Rotary Heat Exchanger, Effect of Mass Flow Rate CFD Simulation

$80.00 Student Discount

- The problem numerically simulates a Rotary Heat Exchanger, Effect of Mass Flow Rate on heat transfer coefficient in ANSYS Fluent software.

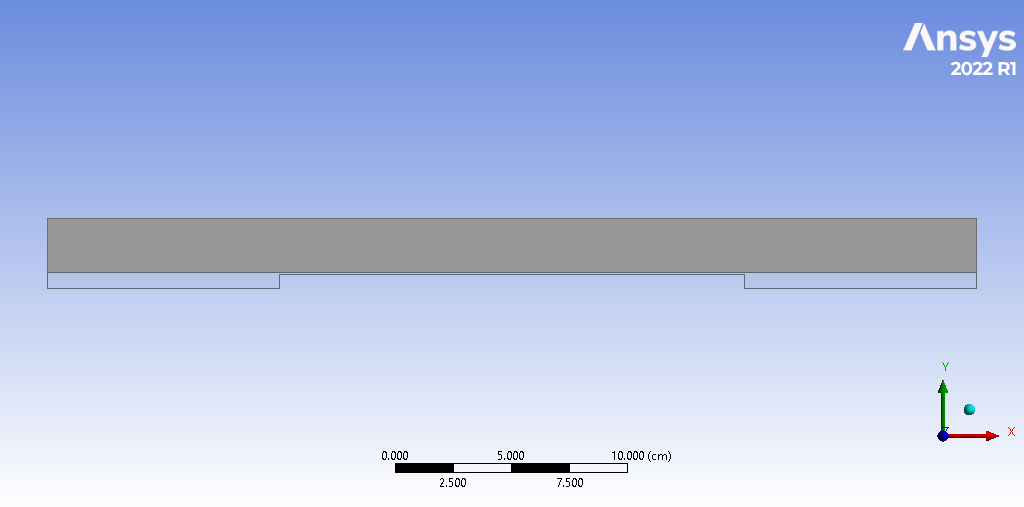

- The 2D geometry of the model is created in Design Modeler software.

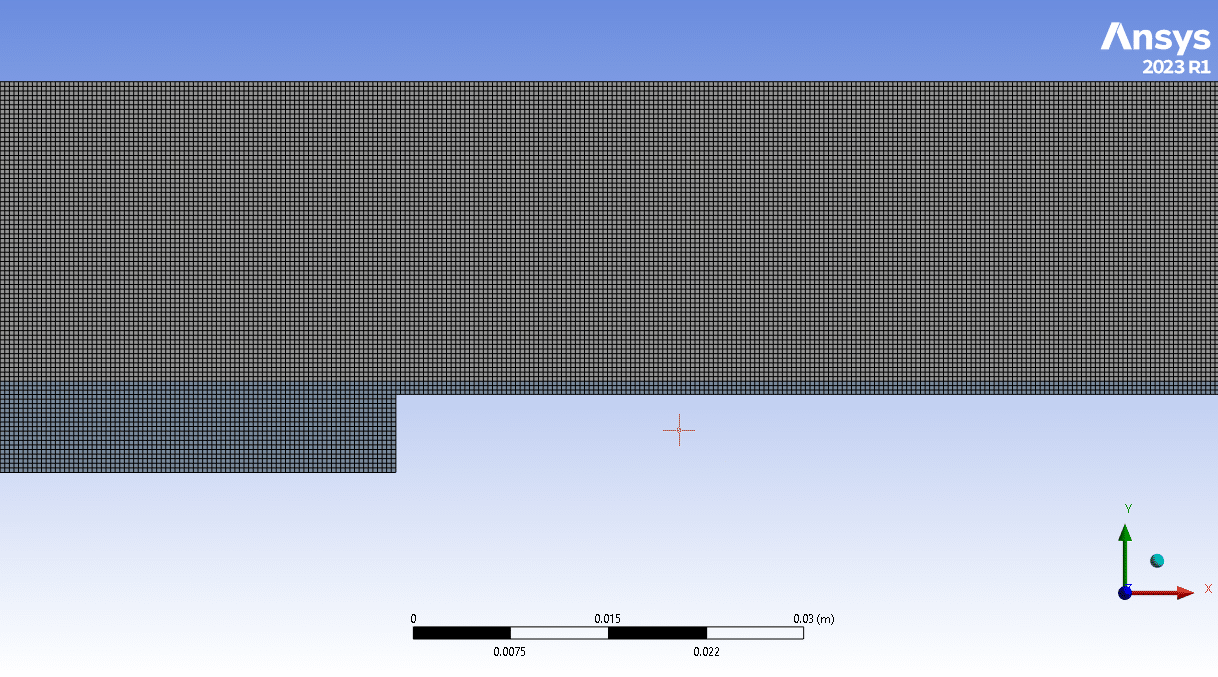

- The model is meshed in ANSYS Meshing creating 86,598 elements.

- The Standard k-epsilon model is used to describe turbulency of the flow.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Rotary Heat Exchanger, Effect of Mass Flow Rate on Heat Transfer Coefficient CFD Simulation, ANSYS Fluent

Description

In this project, the simulation of a 2D rotary heat exchanger is performed. The rotary heat exchanger, also known as a rotary regenerator, is a type of heat recovery system that recovers heat from a hot gas stream. This equipment is commonly used in various industries, including power generation and HVAC systems, to improve energy efficiency. The simulation model developed here aims to provide an accurate representation of the thermal performance of a 2D rotary heat exchanger. The model is based on fundamental principles of heat transfer and fluid dynamics, and it can be used to predict the performance of the exchanger under various operating conditions.

The geometry of the heat exchanger is designed in Design Modeler software. The model consists of 2 regions. One is dedicated to the hot fluid and the other one is designed for the cold one. Next, the model is meshed in ANSYS Meshing software. A structured grid is generated and the total number of elements is 86,598.

Methodology

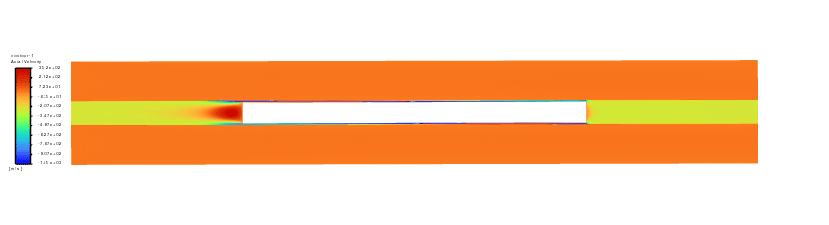

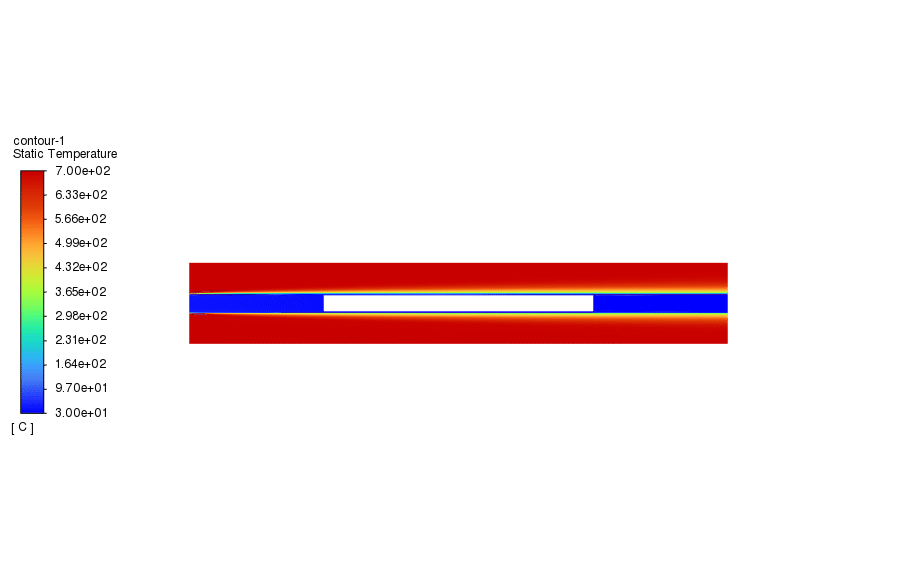

The aim of the study is to study the effect of mass flow rate on the heat transfer coefficient. Four different mass flows are studied including 0.02, 0.04, 0.06 and 0.08 kg/s. The hot Co2 with 700°C temperature flows into the hot domain and on the other side, cold water vapor with 30°C flows. Due to symmetrical physics, only half of the heat exchanger is modeled and instead, the axisymmetric boundary type is used. The rod inside is rotating with a constant rotational velocity of 100rpm. Also The Standard k-epsilon model is used to describe turbulence of the flow.

Conclusion

After the simulation process, velocity and temperature contours are extracted. In order to study the effect of mass flow rate on heat transfer, heat transfer coefficient is reported in each case. The following table represents the correlation between mass flow and heat transfer. As the data indicates, even though the mass flow rate increases linearly, the heat transfer demonstrates non-linear behavior.

| Mass Flow Rate(kg/s) | h (W/m2.K) | Changes(%) |

| 0.02 | 33.7 | |

| 0.04 | 90.1 | 167.35905 |

| 0.06 | 155.6 | 72.6970033 |

| 0.08 | 224.6 | 44.344473 |

Lonzo Wisoky –

I really appreciated how the mass flow rate’s effect on the heat transfer coefficient was highlighted. The non-linear relationship insights were particularly valuable for understanding the complex behavior of heat transfer in a rotary heat exchanger.

MR CFD Support –

We are pleased to read that you found the effect of the mass flow rate on the heat transfer coefficient insightful. It is great to know that the data provided useful information on the complex heat transfer characteristics of the rotary heat exchanger. Thank you for your positive comment!

Mireille Larkin DDS –

This review is comprehensive, but I’m interested in how the rotational velocity of the rod inside the heat exchanger impacts the heat transfer efficiency. Is there an analysis showing different rotational speeds along with their respective heat transfer coefficients?

MR CFD Support –

The study mentioned in the description focuses on the impact of mass flow rate on the heat transfer coefficient. Effects of the rotational velocity of the rod on heat transfer haven’t been discussed in this simulation. Such analysis would require additional simulations with variable rotational speeds while keeping other parameters constant to accurately assess their impact on heat transfer efficiency.

Porter Collier –

The simulation helped me understand the performance complexities of rotary heat exchangers. Could you explain how changing the mass flow rate impacts the heat transfer coefficient significantly and causes a non-linear relationship, as shown in the results?

MR CFD Support –

In the simulation, as mass flow rate increases, more mass carries heat through the exchanger per unit time, which enhances the overall heat transfer. However, this relationship is non-linear due to several factors such as fluid properties, flow turbulence and the heat exchanger’s geometric characteristics. As flow rate increases, turbulence generally increases, which can improve heat transfer. But this relationship is complex due to mixed convective heat transfer mechanisms and possible changes in the boundary layer thickness affecting overall heat transfer.

Damien Moore –

Would increasing the mass flow rate indefinitely keep improving the heat transfer coefficient?

MR CFD Support –

In theory, increasing the mass flow rate initially increases the heat transfer coefficient because it enhances the convective heat transfer due to higher fluid velocities and turbulence. However, this relationship doesn’t continue indefinitely. There are limitations due to the physical design of the heat exchanger, flow disturbances, pressure drops, and potential transition to turbulent flow which may cause an optimal mass flow rate above which the efficiency gains diminish or even become negative. Therefore, to achieve the most efficient design, it’s crucial to find an optimal mass flow rate for the particular heat exchanger being modeled.

Janelle West –

I’ve learned a lot from the rotary heat exchanger CFD simulation. It seems that the correlation between the mass flow rate and heat transfer coefficient is quite complex. I am curious, does the report include any details on how pressure drop varies with different mass flow rates?

MR CFD Support –

Thank you for your question and compliment! I’m glad to hear that you found the simulation insightful. Yes, the pressure drop analysis across varying mass flow rates is typically considered in such simulations. However, as the focus of this report was specifically on the heat transfer coefficients, additional details on pressure drop were not included in the provided text. Pressure drops are indeed important for complete performance evaluation, and such data can be gathered and analysed within the simulation environment.

Korey Moore –

I am thrilled with the clarity of the results from the simulation! Especially how the correlation between mass flow and heat transfer coefficient was non-linear, which was unexpected. It goes to show the dynamism in heat exchange systems.

MR CFD Support –

Thank you for your feedback! We appreciate the time you have taken to compliment our simulation. It’s great to hear that the results met your expectations and provided you with clear insights into the thermal dynamics of the heat exchanger. If you have any further questions or need more information, don’t hesitate to reach out.

Lyla Spencer –

The methodology for determining the mass flow rate’s impact on the heat transfer coefficient was clear and well-executed. I can see how flow rate increases led to non-linear improvements in the heat transfer coefficient, beneficial for optimizing system performance.

MR CFD Support –

Thank you for your positive feedback on our simulation methodology. We are pleased to hear that our detailed approach to studying the impact of different mass flow rates on heat transfer efficiency has provided clear and useful insights for optimizing heat exchanger performance.

Sebastian Weimann –

The analysis of how mass flow rate affects the heat transfer is fascinating. Could you please explain why the relationship between mass flow rate and heat transfer coefficient isn’t linear?

MR CFD Support –

The relationship between mass flow rate and heat transfer coefficient is not linear due to the complexity of the heat transfer mechanisms involved in the process. As the mass flow rate increases, the ability of the fluid to absorb or transfer heat changes, and this interplay of variables leads to a non-linear response. Additionally, factors such as turbulence, flow velocity, and temperature gradients can dramatically influence the heat transfer coefficient, contributing to its non-linear behavior.

Connie Hill –

The efficiency of heat transfer seems impressive. The non-linear increase in heat transfer coefficient with mass flow rate is particularly noteworthy.

MR CFD Support –

Thank you for your review of the MR CFD Rotary Heat Exchanger simulation study. We’re glad to hear that you find the results impressive and appreciate the observation regarding the non-linear relationship between mass flow rate and heat transfer coefficient. Your feedback is valuable to us as we continuously strive to provide high-quality and informative simulations.

Andreanne Kshlerin –

I’ve gone through the project on the 2D rotary heat exchanger simulation, and I am really impressed with the detail in results! I’m curious though, how is turbulence affecting the heat transfer at different mass flow rates?

MR CFD Support –

Hello and thank you for your positive feedback! The turbulence in the flow plays a significant role in enhancing the heat transfer process by promoting mixing of the fluid particles. As the mass flow rate increases, the turbulent kinetic energy increases, which assists in disturbing the thermal boundary layer, thereby improving the convective heat transfer. This correlates with the increase in the heat transfer coefficient as the mass flow rate rises. Additionally, the use of the Standard k-epsilon model in the simulation accounts for the average effects of turbulence, providing a more reliable approximation for these changes in the heat transfer coefficient at different mass flow rates.

Prof. Erika Stracke –

I was impressed with how the influence of varying mass flow rates on heat transfer was explored. The detailed methodology and specific rapid rotation incorporated in the simulation made it interesting. Could you explain the reason behind the observed non-linear relationship between mass flow rate and the heat transfer coefficient?

MR CFD Support –

The non-linear relationship between mass flow rate and heat transfer coefficient is due to the complex interplay between increased fluid velocity energizing the boundary layer and accelerating convective heat transfer, and the limits imposed by the thermophysical properties of the fluids as flow rates change. As mass flow rate increases, the convective heat transfer coefficient initially rises due to enhanced mixing and higher Reynolds number, but this relationship is not simply proportional as other factors such as turbulence and boundary layer characteristics dominate at different flow regimes, leading to the non-linear trend observed in the simulation findings.

Destin Pfannerstill –

I’m curious about the specific reasons for the non-linear increase in the heat transfer coefficient. Can this be attributed to the intricacies of flow dynamics within the rotary heat exchanger?

MR CFD Support –

Yes, the non-linear increase in the heat transfer coefficient as the mass flow rate rises is influenced by the complexities of flow dynamics. With higher mass flow rates, the heat transfer rate increases due to heightened convective heat transfer, but it’s not directly proportional because other factors such as turbulence intensification and potential flow separation play a role as the dynamics shift within the exchanger.

Mrs. Brenna Labadie –

I appreciate how the rotary heat exchanger simulation accounts for different mass flow rates. Has there been an analysis on the impact of rotational speed variation on heat transfer?

MR CFD Support –

Thank you for your commendation! In this particular study, we focused on the effect of mass flow rates on the heat transfer coefficient. We did not vary the rotational speed, which was maintained at 100rpm throughout the simulation. However, analyzing the impact of varying rotational speeds on heat transfer is an important aspect that could be explored in a separate study to understand its influence on the heat exchanger’s performance.

Vern Gleason –

This is absolutely brilliant! I was able to run comparative analyses for my own rotary heat exchanger designs based on the detailing and findings in this well-structured simulation. The non-linear relationship between heat transfer coefficient and mass flow rate is remarkably demonstrated!

MR CFD Support –

Thank you for your kind words! We are delighted to know that our simulation has been helpful for your comparative analyses and that you found the results on the non-linear relationship convincing. Your positive feedback is greatly appreciated, and if you have any further questions about our product or need additional insights, feel free to reach out.

Mr. Carol Rath –

The results of this rotary heat exchanger simulation are fascinating! How does the increase in mass flow rate result in a non-linear increase in heat transfer coefficient? Could you please elaborate on that phenomenon?

MR CFD Support –

In the simulation study, the non-linear increase in heat transfer coefficient with the increase of mass flow rate can be attributed to the enhanced turbulent mixing and the reduced thermal resistance at higher flow rates. As the mass flow rate increases, the fluid particles travel faster which improves the exchange of energy between the hot and cold streams due to turbulent eddies. However, after a certain point, the increase in heat transfer efficiency may diminish due to limitations in heat exchanger surface area or other factors. This complex relationship between flow rate and heat transfer is precisely what this simulation aimed to examine and has been nicely captured in our CFD analysis.

Zion Crooks –

I’ve been curious about the rotary heat exchanger after going through the CFD simulation. Could you provide some clarity on why the heat transfer coefficient doesn’t increase linearly with mass flow rate?

MR CFD Support –

The heat transfer coefficient doesn’t increase linearly with mass flow rate due to the complex relationship between flow properties and heat transfer dynamics. Factors such as turbulent mixing, flow velocity, and temperature gradients all influence heat transfer. As mass flow rate increases, each of these factors is affected differently, leading to a non-linear relationship between mass flow rate and heat transfer coefficient.

Marlene Bednar –

The simulation really helped me comprehend the relationship between mass flow rate and heat transfer coefficient. But I’m curious, how is the rotational velocity of 100rpm applied to the model inside ANSYS Fluent, and does it affect the turbulence model settings?

MR CFD Support –

The rotational velocity of 100rpm is applied within ANSYS Fluent using a moving reference frame or by defining a rotating wall boundary condition. Indeed, this setting can affect turbulence in the analysis. By specifying the rotational speed of the rod, the solver adjusts the velocity field calculations accordingly. The turbulence model settings, like the k-epsilon model used here, include empirical constants that account for rotational effects, ensuring that predictions of turbulence-driven transfer phenomena remain accurate, even in spinning applications. The rotation influences the formation of local turbulent structures and, consequently, the heat transfer between the fluids and the rotating parts of the heat exchanger.

Ms. Queen Hermann II –

The structured grid in this model; could you let me know why this choice was made over other mesh types?

MR CFD Support –

The choice to use a structured grid in the rotary heat exchanger model facilitates a more orderly division of the grid space, which can result in greater numerical stability and accuracy of the simulation, especially in analyzing the heat transfer coefficient with varying mass flow rates.

Baron Bruen DDS –

The results highlight a non-linear relationship between mass flow rate and heat transfer; does the heat exchanger efficiency also increase with mass flow rate in a similar pattern, or is there a point where it starts to diminish?

MR CFD Support –

In a heat exchanger, the efficiency generally improves with an increase in the mass flow rate up to a certain point, as this enhances the convective heat transfer. However, practically, this efficiency gain may start to diminish if the flow becomes too fast, which reduces the time for heat exchange between the fluid streams. Factors such as flow turbulence and potential pressure drop also become more significant at higher flow rates and can influence the heat exchanger’s performance. For precise behavior in your specific case, examining the efficiency vs. mass flow rate plot would give the most accurate representation.

Junius Reichert –

The project review was fantastic! I’m highly impressed by the detailed analysis performed on the rotary heat exchanger and the effects of varying mass flow rates. It really highlights the practical application of CFD in optimizing such critical components in the industry. The simulated correlation between mass flow and heat transfer is particularly valuable; it provides a clear understanding of the system’s efficiency based on real operational changes.

MR CFD Support –

Thank you so much for your positive feedback! We are pleased to hear that our CFD simulation met your expectations and provided insightful data for your understanding of the rotary heat exchanger. It’s great to know that the detailed report on heat transfer variabilities with respect to mass flow rates was helpful. We always strive to offer practical and clear CFD analyses to support industry professionals in optimizing their designs and processes. Your satisfaction is our main goal!

Mr. Dino Fahey Jr. –

I was very intrigued by the clear relationship between mass flow rate and heat transfer coefficient shown in the results. What applications would particularly benefit from understanding this correlation in a rotary heat exchanger context?

MR CFD Support –

Industries such as power generation, waste heat recovery systems, and HVAC systems can greatly benefit from understanding the correlation between mass flow rate and heat transfer coefficient. These insights enable optimizing energy efficiency and performance in these systems.

Erin Predovic –

The product seems highly detailed and precise, but I’m curious about the numerical settings for achieving convergence. Can you please provide insight into the convergence criteria and relaxation factors used in these simulations?

MR CFD Support –

The convergence criteria typically aim for the residual value for all the equations below 1E-3, which is a common benchmark ensuring the solution’s stability and accuracy. The specific relaxation factors are adjusted towards more conservative values for complex simulations, possibly around 0.3 to 0.7 range, to ensure steady convergence without fluctuations caused by rapid changes in the computational domain. Exact values might vary based on the simulation requirements and are gauged through trial runs.

Edd Langworth –

The simulation of a rotary heat exchanger looks incredibly detailed. This could be extremely useful for optimizing energy recovery in various industries. I’m curious – were any specific challenges faced in balancing the trade-offs between simulation accuracy and computational resource demands with such detailed models?

MR CFD Support –

We appreciate your positive feedback on the intricacy of our simulation work! When tackling simulations that involve detailed models, such as the rotary heat exchanger, we certainly encounter the challenge of maintaining a balance between precision and computational efficiency. To address this, our experts carefully optimize the mesh density, calibrate solver settings, and selectively refine the computational domain only where the highest accuracy is required. This targeted approach helps us reduce unnecessary computational workload while ensuring critical aspects of the simulation maintain high fidelity. The end result aims to provide a realistic performance prediction that is both robust and resource-conscious.

Mrs. Mariam Murray –

Wow, impressive report on the rotary heat exchanger! The level of detail in the simulation methodology is greatly appreciated. Testing varying mass flow rates to analyze the thermal efficiency could definitely aid in optimizing HVAC systems.

MR CFD Support –

Thank you for your kind words! We’re thrilled you found the report on the rotary heat exchanger simulation insightful. It’s always our goal to provide an in-depth analysis that can help improve energy efficiency in real-world applications. We appreciate you taking the time to review our product!

Grace Turner –

I’ve been curious if the research saw any notable anomalies in heat transfer at higher mass flow rates. Were there any unexpected patterns?

MR CFD Support –

In our simulations for the rotary heat exchanger, we observed that the heat transfer coefficient increased with the mass flow rates. However, the increase was not linear; it exhibited a diminishing return with higher flow rates. No significant anomalies were reported, indicating that the equipment has effective design parameters for handling the range of mass flow rates tested.