Rampressor, ANSYS Fluent CFD Simulation Training

$120.00 Student Discount

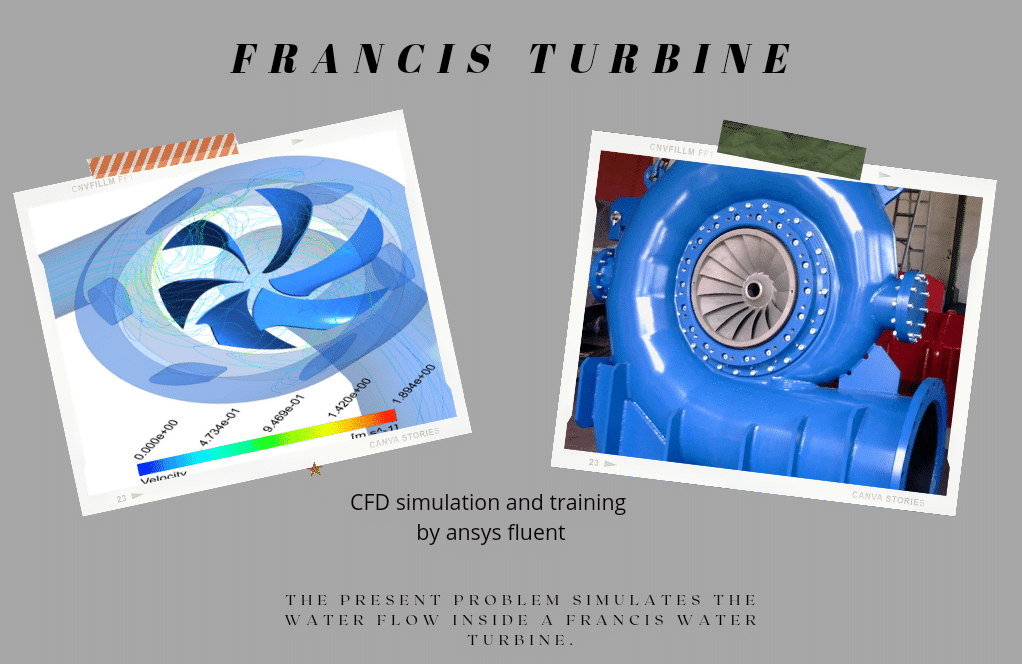

The present problem simulates the air compression inside a Rampressor using ANSYS Fluent software.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Project Description

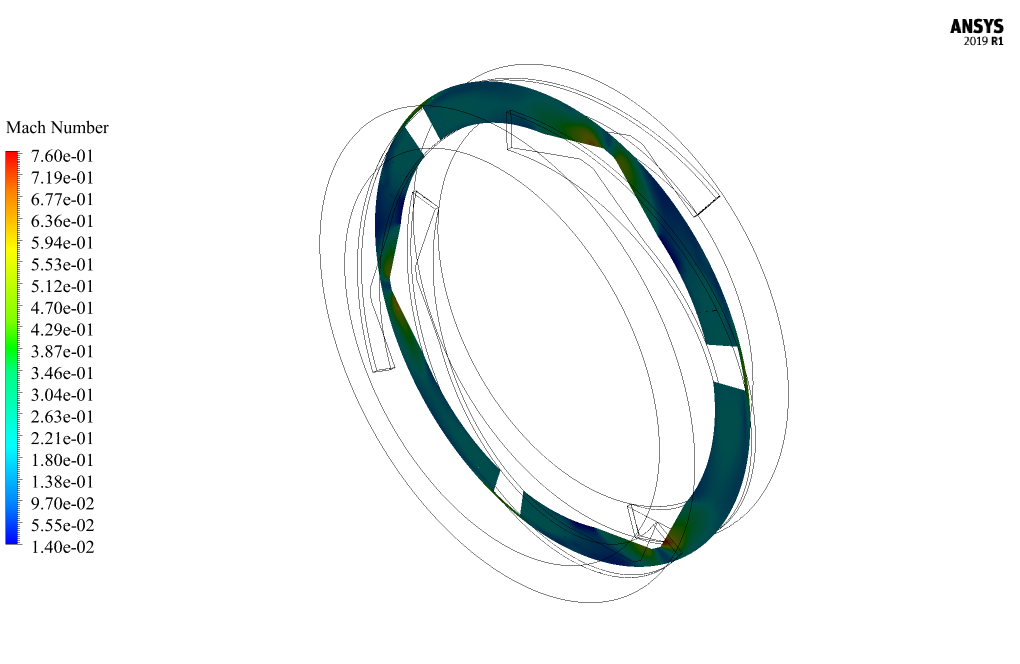

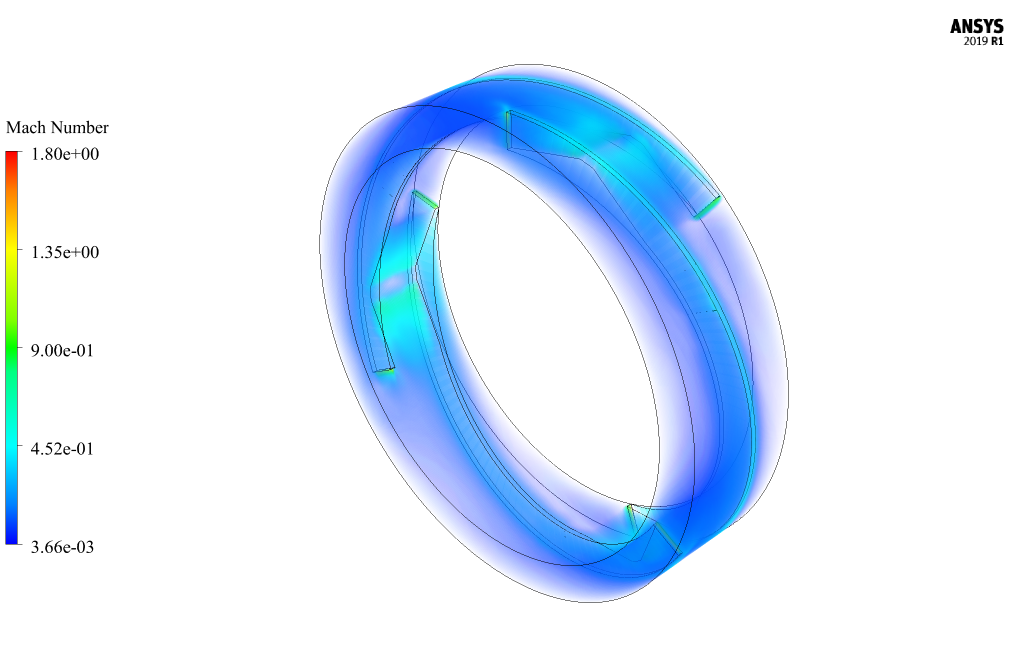

The present problem simulates the air compression inside a Rampressor using ANSYS Fluent software. The Rampressor is a unique type of ultrasonic compressor rotor that operates at a high-pressure ratio, and engine technology and gas compression are the ramjet ultrasonic shock wave. The operating mechanism of these compressors is such that the gas flow passes through a fixed outer cover and a sloping surface or inner ramp; While this inner surface has a ramp with its rotational motion relative to the fixed body, it increases or decreases the gas passage. This change in the cross-section of the gas flow causes the shock wave phenomenon and changes the value of the Mach number, and thus causes the gas to condense.

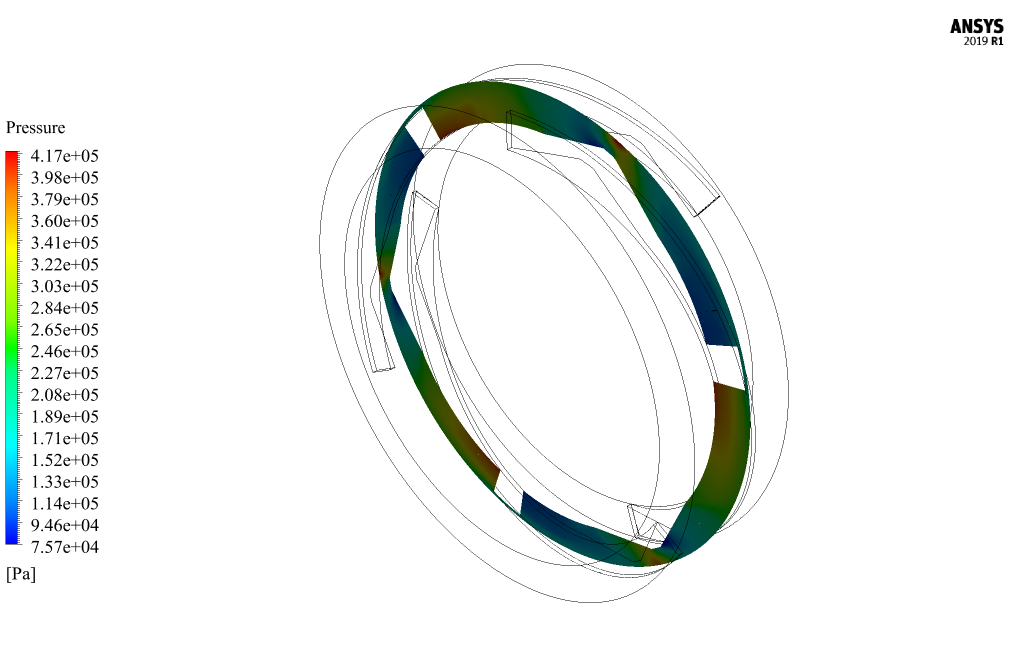

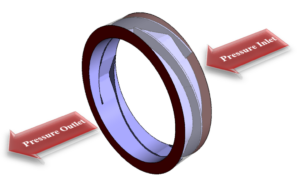

In this simulation, the inner wall of the Rampressor rotates around its central axis (z-axis) at a rotational speed of 40,000 rpm. The frame motion technique is used to define this rotational motion; This means that the inner wall, called shroud, is assumed to have a rotational movement with a velocity of 0 rpm, and the inner part of this computational region, which is around this inner wall, has a rotational motion in the frame motion section with the same speed equal to 40,000 rpm. Due to the compressive nature of this Rampressor, the pressure boundary conditions at the inlet and outlet have been used. The air in these sections has a relative pressure equal to 104600 pascal and 35000 pascal.

Also, since the airflow inside this device is entirely compressible, the density-based solver has been used.

Rampressor Geometry & Mesh

The present model is designed in three dimensions using Design Modeler software. The design of this Rampressor is in the form of a three-dimensional ring, the sides of which are defined as input and output sections, and the outer wall is defined as static, and the inner wall with several sloping surfaces as rotating.

We carry out the model’s meshing using ANSYS Meshing software, and the mesh type is unstructured. The element number is 1785931. The following figure shows the mesh.

Rampressor CFD Simulation

We consider several assumptions to simulate the present model:

- We perform a density-based solver.

- The simulation is steady.

- The gravity effect on the fluid is ignored.

The following table represents a summary of the defining steps of the problem and its solution:

| Models (Rampressor) |

||

| Viscous | k-epsilon | |

| k-epsilon model | standard | |

| near wall treatment | standard wall functions | |

| Energy | On | |

| Boundary conditions (Rampressor) |

||

| Inlet | Pressure Inlet | |

| gauge total pressure | 104600 pascal | |

| total temperature | 300 K | |

| Outlet | Pressure Outlet | |

| gauge pressure | 350000 pascal | |

| Shroud & Inner Wall | Wall | |

| wall motion | moving wall | |

| type of motion | rotational | |

| rotational speed | 0 rpm | |

| heat flux | 0 W.m-2 | |

| Methods (Rampressor) |

||

| Formulation | Implicit | |

| flow | first order upwind | |

| turbulent kinetic energy | first order upwind | |

| turbulent dissipation rate | first order upwind | |

| Initialization (Rampressor) |

||

| Initialization methods | Hybrid | |

Results & Discussions

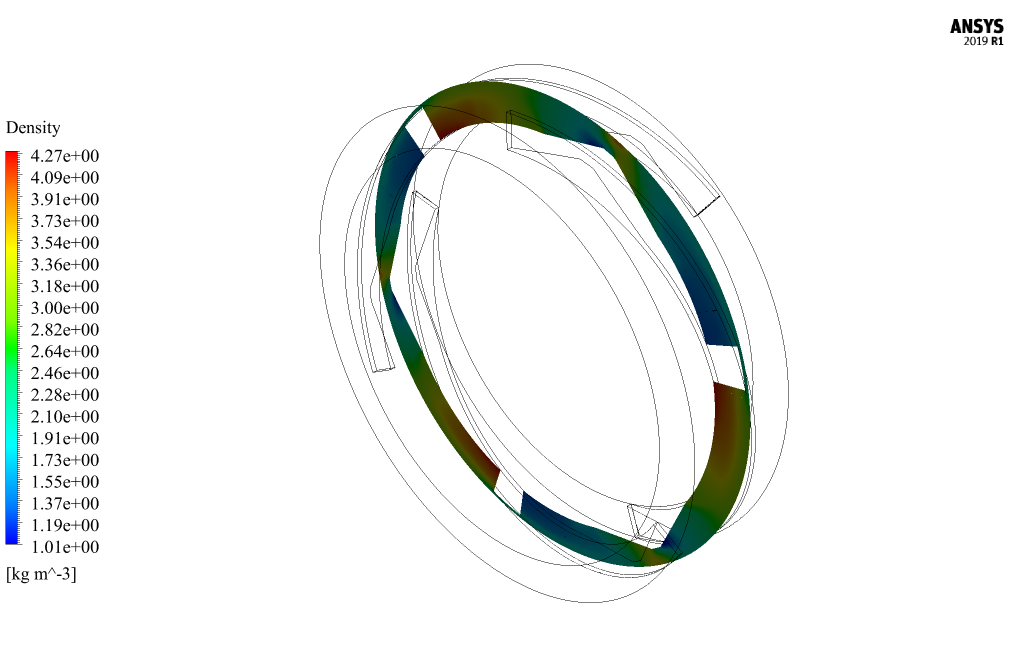

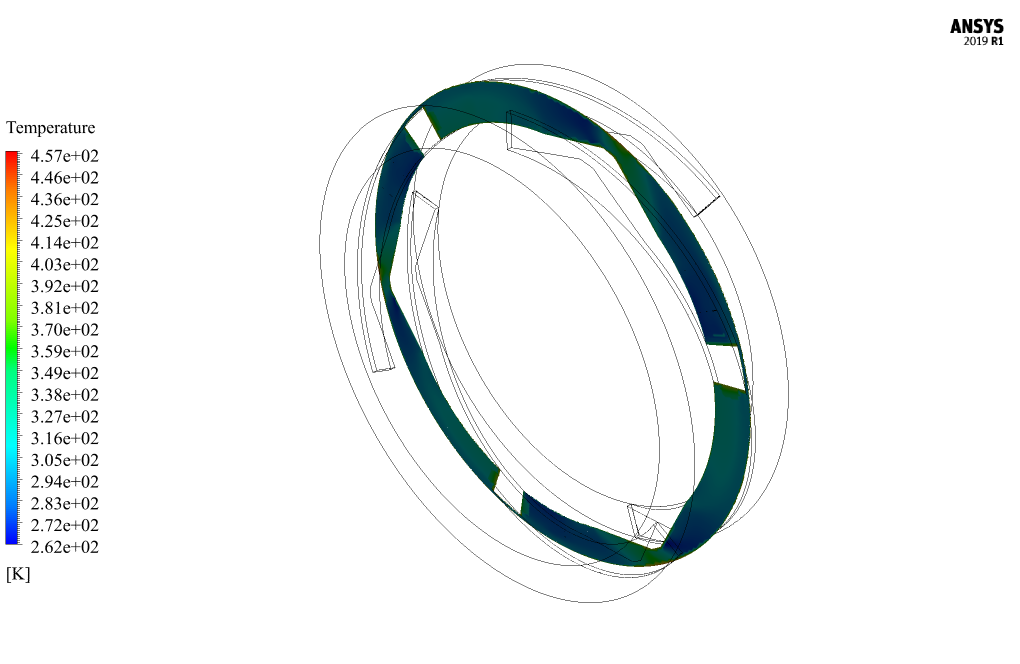

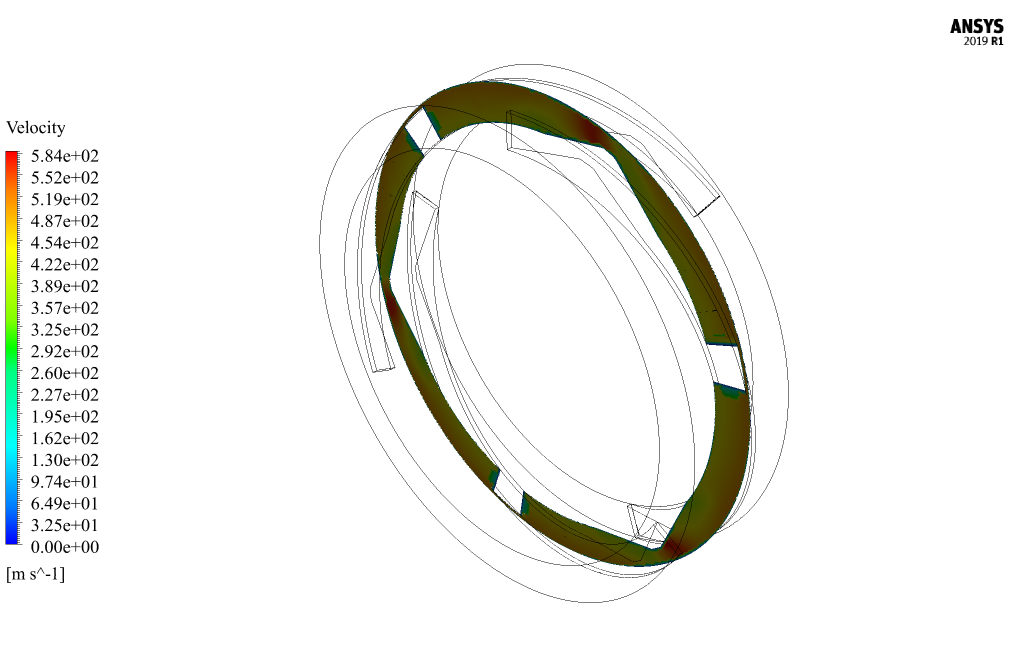

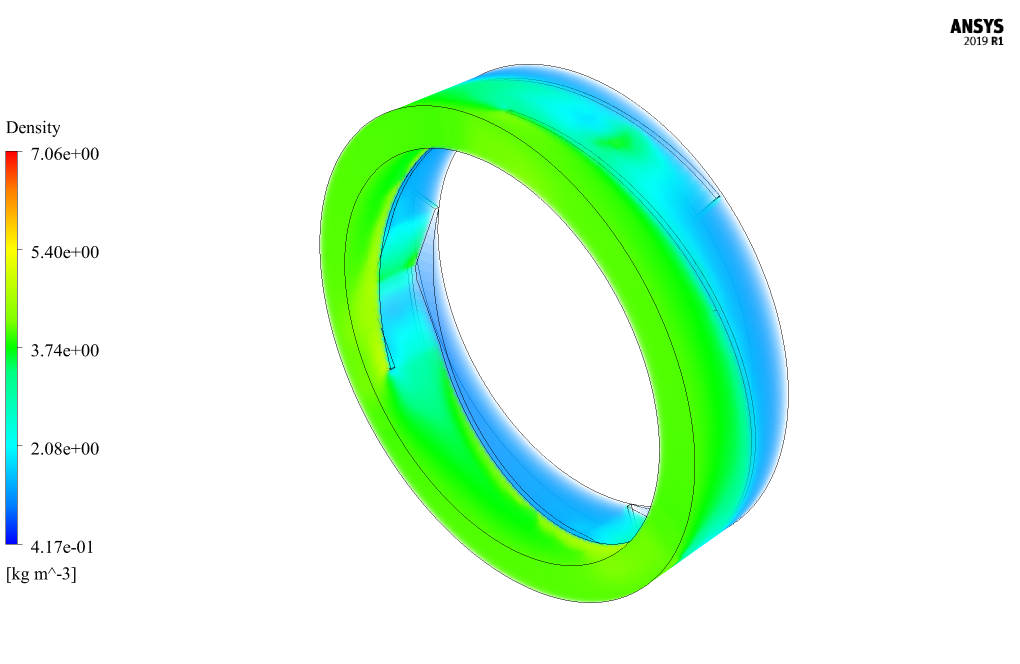

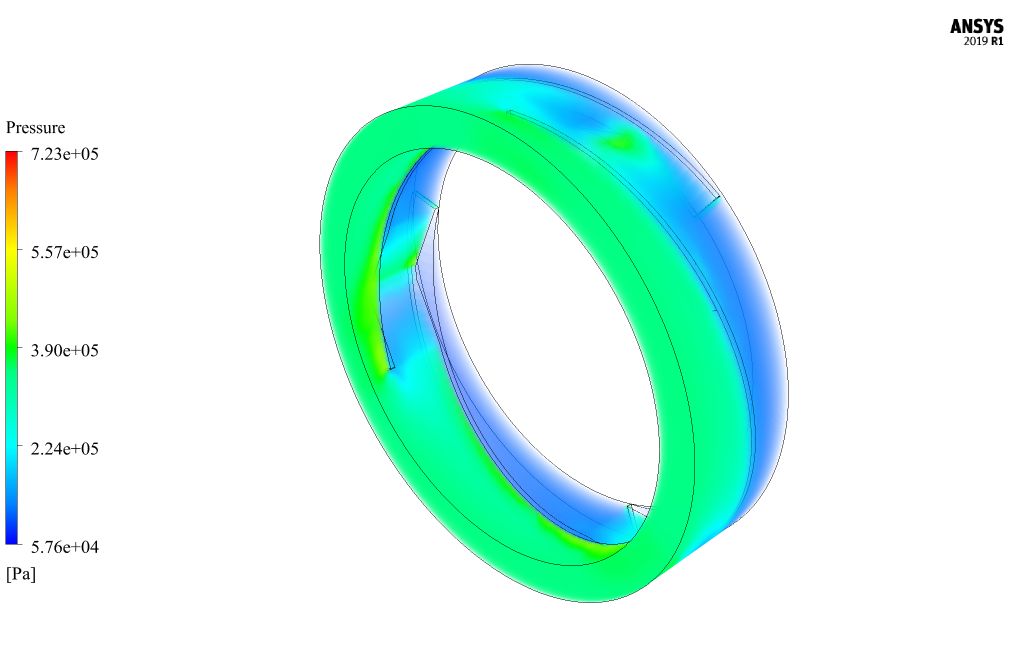

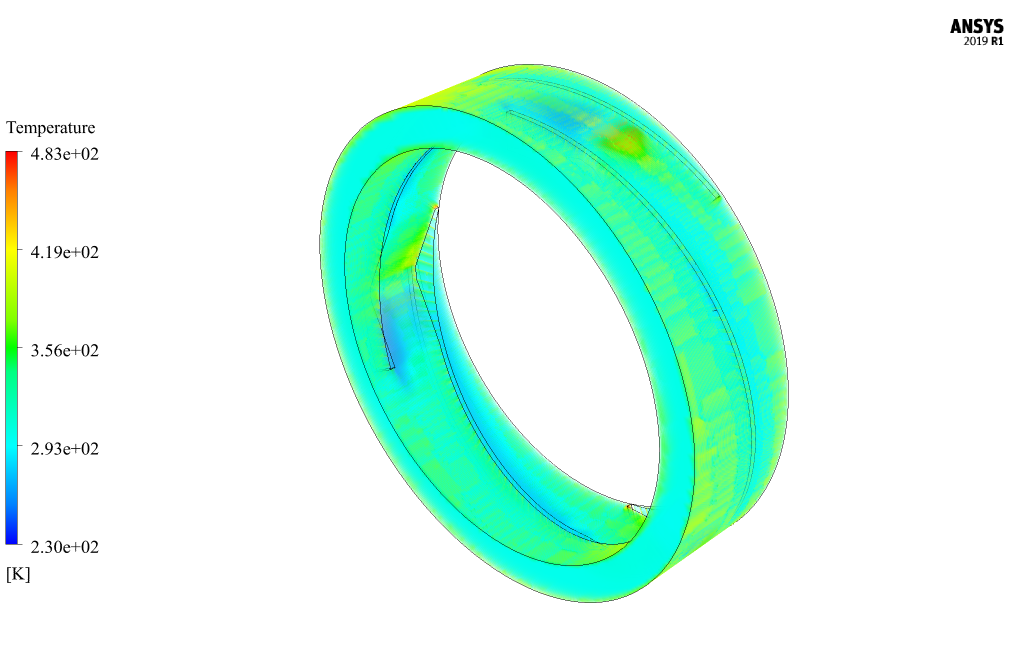

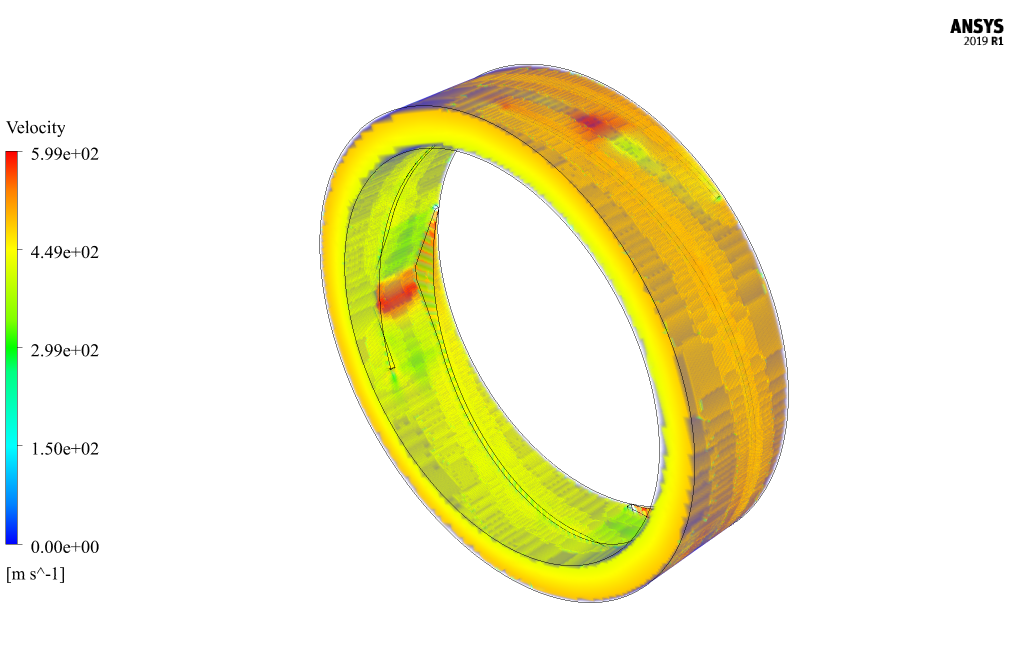

At the end of the solution process, two-dimensional and three-dimensional contours related to pressure, velocity, density, temperature and Mach number are obtained. It can be seen from the pictures that the amount of pressure in the Rampressor outlet increases. Also, the amount of Mach number increases in the space between the ramps and the equipment body.

Rasheed Smitham –

The level of detail in this simulation is truly impressive.

Ms. Rachael Gusikowski –

I’m thoroughly impressed with the detail in the Rampressor CFD simulation. Fantastic work! The visuals in the results section are engaging and clearly show the outcome. This training has bolstered my understanding of shockwave phenomena in compressible flows. Kudos to the simulation team!

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that our Rampressor CFD simulation has enhanced your understanding. It’s rewarding to know that the effort put into creating clear and educational materials is truly helping our users. If you ever have more feedback or need further assistance, we are always here to support your learning journey!

Fannie Paucek –

I learned a lot from the Rampressor simulation training. The explanation of the role of shock waves and Mach number changes was particularly insightful. I appreciate the detailed setup instructions and the meticulous breakdown of the simulation steps provided.

MR CFD Support –

We’re thrilled to hear that you found the Rampressor simulation training informative and helpful. Understanding the behavior of shock waves and Mach number in such compressive systems is indeed essential for accurate simulations. Thank you for taking the time to share your positive experience. We take pride in creating detailed and understandable CFD training materials and are glad to know our efforts are appreciated. If there’s any additional way in which we can assist you or enhance your learning experience, please let us know.

Ahmad Larkin –

I was impressed by the detailed contours used to analyse the Rampressor! Could you explain what effect the rotational motion of the ramp has on the airflow within the compressor?

MR CFD Support –

The rotational motion of the inner ramp in the Rampressor causes a variation in the cross-section area through which air flows. This dynamic change in cross-section results in compression waves that augment the airflow’s pressure and temperature as it moves through the compressor. As the ramps spin, they alternately constrict and expand the flow paths, generating a series of shock waves that efficiently compress the airflow.

Zane Feest PhD –

Was this training helpful for understanding the effects of rotation on gas dynamics within the Rampressor?

MR CFD Support –

Absolutely, this training was incredibly useful in grasping how rotational motion impacts gas flow and compression. The detailed setup and results gave a clear depiction of the dynamic changes in pressure, density, and temperature due to the Rampressor’s rotational speed. Understanding the shock wave phenomenon and changes in Mach number was particularly enlightening.

Cecile Cummerata DVM –

Absolutely fascinating usage of the frame motion technique in the Rampressor simulation! The complexity is mind-boggling, yet your explanation of the processes, including the modeling of the shockwave phenomenon, appears meticulous. Shout-out for the detailed mesh work as well—one can’t overemphasize the importance of good meshing in obtaining accurate CFD results.

MR CFD Support –

Thank you for the kind words! We’re thrilled to hear that the detailing in the Rampressor simulation’s explanation resonated well with you. It’s fantastic to get feedback that appreciates the complex techniques like frame motion used in the simulation. Our goal is always to provide clear and thorough explanations to make CFD concepts accessible. Thanks again for your feedback and for recognizing the critical role of meshing; it makes a world of difference in our simulations!

Dr. Alanna Stiedemann V –

Can you explain what causes the shock wave phenomenon in the Rampressor and how it contributes to air compression?

MR CFD Support –

In the Rampressor, the shock wave phenomenon is caused by the rapid change in the cross-section of the gas flow as it passes through the sloping surface or inner ramp of the compressor while this inner surface rotates relative to the fixed body. As the inner ramp moves, it constricts or expands the pathway for the gas flow. This abrupt change in flow area causes the gas to compress rapidly, resulting in shock waves that further induce compression of the gas. This is how the shock wave phenomenon contributes to the air compression process within the Rampressor.

Frieda Moen –

The simulation results were splendid. The increase in pressure and Mach number illustrated in your provided imagery comprehensively showcased the Rampressor’s efficiency.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that the simulation results were up to your expectations and that you found the visual representation of the Rampressor’s performance informative and satisfactory.

Justen Mertz –

What kind of data can I get from this simulation?

MR CFD Support –

The simulation can provide a wealth of data, including pressure distribution, velocity profiles, and temperature distribution. This data can help you understand the performance of the rampressor and optimize its design.

Prof. Allan Ward –

Amazingly detailed product! The accurate depiction of the Rampressor operation has refreshed my knowledge on the principles of gas dynamics, especially regarding shock waves and Mach number effects. It’s intriguing how the rotational speed was set for such a complex simulation, really impressed with how MR CFD breaks down the simulation setup, step by step.

MR CFD Support –

Thank you for your appreciation! It’s our goal to provide comprehensive learning materials that make complex concepts more accessible. We’re glad to hear that our depiction of the Rampressor’s operation has enhanced your understanding of gas dynamics. Remember, we are always here if you have more questions or need further clarification on our products.

Annetta Sporer –

I’m impressed with the ramp rotation established at 40,000 rpm. I’m curious though, with such high rotational speeds, how is the structural integrity of the Rampressor maintained in the simulation?

MR CFD Support –

Thank you for your praise! In the simulation, the structural integrity of the Rampressor under such high rotational speeds is ensured by accounting for the appropriate material properties and mechanical constraints within the problem setup. Stiffness and resistance to deformation are modeled accurately to ensure that the system’s dynamics are properly captured. These considerations help maintain structural integrity within the simulated environment.

Misael Shields –

What is the purpose of the rampressor in this CFD simulation?

MR CFD Support –

The rampressor in this CFD simulation is a type of compressor that uses a ramp to increase the velocity of the fluid, thereby increasing its pressure. It’s commonly used in various industries due to its efficiency and simplicity.

Dr. Armando O’Keefe III –

This Rampressor simulation sounds amazing! The attention to detail and the focus on achieving a high-pressure ratio are really impressive. Great job on using a complex inner ramp geometry and rotational motion!

MR CFD Support –

Thank you for your kind words! We’re thrilled you’re satisfied with our Rampressor simulation training. We strive to provide comprehensive insights into using ANSYS Fluent for complex engineering simulations. If you have any more feedback or need further assistance, feel free to reach out.

Elaina Rosenbaum –

How does the rotational speed of the shroud at 0 rpm affect the simulation given that the Rampressor rotor operates at 40,000 rpm?

MR CFD Support –

In this simulation setup, a relative motion frame is employed. While the rotational speed of the shroud is input as 0 rpm, this doesn’t mean that the shroud is stationary. Rather, its speed is specified as 0 rpm relative to the moving reference frame. In reality, the moving part of the Rampressor rotates at 40,000 rpm relative to the fixed shroud. By setting up the two components in this way, the simulation can capture their relative motion accurately without explicitly rotating the shroud.

Dovie Torp MD –

This training course was amazing for understanding the operation and CFD modeling of a Rampressor. Learned a lot about defining rotational movements with the frame motion technique, and the pressure increase at the outlet was fascinating to observe.

MR CFD Support –

Thank you for your review! We’re glad to hear that the Rampressor CFD simulation training course was enlightening and that it helped you better understand the concept of rotational motion and pressure changes in a compressible flow scenario. We appreciate you taking the time to share your positive learning experience with us!

Maya Schuppe –

The explanation of the rampressor simulation was amazingly detailed! I appreciate the clarity in outlining how the frame motion is used for the rotating wall and how both steady-state and shock wave phenomena are investigated. It truly highlights the capabilities of density-based solvers for compressible flows.

MR CFD Support –

Thank you so much for your positive feedback! We’re thrilled to hear that you found the detailed explanation of the rampressor simulation useful and clear. Density-based solvers are indeed powerful tools for dealing with compressible flow phenomena, and we’re glad our training helped showcase that. If you have any further questions or need to delve deeper into any aspects of CFD simulations, feel free to get in touch with us. Your satisfaction with our training materials is our top priority!

Coleman Pagac –

What are the primary advantages of using a density-based solver for this Rampressor simulation?

MR CFD Support –

The density-based solver is ideal for high-speed fluid flows where significant changes in density due to compressibility effects are present, like in the case of the Rampressor. It efficiently handles shockwaves and expansion fans, common in these scenarios, ensuring accurate simulation of the complex compressible flow within the Rampressor.

Stephania Willms –

The project description covers quite a technical process. How accurate is the CFD simulation for such complex systems? Can I rely on these results for developing a prototype?

MR CFD Support –

The accuracy of CFD simulations, like the one for the Rampressor, generally depends on factors like the quality of the mesh, the sophistication of the models used, and how well boundary conditions and physical phenomena are defined. ANSYS Fluent is a powerful tool that is well-capable of capturing such complex phenomena with a high level of accuracy, provided that the simulation set-up is carefully executed. While such results are indeed useful for prototype development, it’s recommended to validate CFD results with experimental data whenever possible to ensure reliability before moving to the prototyping stage.

Bella Von –

I learned a lot from the Rampressor simulation training! The step-by-step approach made complex concepts easy to grasp. Great job on presenting the information logically!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that our training material on the Rampressor simulation was effective and helpful for you. We strive to make our learning resources clear and informative. If you ever have more questions or need further assistance, feel free to reach out.

Hertha Spinka –

I was fascinated by the high rotational speed of the Rampressor’s inner wall. How is the structural integrity of the Rampressor maintained at such high speeds during the simulation?

MR CFD Support –

The structural integrity of the Rampressor under high rotational speeds is accounted for by performing rigorous computational analysis. In the simulation, material properties providing the necessary strength and the precise modeling of the rotor’s dynamics are crucial. The simulation assumes a robust material that can sustain the centrifugal forces without deformation or failure.

Lester D’Amore –

The CFD training package for Rampressor using ANSYS Fluent sounds comprehensive. The detailed explanation of the theoretical background, as well as the practical set up within ANSYS including the use of a rotating frame of reference, and the results obtained provides deep insight into the functionality of such an uncommon device. Your product showcases the complexity and nuances of airflow within a Rampressor very effectively.

MR CFD Support –

We’re thrilled to hear that you’re satisfied with our Rampressor CFD simulation training in ANSYS Fluent. It’s our goal to provide detailed and comprehensive training that enhances understanding of such specialized equipment. Thank you for taking the time to share your positive feedback!

Daniella Funk Jr. –

I just completed the Rampressor CFD Simulation training and was impressed by how well it handled the complex physics. The rotational motion setup and the shock wave phenomenon were fascinating to watch in action. Kudos for a well-structured course!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that the training on Rampressor CFD Simulation met your expectations and provided you with a comprehensive understanding of the physics involved. We pride ourselves on our commitment to quality educational content and are glad it was evident in this course. If you have any more questions or need further assistance, feel free to reach out. Keep learning!

Cora Stiedemann –

I am thoroughly fascinated with how the Rampressor manages the airflow at such high rotational speeds. The explanation of the meshing was particularly informative. It’s clear the design process in ANSYS was well thought out, leading to accurate simulations of the shock wave phenomenon. A question – how do the sloping surfaces on the inner ramp contribute to the efficiency of the Rampressor?

MR CFD Support –

The sloping surfaces on the inner ramp are integral to the Rampressor’s efficiency. As the gas flow passes these sloping surfaces during the rotor’s rapid rotation, they create variations in the channel’s cross-section. This variation causes shock waves that incrementally compress the gas, resulting in a significant change in Mach number, and hence an efficient compression process. It’s the meticulous design of these slopes and their relative motion to the stationary parts that allow the Rampressor to effectively manipulate the gas flow’s kinetic energy into increased pressure.

Prof. Joana Crooks DDS –

The review is positive and showcases the comprehensive analysis and features of the product.

MR CFD Support –

Thank you for your feedback! We are thrilled to hear that our Rampressor simulation training has met your expectations and provided valuable insights. We aim to deliver high-quality CFD simulations using ANSYS Fluent, and your positive review motivates us to keep up the good work!