Airflow Inside the Air Intake Room, Design Improvement CFD Simulation

$110.00 Student Discount

- The problem numerically simulates an Airflow Inside the Air Intake Room in ANSYS Fluent software.

- The 3D geometry of the model is created in SpaceClaim software.

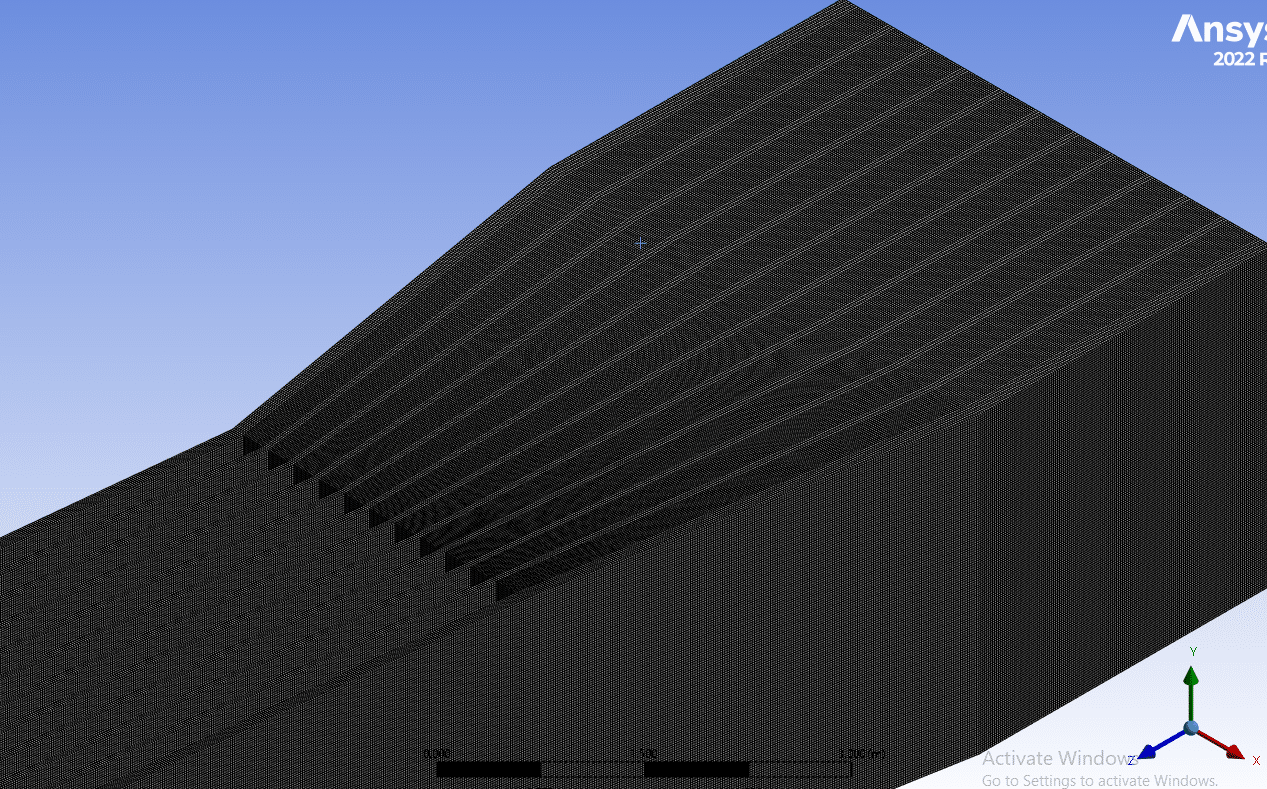

- The model is meshed in ANSYS Meshing creating 13,103,505 and 13,867,650 elements for the first and second case respectively.

- The Discrete Phase Model (DPM) is used to simulate purifying process.

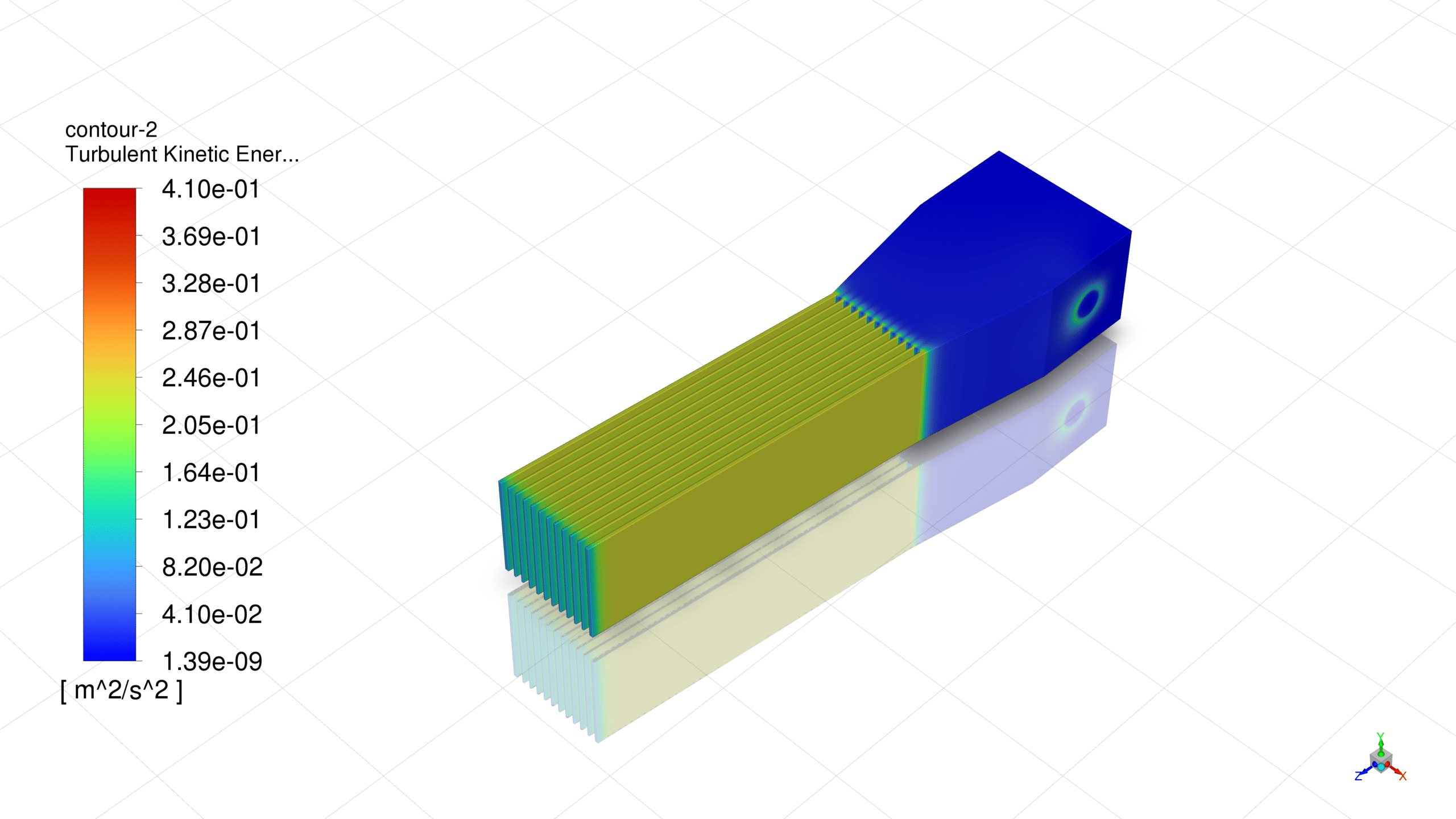

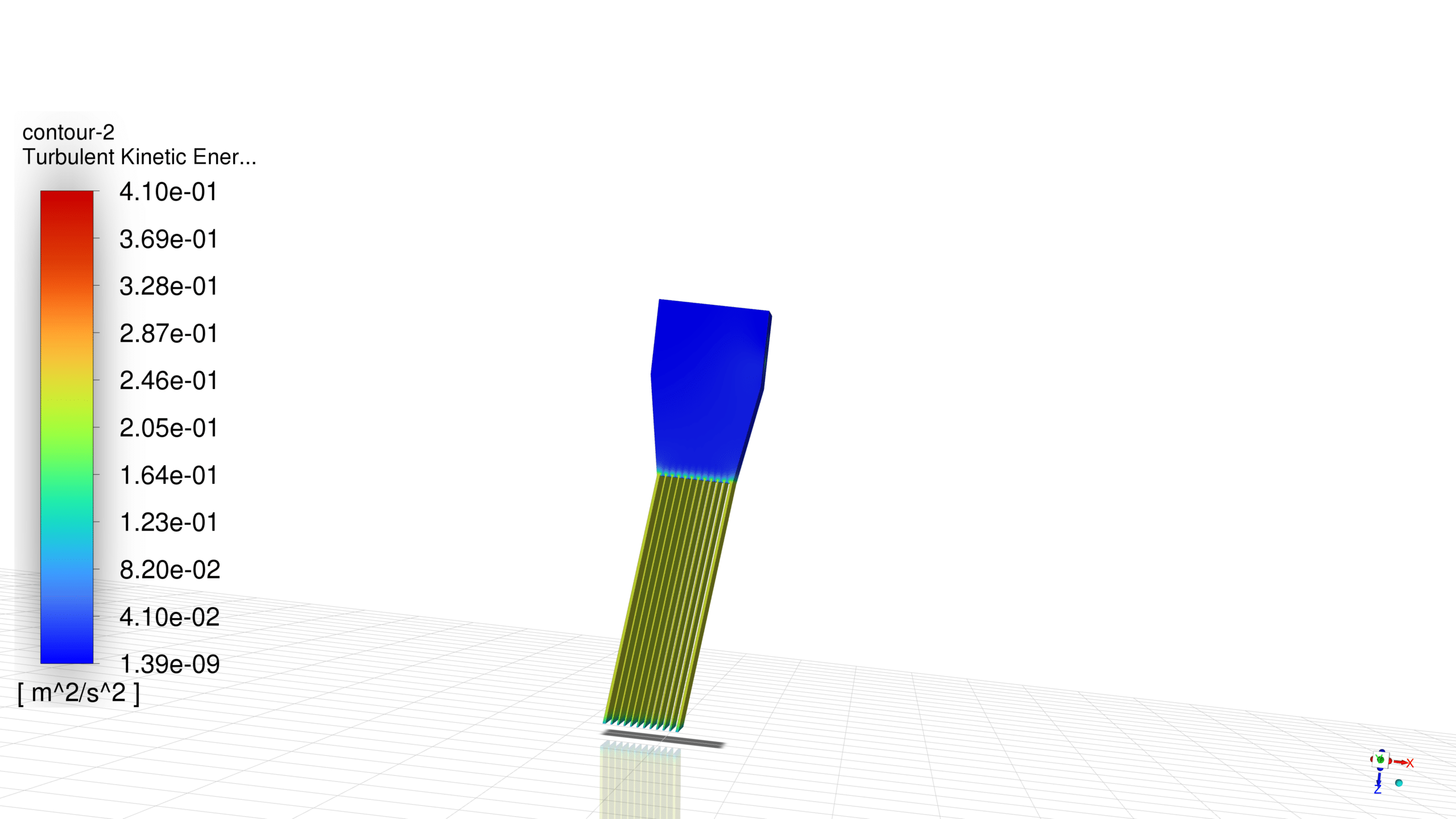

- The Realizable k-epsilon model is used to describe turbulence of the flow.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Airflow Inside the Air Intake Room Description

The present simulation is about airflow inside the air intake room for a gas turbine via ANSYS Fluent. In this project, an air intake room is designed for gas turbines. An air intake filtration system is essential for the successful operation of a gas turbine.

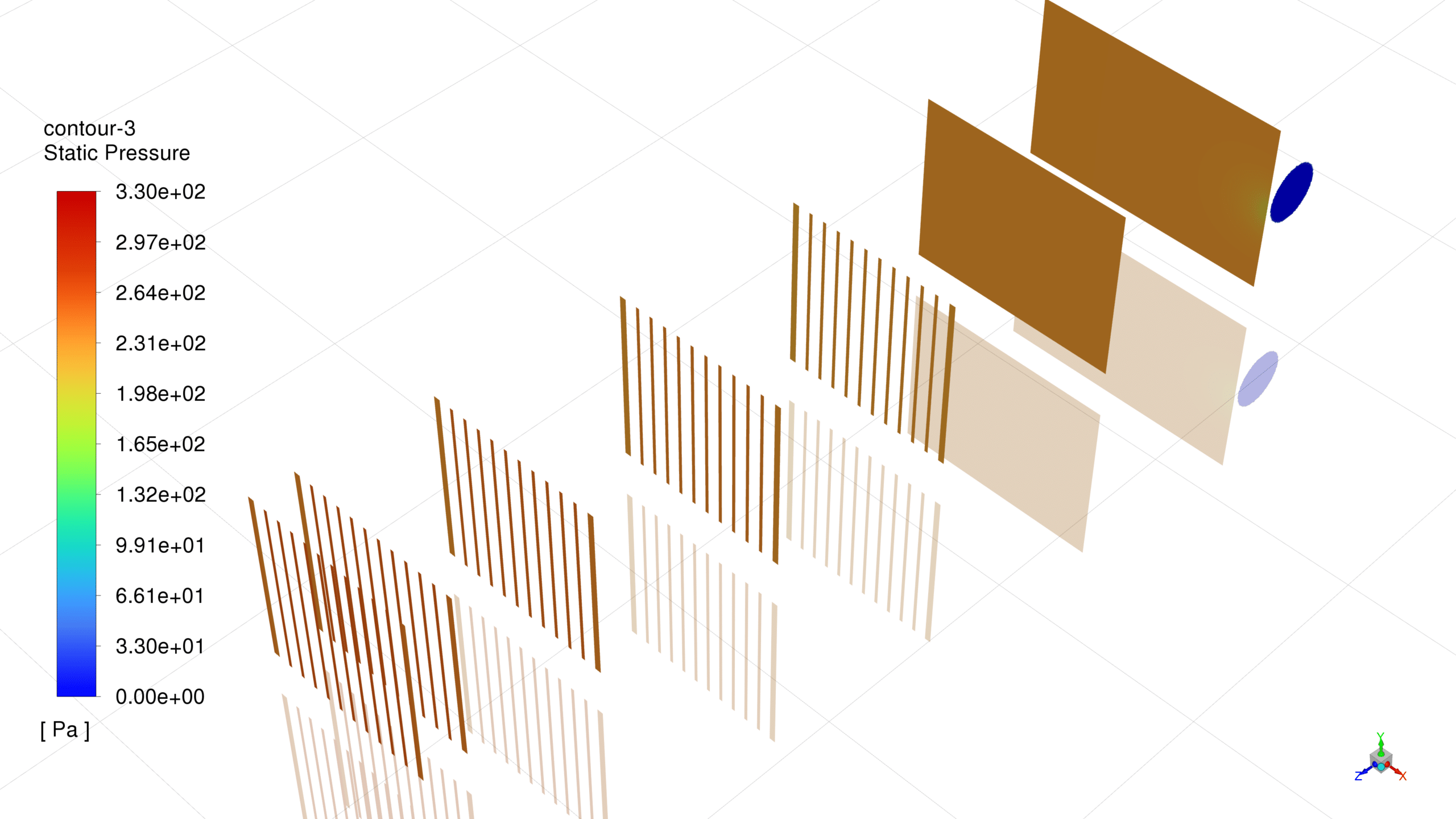

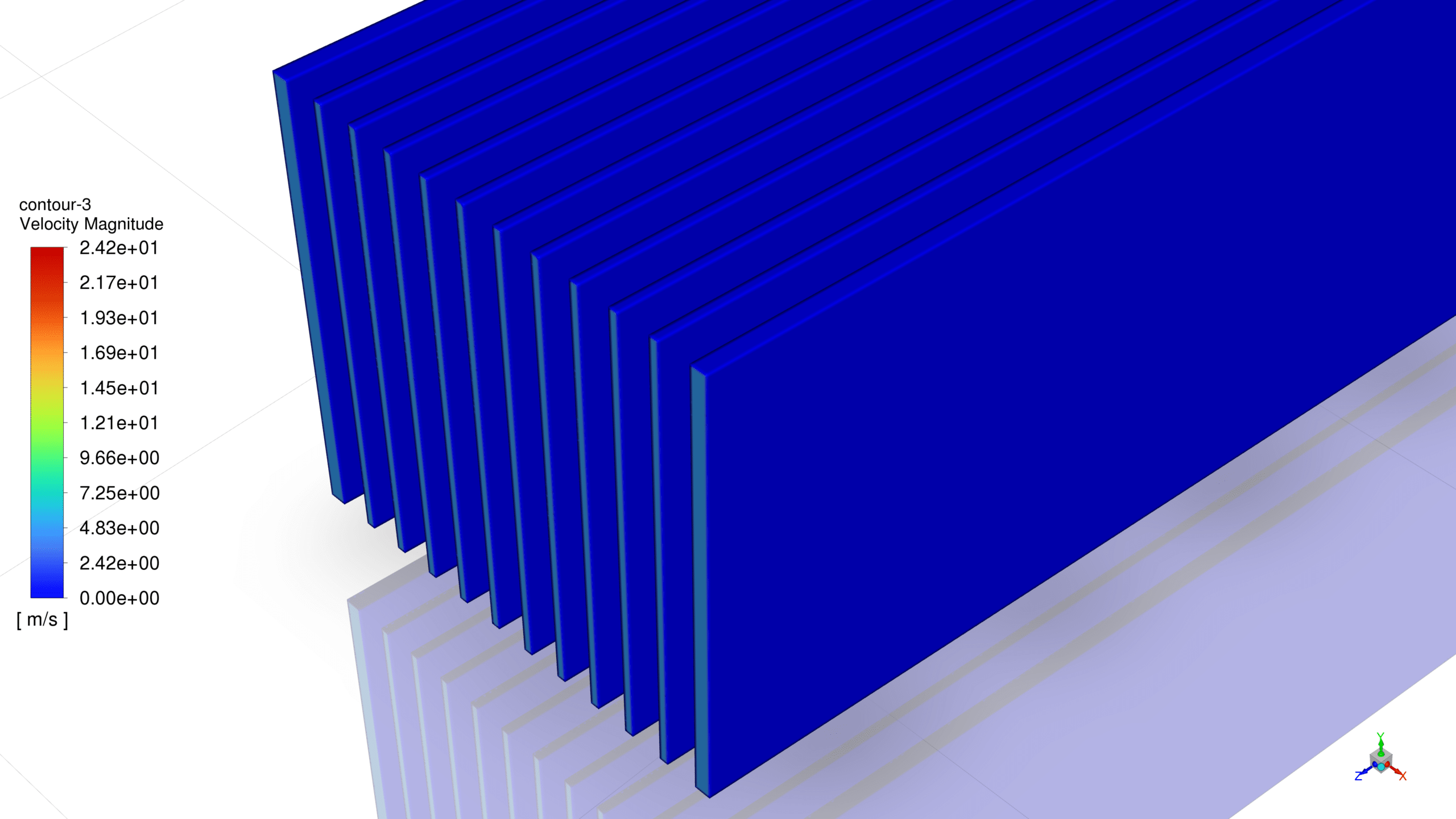

This system protects the gas turbine from dust particles in the ambient air; Because these suspended particles in the air cause destructive phenomena such as erosion, fouling, collision, etc. This system consists of some rows of parallel plates in the input section.

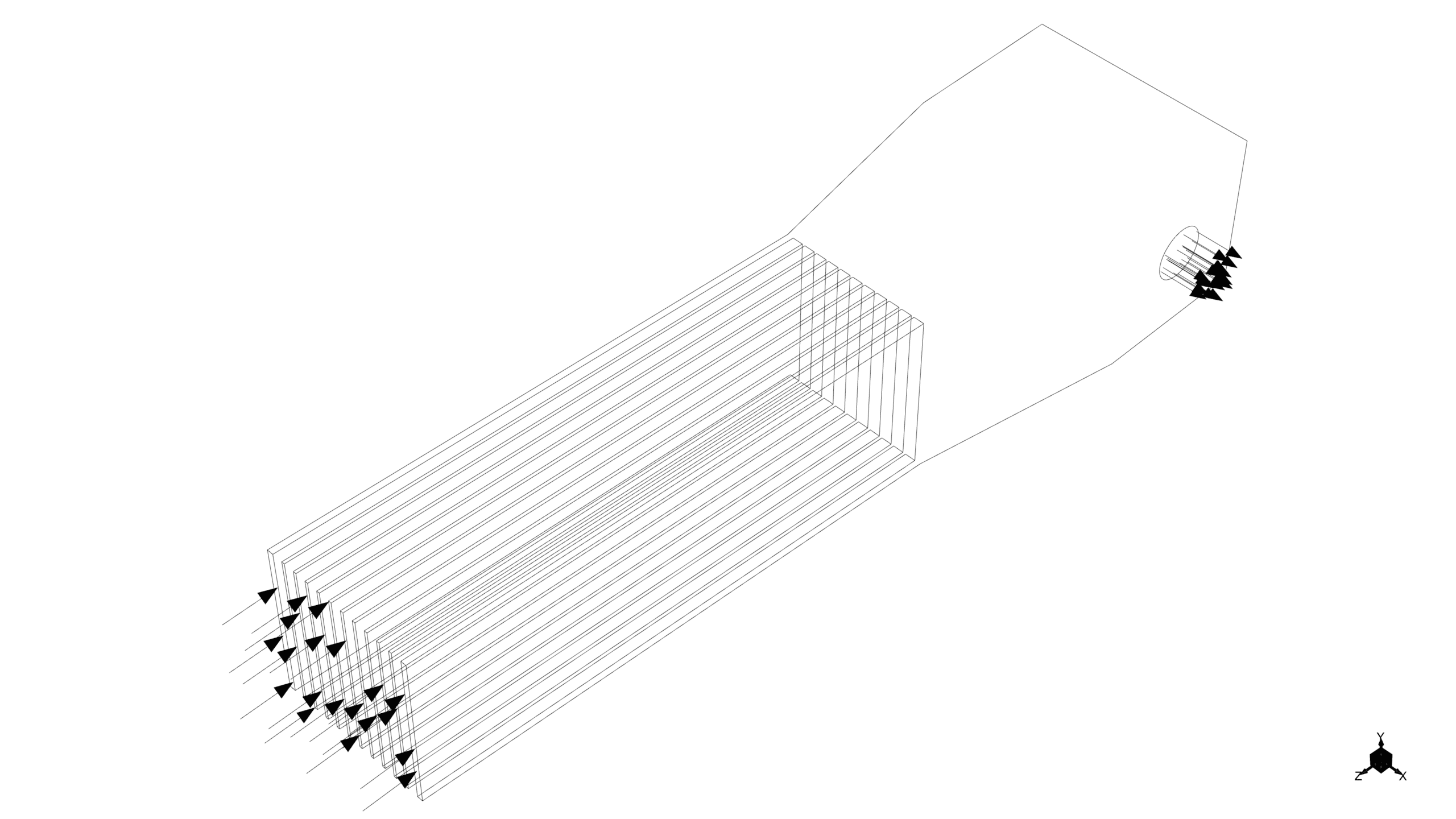

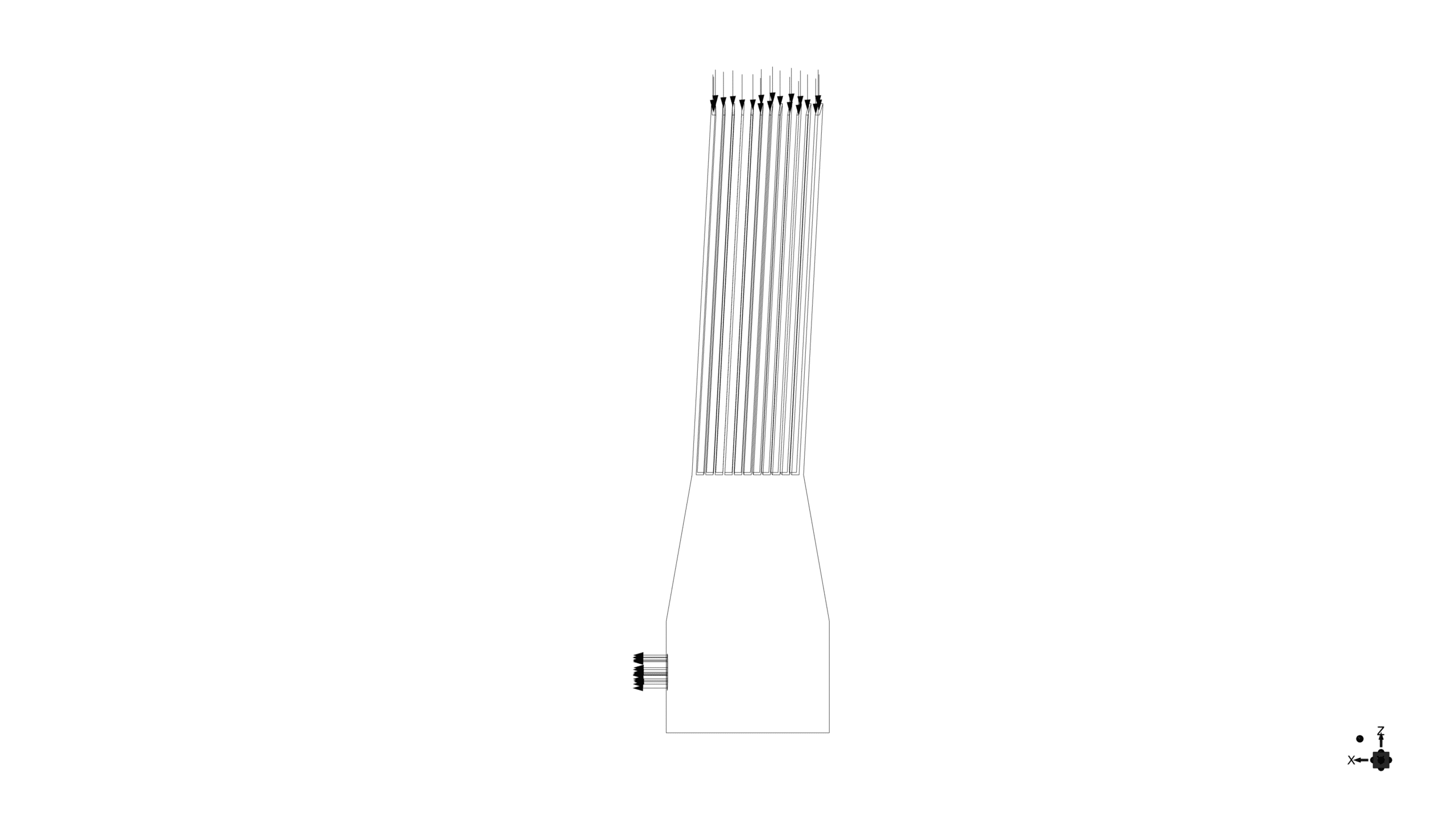

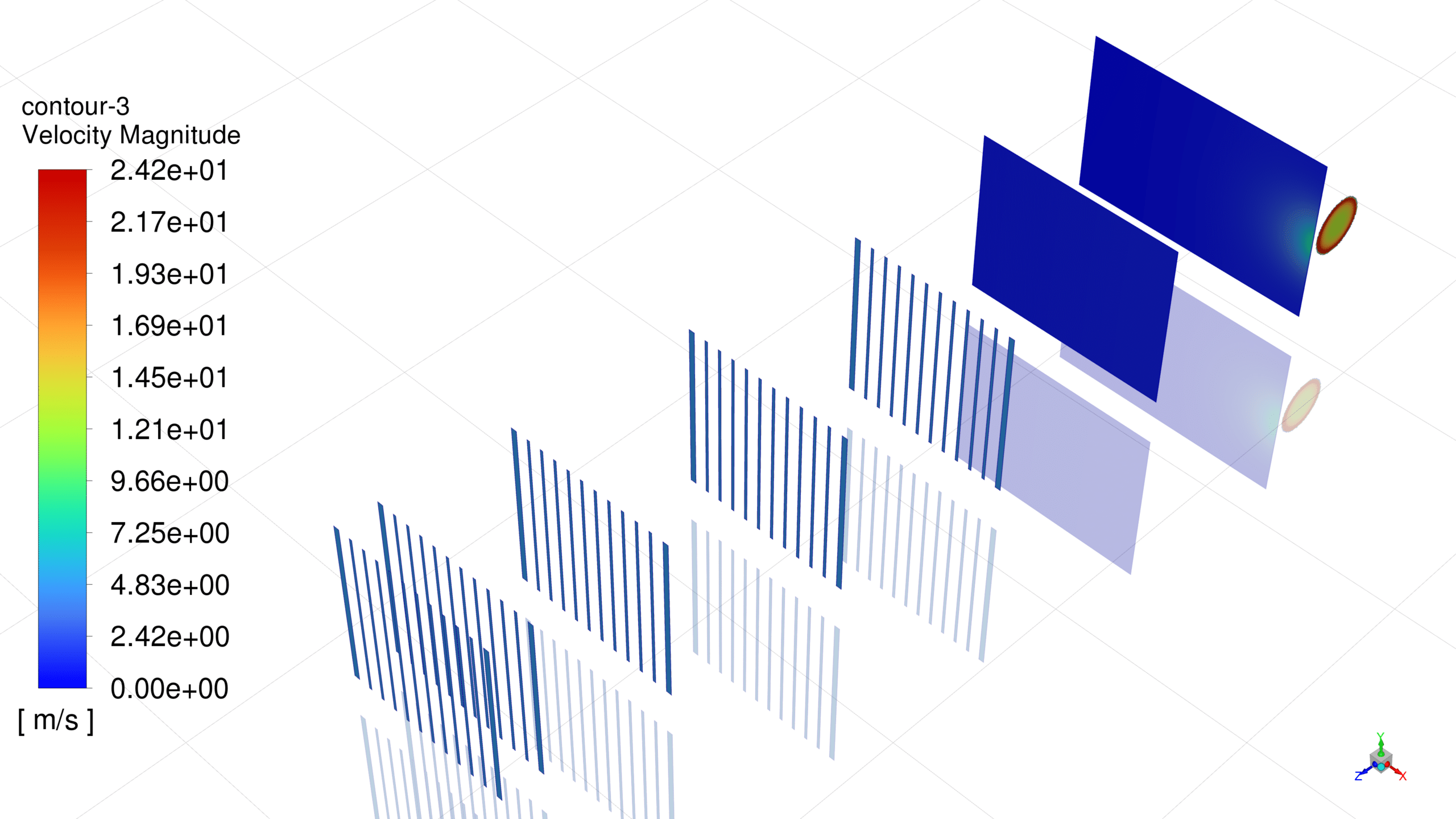

The present geometry is designed in a 3D model via SpaceClaim. The computational zone is the interior of the air intake room for a gas turbine. Inside this air intake room, some rows of parallel plates with angle of 3 and 6 degrees around the Y axis, are used. The air enters the domain through the narrow inlets with 0.06 meters width and its velocity is 5 m/s. Its outlet is in the side part of the end of the system. The meshing of the present model has been done via ANSYS Meshing and the number of produced structured elements equals 13,103,505 and 13,867,650 for the first and second case respectively.

Methodology

In this simulation designing an air intake room with efficient input section configuration is considered so that the air inlet is purified as much as possible. The process of purification is simulated via Discrete Phase Model (DPM) in which the solid particles (SiO2) with max diameter of 0.002 meters are injected from inlet surfaces entering with air flow. Note that the particles volume fraction is considered 8% of the air. The plates walls are considered as trapping walls in order to trap the particles and the other walls should be set as reflect walls not to trap the particles.

Design Improvement and Conclusion

To observe the effect of intake configuration on purification, we designed two cases. The first one including parallel plates with 3 degrees angle around the Y axis and second one containing parallel plates with 6 degrees angle around the Y axis. The main goal is to investigate how purifying is done via first one and how to improve this process by increasing the angle of plates around the Y axis in order to see if the more particles are trapped. We monitored the number of tracked and trapped particles during the simulation to see how purification is done. In the first case among the 63000 tracked particles, 54,472 particles were trapped which means that the purification process simulated by DPM model has about 80% efficiency. But in the second design, by increasing the angle of plates, this efficiency reaches to 88%.

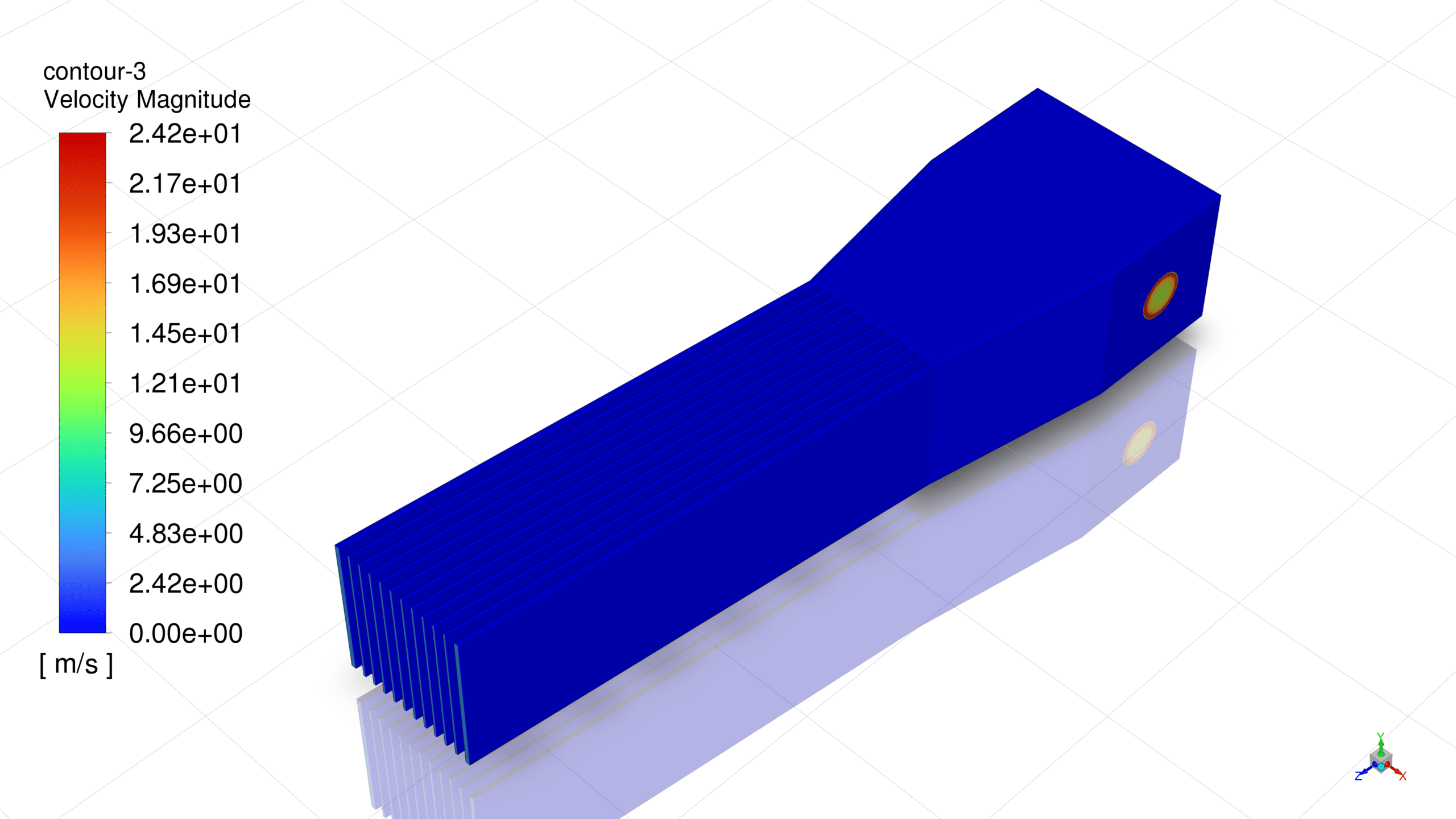

As one of results, we got the DPM concentration in inlet and outlet which was 0.1527 and 0.00012(kg/m3) respectively in the second case that means we have obtained clean air so that it can enter the gas turbine. Also the outlet velocity increases to 17(m/s) because of the small outlet area.

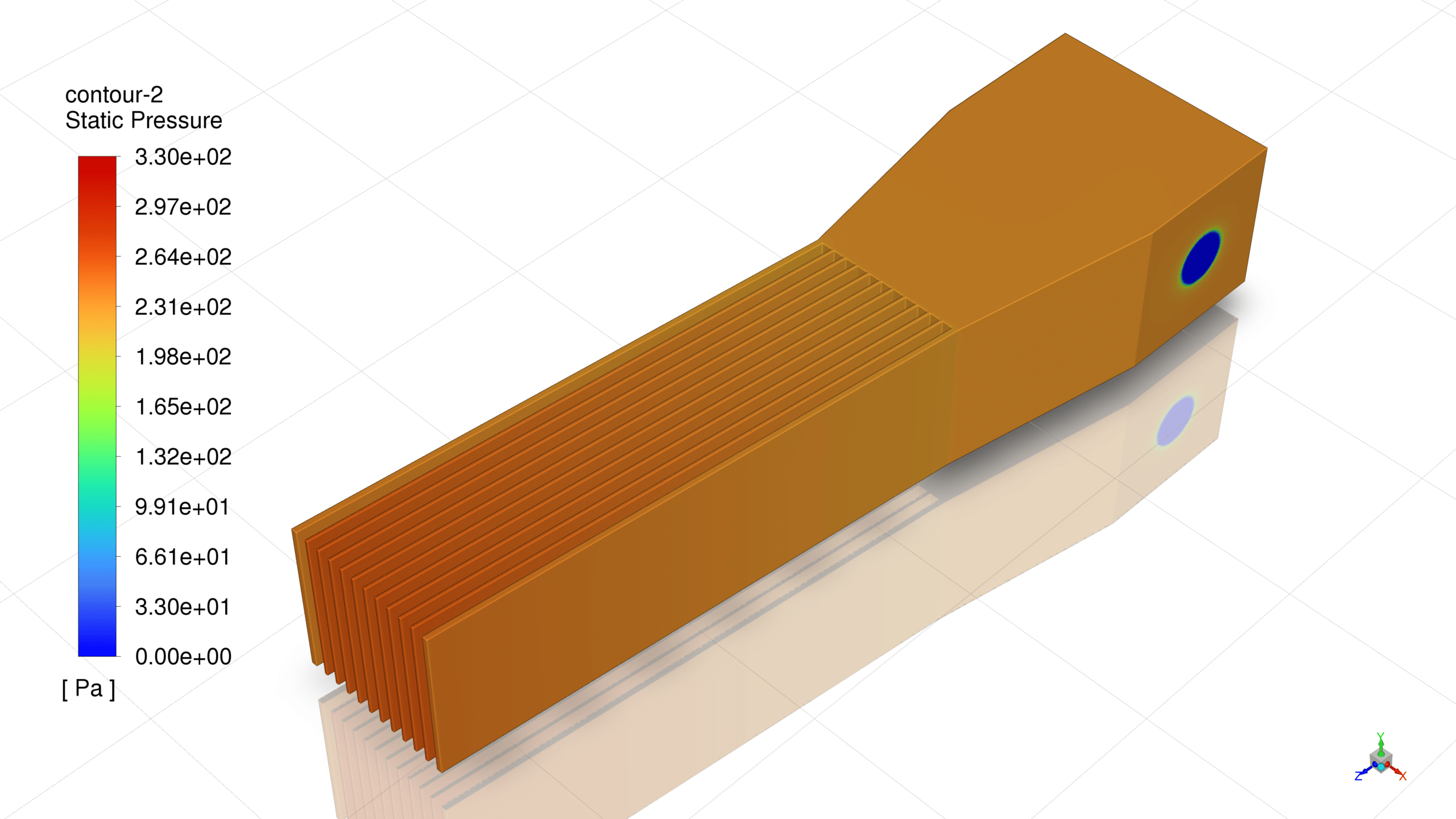

After calculation, 2D and 3D contours related to pressure and velocity are obtained. The contours show that when airflow passes through the space between the plates at high speed, the air pressure decreases after colliding with the parallel plates.

Katheryn Hammes Jr. –

The improvements in air purification comparing the first and second design mentioned, but does this enhancement in trapping efficiency affect the pressure drop through the system?

MR CFD Support –

Yes, the enhancement in trapping efficiency is concurrent with changes in aerodynamics within the intake room, which would certainly affect the pressure drop observed. Generally, increased obstruction or redirection in flow, as might happen with a higher angle of plates, may create higher resistance to flow, thereby potentially increasing the pressure drop across the system.

Owen Nicolas –

This review highlights the major sophisticated elements in the design and performance of airflow analysis within the air intake room for a gas turbine. Notable is the incorporation of Discrete Phase Model simulations to evaluate filtration efficiencies and how the adjustment of plate angles significantly improved purification. The information is not only practically useful for industry applications, but also underscores the level of detail and technical insight MR CFD Company’s offerings embody.

MR CFD Support –

Thank you for your kind and comprehensive review! We’re glad to hear how this simulation has demonstrated valuable industrial insights and the effectiveness of our product. Your feedback is important to us, and we look forward to continually providing high-quality learning resources in the field of CFD. If you require further guidance or have more interest in our simulations, do not hesitate to reach out.

Dr. Rosamond Hagenes Jr. –

What a thorough analysis on the impact of plate angles on the filtration efficiency! The use of DPM to simulate particle behavior provided clear insights into the design improvements. Well done on achieving clean air for the gas turbine and optimizing airflow dynamics!

MR CFD Support –

Thank you for appreciating the depth of our analysis on the air intake room design and the effectiveness of Discrete Phase Modeling in optimizing the filtration system. We’re pleased that our simulation could accurately demonstrate the impact of plate angle adjustments and result in a more efficient system design.

Dr. Nat Brekke –

The improvement in particle trapping efficiency when increasing the angle of the plates is impressive. This optimized design helps provide cleaner air for the gas turbine. Great work by MR CFD in showing how applied simulation studies can significantly enhance performance!

MR CFD Support –

Thank you for your positive review! We’re glad to hear how our simulation and the applied changes in the design of the air intake room have led to tangible improvements in operation. If our product can contribute to the efficient and clean functioning of gas turbines, it fulfills a key aspect of our mission at MR CFD. If you need further information or another service, please don’t hesitate to reach out.

Felipe Bernier –

After increasing the plate angle to 6 degrees, how much did the air outlet velocity change compared to the 3-degree angle setup?

MR CFD Support –

With the increase of the plate angle to 6 degrees, the air outlet velocity increased to 17 m/s, demonstrating that the alteration in the design resulted in an enhancement in air speed through the air intake room, contributing to the larger purification efficiency of the system.

Mrs. Deanna Wyman IV –

I was impressed by the particle trapping efficiency improvement in the second design. Could you explain how increasing the plate angle improves purification?

MR CFD Support –

When the angle of the plates is increased, the air flows and turbulent structures can interact more effectively with the particles suspended in the air. This change in flow direction augments the chances for particles to impact the plates and be trapped. As a result, the filtration efficiency increases as particles are prevented from passing through the parallel plates along with the air and are instead captured by the plates.

Dagmar Rolfson –

I thoroughly enjoyed learning from the simulation of the airflow inside the air intake room. The clarity of the simulation steps and the utilization of DPM to exhibit purification were impressive. The unique strategies implemented for trapping fine particles demonstrated the depth of your product. Great learning experience with practical insight!

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that you found our simulation product insightful and helpful for understanding the complexities of air intake systems. We always strive to deliver clear, practical, and in-depth learning experiences. Your satisfaction is our top priority!

Prof. Miller Smitham IV –

I was impressed by the level of detail in the airflow simulation for the air intake room. The DPM model seems essential for ensuring the air is cleansed of particles. Great to know that the design improvement resulted in a significant increase in efficiency with the angle adjustment.

MR CFD Support –

Thank you for recognizing the detailed approach we’ve taken with our airflow simulation for the air intake room. We are glad to hear that the details on the DPM model and the efficiency gains from the design improvement were insightful to you. High quality and precision are priorities for us, and it’s wonderful to receive such positive feedback on our efforts. If you need further information or have more interest in our CFD products, feel free to contact us. We appreciate your review!

Therese Huel –

This CFD course was absolutely helpful for me! Especially understanding how trapping walls and different angles can impact purification efficiency. The practical approach applied in the simulation perfectly underlines the theory behind particle behavior and airflow inside the air intake room.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you found the course on Airflow Inside the Air Intake Room useful for understanding the practical applications of air purification systems. If you have any further questions or want to delve even deeper into such applied CFD problems, please don’t hesitate to reach out.

Kailee Champlin –

What specifically causes the increased efficiency in particle trapping when the angle of the plates is increased?

MR CFD Support –

The increased efficiency in particle trapping when the angle of the plates is increased is likely due to the fact that the steeper angle enhances the impaction of the particles onto the plate surfaces. This angle change might create a more turbulent flow around the plates, leading to increased contact of the airflow carrying particles with the plate surface, thereby improving the chances of particle capture.

Bettye Lesch V –

I really appreciate the detailed design improvements and results in the simulation! It’s great to see increased efficiency in particle trapping with the modified plate angles.

MR CFD Support –

Thank you for your kind words and positive feedback! We’re glad that you found the design improvements and the detailed results of the simulation valuable. If you have any more questions or need further details on CFD simulations, do let us know.

Walter McGlynn –

I am impressed with the level of detail in the airflow simulation within the air intake room and how different angles of parallel plates were used to improve gas turbine performance. The use of DPM to model the purification process and the clear demonstration of efficiency improvements provides great insight into the design process. Well done on the rigorous simulation analysis!

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear that our detailed simulation and the application of the Discrete Phase Model (DPM) provided you with clear insights into the design process and its effects on gas turbine performance. Our goal is to ensure that our simulations are not only thorough but also practical and informative. We appreciate your commendation on our work and look forward to providing you with more high-quality simulation analyses in the future.

Dr. Domenico Smith IV –

I’m very happy with the results I achieved using the ANSYS Fluent Airflow Inside the Air Intake Room CFD tutorial. It really enlightened me on design improvement strategies for air purification. After going through the CFD process and understanding the methodology, I feel more confident in optimizing air intake systems.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that our tutorial has helped boost your confidence in CFD and air intake system optimization. Your success is what drives us to continue providing high-quality learning resources.

Prof. Pete Tremblay Sr. –

I am thrilled with the Design Improvement results! It’s impressive to see that by simply adjusting the angle of the plates from 3 to 6 degrees around the Y axis, the efficiency of particle trapping has increased remarkably from 80% to 88%. The detailed simulation process, paired with the clear step-by-step methodology, made it very insightful to understand the airflow dynamics and the particle purification process within the air intake room. Great job on utilizing DPM to optimize the air quality for the gas turbine!

MR CFD Support –

Thank you for taking the time to write such a positive review! We’re delighted to hear that you found the design improvements and simulation details insightful and helpful. It’s always our goal to provide clear and effective solutions for complex engineering problems. We appreciate your feedback, and we’re glad that you were impressed with the results of our study. Thank you for choosing our services!

Jerad O’Hara DVM –

I just wanted to say the detailed outcomes of the simulation are impressive! It’s fascinating how changing the angle of the plates can lead to a substantial increase in purification efficiency.

MR CFD Support –

Thank you for your kind words! We’re thrilled that our simulation results provided clear insights and valuable outcomes. Our team works hard to ensure that each simulation is accurate and informative. Your feedback is much appreciated!

Dr. Jamel Jenkins –

I’m really impressed with the design improvement for the air intake room CFD simulation. It seems increasing the angle of the plates can significantly enhance the filtration process. Well done on achieving higher efficiencies with the second design!

MR CFD Support –

Thank you for your appreciation! We take pride in continuously working to enhance our designs and improve the effectiveness of our simulations. It’s uplifting to know that the design improvements and their positive impact on purification efficiency made a good impression. If you have any further questions or need assistance with similar projects, feel free to reach out. Thanks again for your thoughtful review.

Prof. Cristian Braun –

I’m absolutely pleased with the detailed analysis provided for the airflow inside the air intake room simulation. It’s fascinating to see how changing the angle of the plates can significantly increase the efficiency of the air purification process for a gas turbine which is vital for its operation. It’s clear that MR CFD has done an extensive study to ensure the air intake system is optimized by utilizing discrete phase modeling to track particles. Excellent work on both the simulation design and the comprehensive results!

MR CFD Support –

Thank you so much for your kind words and for appreciating our work on the airflow inside an air intake room simulation. We’re thrilled to hear that you find the study and the resulting increase in air purification efficiency fascinating. Our team at MR CFD is dedicated to conducting thorough and comprehensive analyses to optimize systems such as these. Your feedback motivates us to keep delivering high-quality simulation services. If you have any more questions or need further assistance, please don’t hesitate to reach out!

Mr. Esteban Keeling DDS –

Is the decrease in air pressure after colliding with the parallel plates, advantageous or detrimental to the air intake system’s overall performance?

MR CFD Support –

The decrease in air pressure when the airflow collides with parallel plates within an intake system can be advantageous, as this may help in reducing the velocity of air and separating out particles more effectively. This phenomenon is essentially beneficial in an air filtration system designed for a gas turbine, where maintaining high purification efficiency is crucial.