Cooling Process of a Hot Rotating Steel Structure

$60.00 Student Discount

In this project, the unsteady cooling process of a hot rotating steel structure is investigated.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Cooling Process of a Hot Rotating Steel Structure, CFD Simulation Training by ANSYS Fluent

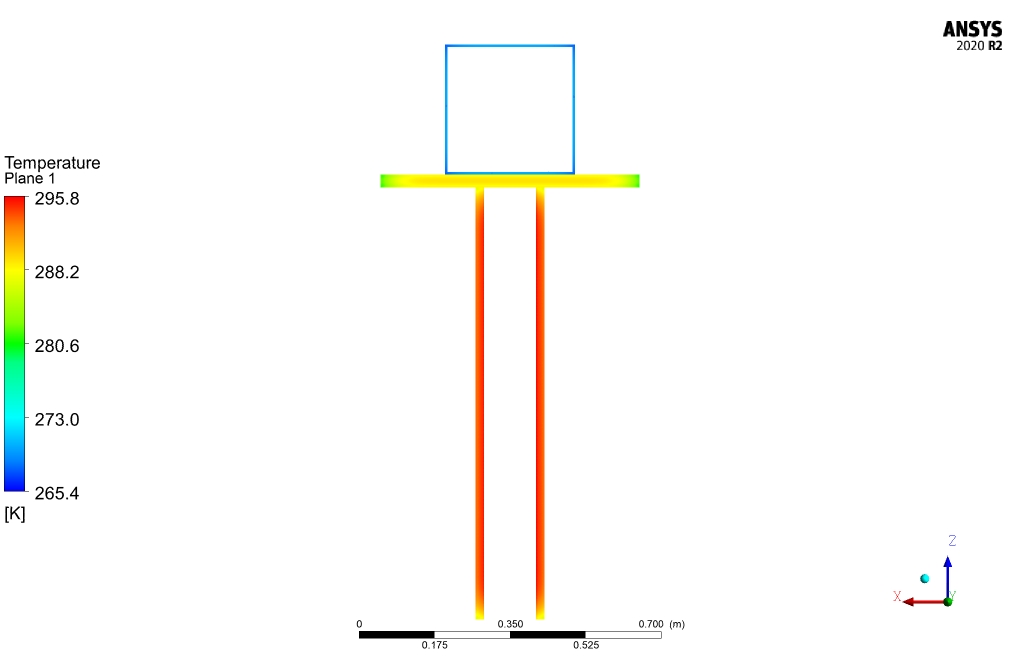

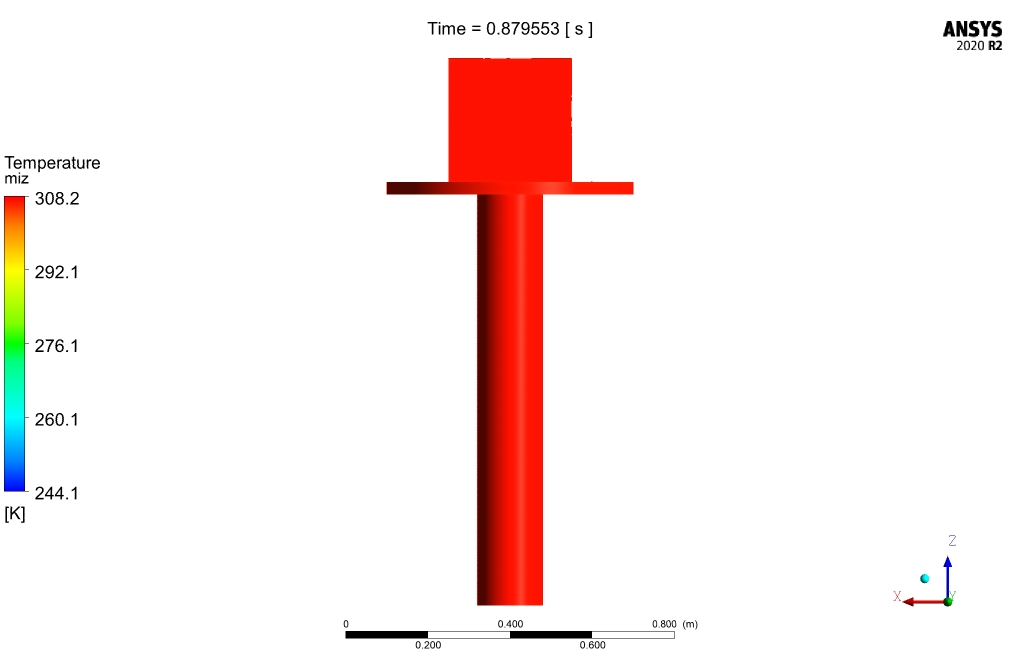

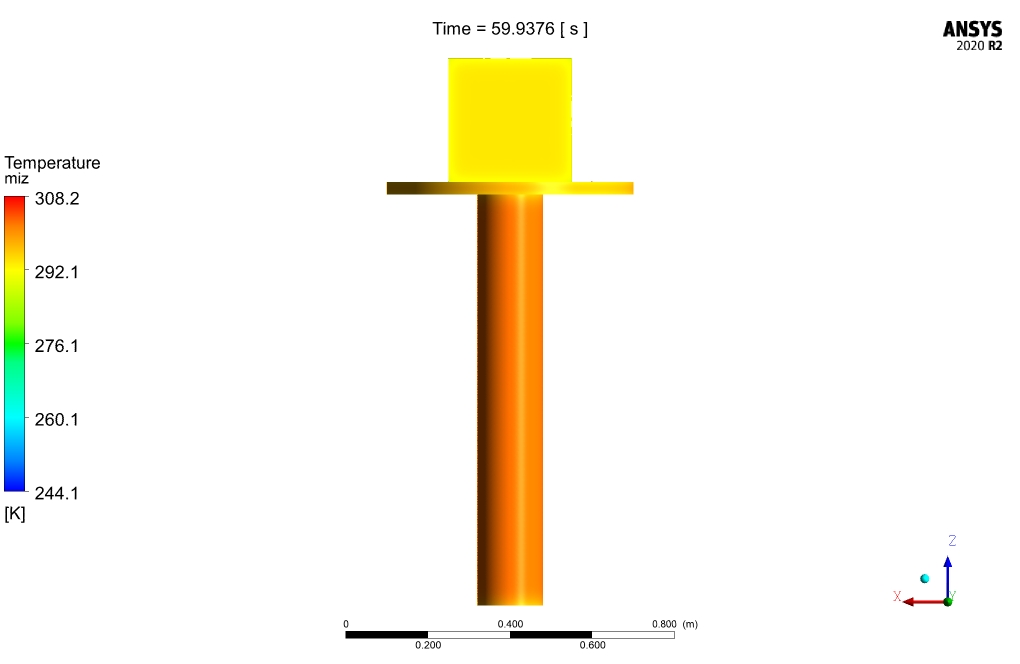

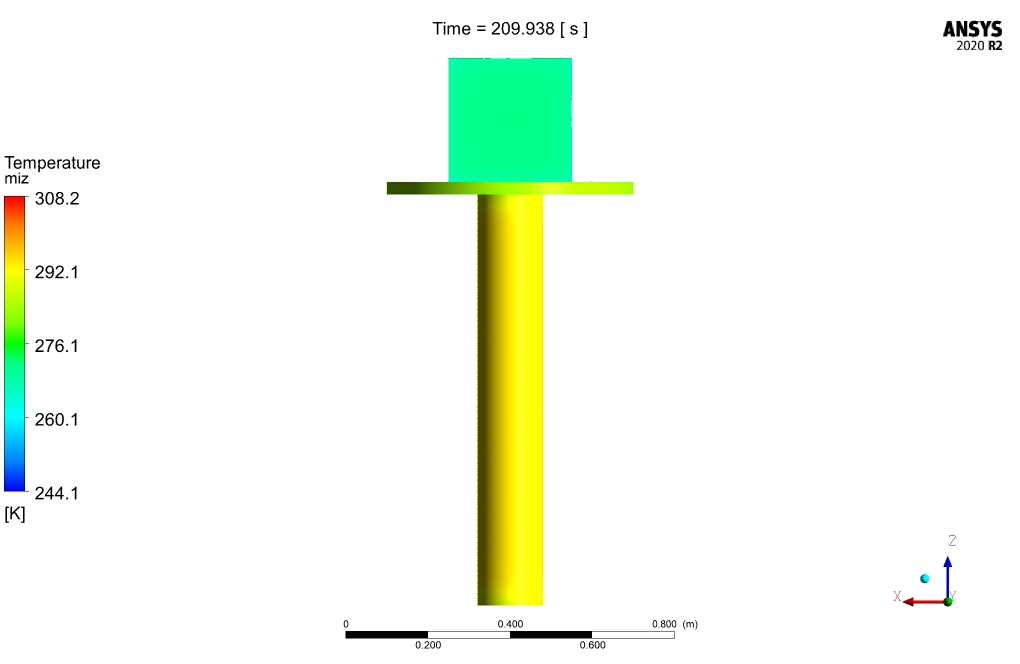

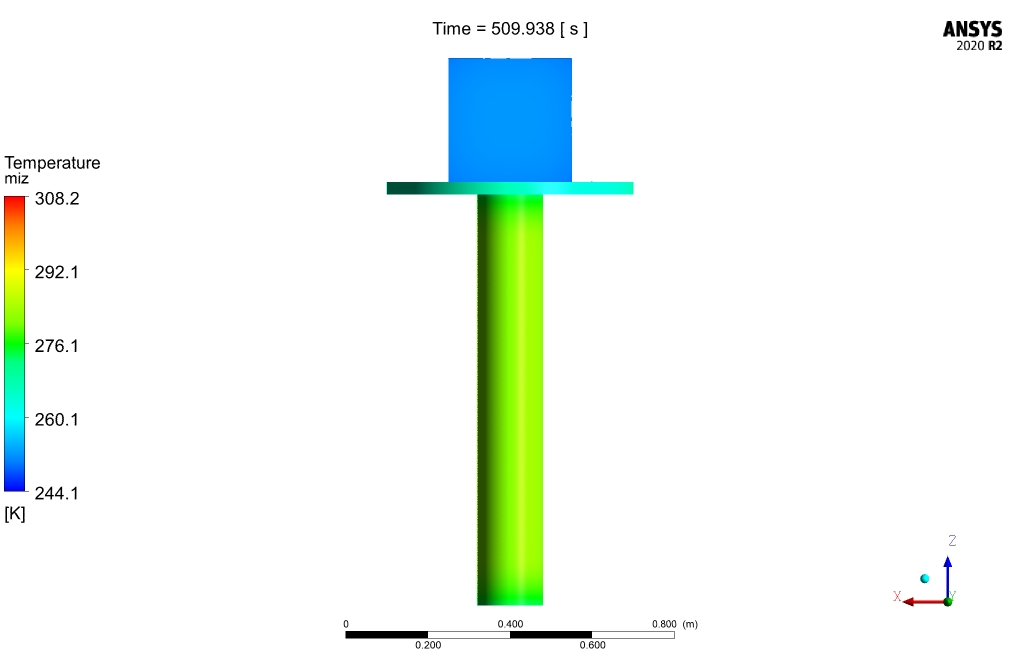

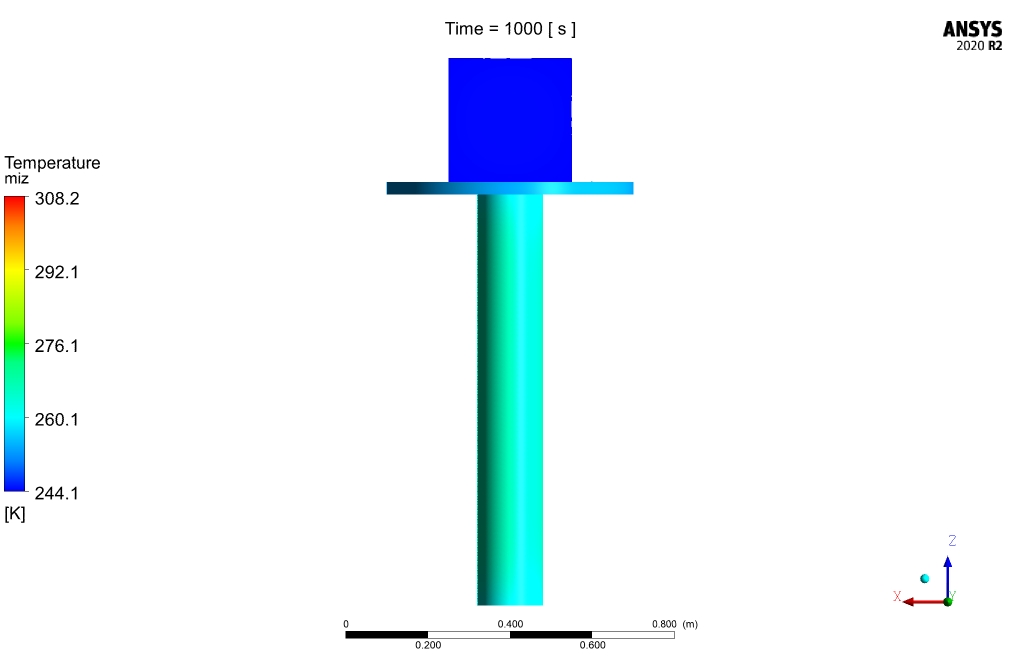

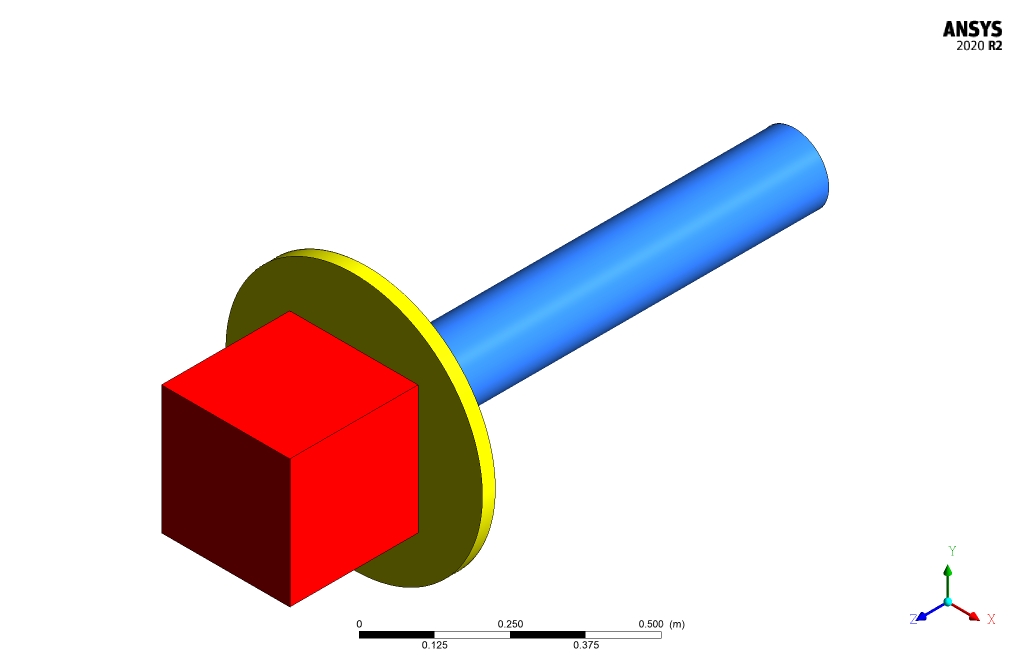

In this project, the unsteady cooling process of a hot steel structure is investigated by ANSYS Fluent software. In the exact model, the structure is rotating around Z-axis. The actual simulation involving rotation and resulting forced convection requires extreme computational resources. However, in this simulation, the structure is assumed to be rigid, and heat transfer boundary conditions on each surface are modified in such a manner as to mimic the forced convection effects in rotation. In this project, the only energy equation is solved. Free stream convection heat transfer coefficients of red, yellow, and blue sections are considered equal to 80, 90, and 73 w/K.m2, respectively. The free stream flow temperature is assumed to be 243K. The volume average temperature of the whole structure at the start of the simulation and after 1000s is equal to 308.15K and 259.44K, respectively.

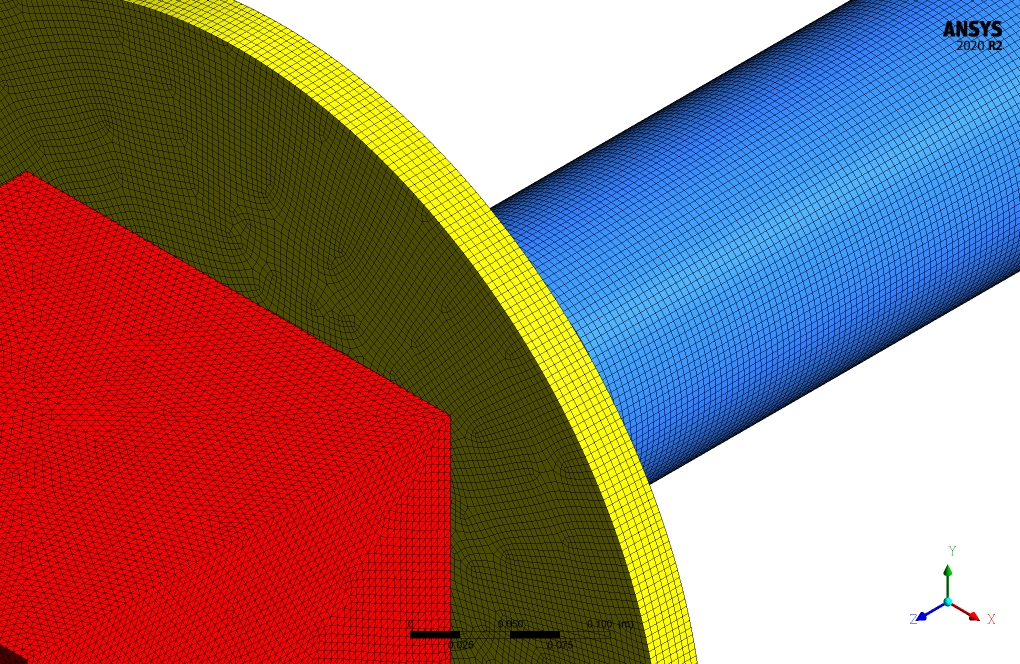

Geometry & Mesh

This project’s 3D geometry is modeled in Design Modeler, and the computational grid is generated using Ansys Meshing software. The mesh type in structured and the element number is 600405.

Cooling CFD Simulation Settings

Critical assumptions of this simulation are:

- Solver type is assumed to be Pressure-Based.

- Time formulation is Transient.

- The gravity effect is ignored.

The applied settings are recapitulated in the following table.

| models | ||

| Viscous | Laminar

(is then deactivated in Controls) |

|

| Energy | On | |

| Material properties | ||

| Steel | Definition type | Fluent database |

| Density | 8030 kg/m3 | |

| Specific heat | 502.48 j/kg.K | |

| Thermal conductivity | 16.27 W/m.K | |

| Cell zone conditions | ||

| Zone name | Fluid | |

| Material name | Steel | |

| Boundary conditions | ||

| Tube | Type | Convection |

| Heat transfer coefficient | 73 W/m2.K | |

| Free stream temperature | -30 C | |

| Table | Type | Convection |

| Heat transfer coefficient | 90 W/m2.K | |

| Free stream temperature | -30 C | |

| Type | Convection | |

| Box | Heat transfer coefficient | 80 W/m2.K |

| Free stream temperature | -30 C | |

| Type | Convection | |

| Solver configuration | ||

| Pressure velocity coupling | Scheme | PISO |

| Spatial discretization | Gradient | Least square cell-based |

| Pressure | Standard | |

| Momentum | First order Upwind | |

| Energy | First order Upwind | |

| Initialization | Gauge pressure | 0 Pa |

| X velocity | 0 m/s | |

| Y velocity | 0 m/s | |

| Z velocity | 0 m/s | |

| Temperature | 35 C | |

Results & Discussion

Contours of temperature at different simulation times are extracted and presented .

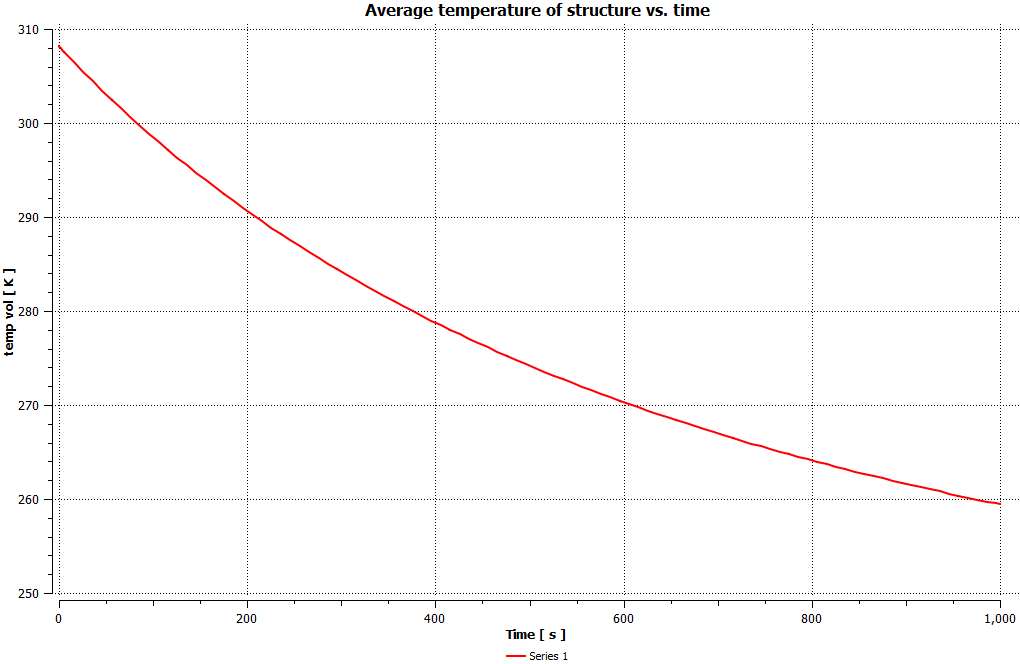

As shown in the chart below, which shows the volume average temperature of the structure as moving further in time, the cooling down rate is very high at the beginning, but as time passes temperature of the structure begins to reach a steady-state which has not yet occurred so far (1000s).

Oceane Gibson MD –

I recently purchased the ‘Cooling Process of a Hot Rotating Steel Structure’ CFD simulation training, and it has been eye-opening. The level of detail and clarity provided in the step-by-step processes along with the included results and discussions have greatly enhanced my understanding of heat transfer in rotating systems. Outstanding job on creating such a practical learning tool for complex simulations!

MR CFD Support –

Thank you very much for your kind words! We’re thrilled to hear that our simulation training has provided you with a clear understanding of the Cooling Process in rotating steel structures and that it has been a valuable learning experience. If you ever have any questions or need further assistance, please don’t hesitate to reach out. We’re here to help. Keep up the great work with your CFD studies!

Dr. Dorothy Lueilwitz –

I found the strategy to mimic forced convection effects interesting. How does the adjustment of heat transfer coefficients impact the simulation compared to actual rotation of the steel structure?

MR CFD Support –

In the absence of actual rotational movement in the simulation of the steel structure, adjusting the heat transfer coefficients is crucial for mimicking the forced convection effects that would result from rotation. Higher coefficients simulate the increased convective heat transfer that occurs as the structure’s surfaces move through the air. Although this method doesn’t capture all the nuances of a rotating body, such as centrifugal and gyroscopic effects, it effectively approximates the cooling impact on the temperature distribution over the structure’s surfaces.

Molly Jast II –

The project summary for the hot rotating steel structure CFD simulation was really insightful. I appreciate the detailed explanation of how the heat transfer simulation was carried out, especially the adaptation to mimic forced convection through boundary condition adjustments. The mesh structure, solver settings, and results interpretation are all well-explained, showcasing the models’ efficacy in simulating the cooling process. Great job on the culmination of practical assumptions and computational techniques to achieve the project’s aim.

MR CFD Support –

Thank you for your positive feedback regarding the CFD simulation of the cooling process for a hot rotating steel structure. We’re thrilled to hear that you found the explanation of the simulation’s implementation and the particular approaches used to replicate forced convection insightful. We strive to provide a detailed and practical understanding of simulation processes, so we’re delighted that our efforts resonated well with you. If you ever have any questions or need further insights into our simulations, please feel free to ask.

London Turcotte –

I just completed the

MR CFD Support –

We’re glad to hear you had such a positive learning experience with our CFD simulation tutorial. We always aim to give clear and comprehensive guidance to make complex simulations more understandable.

Prof. Myrtis Bogisich PhD –

The attention to detail in the cooling process simulation is commendable! The temperature gradients over time really showcase the effectiveness of the cooling strategy.

MR CFD Support –

Thank you for your appreciation of our simulation project! We’re glad to hear that the level of detail and the outcomes presented meet your expectations. If you have any more insights or feedback, we’d love to hear about them.

Rolando Weissnat –

The simulation results mentioned are very informative. Can you clarify if the rotation of the steel structure affects the heat transfer coefficients assigned to different sections or are they constant throughout the simulation?

MR CFD Support –

In this simulation, the rotation of the steel structure itself is not directly modeled to conserve computational resources. Instead, the heat transfer coefficients for the red, yellow, and blue sections are predetermined values chosen to mimic the effect of forced convection on the rotating body. Those coefficients are held constant throughout the simulation, representing an approximation of the changing convection effects due to rotation.

Hilario Prohaska I –

I’m impressed by the level of detail in cooling simulation of a rotating steel structure. Great blend of rotational effects and heat transfer!

MR CFD Support –

Thank you for your kind words! We’re delighted to know the simulation’s intricate details, combining rotational effects and heat transfer with a substantial computational approach, impressed you. We always strive to create detailed and accurate simulations for effective training and learning experiences.

Francisco Spinka –

I am quite impressed with how the simulation captures the different convection rates across the distinct parts of the steel structure. How accurate is the representation of the forced convection from the rotating part within the simulation?

MR CFD Support –

Thank you for your appreciation! While exact replication of forced convection induced by rotation is computationally intensive, the modifications to the heat transfer boundary conditions in this simulation have been carefully calibrated to resemble the real-world cooling effects of rotation as closely as possible. Despite assumptions and simplifications, the method used is quite accurate and provides a good approximation of the forced convection cooling behaviour in a rotating steel structure.

Dr. Jody Bosco –

I appreciated the clarity of the simulation settings for the cooling process! It helped me to understand the complexity of thermal processes in rotating steel structures.

MR CFD Support –

Thank you for your kind words! We’re glad that the information provided in the cooling process simulation was helpful and clear. If you have any further questions regarding our products or need some guidance, don’t hesitate to ask. We’re here to help!

Libby Little –

The simulation did an excellent job showing how to model the cooling process of a hot rotating steel structure in ANSYS Fluent. The detailed explanation of boundary conditions and solver settings provided a clear understanding of the setup. Also, the structured mesh with a high element count likely helped to capture the complex heat transfer phenomena more accurately.

MR CFD Support –

Thank you for your positive feedback! It’s gratifying to hear that our explanation of the simulation was clear and easy to understand. We strive to provide detailed walkthroughs in our training materials to ensure users can grasp complex scenarios in fluid dynamics simulations. If you have any further inquiries or need assistance with similar projects, feel free to reach out to us.

Milton Sporer –

Using the product was both educational and enjoyable. The simulation perfectly mimicked the complex behavior of a hot rotating steel structure and how its temperature decreased over time due to forced convection. The approximation technique used to simulate the convection without actually rotating the structure was particularly impressive. Seeing the temperature contours at different times provided practical insight into the cooling process, and the detailed explanation of the settings helped me follow along with the results. Fantastic job!

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that you found our simulation both educational and enjoyable. Our goal is to provide comprehensive learning products that offer practical insights, and it’s rewarding to know that our approximation technique was impressive to you. We appreciate your recognition of the effort that went into explaining the settings, and we hope our product continues to serve as a valuable resource for your learning journey.

Mrs. Myrna Robel –

I’m amazed by how the simulation accurately handles force convection without actually rotating the structure physically. Is there a tutorial that explains this part of the setup, so I can learn to do it myself?

MR CFD Support –

Thank you for your interest in our product. Yes, there is a comprehensive tutorial included with this CFD Simulation Training package by ANSYS Fluent. It covers each step of the setup process in detail, including how to mimic the forced convection effects of a rotating structure without the actual rotation, allowing you to learn and apply these techniques to your own projects.