturi Scrubber simulation product. We are thrilled to hear about your positive experience and are glad that you found it efficient and insightful. Your feedback is highly valuable to us, and it helps us to continue delivering high-quality products and services to our customers. Thank you once again for your support!

Keegan Pagac –

The review and analysis of the simulation seem very comprehensive. Awesome work on conducting an in-depth study! It gives a clear picture of the efficacy of the Venturi scrubber in industrial applications.

MR CFD Support –

Thank you for your kind words! We appreciate you taking the time to review our project. Your feedback is incredibly valuable to us, and we’re glad to hear that the simulation study on the Venturi scrubber was thorough and helpful!

Terrill Kreiger –

I’m impressed with how comprehensive the simulation settings for the Venturi scrubber are. The meticulous design to achieve such high efficiency highlights MR CFD Company’s attention to detail in their products.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that you’re impressed with our simulation design and attention to detail. Our goal is always to create products that are comprehensive, accurate, and effective for our customers’ needs. Your satisfaction is our priority, and we appreciate your compliments!

Kaelyn Towne –

What a thorough analysis! Implementing the Venturi scrubber in the design genuinely seems to enhance efficiency in particle containment based on the simulation data. The utilization rate of the water nozzles and precise control of flow parameters showcase engineering excellence, leading only 0.02% of particles to escape. Applying this technology to the industrial line poised for, it not only minimizes environmental impact but also represents a substantial advancement in industrial pollution control. It’s impressive!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our simulation data has provided such clear insights into the efficiency of the Venturi scrubber design and its potential for industrial applications. Your recognition of our engineering effort and our product’s potential environmental benefits is greatly appreciated. If you have any further questions or need additional information, don’t hesitate to reach out.

Ms. Delpha Dooley –

I’m highly impressed with the level of detail and efficiency of the Venturi Scrubber simulation. It certainly sounds capable and efficient for industrial applications. A special kudos for achieving high effectiveness in particle containment, impressive!

MR CFD Support –

Thank you for the kind words! We’re glad to hear the simulation met your expectations and that you are satisfied with the results. It’s always our goal to provide accurate and efficient simulations for industrial applications. If you need further assistance or more information on our products, feel free to reach out!

Demetris Monahan V –

I’m impressed with the results of the simulation. It appears the Venturi Scrubber model presented is effective in trapping sand particles. Can it also handle finer particles like dust or gases?

MR CFD Support –

Thank you for your positive feedback. The Venturi Scrubber model’s high efficiency referenced in the simulation suggests it should be capable of handling finer particles like dust. As for gases, while the report emphasizes particle removal, Venturi Scrubbers are also known to remove gaseous pollutants by engaging similar mechanisms, albeit depending on the specific chemical and physical properties of the contaminants. If you have requirements for dust or gaseous application, adjustments in the simulation parameters might be necessary to match your particular industry needs.

Prof. Lucinda Stark –

What is the significance of the fluid used in the simulation and could this setup handle different contaminants?

MR CFD Support –

In this Venturi scrubber simulation, water is used as the scrubbing liquid mainly due to its ability to effectively capture and remove various particles and contaminants from gas streams. Its physical and chemical properties make it a versatile medium for scrubbing operations. The setup described is capable of handling different types of contaminants, as highlighted by its use in varied industries and efficiency. Customization of simulation settings allows adaptation to specific industry needs, managing different gas flows or particle types, thus enhancing its flexibility and effectiveness.

Roosevelt Abbott –

The efficiency you’ve described sounds quite impressive for the Venturi scrubber. I’m especially interested in how it manages the smaller particles. Could you elaborate on the specific mechanisms that enable the scrubber to trap particulates up to 0.1 micrometers effectively?

MR CFD Support –

The Venturi scrubber’s high efficiency in capturing small particles is mainly due to its design and the high relative velocity between the gas and the scrubbing liquid. In the throat section, where the gas stream is accelerated and the liquid is introduced, tiny droplets of the liquid are created. These droplets capture the small particles by mechanisms such as inertial impaction and Brownian motion. Moreover, the turbulent flow enhances the interaction between droplets and particles, leading to effective capturing. Additionally, the high scrubbing liquid-to-gas ratio also means more chances for particle and droplet interaction, increasing efficiency for sub-micrometer particulates.

Selena Kutch –

The detailed explanation of the Venturi scrubber’s operation and results is excellent! I’m particularly impressed with the high efficiency of particle containment reported. It’s reassuring to know that only 0.02% of particles could escape.

MR CFD Support –

Thank you for your positive feedback on our Venturi scrubber simulation study! We’re thrilled to hear that you’re satisfied with the level of detail and the results of the simulation. It’s our goal to provide thorough and accurate analyses to aid in the efficient design of industrial applications. If you have any further inquiries or require assistance with future projects, please feel free to reach out to us.

Mayra Cremin –

Which turbulence model was used in the simulation of the Venturi scrubber, and why was it chosen?

MR CFD Support –

The k-ε RNG turbulence model was used in the Venturi scrubber simulation. This model was chosen due to its capability in handling complex turbulent flows with high accuracy, and it’s particularly useful for engineering applications like scrubber systems where prediction of intense swirling and recirculation is key.

Alexandre Zboncak –

I’m impressed by the efficiency of the Venturi Scrubber simulation! It looks like it has excellent potential for industrial use. Great work on achieving such accuracy in particle containment.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our Venturi Scrubber simulation meets your expectations with its high efficiency and accurate particle containment. Our team works hard to ensure our simulations have the potential for practical industrial applications. Your satisfaction with the simulation’s results is very affirming for us. If you need further assistance or information on implementing this technology in an industrial setting, don’t hesitate to reach out.

Dr. Shanon Hamill Sr. –

Absolutely fabulous work on demonstrating the functionality of the Venturi Scrubber through CFD simulation. It’s enlightening to see both the efficiency and areas for improvement touched upon, along with a comprehensive understanding of its application in various industries. The inclusion of geometry and mesh details alongside velocity contours and particle tracking visuals provides a clear window into your simulation processes and results. Great job!

MR CFD Support –

Thank you for taking the time to review our Venturi Scrubber CFD simulation product. We are pleased to hear that you found the details and visuals provided to be comprehensive and helpful. It’s our goal to ensure clarity and relevance in our simulations to give users a significant insight into the workings and applications of industrial equipment like the Venturi Scrubber. Your encouragement means a lot to us. If you need any further assistance or information, please do not hesitate to contact us.

Karianne Renner –

Very impressed with the depth and detail of the Venturi scrubber simulation project using ANSYS Fluent! The comprehensive study on the efficiency and operation of scrubbers is crucial for various industrial applications. The attachment showcasing the geometry, mesh, and results is particularly useful. Great work in demonstrating the device’s capability for particulate matter removal!

MR CFD Support –

Thank you so much for your positive feedback! We’re thrilled to hear that you found the Venturi scrubber simulation project comprehensive and informative. Providing in-depth analysis and ensuring our simulations are detailed and accessible is our top priority. Your compliments motivate us to keep delivering high-quality simulation studies. If you have any further questions or require assistance, feel free to reach out.

Mrs. Shanna Donnelly Jr. –

Is this software suitable for other kinds of scrubbers, like wet scrubbers or cyclone scrubbers, or is it just for Venturi scrubbers?

MR CFD Support –

The software is versatile and can simulate different types of scrubbers, including Venturi, wet, and cyclone scrubbers. The simulation settings provided in the Venturi scrubber case study are adaptable and can be tailored to simulate various sizes and conditions specific to different types of scrubbers within different industries.

Dr. Judah Miller Sr. –

Are the simulation parameters such as gas inflow rate and water pressure adjustable for different industrial scenarios, and will that affect the efficiency depicted in the study?

MR CFD Support –

Yes, the simulation parameters like gas inflow rate and water pressure in the Venturi scrubber can be adjusted to suit various industrial scenarios. Changes in these parameters may affect the efficiency of particle removal, which is why simulations are invaluable to determine the optimal settings for each specific application before implementation.

Orpha Morissette Jr. –

How significant is the impact of liquid-to-gas ratio on the efficiency of the Venturi scrubber, and can the model simulate that effectively?

MR CFD Support –

The liquid-to-gas ratio is a critical factor in determining the efficiency of a Venturi scrubber, since it influences the degree of contact between the particles and the liquid, impacting the scrubber’s effectiveness at trapping particles. The provided simulation model has the capabilities to analyze and optimize the liquid-to-gas ratio for enhanced removal efficiencies for different industries and pollutant types.