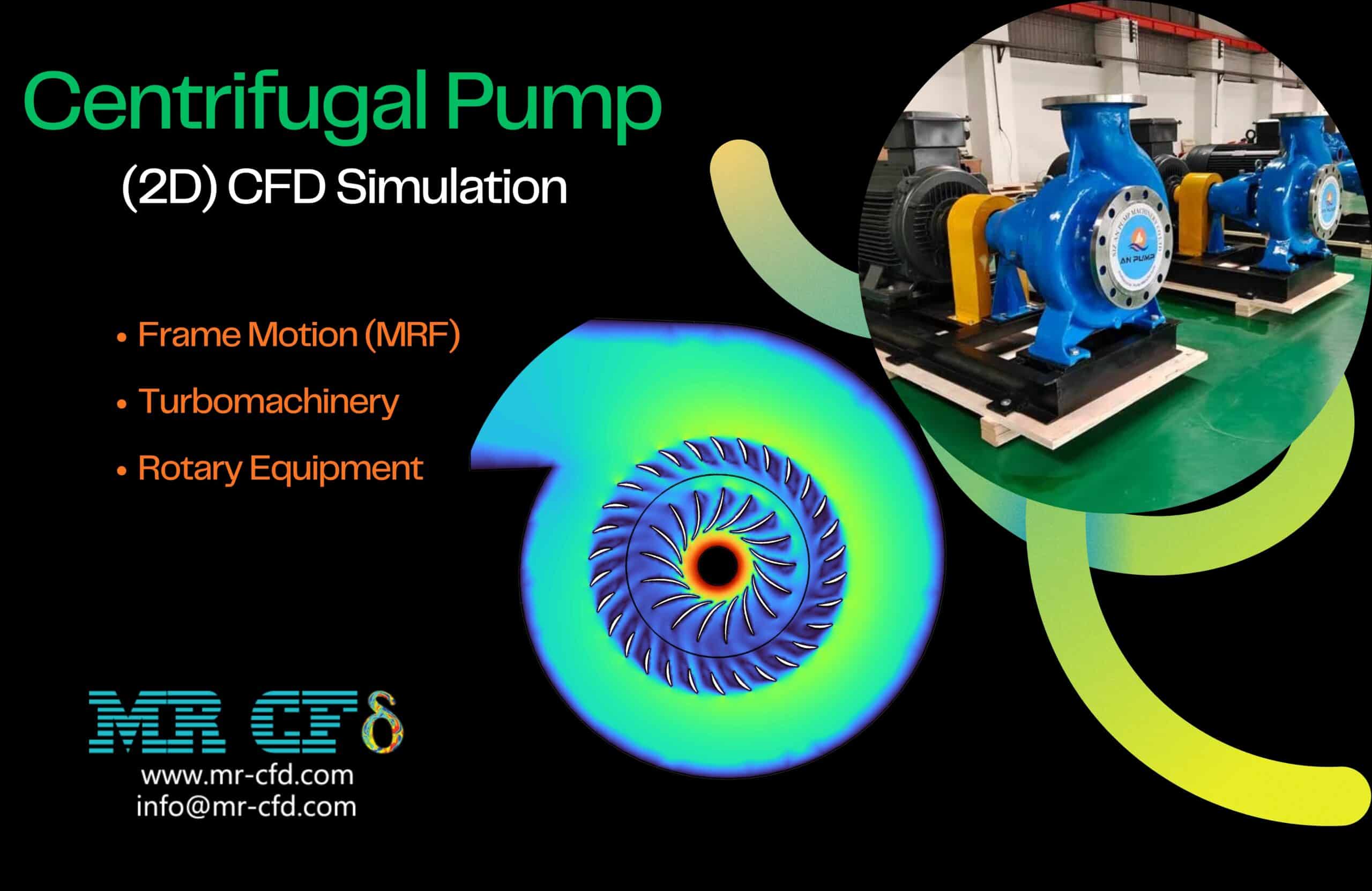

Centrifugal Pump (2D) CFD Simulation Using MRF Approach in ANSYS Fluent

$100.00 $40.00 HPC

- The centrifugal pump was modeled in ANSYS with two zones: the stationary casing and the rotating impeller.

- A triangular mesh with 17,536 cells was generated to discretize the geometry.

- The impeller was simulated using the Moving Reference Frame (MRF) approach with a rotation speed of 1500 RPM.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

CFD Simulation of a 2D Centrifugal Pump Using Frame Motion in ANSYS Fluent

Description

This project focuses on the computational fluid dynamics (CFD) analysis of a centrifugal pump to study the pressure and velocity distribution within the casing and impeller. The main objective is to understand the impact of impeller rotation on fluid motion and pressure rise. By creating a two-dimensional model of the pump and simulating its operation in ANSYS Fluent, the analysis provides insight into how kinetic energy is transferred from the rotating impeller to the working fluid, and how this energy is converted into pressure as the flow progresses toward the outlet.

Geometry and Mesh

The pump geometry was developed in ANSYS SpaceClaim and consists of two distinct zones: the casing and the rotating impeller. After designing the model, it was imported into ANSYS Meshing where an unstructured triangular grid was generated to resolve the complex flow paths. The final mesh contained 17,536 triangular cells, providing adequate resolution to capture the flow behavior around the impeller blades while maintaining computational efficiency. The mesh density was kept higher near the impeller region to accurately capture velocity gradients and turbulence effects created by the rotating blades.

Model and Solver Settings

The simulation was carried out in ANSYS Fluent using a pressure-based, steady-state solver. The governing equations were solved for incompressible turbulent flow with two computational zones: a stationary casing and a rotating impeller modeled using the Moving Reference Frame (MRF) approach. The impeller was assigned a rotational speed of 1500 RPM, while a velocity inlet boundary condition of 140 m/s was set at the entrance, and a pressure outlet condition was applied at the exit. For pressure–velocity coupling, the SIMPLE algorithm was selected to ensure numerical stability and reliable convergence.

Results

The simulation results show a clear interaction between the impeller rotation and the fluid flow, leading to both velocity rise and pressure build-up. The velocity contour indicates a strong acceleration of flow near the impeller blades, where maximum velocities reach values above 500 m/s before gradually diffusing inside the volute casing. The pressure contour reveals a significant pressure increase, with values reaching approximately 1.74 × 10⁸ Pa near the outlet regions, confirming efficient energy transfer from the impeller to the working fluid. Overall, the results capture the expected centrifugal pump behavior of converting mechanical rotational energy into increased fluid pressure and velocity, demonstrating the effectiveness of CFD in analyzing turbomachinery performance.

You must be logged in to post a review.

Reviews

There are no reviews yet.