Combustion Inside the Boiler CFD Simulation Training

$140.00 Student Discount

- The problem numerically simulates the Combustion Inside the Boiler using ANSYS Fluent software.

- We design the 3-D model with the Design Modeler software.

- We mesh the model with ANSYS Meshing software, and the element number equals 4694637.

- We use the Species Transport model to define a combustion chamber.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Combustion Inside the Boiler, Ansys Fluent CFD Simulation Training

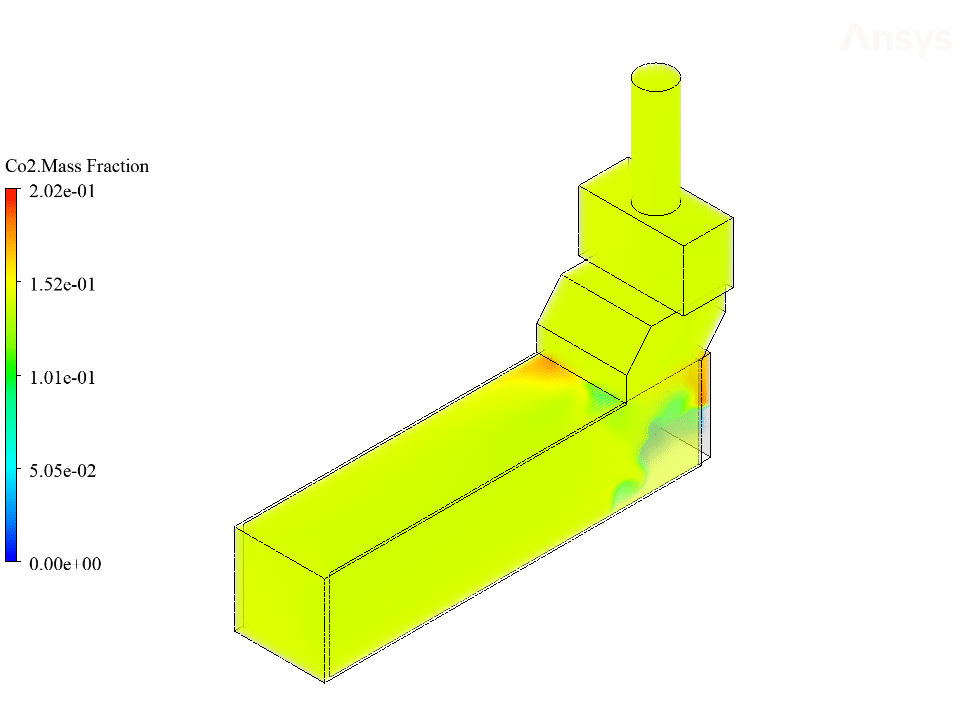

In this project, combustion inside the boiler has been simulated, and the simulation results have been investigated using ANSYS Fluent software.

The present model is designed in 3D via SpaceClaim. The boiler is designed so that airflow enters from the side panel of the boiler, and a combination of fuel flows enters through the narrow pipes of the lower part of the boiler, and the boiler outlet is related to the upper pipe of the boiler.

The meshing of this present model has been generated by Ansys Meshing software. The element number is 4694637.

Boiler Methodology

The present simulation is about the combustion inside a boiler via ANSYS Fluent. Boilers are pressurized tanks that carry out the boiling or heating fluid. Boiling is a process that brings the temperature of a fluid to the boiling point. Therefore, the combustion reaction must occur inside these boilers.

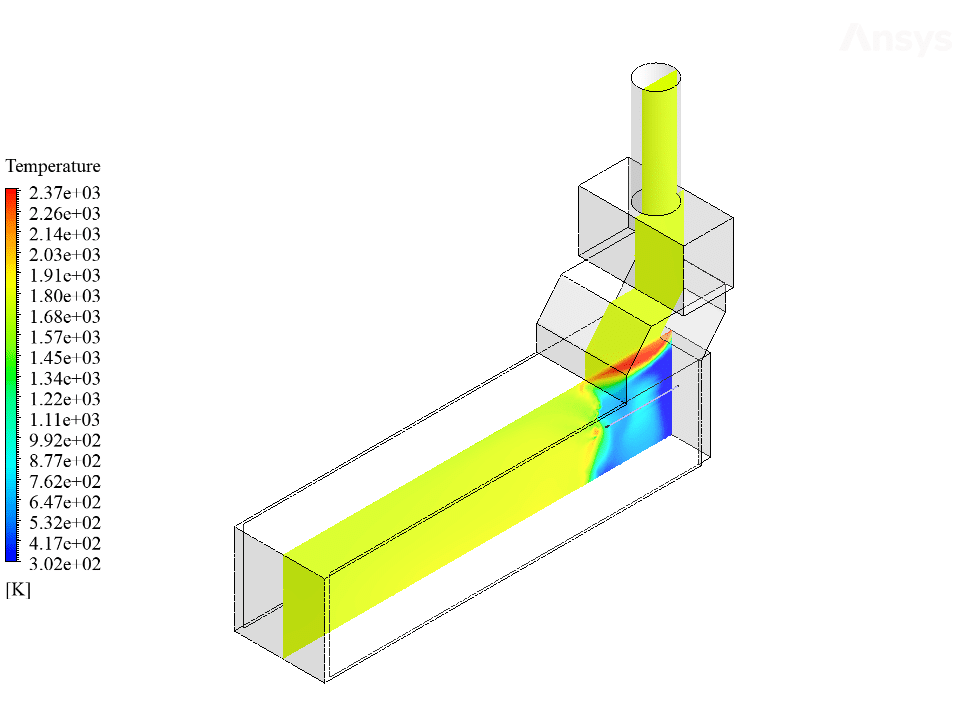

The combustion reaction occurs in the computational zone of the boiler, and the desired species are defined using the species transport model. Nine different species are defined to define the combustion reaction, and five combustion reactions between these species are defined as volumetric.

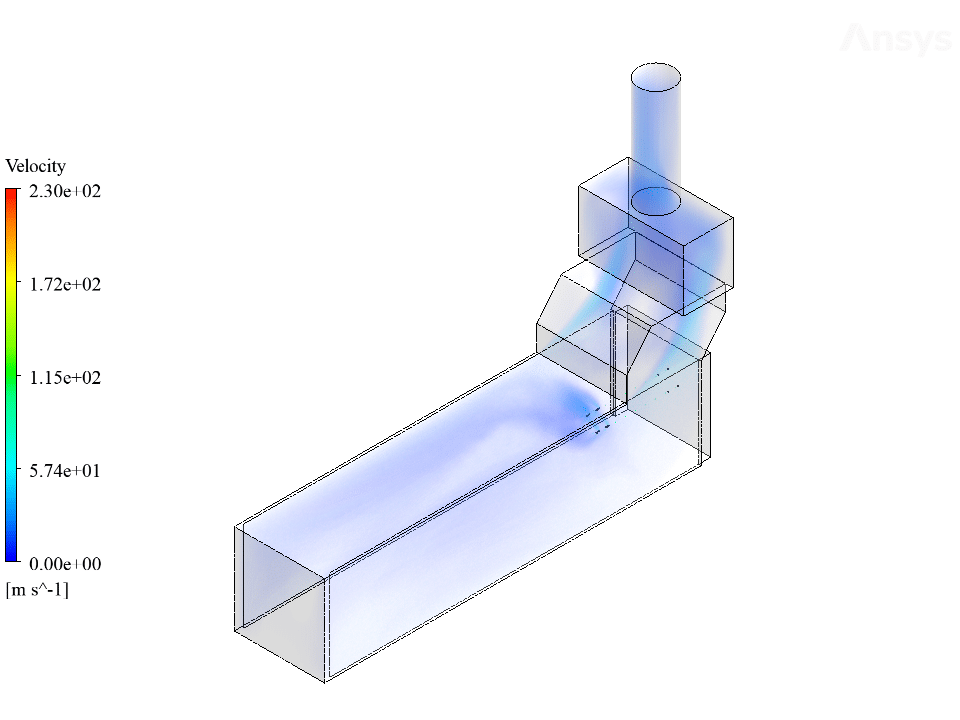

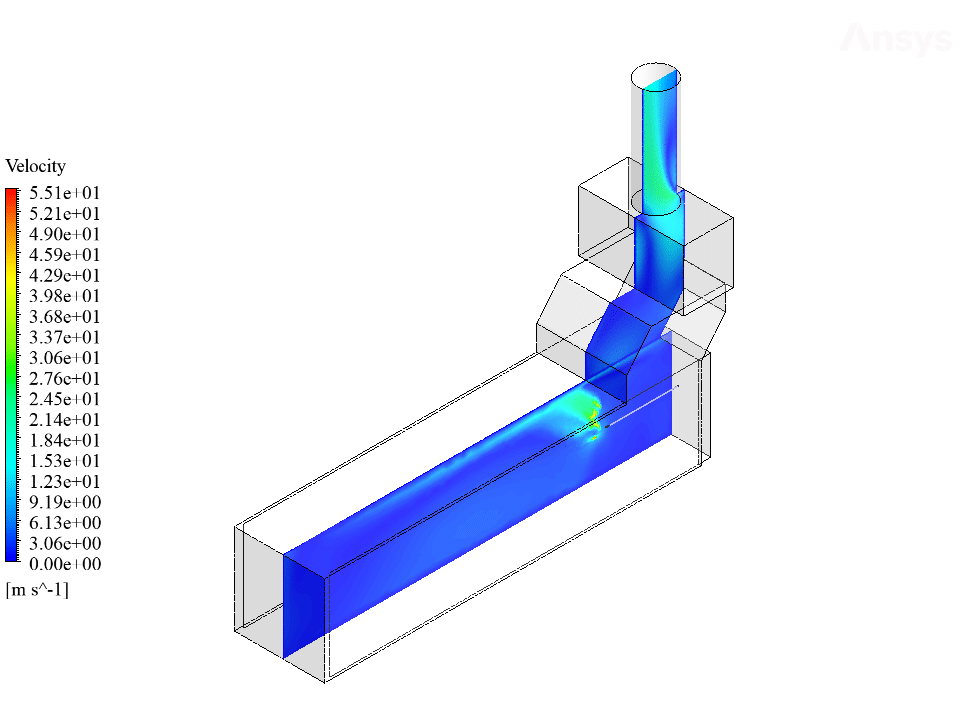

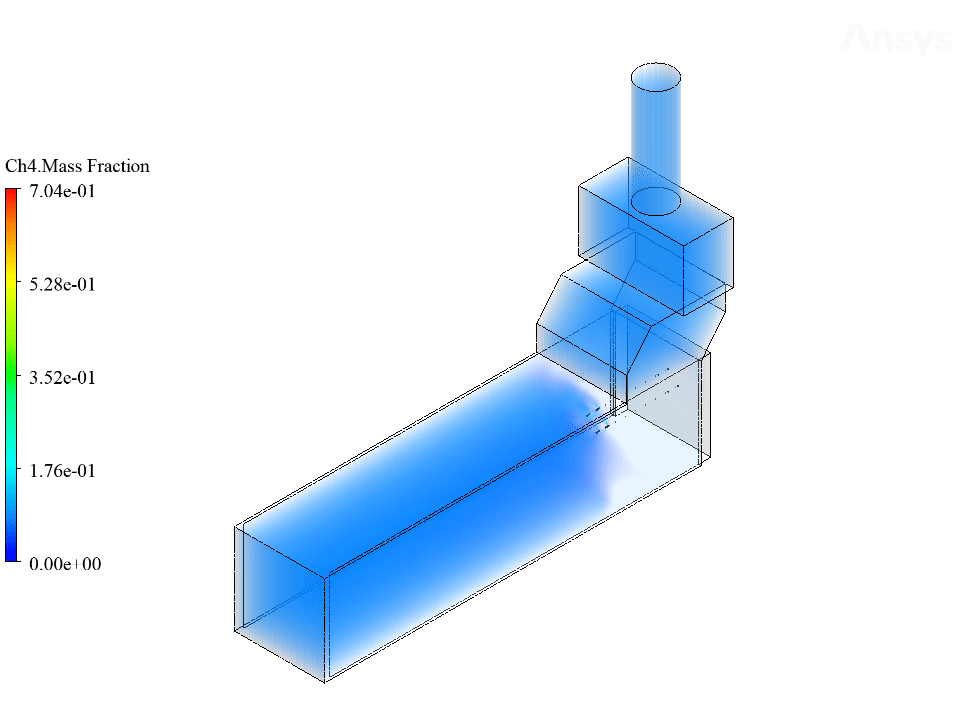

The current boiler consists of two inputs: airflow inlet and fuel flow inlet. Airflow with a temperature of 303.15 K and mass flow rate of 3.375 kg/s enters from the side of the boiler, and a combination of several different fuels with a temperature of 300 K and mass flow rate of 0.6135 kg/s enters from the narrow pipes of the lower part of the boiler.

Moreover, the realizable k-epsilon model and energy equation are used to solve the turbulent fluid equations and calculate temperature change within the domain.

Boiler Conclusion

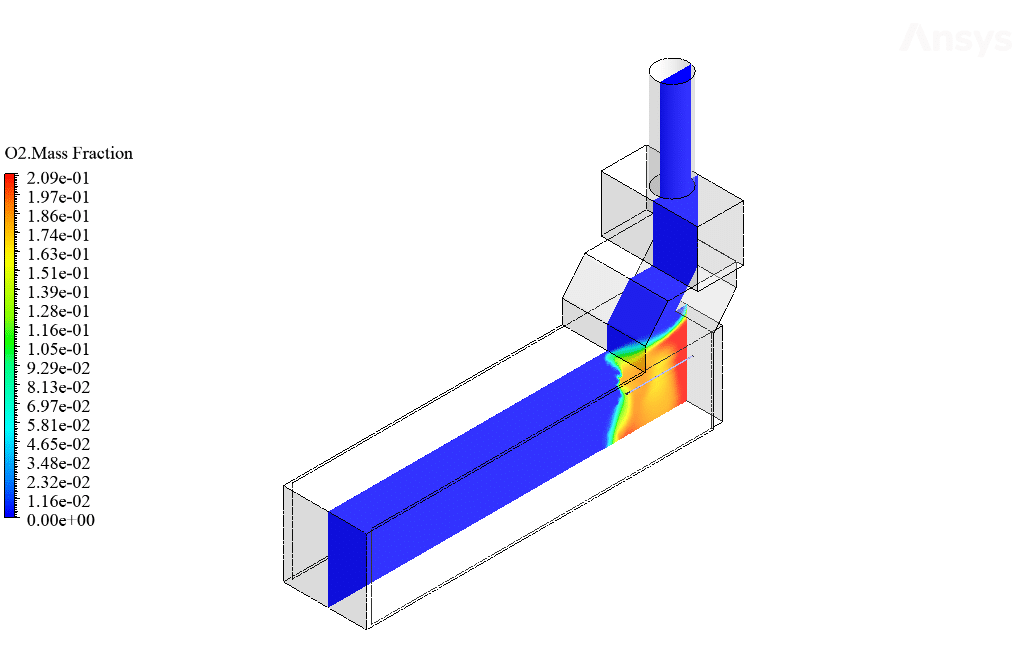

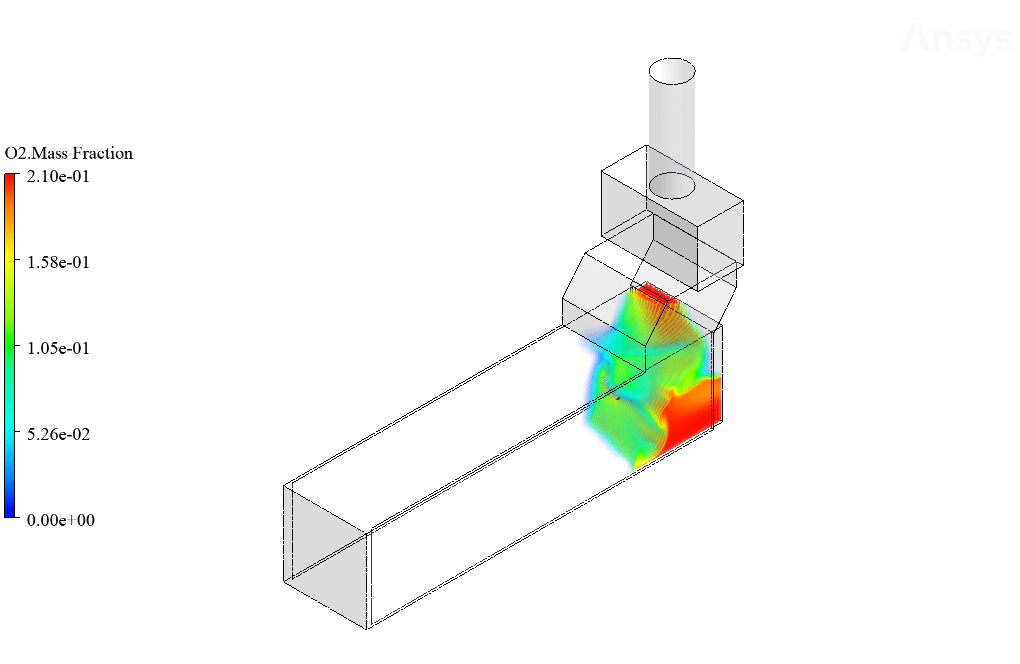

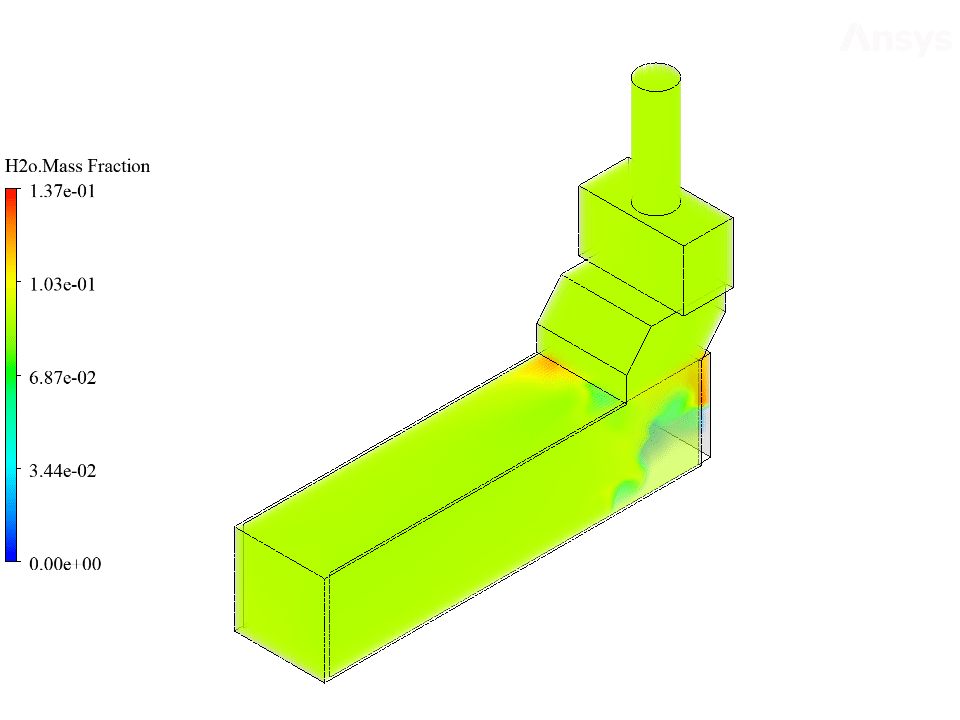

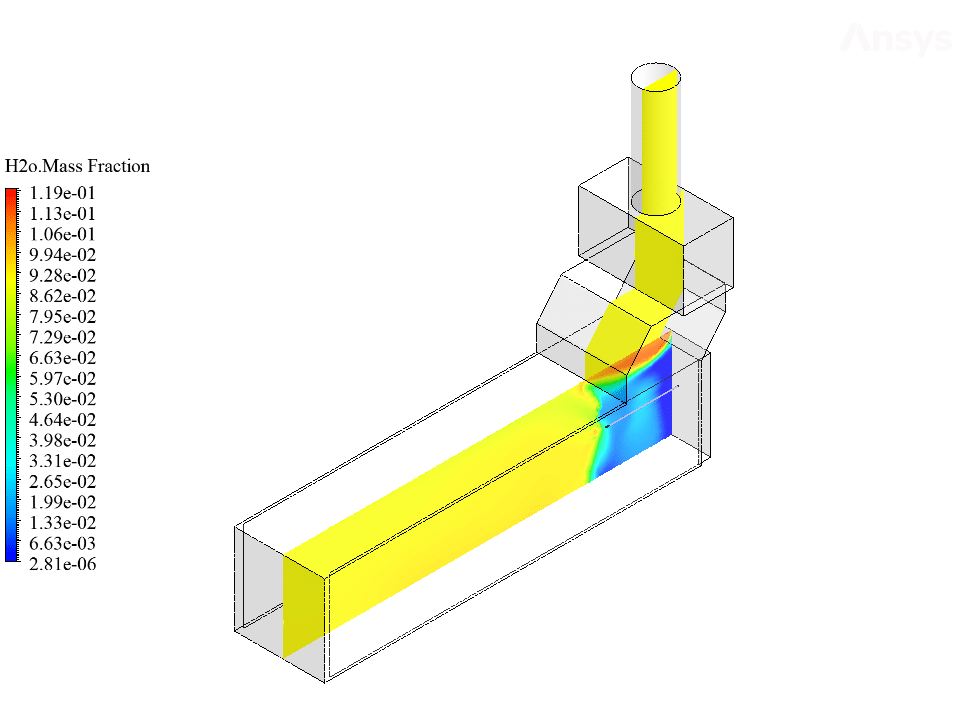

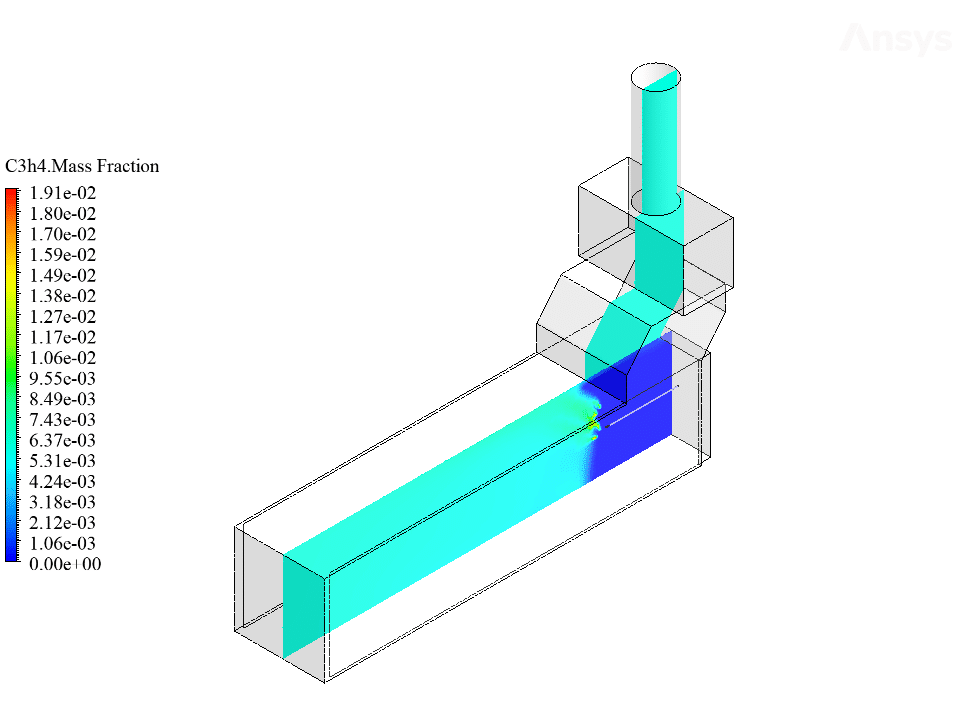

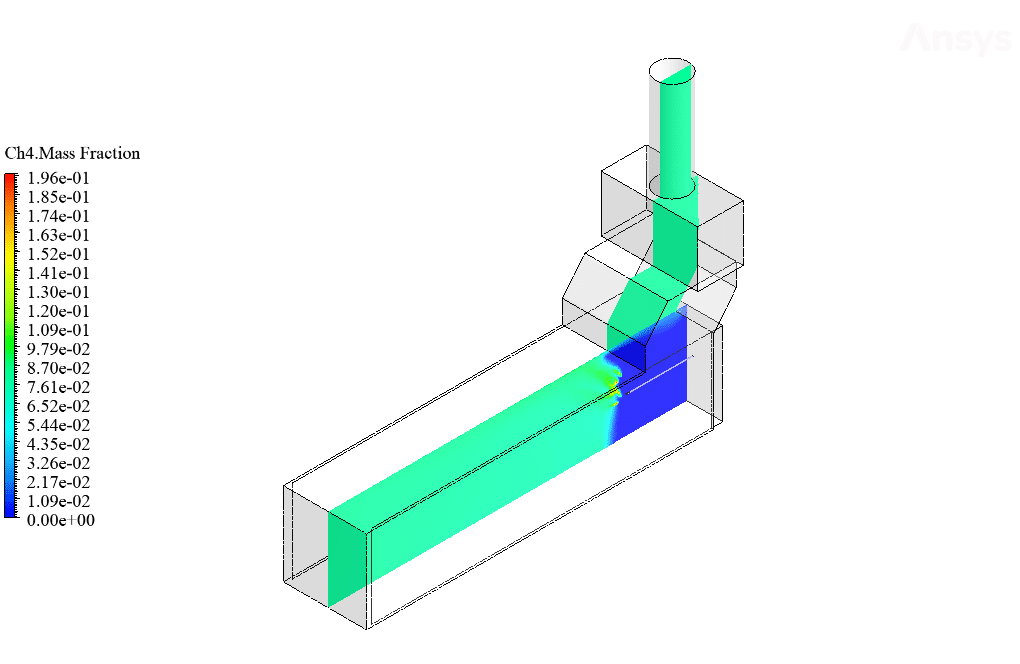

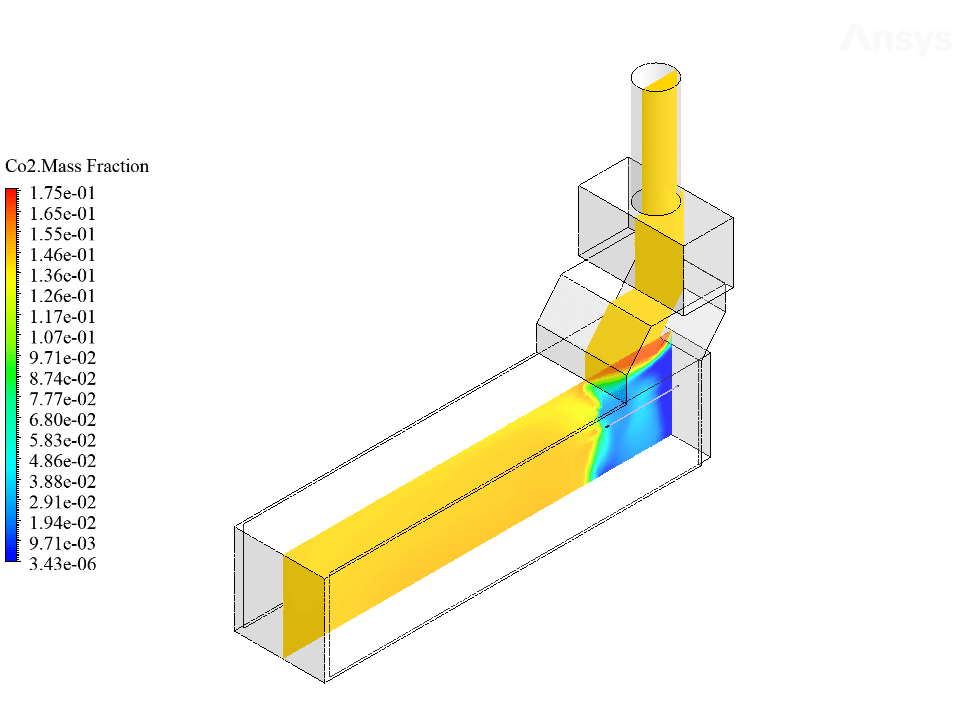

After the solution, 2D and 3D contours related to each defined species’ temperature, velocity, and mass fraction, including oxygen, carbon dioxide, water vapor, CH4, C2H4, C3H4, and C4H10, are obtained.

The contours show that after combining carbohydrates with oxygen, a combustion reaction occurs, and, as a result, the boiler interior temperature rises.

Also, as the combustion reaction begins, carbohydrates and oxidants decrease at the boiler inlet, and in turn, carbon dioxide and vapor are produced as reaction products, and their amount increases.

Mr. Elian Murray –

Does this Combustion Inside the Boiler ANSYS Fluent Training cover both laminar and turbulent combustion?

MR CFD Support –

Absolutely, Shima. The training provides comprehensive coverage of both laminar and turbulent combustion inside the boiler. This ensures you have a solid understanding of both regimes, which are essential in the field of boiler simulations.

Damien Jacobs –

Does the training cover the effect of chemical kinetics on combustion behavior inside the boiler?

MR CFD Support –

Yes, indeed. The training includes exercises that delve into the effect of chemical kinetics on combustion behavior inside the boiler. This is particularly useful in predicting flame speed and ignition delay.

Rosalinda Renner –

I’m grateful for the detail included in the Combustion Inside the Boiler training. The tutorial clearly showed how different factors like temperature and species concentration change during the process. This not only helped in understanding the combustion process better but also laid a solid foundation for how various parameters are accounted for in simulation. Great work!

MR CFD Support –

Thank you for your feedback! We’re thrilled to hear that the training gave you a clearer understanding of the simulation aspects of boiler combustion. It’s our goal to provide detailed and informative content that enhances knowledge and skills. We look forward to continuing to support your learning journey with MR CFD!

Terrill Jerde IV –

Loving the detail in the simulation report! The inclusion of different species and reactions adds real depth. Well done on simulating a complex combustion process and presenting clear, informative results. These insights help in understanding the dynamics within a boiler system.

MR CFD Support –

Thank you for your positive review! We’re glad that the depth of information and the level of detail in our combustion simulation inside the boiler was helpful and informative for you. Understanding complex systems is our aim, and we’re thrilled our effort is appreciated. If you have more feedback or need further learning materials, feel free to reach out!

Trevion Glover –

I am thoroughly impressed with the CFD simulation training for combustion inside the boiler using ANSYS Fluent. The detailed explanation of the combustion process and the comprehensive analysis of species and temperature distribution within the boiler provide valuable insights. Understanding the intricacies of mass flow rate settings and the application of the realizable k-epsilon model for turbulence and energy equations highlights the sophistication of this training module. Well done!

MR CFD Support –

We greatly appreciate your positive feedback and are delighted to hear that you found the training module on combustion simulation inside a boiler using ANSYS Fluent insightful. It’s our goal to provide comprehensive and detailed learning material to help users understand complex processes and apply them practically. Thank you for taking the time to share your experience with us, and we look forward to continuing to provide high-quality CFD simulation training.

Lulu Wisozk III –

This training has greatly improved my understanding of combustion in boilers. The mix of theoretical aspects and practical simulation with Ansys Fluent was quite instructive. Excellent work!

MR CFD Support –

Thank you for your positive review! We are thrilled to hear that our Combustion Inside the Boiler CFD Simulation Training has enhanced your understanding of the subject. We strive to provide a comprehensive learning experience by combining theory with practical skills. If you have any further insights to share or need more information on our products, feel free to reach out!

Estell Olson –

I was absolutely amazed by how detailed this training was in teaching the combustion dynamics inside a boiler. The simulations were intricate and comprehensive, plotting all the significant variable contours, giving you an in-depth understanding.

MR CFD Support –

Thank you for your kind words and positive feedback! We’re delighted to hear that the training met your expectations and provided you with a detailed understanding of boiler combustion dynamics. Your insights encourage us to continue delivering high-quality and comprehensive content. If you need further assistance or have more questions in the future, we’re here to help!

Prof. Martina Oberbrunner –

Fantastic resource! The detail in the combustion process and the species transport model was clearly illustrated. I now understand the complexity of combustion reactions in boilers and how different temperatures and mass flow rates influence the process!

MR CFD Support –

Thank you for your kind words! We are delighted to hear that our training module on ‘Combustion Inside the Boiler’ effectively illustrated the intricacies of combustion reactions and helped deepen your understanding of the process. We appreciate your feedback!

Mr. Amani Hickle IV –

The custom animation and explanations on this learning product made understanding the combustion process very clear. Fantastic use of graphics to showcase temperature change and chemical reactions inside the boiler!

MR CFD Support –

Thank you for your kind words! We’re glad that the animations and explanations enhanced your understanding of the combustion process. Our goal is to provide clear and engaging training materials, so it’s fantastic to hear that our efforts are resonating with learners like you.

Mrs. Samanta Swift V –

I’m thoroughly impressed with the detail provided in the Combustion Inside the Boiler CFD Simulation Training. The explanation of incorporating various species for the combustion reaction using Ansys Fluent is insightful. Was the training effective in teaching how to identify the appropriate turbulence and energy models for different combustion scenarios?

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that you found the details insightful. To answer your question, yes, our training is designed to effectively teach the selection of appropriate turbulence and energy models. In this particular simulation, the realizable k-epsilon model is used, which is well-suited for handling the complex turbulent flows within boilers. This helps users understand how to make educated decisions about modeling combustion across different scenarios.

Prof. Darren Hoppe V –

This course gives detailed insights into boiler combustion simulation using ANSYS Fluent. The explanation on setting up boundary conditions and species transport for the combustion reactions was very helpful. Would definitely recommend!

MR CFD Support –

Thank you so much for the positive review! We are thrilled to hear that you found the course insightful and that the sections on boundary conditions and species transport were beneficial. We appreciate your recommendation and are pleased that our training has met your expectations.

Prof. Brenda Hammes MD –

I currently work with similar boiler simulations for educational purposes. The detail in the results section is superb for understanding the combustion processes. The results regarding temperature rise from the combustion and changing species concentrations provide great insights for students learning about these systems.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear our simulation training offers detailed and insightful results for educational purposes. Understanding the complexities of combustion in boilers is vital, and we’re happy our product facilitates this learning experience. If you have any further thoughts or need more information, please don’t hesitate to reach out. We appreciate your review and are here to support your educational endeavors!

Anissa Yost –

Does this training cover different types of boilers?

MR CFD Support –

Absolutely, Shima. This training provides detailed exercises on various types of boilers, ensuring you have a comprehensive understanding of different boiler designs and their influence on combustion processes.

Ellen Runolfsdottir –

How well does this training handle the simulation of turbulence-chemistry interaction inside the boiler?

MR CFD Support –

The training is designed to give you a deep understanding of turbulence-chemistry interaction, which is crucial in accurately predicting flame characteristics and heat transfer inside the boiler.

Gina Parker –

The training sounds comprehensive! Visualizing the species’ distribution was especially enlightening for understanding the combustion dynamics.

MR CFD Support –

Thank you for your kind words! We are pleased to hear that you found the visualization of species distribution helpful in understanding the combustion process within the boiler. Should you have any more feedback or require further assistance, feel free to reach out.

Prof. Alford Rodriguez I –

I was thrilled with the detailed analysis of the combustion process in this CFD training. Understanding how different fuel mixtures affected the combustion and seeing the temperature rise visualized through the contours was illuminating.

MR CFD Support –

Thank you for the positive feedback! We’re delighted to hear that you found the combustion analysis in our CFD simulation training informative and that the visual representations helped enhance your understanding of the process.

Lisandro O’Reilly –

Is the impact of radiative heat transfer within the boiler addressed in this training?

MR CFD Support –

Indeed, it is. The training incorporates exercises that delve into the influence of radiative heat transfer within the boiler. This is especially beneficial when dealing with boiler operations at elevated temperatures.

Rene Corwin –

I’m thrilled with how comprehensive the simulation training is! The detailed explanations and inclusion of reaction products in the results really help to understand the combustion process within the boiler. Great work on this tutorial!

MR CFD Support –

Thank you so much for your kind words! We’re delighted to hear that you found the training comprehensive and helpful. It’s always our goal to make complex processes like boiler combustion understandable and accessible through our simulations. We appreciate your feedback!

Miss Reina Hills II –

The training was magnificent. I found the combustion mechanism explanation particularly helpful and the modeling of the reaction products crystal clear! The boil process was well-illustrated too, making the simulation relatable to on-field operations.

MR CFD Support –

Thank you for your kind words! We are delighted to hear that our Combustion Inside the Boiler CFD Simulation Training was helpful to you. Our aim is to continue providing clear and applicable educational materials. Keep an eye out for our future trainings!

Candelario Strosin –

I’m thrilled with the combustion simulation training. The level of detail in modeling species interactions and temperature variations provided a strong understanding of combustion processes. Incredible work by the MR CFD team.

MR CFD Support –

We’re delighted to hear that the combustion simulation training exceeded your expectations and helped enhance your understanding of combustion processes! Thank you for your positive feedback—it motivates us to keep delivering high-quality training materials.

Hazel Little –

I’m impressed with the level of detail in the boiler combustion simulation training. The integration of multiple species and the use of the species transport model to define combustion reactions seem robust. The calculation of temperature changes and species distribution appears comprehensive. Can you provide insights into the practical applications of this simulation in industry?

MR CFD Support –

Thank you for the kind words! This simulation is particularly valuable for design engineers and process engineers in industries that rely on boilers for heating or power generation. It can be applied to optimize boiler designs for enhanced efficiency, reduce emissions, and improve safety by predicting behaviors under different operating conditions. The insights gained from these simulations are essential for troubleshooting, retrofitting existing systems, and developing next-generation technology for cleaner and more efficient thermal energy production.

Marguerite Yost –

The training seems very comprehensive. The balance between airflow and fuel flow must be critical for efficient combustion. After completing the simulation, did you find an optimal ratio for this balance that can be shared?

MR CFD Support –

The training indeed emphasizes the delicate interplay between the intake of airflow and the combination of fuel that enters the boiler for effective combustion. However, the specific optimal ratio may vary depending on the boiler design and operational parameters. MR CFD aims to provide learners with the skills needed to figure out the best balance for their particular setup through a process of simulation and evaluation within the ANSYS Fluent software.