Crude Oil Cooling in a Finned Tube Heat Exchanger

$80.00 Student Discount

In this project, the cooling of crude oil in a heat exchanger has been simulated, and the results of this simulation have been analyzed.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Crude Oil Cooling in a Finned Tube Heat Exchanger, CFD Simulation ANSYS Fluent Training

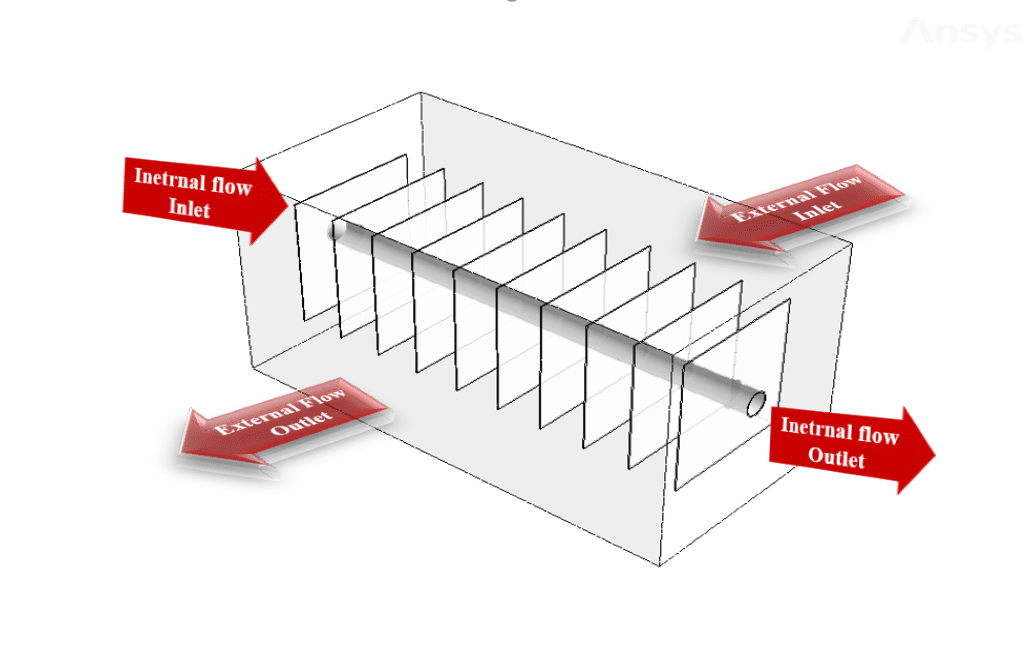

The present simulation is about the cooling of crude oil in a heat exchanger via ANSYS Fluent. In this project, a heat exchanger is designed with a central tube and several parallel plates.

The flow of crude oil enters the central pipe at a speed of 2 m.s-1 and a temperature of 200 C, and the flow of outside air moves at a speed of 0.3 m.s-1 and a temperature of 25 C towards the central pipe.

The temperature difference between the pipe and the external current leads to heat transfer, and the presence of parallel plates made of copper also contributes to the heat transfer process.

Geometry & Mesh

The present geometry is designed in a 3D model via Design Modeler. The computational zone is the interior space of a heat exchanger. In this heat exchanger, a central tube and several rows of parallel plates perpendicular to the pipe are designed.

The mesh of the present model has been done via ANSYS Meshing. Mesh is done unstructured, and the number of production cells is equal to 5945156.

Set-up & Solution

Assumptions used in this simulation :

- Pressure-based solver is used.

- The present simulation is steady.

- The effect of gravity is ignored.

| Models | ||

| Viscous | k-epsilon | |

| k-epsilon model | realizable | |

| near wall treatment | enhanced wall treatment | |

| Energy | On | |

| Boundary conditions | ||

| Inlet (external) | Velocity Inlet | |

| velocity magnitude | 2 m.s-1 | |

| temperature | 25 C | |

| Inlet (internal) | Velocity Inlet | |

| velocity magnitude | 0.3 m.s-1 | |

| temperature | 200 C | |

| Walls | Wall | |

| wall motion | stationary wall | |

| thermal condition | coupled | |

| Outlet (internal) | Pressure Outlet | |

| gauge pressure | 0 pascal | |

| Outlet (internal) | Pressure Outlet | |

| gauge pressure | 0 pascal | |

| Methods | ||

| Pressure-Velocity Coupling | SIMPLE | |

| pressure | second-order | |

| momentum | second-order upwind | |

| energy | second-order upwind | |

| turbulent kinetic energy | first-order upwind | |

| turbulent dissipation rate | first-order upwind | |

| Initialization | ||

| Initialization methods | standard | |

| gauge pressure | 0 pascal | |

| velocity (x,y,z) | 0 m.s-1 | |

| temperature | 30 C | |

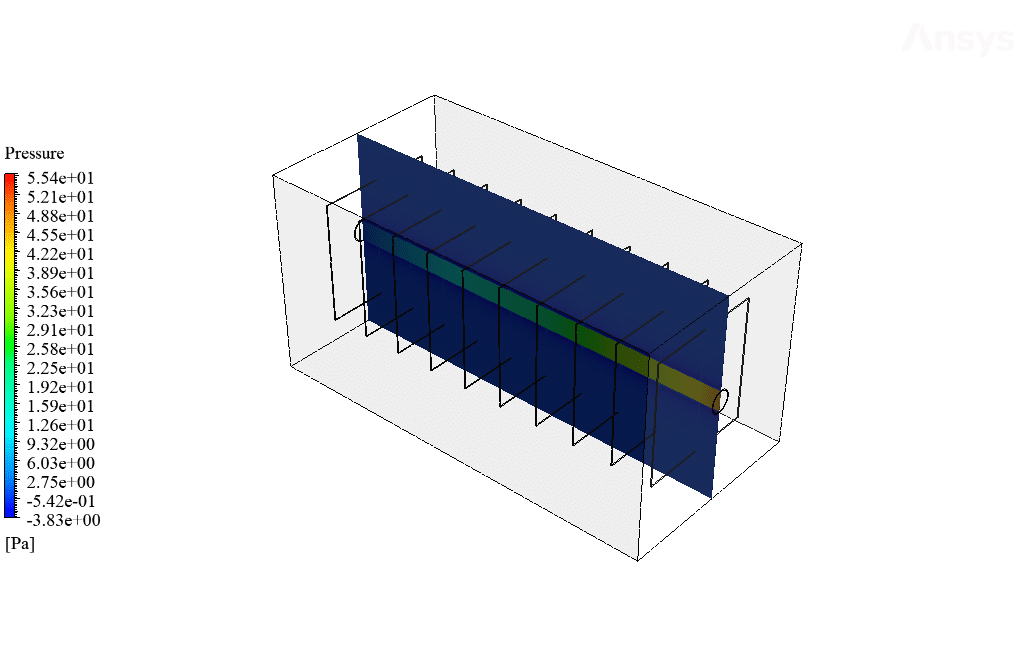

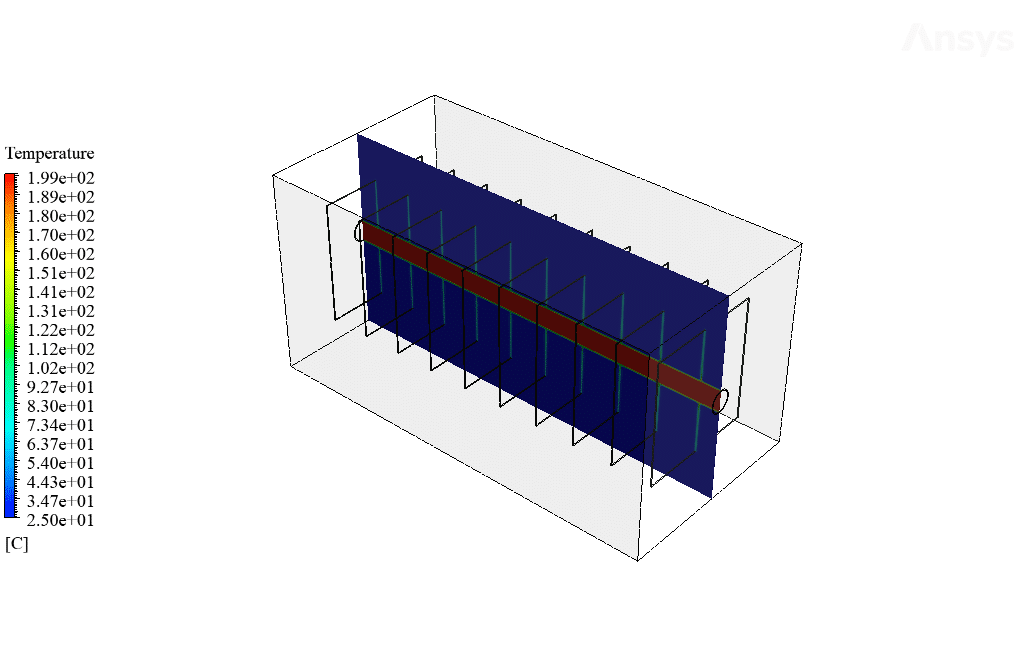

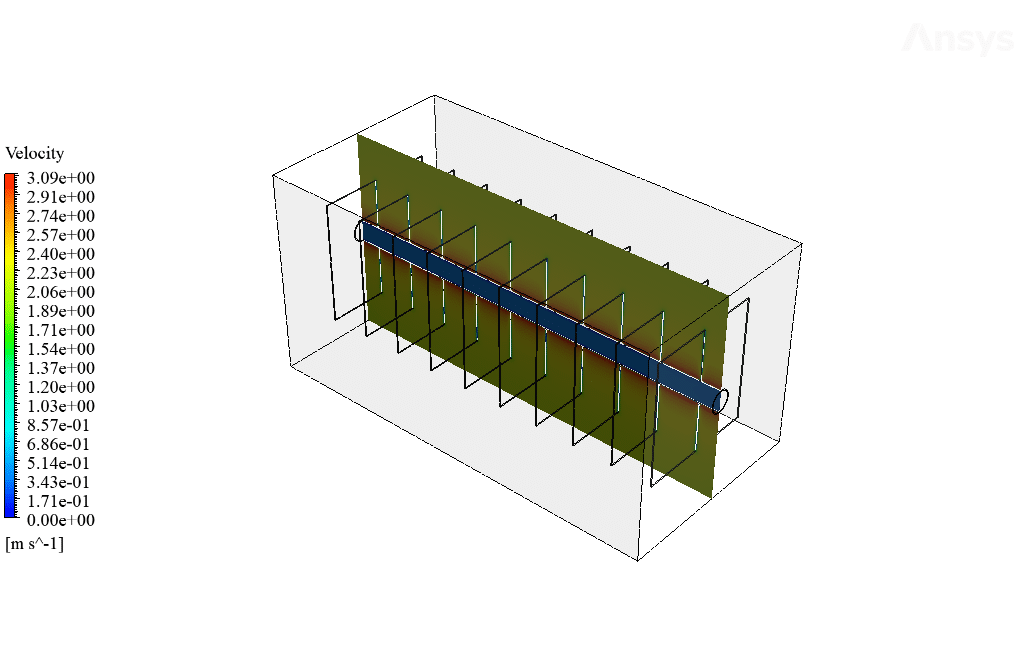

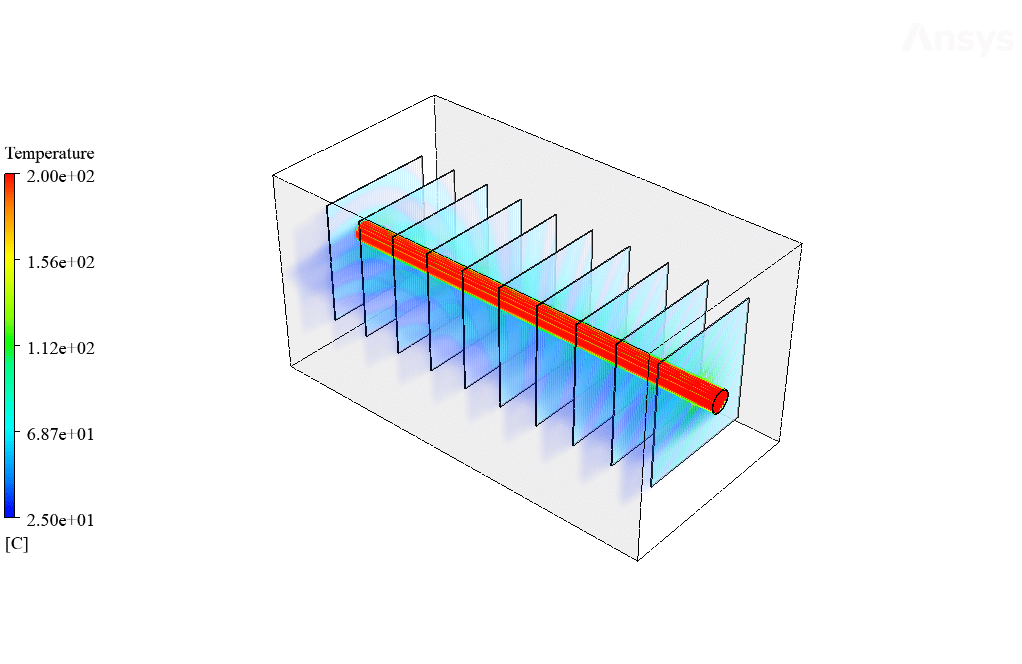

Crude Oil Cooling in a Heat Exchanger Results

After calculation, 2D and 3D contours related to temperature, pressure, and velocity are obtained.

The contours show that heat transfer occurs between the crude oil flow inside the pipe and the outside airflow, causing the crude oil to cool inside the tube.

You can obtain Geometry & Mesh file and a comprehensive Training Movie that presents how to solve the problem and extract all desired results.

Jerad Bogisich –

The training provides impressive results! It’s fascinating to see how effectively the finned tube heat exchanger cools down hot crude oil. Well done on showcasing the process of setting up the simulation and interpreting the results.

MR CFD Support –

Thank you for taking the time to provide feedback on our Crude Oil Cooling in a Finned Tube Heat Exchanger CFD Simulation training. We’re thrilled to hear that you found it fascinating and effective. If you need any further information or assistance with our products, feel free to reach out. Your satisfaction is our top priority!

Retha Barton –

I really appreciated the detailed explanation of the crude oil cooling process in the finned tube heat exchanger and how the presence of copper plates enhances heat transfer. Your training made understanding the complex heat exchange mechanism quite simple!

MR CFD Support –

We’re thrilled to hear that you found the training helpful and easy to understand! Thank you for taking the time to share your positive experience. If you ever have more questions or need further clarification on similar topics, feel free to reach out!

Stacy Nicolas II –

The CFD simulation course on crude oil cooling in a finned tube heat exchanger was top-notch! The steps were clear, and the training video made it super easy to follow along. I’ve learned a lot about heat transfer processes and the setup for CFD analysis!

MR CFD Support –

Thank you for your positive review of our crude oil cooling CFD simulation course! We’re thrilled to hear that the training materials and video were helpful and that you’ve gained valuable knowledge about heat transfer in heat exchangers. If you ever have more questions or need assistance with future simulations, feel free to reach out. Happy simulating!

Abby Hane –

This CFD training for cooling crude oil seems quite comprehensive. The finned tube heat exchanger model covers crucial aspects, and the detailed results must provide good insights on efficient cooling practices.

MR CFD Support –

Thank you for your compliment on our Crude Oil Cooling in a Finned Tube Heat Exchanger CFD Simulation training product. We are thrilled to hear that you find it comprehensive and insightful!

Augusta Zulauf –

Fantastic resource for understanding complex heat transfer in finned tube heat exchanger CFD simulations. The attention to detail, from meshing to the solver settings, provided me with a crystal-clear insight into the process. Well done on the clear presentation and thorough explanation in the training material!

MR CFD Support –

Thank you for your kind words! It’s wonderful to know that our training material on the crude oil cooling process in a finned tube heat exchanger has provided you with valuable insights. We strive to present detailed and clear explanations to help our customers understand the complexities of CFD simulations. We appreciate your feedback and are glad you found the resource helpful!

Willy Parker –

Great learning product! The step-by-step training material was excellent—especially the Geometry & Mesh details and the setup steps. Watching the temperature of the crude oil drop as heat is transferred was fascinating and a brilliant practical example!

MR CFD Support –

We’re delighted to hear about your positive experience with our training material! It’s wonderful to know that the Geometry & Mesh details were helpful and that the setup steps were clear and instructive. Thank you for your kind words, and we hope our product will continue to provide useful and practical knowledge in your future CFD ventures!