5 Real-World Examples of Successful CFD Service Projects

In the high-stakes world of industrial engineering, the difference between a market-leading product and a costly failure often comes down to how well you understand fluid dynamics before metal is ever cut. For over two decades, I have stood at the intersection of theoretical physics and hard-nosed business reality. I’ve seen projects where a single insight derived from a cfd service saved millions in prototyping costs, and I’ve seen others where neglecting simulation led to catastrophic thermal failures.

Computational Fluid Dynamics (CFD) is no longer just a luxury for aerospace giants; it is a critical competitive lever for any industry dealing with fluid flow, heat transfer, or aerodynamics. However, hiring a cfd service company is not just about generating colorful flow visualization plots. It is about solving specific, painful engineering problems—reducing drag, optimizing cooling, or ensuring chemical mixing efficiency—with mathematical certainty.

In this comprehensive guide, we will pull back the curtain on five real-world success stories from the archives of MR CFD. These aren’t theoretical textbook problems; they are verified industrial simulations that solved tough challenges, validated against experimental data, and delivered massive Return on Investment (ROI). 🚀

Whether you are an R&D director in the automotive sector or a startup founder in renewable energy, these examples will demonstrate exactly how expert CFD Consulting translates complex physics into profitable engineering solutions.

What Makes a CFD Service Project Truly Successful?

Before we dive into specific case studies, we must define what “success” actually looks like in the context of engineering simulation services. In my 20 years as a consultant, I have found that a simulation is useless if it doesn’t drive a business decision. A project is not successful simply because the mesh converged or the residuals dropped below 10^-6.

True success in a cfd service engagement relies on a trifecta of outcomes: Accuracy, Turnaround, and ROI.

1. Technical Accuracy and Validation

The foundation of any reputable industrial cfd analysis is validation against experimental data. If the simulation cannot reproduce known physical behaviors or benchmarked results, it is merely a digital painting. At MR CFD, we rigorously validate our baseline models against physical tests or peer-reviewed literature before exploring design iterations. This ensures that the physics we model—be it turbulence, combustion, or multiphase flow—matches reality.

2. Scalability and Turnaround Time

Time-to-market is the currency of modern engineering. A perfect simulation that takes six months to run is often worthless if the design review is next week. Successful projects leverage high performance computing for cfd (HPC) to deliver results when they matter. We optimize mesh density and solver settings to balance fidelity with speed, ensuring clients get answers while the design window is still open.

3. Tangible ROI (Return on Investment)

This is the differentiator. Did the simulation reduce the number of physical prototypes required? Did it identify a flaw that would have caused a warranty recall? A successful cfd consulting project must pay for itself. Our methodology at MR CFD follows a strict path:

- Problem Definition: diagnosing the root cause, not just the symptom.

- Simulation Strategy: Selecting the right physics (e.g., Steady vs. Transient).

- Optimization: Iterating designs virtually.

- Value Delivery: converting data into engineering recommendations.

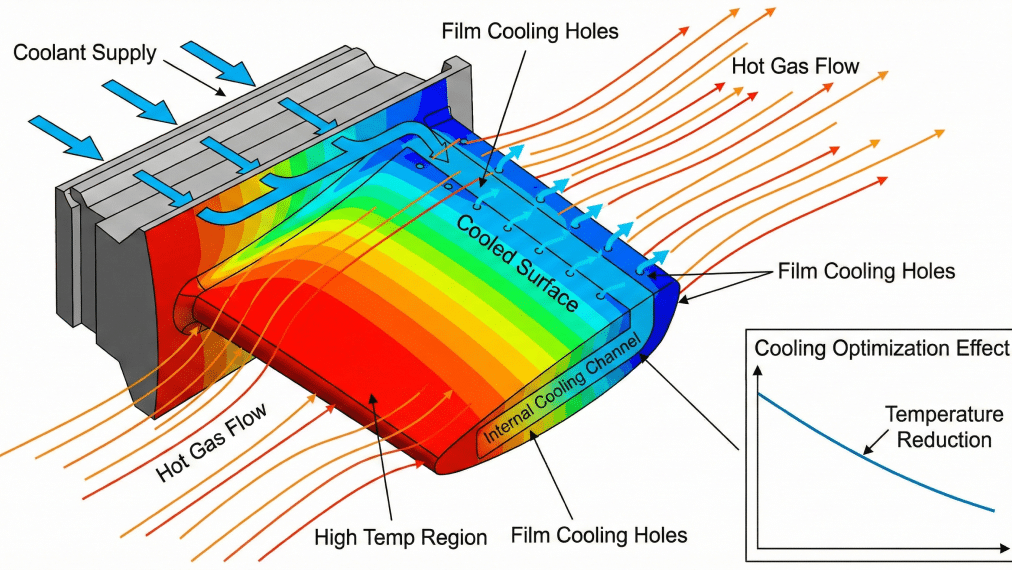

How Did MR CFD Optimize an Aerospace Cooling System Using CFD?

The aerospace industry (cfd in aerospace industry) operates on razor-thin margins regarding weight and thermal efficiency. One of our most challenging projects involved a mid-sized aerospace manufacturer struggling with the thermal management of a compact avionics bay.

The Challenge: Thermal Runaway in Tight Spaces

The client was developing a new flight control unit housed in a sealed enclosure. Preliminary physical testing showed that under peak load, the junction temperatures of critical PCBs were exceeding safety limits, threatening reliability. The traditional solution—adding larger, heavier heat sinks—was impossible due to strict weight penalties. They needed a cfd service to find a solution that improved cooling without adding mass.

The Simulation Strategy: Conjugate Heat Transfer (CHT)

We deployed a high-fidelity thermal management simulation using Ansys Fluent. The complexity lay in the physics: this was a Conjugate Heat Transfer (CHT) problem, where we had to solve for conduction within the solid components (chips, heat sinks, chassis) and convection in the cooling airflow simultaneously.

- Geometry & Meshing: We utilized a poly-hexcore mesh to accurately capture the boundary layers around the complex fin geometries while keeping the cell count manageable for rapid iteration.

- Turbulence Modeling: We selected the k-ω SST turbulence model, which is the industry standard for predicting flow separation and heat transfer near walls.

- Optimization Loop: By visualizing the airflow, we identified “dead zones” where air was recirculating rather than extracting heat.

The Result: 18% Gain in Cooling Efficiency

The simulation revealed that the original fan placement was creating a high-pressure zone that bypassed the hottest components. By redesigning the internal ducting and optimizing the fin spacing of the heat sinks based on the CFD results, we directed high-velocity air exactly where it was needed.

The outcome was significant:

- Temperature Reduction: Peak junction temperatures dropped by 12°C.

- Efficiency: Overall cooling efficiency improved by 18%.

- Weight Savings: We were actually able to reduce the size of the heat sinks, saving 0.4 kg per unit—a massive win in aerospace engineering.

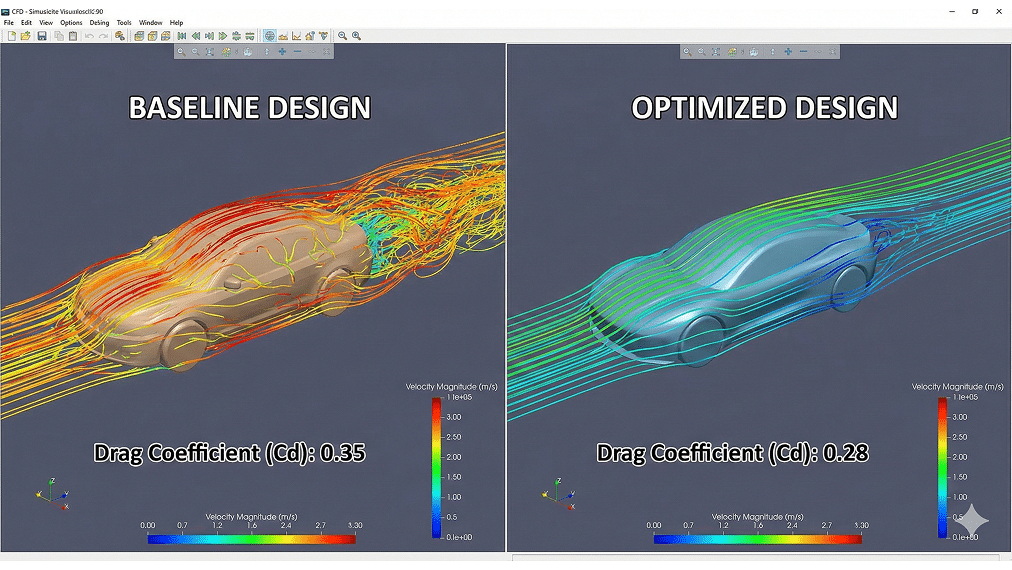

How Was CFD Used to Enhance Automotive Aerodynamics and Fuel Efficiency?

In the automotive sector, aerodynamics is directly tied to fuel economy (for ICE vehicles) or range (for EVs). We partnered with an automotive Tier 1 supplier tasked with reducing the drag coefficient (Cd) of a side-mirror assembly and A-pillar region for a new sedan.

The Problem: Aeroacoustic Noise and Drag

The client’s initial design was creating significant wake turbulence, contributing to both aerodynamic drag and wind noise (aeroacoustics). Wind tunnel testing is incredibly expensive—often costing thousands of dollars per hour—and visualizing the root cause of turbulence in a wind tunnel is notoriously difficult. They approached MR CFD for automotive aerodynamics optimization.

The MR CFD Approach: Transient Simulations

Steady-state RANS simulations are often insufficient for capturing the complex, shedding vortices behind a side mirror. We utilized a hybrid simulation approach:

- Baseline Analysis: Steady-state RANS to get a general flow field.

- Detailed Analysis: Transient (time-dependent) Scale-Resolving Simulations (SRS) to capture the unsteady wake structures.

We focused heavily on the turbulence modeling services aspect, ensuring that the separation points on the mirror housing were predicted accurately. The simulation highlighted that the curvature of the mirror arm was inducing a strong vortex that impacted the vehicle’s window, causing drag and noise.

Success by the Numbers 📉

Through 40+ virtual design iterations—something impossible to do in a physical wind tunnel within the project timeframe—we reshaped the mirror housing and added vortex generators to the A-pillar.

- Drag Reduction: The final design reduced the assembly’s contribution to drag by 4.5%.

- Fuel Economy: This seemingly small aerodynamic improvement translated to an estimated 0.8% improvement in overall highway fuel efficiency.

- Cost Savings: The client estimated that cfd simulation in aerospace engineering and automotive workflows saved them roughly $150,000 in wind tunnel rental and prototyping costs.

How Did MR CFD Support a Renewable Energy Startup with Wind Turbine CFD Analysis?

Startups in the renewable energy sector often face a “Valley of Death”—they need high-efficiency designs to secure funding, but they lack the capital for full-scale prototyping. MR CFD acted as the dedicated R&D partner for a small wind turbine company developing a novel vertical-axis wind turbine (VAWT) for urban environments.

The Challenge: Complex Wake Interactions

Vertical axis turbines are notoriously difficult to model because the blades are constantly changing their angle of attack relative to the wind, leading to massive flow separation and dynamic stall. The startup needed to prove their efficiency numbers to investors but had no working full-scale prototype.

The Solution: High-Fidelity Energy System CFD Modelling

We positioned ourselves as their best cfd outsourcing partner, providing the high performance computing for cfd resources they lacked internally.

- Dynamic Meshing: We used sliding mesh techniques in Ansys Fluent to simulate the actual rotation of the turbine.

- Wake Analysis: The critical factor was how the wake of one blade affected the others. We visualized the vorticity magnitude to refine the blade pitch angle.

- Validation: We cross-referenced our results with benchmarked CFD results from similar NREL (National Renewable Energy Laboratory) studies to ensure credibility.

The Impact 🌍

The energy system cfd modelling allowed the startup to optimize the blade airfoil profile before building a single mold.

- Power Output: The optimized design showed a 15% increase in power coefficient (Cp) at low wind speeds, which is crucial for urban environments.

- Investor Confidence: The detailed simulation reports and flow visualizations served as technical due diligence, helping the startup secure their Series A funding. This project highlighted how CFD consulting services can be a strategic business asset, not just an engineering tool.

How Did CFD Improve Thermal Management in Power Electronics?

As power electronics become smaller and more powerful, heat flux densities are skyrocketing. A leading manufacturer of industrial power inverters approached us with a critical failure mode: their IGBT modules were overheating during cyclic loading, leading to premature bond wire failure.

The Engineering Hurdle: Transient Thermal Spikes

The problem wasn’t steady-state operation; it was the transient spikes during start-up and load shifting. A standard steady-state thermal analysis missed these spikes entirely.

The Intervention: Thermal-Fluid Coupling & PCM

We conducted a comprehensive thermal management simulation that coupled the electrical losses (heat generation) with the fluid dynamics of the cooling system.

- Phase Change Materials (PCM): We explored the integration of a PCM layer within the heat sink. We simulated the melting and solidification cycles of the PCM to see if it could absorb the transient heat spikes.

- Heat Sink Optimization: We used parametric optimization to vary the fin thickness and density to find the “sweet spot” between surface area and pressure drop.

ROI in Reliability

The industrial cfd analysis proved that a standard aluminum heat sink was insufficient for the load spikes. However, the simulation predicted that incorporating a specific paraffin-based PCM would buffer the temperature fluctuations.

- Lifespan Extension: The simulations predicted a reduction in thermal cycling stress by 30%, theoretically doubling the operational lifespan of the inverter.

- Field Validation: Subsequent accelerated life testing confirmed the CFD predictions, validating the use of best practice modeling guidelines.

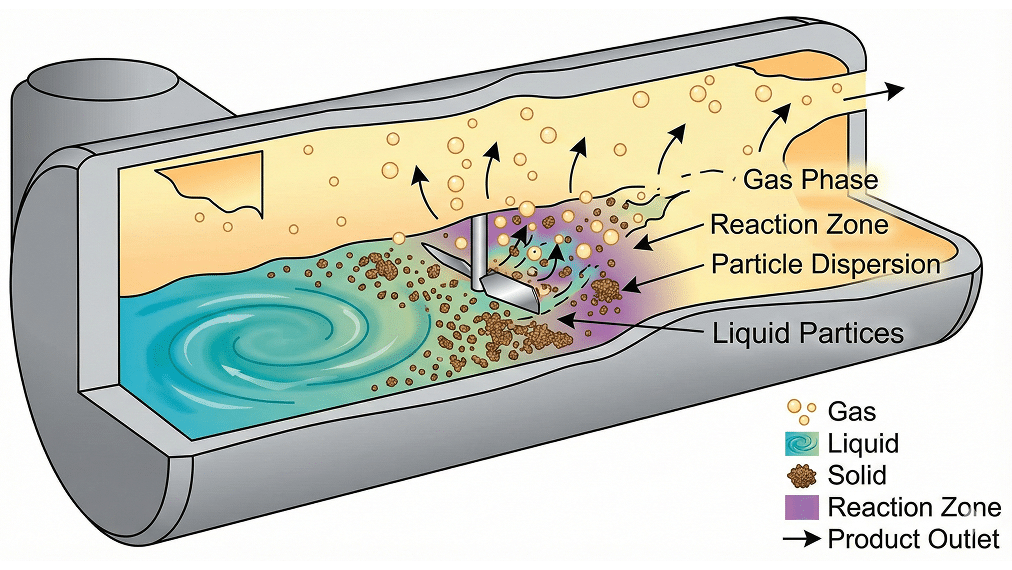

How Did MR CFD Model a Complex Multiphase Process in the Chemical Industry?

Perhaps the most complex physics we encounter involves multiphase flow cfd analysis—where gas, liquid, and solids interact simultaneously. A chemical processing client needed to scale up a stirred tank reactor from a 5-liter lab bench model to a 5,000-liter industrial vessel.

The Risk: The Scale-Up Trap

Scaling up chemical reactors is linear in geometry but non-linear in physics. What mixes well in a beaker often separates or fails to react in a giant tank due to poor circulation. The client could not afford a failed batch at the 5,000-liter scale.

The Simulation: Eulerian-Eulerian Multiphase Model

This project required the highest level of certified Ansys Fluent expert knowledge.

- Multiphase Physics: We used the Eulerian-Eulerian multiphase model to track the volume fraction of gas bubbles dispersed in the liquid reactant.

- Reaction Modeling: We coupled the flow with species transport equations to simulate the chemical reaction rate based on local mixing intensity.

- Impeller Design: We analyzed different impeller shapes (Rushton vs. Pitch Blade) to maximize gas hold-up and interfacial area.

The Outcome: First-Time-Right Engineering ⚗️

The CFD results showed that the geometric similarity scale-up would result in dead zones at the bottom of the tank. We recommended a modified baffle design and a dual-impeller setup.

- Yield Improvement: The optimized design achieved a 98% reaction yield, matching the lab-scale performance.

- CAPEX Savings: By simulating the process first, the client avoided purchasing an expensive, under-performing agitation system. This project exemplifies the power of cfd service work in de-risking capital projects.

What Key Lessons Can Engineers and Managers Learn from These CFD Projects?

Analyzing these five diverse success stories, several common threads emerge that can guide engineering managers and technical leads. Whether you are looking for cfd simulation in aerospace engineering or automotive aerodynamics optimization, the lessons remain consistent.

1. Detailed Problem Definition is 80% of the Battle

In every case—from the wind turbine to the avionics bay—the success was not just in the software usage but in defining the right boundary conditions and physics. Simulating the wrong problem correctly is still a failure.

2. Validation is Non-Negotiable

You cannot trust a colorful fluid dynamics picture without backing it up. Validation against experimental data or established benchmarks is what separates a cfd service company from a graphic design house.

3. Leverage HPC and Automation

Complexity is free in the real world, but expensive in simulation. To capture transient effects (like the car mirror) or multiphase interactions (like the reactor), you must have access to high performance computing for cfd. Attempting these on a standard workstation leads to over-simplified models and poor accuracy.

4. Cross-Functional ROI Communication

The most successful projects occur when the engineering results are translated into business language. Don’t just report “turbulence kinetic energy”; report “fuel savings” or “warranty reduction.”

Why Partner with MR CFD for Your Next Industrial CFD Project?

At MR CFD, we don’t just sell hours of calculation time; we sell engineering certainty.

With over 20+ years of experience, we have refined our workflow to handle the most demanding computational fluid dynamics projects. Our team consists of certified Ansys Fluent experts who understand the nuances of numerical methods and the realities of manufacturing constraints.

The MR CFD Advantage:

- In-House HPC Infrastructure: We possess the computational power to run high-fidelity LES, DES, and URANS simulations that others shy away from.

- Cross-Industry Versatility: Our insights from aerospace cooling often solve problems in automotive battery thermal management. Cross-pollination of ideas is our strength.

- Educational Partnership: We believe in empowering our clients. We offer CFD Ansys Fluent Courses and training so your team can understand the “why” behind our results.

Whether you need a full-service cfd consulting partner to take a project from concept to validation, or an expert to troubleshoot a specific physics problem, MR CFD is built to deliver measurable ROI.

Frequently Asked Questions

What industries benefit most from CFD service projects?

While almost any industry involving fluid or heat can benefit, the highest ROI is typically seen in Aerospace (aerodynamics, cooling), Automotive (drag reduction, battery thermal management), Energy (wind, oil & gas multiphase), Chemical Processing (mixing, reactors), and HVAC (data center cooling, indoor air quality). These sectors involve complex physics where physical testing is prohibitively expensive or dangerous.

How long does a typical CFD consulting project take?

Project timelines vary based on complexity. A standard steady-state component analysis might take 1–2 weeks, including setup, solving, and reporting. Complex multiphase flow cfd analysis or transient simulations involving moving meshes can take 4–8 weeks. At MR CFD, we provide a detailed Gantt chart during the proposal phase to align with your product development cycle.

Can MR CFD assist with both design and troubleshooting phases?

Absolutely. We support the entire lifecycle. In the design phase, we perform “virtual prototyping” to select the best concepts. In the troubleshooting phase (forensic engineering), we analyze existing failures—such as overheating components or flow-induced vibration—to identify root causes and propose retrofits.

What simulation tools and solvers does MR CFD use?

Our primary workhorse is Ansys Fluent, widely recognized as the gold standard for industrial CFD. We also utilize Ansys CFX for turbomachinery and Ansys Rocky for discrete element modeling (DEM) where particle interaction is key. We complement these with proprietary scripts and peer-reviewed simulation methods to ensure the highest fidelity.

How accurate are CFD predictions compared to experiments?

When best practice modeling guidelines are followed, CFD is incredibly accurate. For single-phase flows, we typically achieve agreement within 3–5% of experimental data. For complex multiphase or combustion problems, accuracy is generally within 10–15%. We always strive for validation against experimental data provided by the client or literature to calibrate our models.

How does MR CFD ensure data confidentiality for client projects?

We treat IP security with the utmost seriousness. We sign comprehensive Non-Disclosure Agreements (NDAs) before seeing any geometry. Our data transfer servers are encrypted, and we have strict internal protocols to ensure your proprietary designs remain confidential. We are a trusted cfd outsourcing partner for major OEMs who require strict security.

What is the cost structure for a typical CFD service engagement?

Costs are determined by the complexity of the geometry, the physics involved (e.g., simple flow vs. reacting flow), and the required turnaround time. We typically operate on a fixed-price project basis so there are no surprises. This investment is almost always a fraction of the cost of building a failed physical prototype.

Are CFD training courses available alongside consulting?

Yes! We believe in knowledge transfer. We offer specialized CFD Ansys Fluent Courses ranging from beginner to advanced levels. Many clients hire us for a consulting project and then have their internal engineers take our courses to learn how to maintain and update the models we created.

What file formats and CAD models can MR CFD work with?

We can work with virtually any industry-standard CAD format. Preferred formats include STEP (.stp) and Parasolid (.x_t) as they provide the cleanest geometry for meshing. We can also work with native files from SolidWorks, CATIA, NX, and Inventor.

How can I start my first CFD project with MR CFD?

Starting is simple. Contact us with a brief description of your problem. We will set up a discovery call to understand your objectives. From there, we define the scope, agree on deliverables, and begin the industrial cfd analysis. You provide the CAD and operating conditions; we deliver the physics-based insights to solve your challenge. ✅

Ready to leverage the power of advanced simulation? Contact MR CFD today to discuss how our cfd service can optimize your next engineering breakthrough.

Comments (0)