Triple Heat Exchanger CFD Simulation, Ansys Fluent

$80.00 Student Discount

- The problem numerically simulates Triple Heat Exchanger using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We mesh the model with ANSYS Meshing software, and the element number equals 1946903.

- The Energy Equation is activated to consider heat transfer in the heat exchanger.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Triple Heat Exchanger, CFD Simulation Ansys Fluent Training

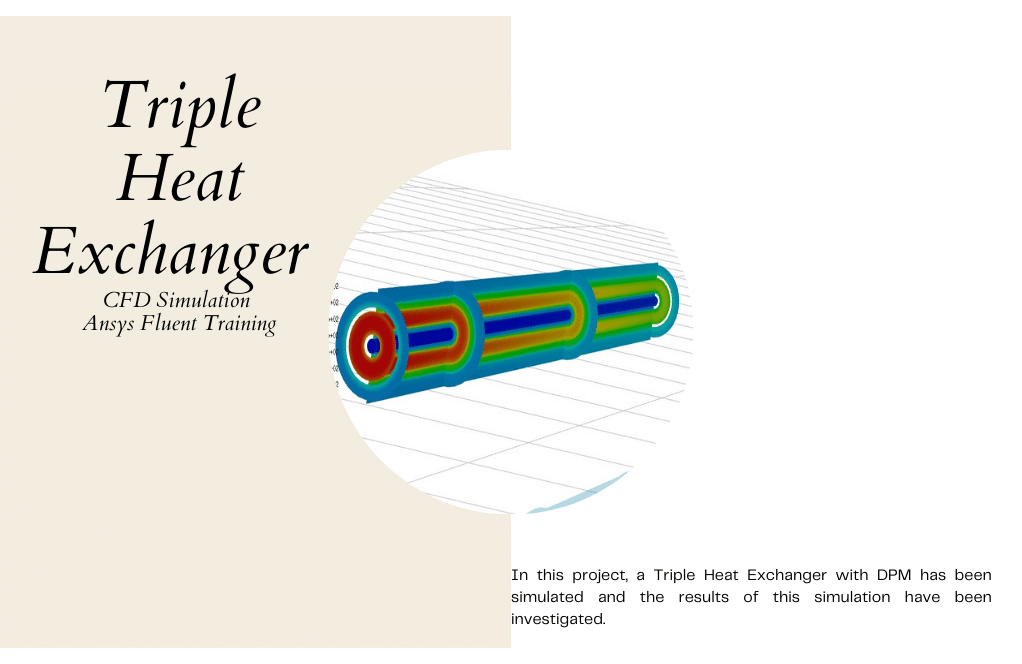

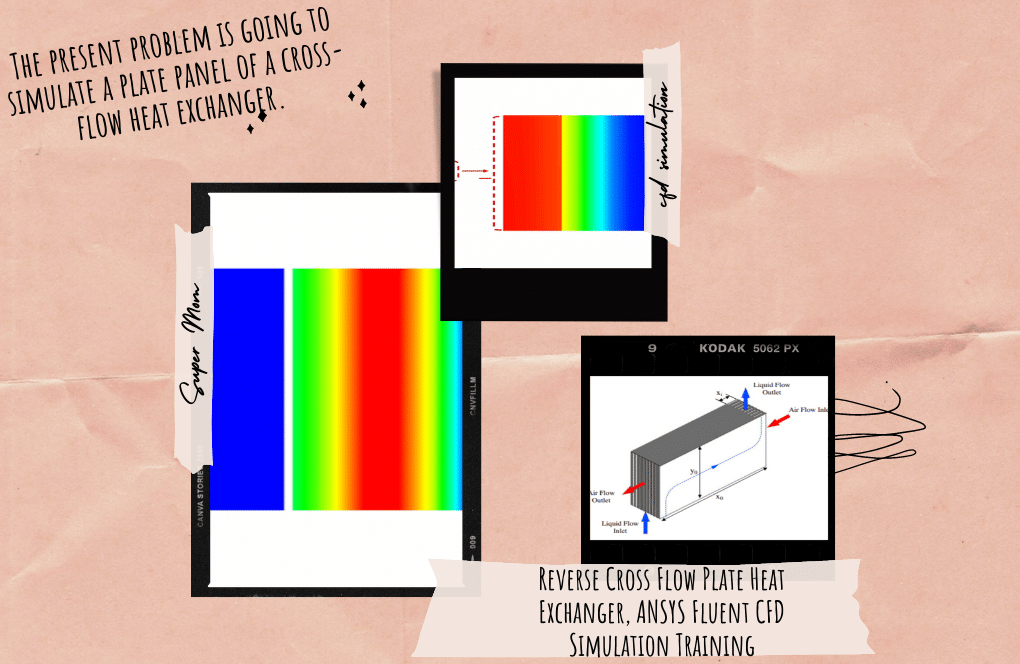

In this project, a Triple Heat Exchanger has been simulated, and the results have been investigated using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

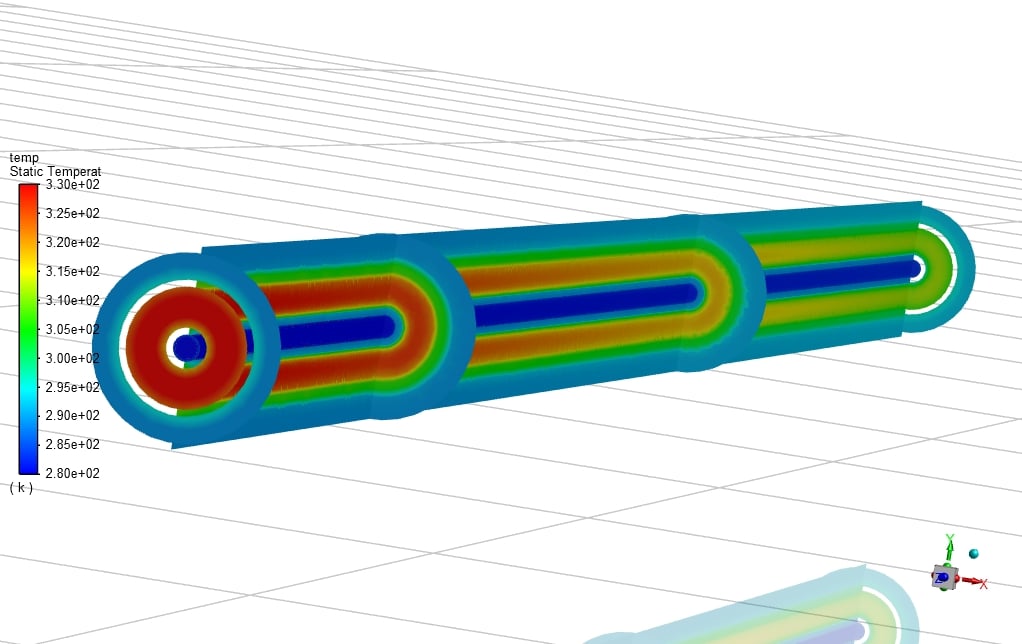

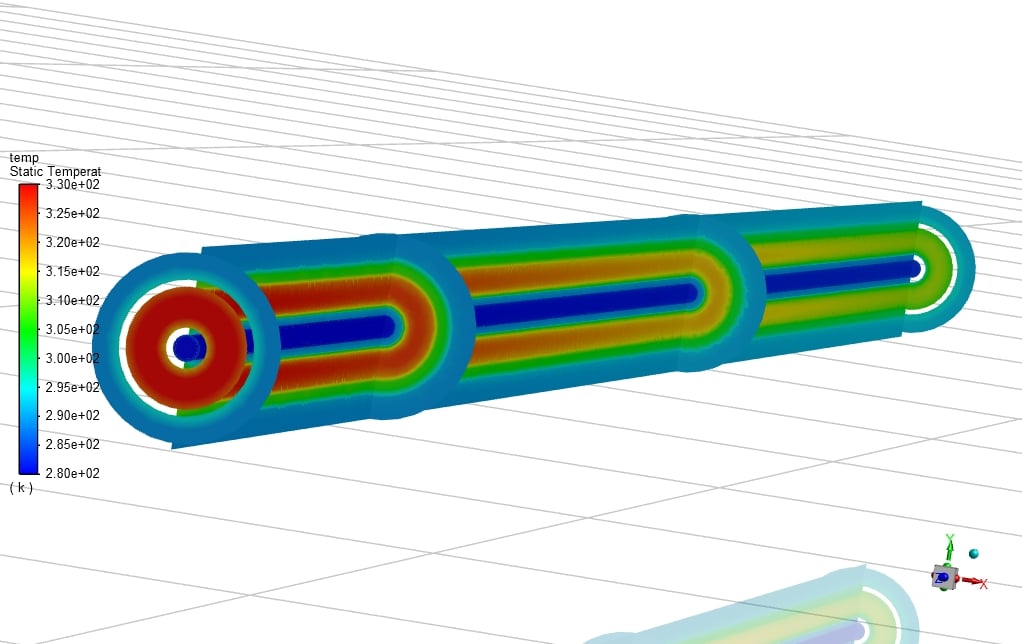

The present model is designed in three dimensions using Design Modeler software. The geometry of the solution consisted of three pipes that were concentrated inside each other.

The triple concentric tube heat exchanger (TCTHE) is a modified constructive version of a double concentric tube heat exchanger by adding an intermediate tube.

The meshing of the model has been done using ANSYS Meshing software. The element number is 1964903.

Triple Heat Exchanger Methodology

This work aims to investigate the heat transfer in a triple concentric tube heat exchanger. Heat exchangers are widely used in industrial applications where the vital need to cool down a fluid and move it is satisfied by using heat exchangers.

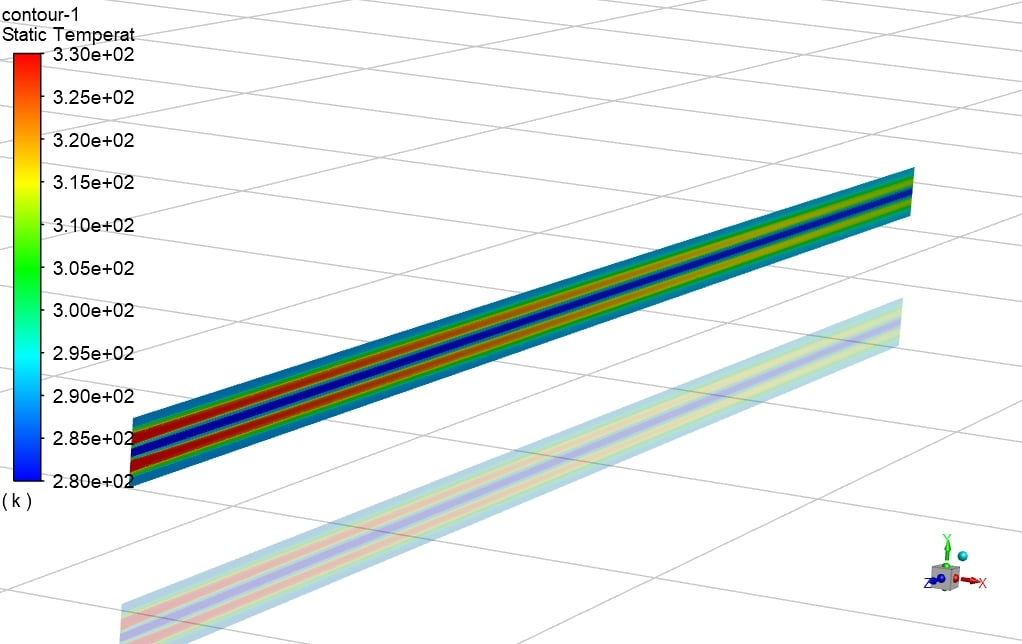

In this project, three concentric tubes are considered, and the heat transfer between each of the two concentric tubes is calculated. The water enters the innermost pipe with a mass flow rate of 0.1 kg/s and a temperature of 280K.

The entering flow into the middle pipe has a mass flow of 0.05kg/s and a temperature of 330K, and finally, the water flow enters the outer pipe with a velocity of 0.05m/s and a temperature of 290K.

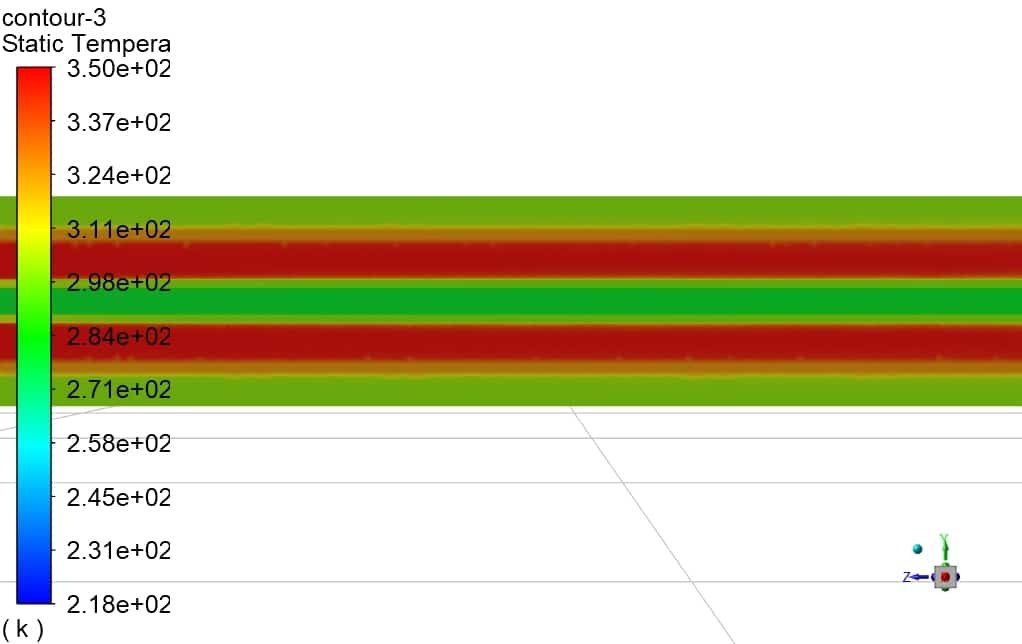

Moreover, the laminar model and energy equation are enabled to solve the fluid equations and calculate the temperature distribution within the domain.

Triple Heat Exchanger Conclusion

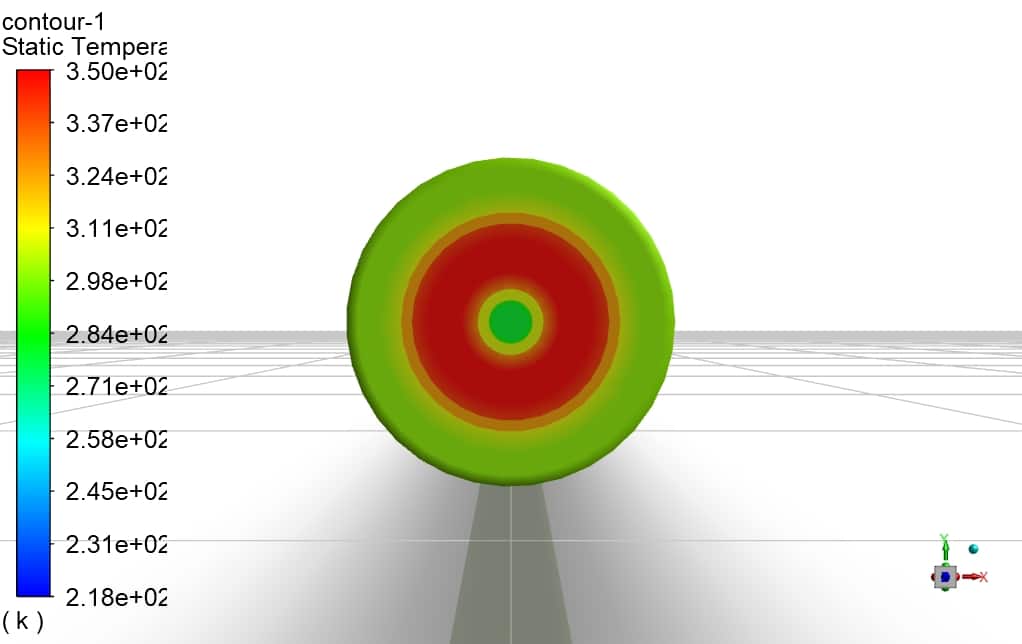

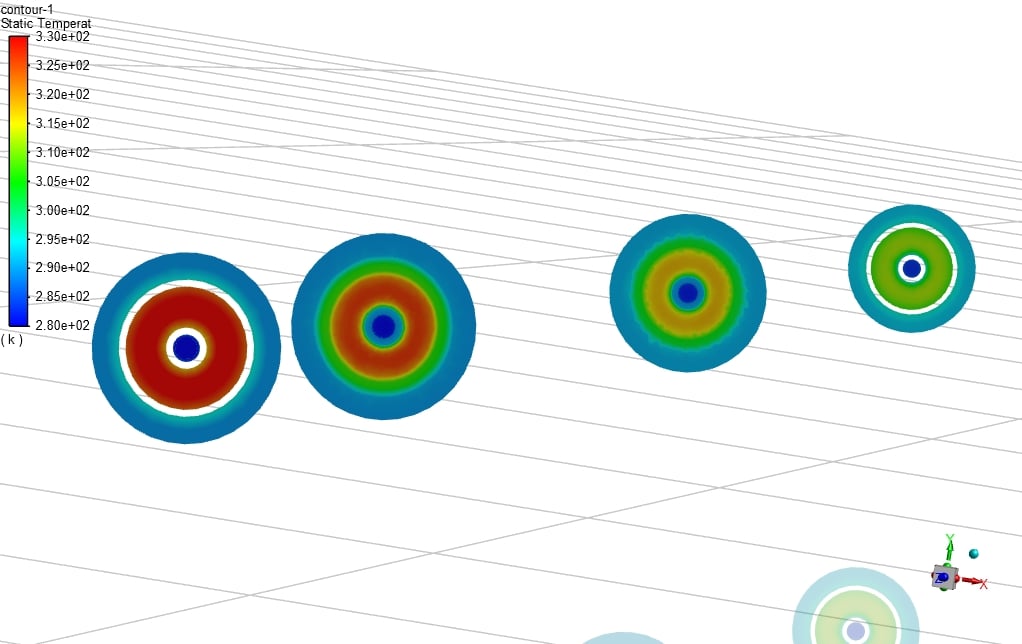

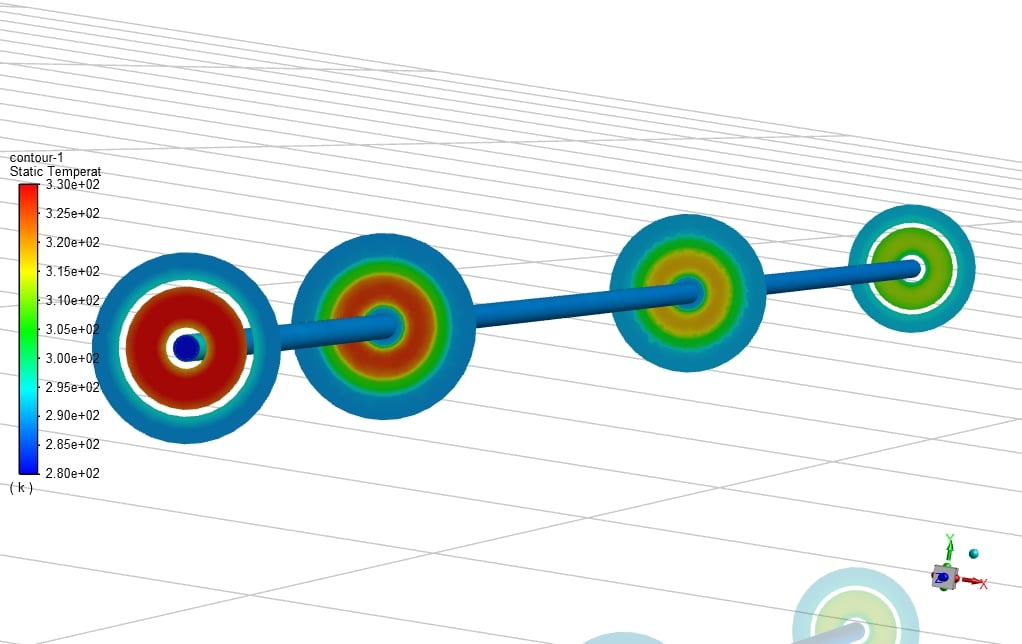

At the end of the solution process, two-dimensional and three-dimensional contours related to temperature are obtained. As can be seen, the water flow temperature within the middle pipe decreases as it loses heat to water flows in the inner and outermost pipes.

Adolphus Parisian –

The review of the Triple Heat Exchanger simulation is very informative!

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that you found the simulation materials informative and helpful.

Odie Pouros –

This course provided a comprehensive insight into the offered Triple Heat Exchanger CFD Simulation in ANSYS Fluent. The clear visuals and detailed approach gave me a strong understanding of both the setup and outcome of such a simulation. Great stuff!

MR CFD Support –

Thank you very much for your positive review! We’re thrilled to hear that our course has effectively conveyed the details of simulating a Triple Heat Exchanger in ANSYS Fluent. Your feedback motivates us to continue creating high-quality educational content. If you have more queries or need further learning resources in the future, please don’t hesitate to reach out.

Mr. Irving Bernier MD –

The triple heat exchanger simulation seems very intricate. What specific post-processing steps were used to analyze the temperature gradients within the three pipes?

MR CFD Support –

For analyzing temperature gradients within the three pipes in the triple heat exchanger simulation, several post-processing steps including the creation of 2D and 3D temperature contours were conducted. These steps allowed for a detailed understanding of how heat transfer occurred between the concentric tubes – evaluating the changes in temperature along the length of the triple heat exchanger and across its cross-section to ensure the effectiveness of heat transfer processes.

Ms. Leanne Hahn Sr. –

The explanation of how heat is transferred in a triple heat exchanger is fascinating. Understanding the temperature distribution through these effects is crucial for optimizing industrial processes.

MR CFD Support –

Thank you for your positive feedback on our Triple Heat Exchanger CFD Simulation! We’re thrilled to hear that the content was informative and useful for understanding complex heat transfer dynamics. If there is anything more we can do to assist with your learning, please let us know!

Euna Skiles DVM –

I’m very impressed with the dedicated simulations for each pipe in predicting heat transfer. Do the simulations also measure the impact of material properties of the pipes, or is it focused solely on fluid flow and temperature?

MR CFD Support –

Thank you for your positive feedback! Yes, the simulations take into account the material properties of the pipes as they greatly affect the heat transfer process. The thermal conductivity, density, and specific heat capacity, alongside the fluid flow and temperature distribution, play crucial roles in accurately determining the heat transfer within the triple heat exchanger system.

Kellie Cassin –

The outcome of such a detailed simulation is truly remarkable. The meticulously rendered temperature contours eloquently illustrate the efficiency of the triple heat exchanger design, providing clear insight into thermal management capabilities in complex systems.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that the detail and clarity of the simulation results have provided you with valuable insights into the performance of the triple heat exchanger. Its efficiency in thermal management is indeed a critical aspect of engineering design, and we appreciate your acknowledgment of the effort put into this CFD analysis. If you have further questions or need additional information on this or any other project, don’t hesitate to reach out to us.