Nanofluid and Twisted Tape Inserts in a Tube, Validation

$240.00 Student Discount

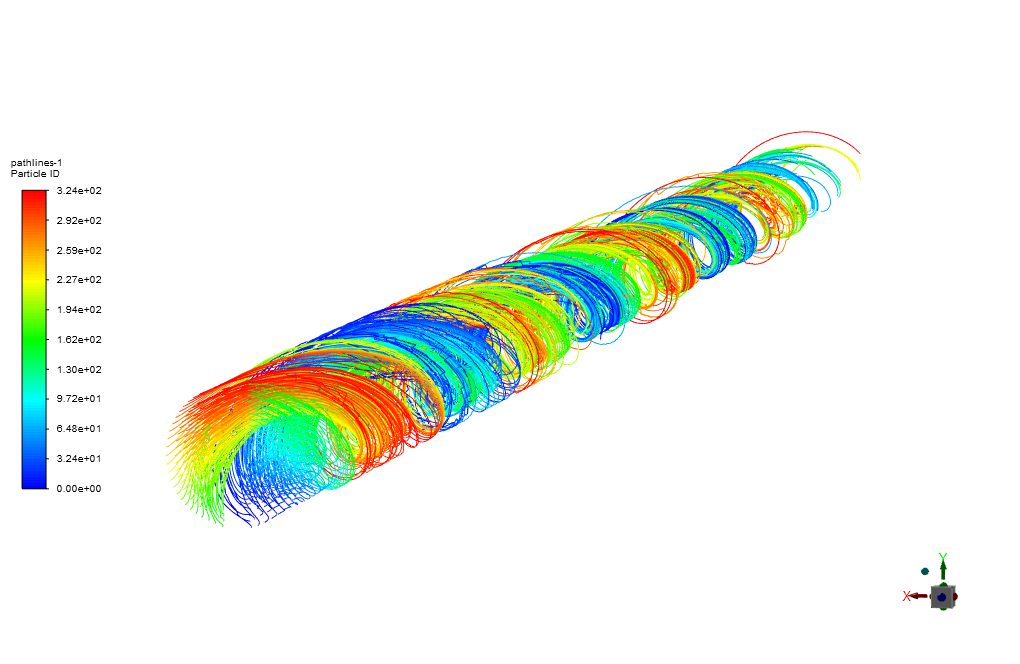

- The problem numerically simulates the Al2O3-Water Nanofluid in a Tube with Twisted Tape Inserts using ANSYS Fluent software.

- We design the 3-D model with the Design Modeler software.

- We mesh the model with ANSYS Meshing software, and the element number equals 2148662.

- We define Nanofluid with two methods, including the Multiphase model and fluid properties.

- This simulation is validated with a reference article.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Al2O3-Water Nanofluid in a Tube with Twisted Tape Inserts, Paper Numerical Validation, CFD Simulation Tutorial by ANSYS Fluent

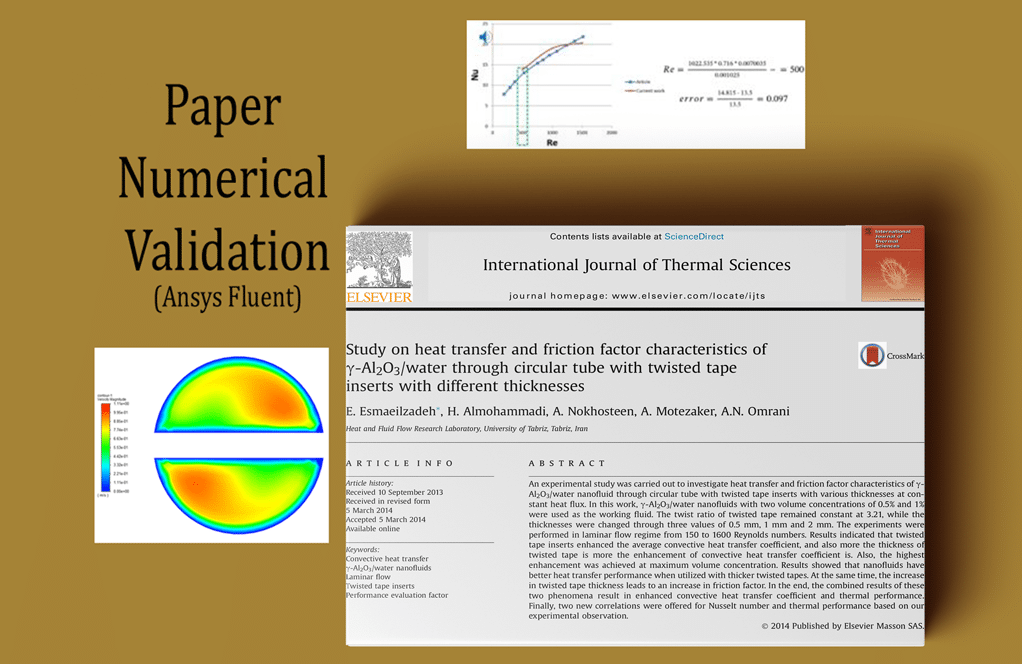

This problem simulates the Al2O3-water flow inside a circular tube with twisted tape inserts by ANSYS Fluent software. The simulation is based on the reference article “Study on heat transfer and friction factor characteristics of Al2O3-water through circular tube twisted tape inserts with different thicknesses’’.

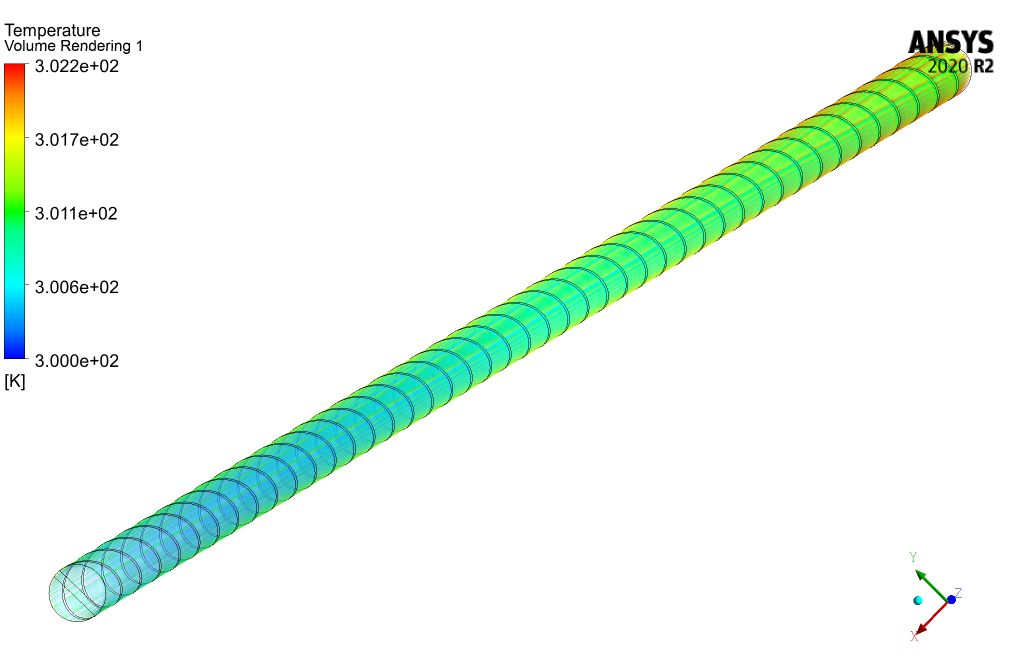

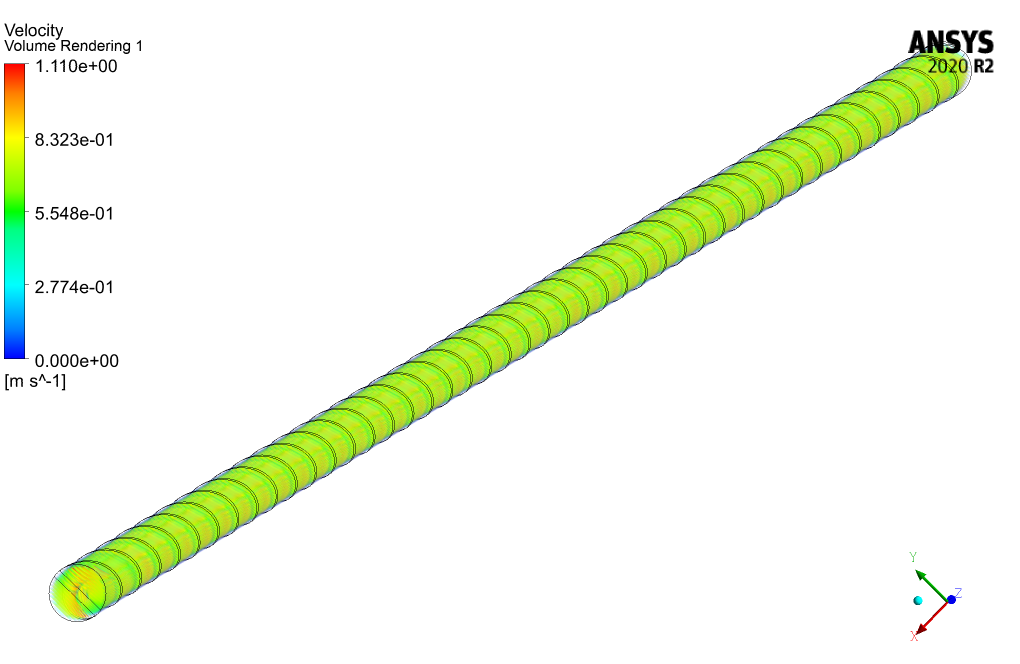

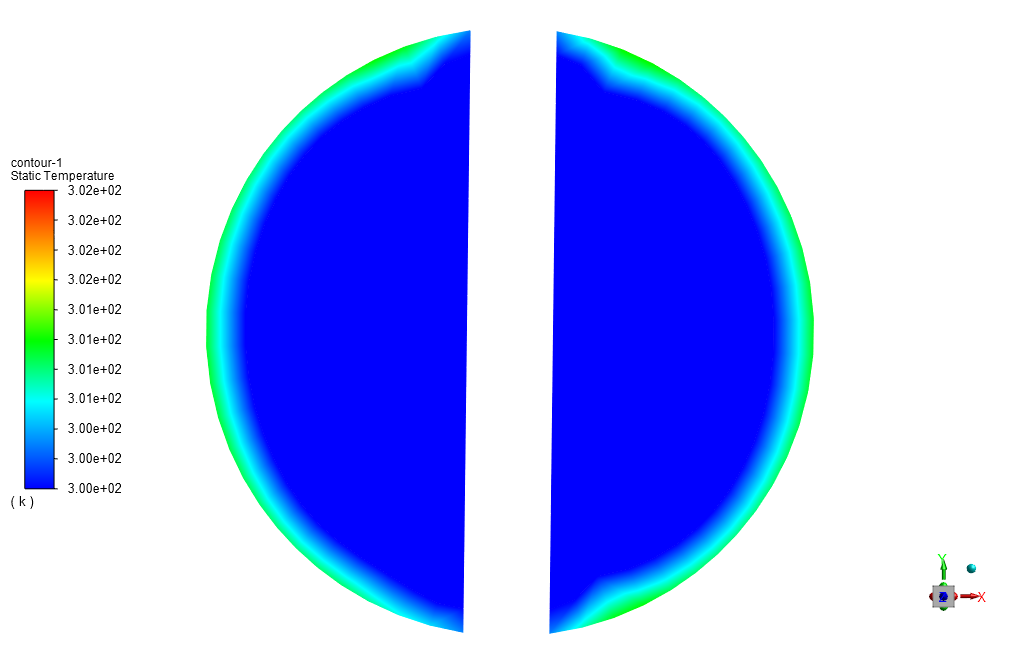

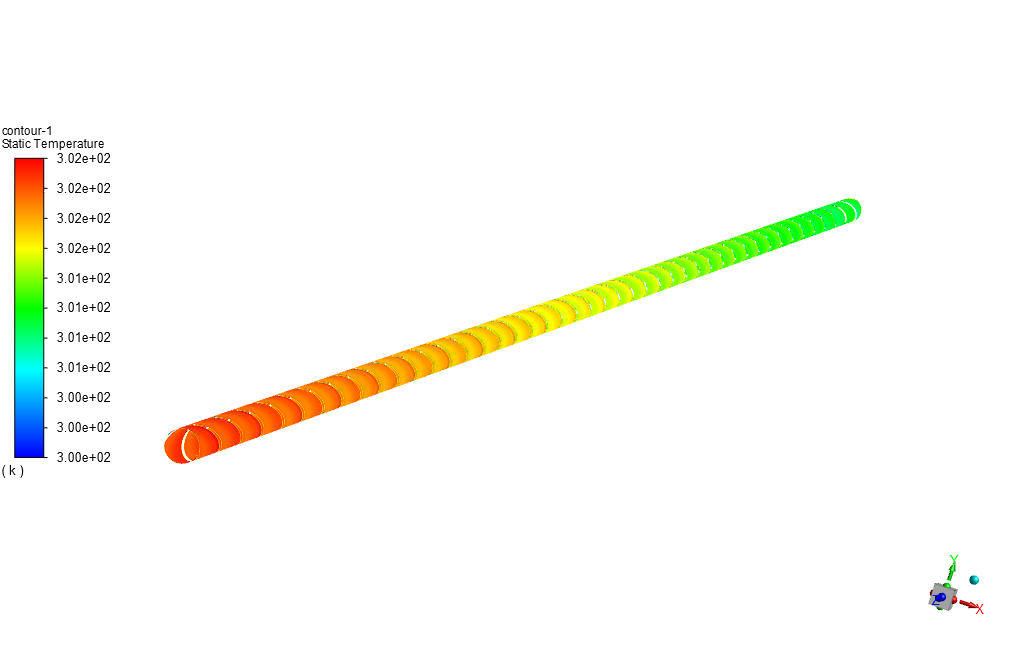

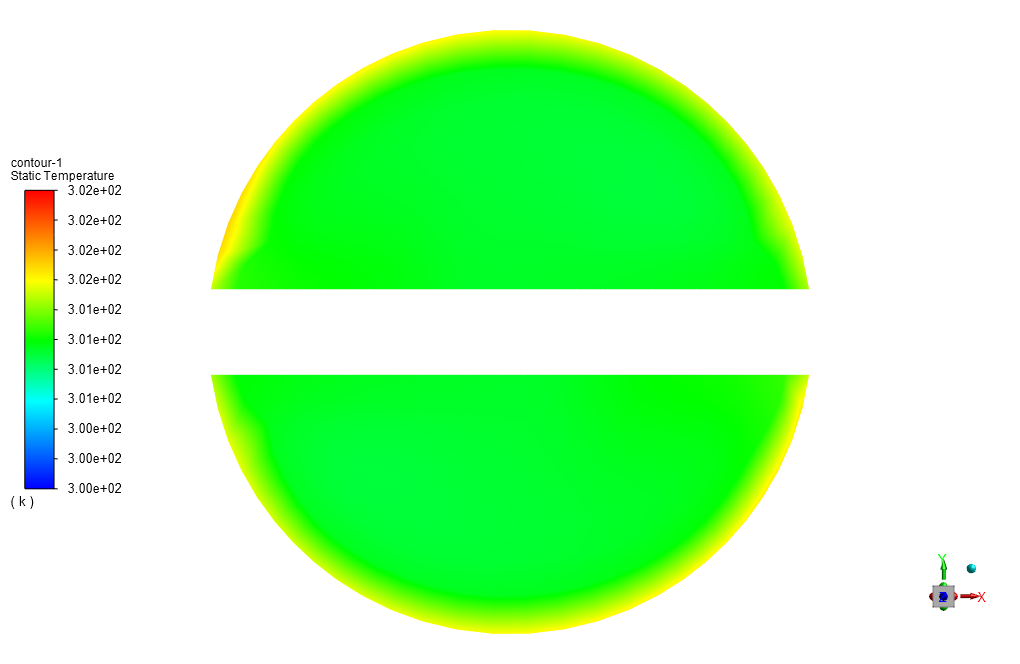

Its results are compared and validated with the results in the article. In this project, the Al2O3-water fluid will enter the computational zone with an initial temperature of 300 K and a velocity of 0.716 m/s (referring to Reynolds number=500) through a multiple-staged twisted circular tube.

The twisted tube’s outer wall is exposed to a heat flux rate of 5000 W/m2 and causing the fluid flow’s temperature to increase.

The geometry of this project is designed in ANSYS design modeler and is meshed in ANSYS meshing software. The mesh type used for this geometry is structured, and the element number is 2146882.

Al2O3-Water Methodology

Nanofluids are compounds consisting of a base fluid that is filled with fine solid particles. The dimensions of these fine particles are at the nanoscale. A multiphase model (including base fluid and solid particles) can be used to model these nanofluids, But this method has a high computational cost.

Then another method is used for this simulation. To determine the properties of nanofluids (such as density, specific heat capacity, thermal conductivity and viscosity), relations and formulas can be used, each of which includes parameters related to the properties of the base fluid and solid particles.

Therefore, a new material called nanofluid can be defined in the computational zone.

Al2O3-Water Conclusion

After simulation, the present work results are compared with results obtained by the paper. For this purpose, the diagram in Figure 10 was used, which shows the Nu number’s changes over different Re numbers. It should also be noted that we have validated the results for Re number =500.

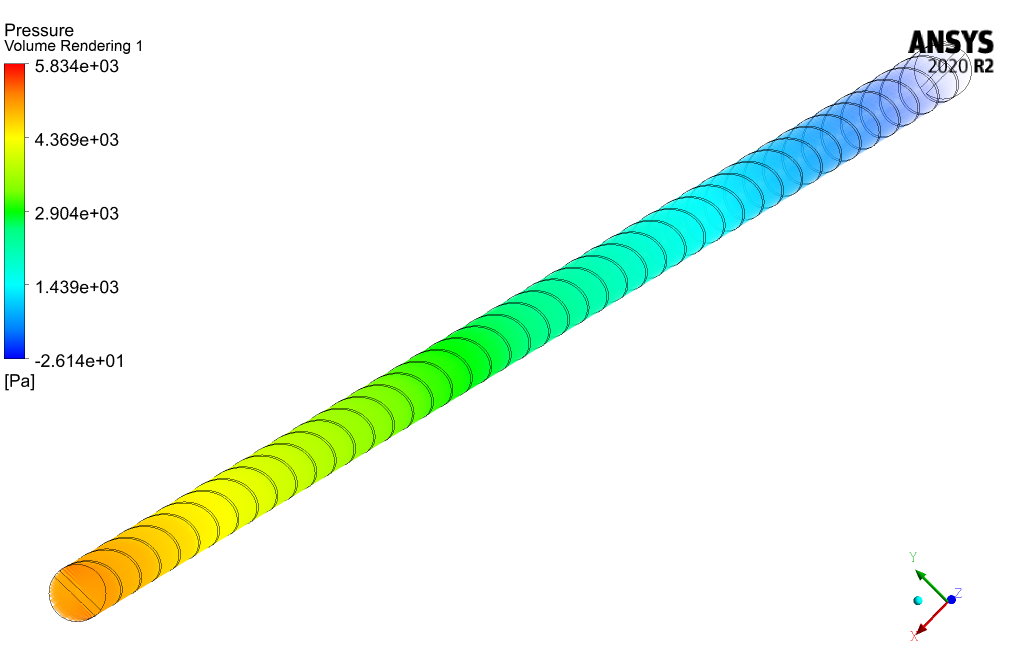

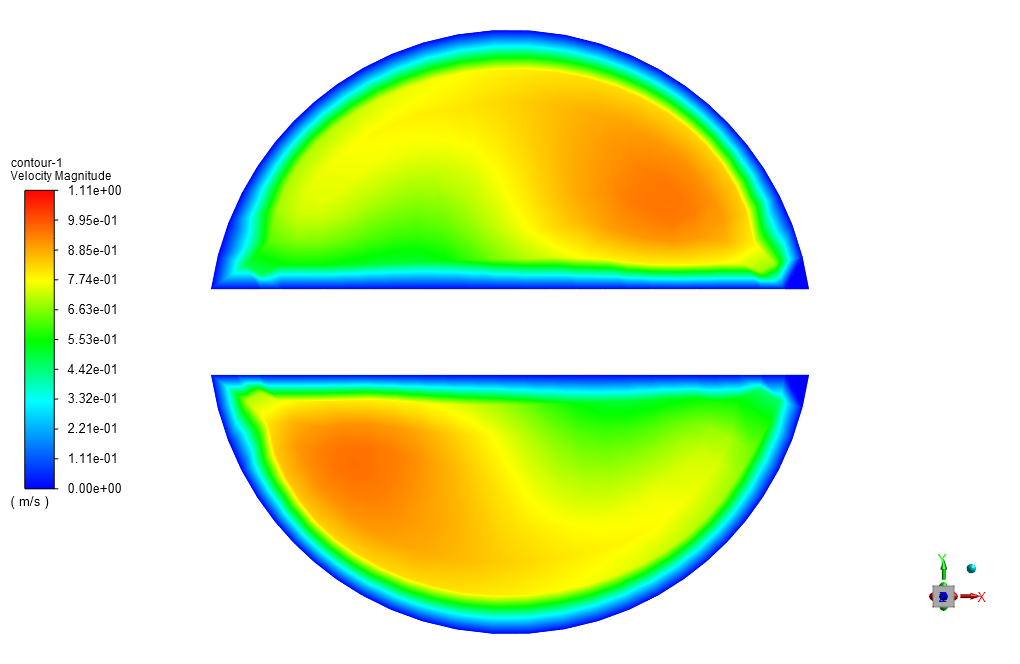

The results show that the error rate is low, and the current simulation is performed correctly. Also, the contours of pressure and velocity are obtained. Contours show that the nanofluid pressure decreases along the path passing through the twisted tapes; Because the presence of these obstacles breaks the pressure.

On the other hand, the temperature of the nanofluid also increases. When a spiral barrier is placed in the path of the nanofluid, the nanofluid travels a longer distance and makes more contact with the outer wall under heat flux.

Irma Stehr –

Hello, are the relationships between fluids and nanofluids different?

And did you use validation in this project?

MR CFD Support –

This work has been used for the simulation correctly using the Study on heat transfer and friction factor characteristics of γ-Al2O3 / water through circular tube twisted tape inserts with different thicknesses. The relationships from this article have also been used.

Mr. Stephon Hackett DVM –

I was satisfied with the production and content of this training, and I think there was no weakness.

Prof. Bettie O’Kon Jr. –

Very great.

Ms. Florine Legros IV –

The results were both informative and interesting, but I’m especially curious about the practical applications of Al2O3-Water in tubes with twisted tape inserts. Can MR CFD provide any real-world examples or case studies where this might be implemented?

MR CFD Support –

Certainly! Twisted tape inserts along with Al2O3-water nanofluids can be effectively used in heat exchanger tubes to improve heat transfer efficiency. This is particularly beneficial in industries where cooling is critical, such as in chemical processing, power generation, and HVAC systems for large buildings. The enhanced thermal properties of nanofluids combined with the turbulent flow induced by twisted tapes can significantly improve heat transfer rates, leading to more compact and cost-effective cooling systems.

Jodie Runolfsson –

I am impressed by how well the simulation results matched with the article’s data for Re=500! Can you tell me the exact error rate mentioned for this data point in your comparison?

MR CFD Support –

We appreciate your interest and are glad you noticed the accuracy of our simulation. Unfortunately, as a chatbot, I do not have the specific numeric error rate. MR CFD endeavors to achieve and report results with minimal error to ensure your simulations provide insightful and accurate data, matching reference material when validated.

Ms. Francisca Keebler –

I’m interested in how accurate the simulation results were when compared with the experimental data in the reference article. Could you provide more detail regarding the degree of accuracy achieved for the Nu number at different Re numbers?

MR CFD Support –

The simulation achieved a high degree of accuracy in reproducing the Nu number changes across varying Re numbers according to the reference article. For the validated case of Re number = 500, as referenced in the comparison to Figure 10 in the article, the error rate was notably low. This indicates that the numerical methods and models applied in the simulation are effectively capturing the required physics for this CFD study.

Akeem Gusikowski –

I was truly impressed with the Al2O3-water nanofluid and twisted tape insert simulation tutorial by MR CFD. The validation step against the scientific paper’s data provided confidence in the simulation results. The structured mesh was detailed and provided great insight into the fluid flow behavior, pressure drop, and heat transfer enhancement due to the twisted tape inserts. The tutorial was a big help in understanding how adding nanoparticles can significantly alter the thermal properties of a fluid. Excellent work!

MR CFD Support –

Thank you for your thoughtful review! We are thrilled to learn that our tutorial on Al2O3-water nanofluid with twisted tape inserts was able to facilitate a deeper understanding of nanofluid behavior and its enhanced heat transfer capabilities. It’s always our goal to provide accurate and reliable simulations that can be validated against reputable sources, and we’re glad that this tutorial met your expectations. We appreciate your feedback and look forward to supporting your future CFD endeavors!

Cordia Davis –

This is such an intriguing simulation study, understanding the impacts of twisted tape inserts on flow dynamics is super important. The CFD approach is detailed and the close match with the reference paper’s findings builds a lot of confidence in the methodology and outcome. Excellent work on visualizing the change in pressure and temperature contours as a result of the twisted tapes!

MR CFD Support –

Thank you for your kind words! We are delighted to hear that you appreciate the depth and accuracy of the simulation. Your understanding of the significance of twisted tape inserts on the flow dynamics and the importance of validation exemplifies the quality we aim for in our education materials. Thank you for your review, and we hope our products continue to support your learning and research endeavors.

Gladyce Heidenreich –

I’ve learned so much from this tutorial! The detailed comparison between the simulation and the actual study along with clear explanations of the methodology have provided a deeper understanding of heat transfer within nanofluids.

MR CFD Support –

We are so happy to hear that you found the tutorial informative and helpful! It is always our goal to ensure that our simulations provide deep, practical insights and are as accurate as possible. Thank you for your positive feedback!

Alaina Senger –

This tutorial seems fantastic! I’m especially impressed by the validation aspect compared to the research paper. Is there any further information about how the error rate was quantitated between the CFD simulation and the experimental results?

MR CFD Support –

In this simulation, the error rate is evaluated by comparing the Nusselt number (Nu) results from the CFD analysis with those provided in the reference paper for a Reynolds number of 500. The comparison typically involves calculating the percentage error between the CFD simulated values and the empirical data. However, specific details on the error calculation process are not provided here.

Creola Murazik –

I appreciate the comprehensive insights into the heat transfer characteristics with varied thicknesses in twisted tape inserts. Good to see that the simulation errors were minimal, showing a precise methodology. Kudos to the team for ensuring accuracy in line with the reference article.

MR CFD Support –

Thank you for your positive feedback! We strive to ensure our simulations provide accurate and reliable results that align well with authoritative references. Your recognition is greatly appreciated, and we are pleased you found the service informative and precise. If you have any further questions or need additional insights, don’t hesitate to reach out.

Dr. Elisabeth Bauch III –

I’m blown away by how well the validation process with the reference paper went! Spot on with the error rates. Just a quick thought, could you tell whether similar twisted tape inserts might be useful in improving heat transfer for other types of nanofluids as well?

MR CFD Support –

Thank you for your kind remarks! Indeed, twisted tape inserts can be effective in improving heat transfer in tubes for various types of nanofluids, not just Al2O3-water. The increased turbulent mixing and extended surface area provided by the tapes generally enhance the thermal performance, although the specific improvements would depend on the properties of the nanofluid in question.

Twila Mills II –

Does the methodology mentioned in the simulation handle the nanoparticle sedimentation issue in nanofluids?

MR CFD Support –

In this tutorial, the nanoparticle sedimentation is not specifically mentioned; instead, a homogeneous single-phase approach to model the nanofluid is used, where the effective properties of the nanofluid are calculated based on relations and formulas. This significantly reduces computational costs and avoids the need to explicitly simulate the particle dynamics that would be required to track sedimentation.

Dr. Braden Buckridge –

I found the section about the pressure and temperature changes in the fluid particularly interesting. Can you explain more about how the twisted tapes affect the heat transfer efficiency in the tube?

MR CFD Support –

The inclusion of twisted tape inserts within the tube enhances the heat transfer efficiency by interrupting the fluid flow which promotes turbulence. This disrupted flow increases the fluid’s contact with the tube’s surface area as it navigates the spirals of the tapes. Consequently, enhanced turbulence and surface contact elevate the heat exchange between the tube wall and the nanofluid, improving the overall effectiveness of heat transfer.

Johnny Kunze –

I am thrilled with how accurate the simulation results align with the referenced article’s data for Reynolds number=500. This validation step gives much confidence in applying these methods for real-life engineering problems.

MR CFD Support –

Thank you so much for your positive feedback! We’re delighted to hear that the accuracy of our simulations has met your expectations and provided valuable insights. It’s rewarding for us to know our product can serve as a reliable tool for your engineering projects. If there’s anything else you need or would like to learn more about, please don’t hesitate to reach out to us.