Seed Drying Via Hydraulic Mechanism, ANSYS Fluent

$180.00 Student Discount

- Seed drying has been simulated.

- Species Transport & Porous model is employed.

- An unstructured mesh grid is carried out.

- Considering Hydraulic mechanism (Evaporation is ignored).

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Seed Drying via Hydraulic Mechanism Project Description

The present problem simulates seed drying via a hydraulic mechanism process using ANSYS Fluent software. Removing moisture from the grain is called drying. The seed drying process should reduce the moisture content of the seeds to a safe moisture level to maintain their viability and stability during storage; otherwise, the seeds may spoil quickly due to mold growth, heating, and increased microbial activity.

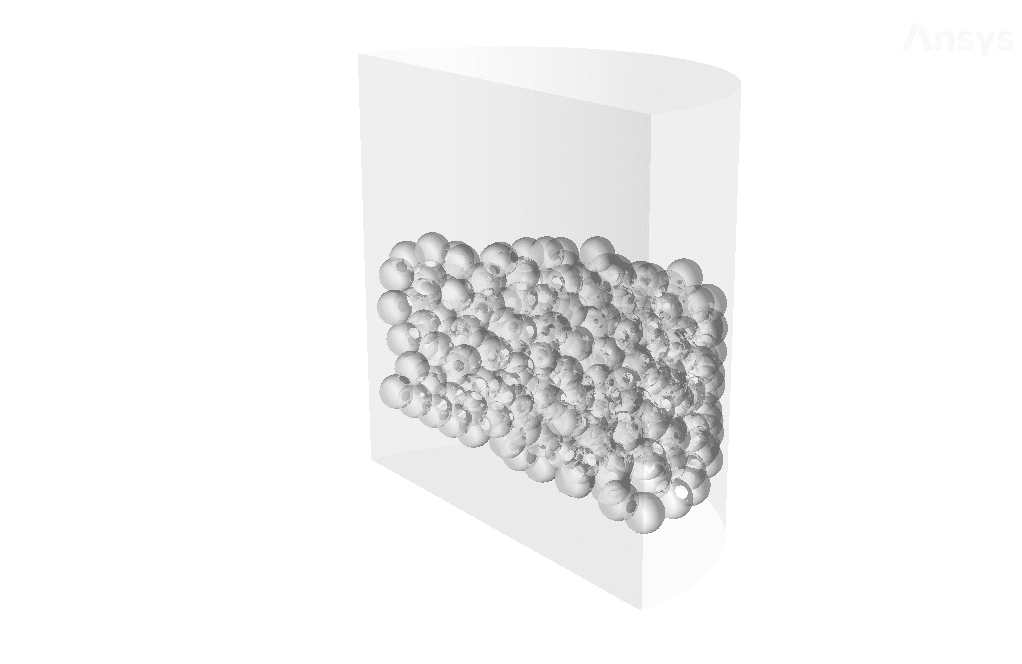

In this project, a simple semi-cylindrical chamber is designed for the drying process. Inside the chamber, a set of grains are moderately quickly due spherically, representing wet seeds. The hot airflow from the bottom of the chamber with a temperature of 303.15 K and a speed of 0.15 m.s-1 moves upwards and exits from the upper part.

The movement of this stream of hot air can carry moisture inside the seeds. Note that, it is not evaporating! It is just a moisture transmission from the seeds region to the surroundings. Therefore, we can call that a hydraulic mechanism of drying. By the way, if you are interested in dying via the evaporation mechanism, you can check the “Grain Drying Device” or “Rice Dryer” projects in which the grains are modeled using the Discrete Phase Model module and evaporation is taken into account.

The present geometry is designed in a 3D model via Design Modeler. The computational zone of the interior is a semi-cylindrical chamber in the middle of which a set of spherical shapes are designed as seeds.

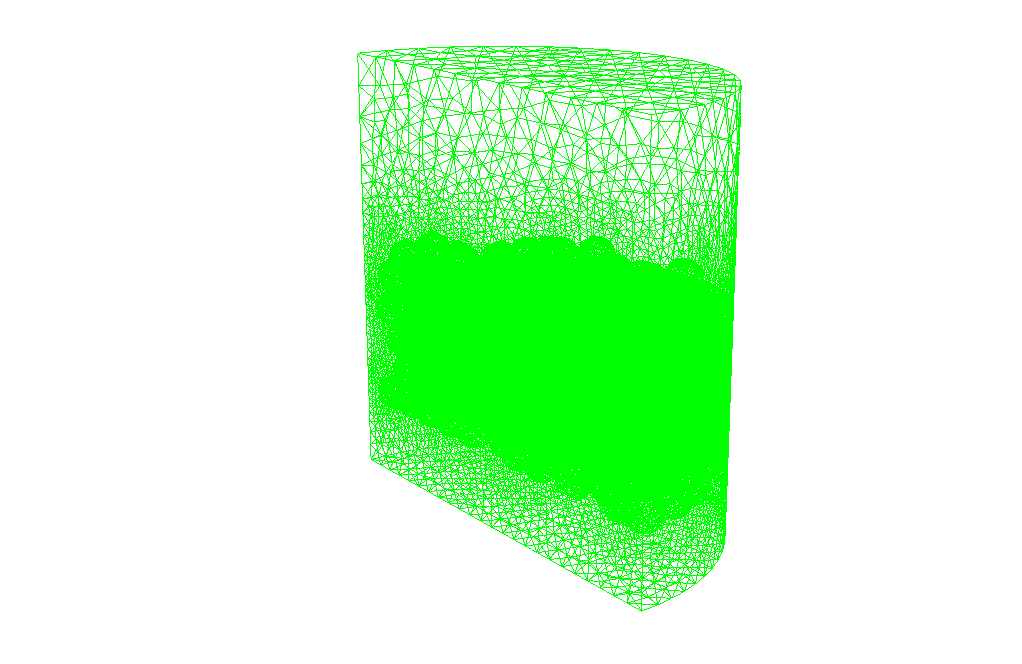

The mesh of the present model has been done via ANSYS Meshing. Mesh is done unstructured, and the number of production cells is equal to 6286496.

Methodology

In this modeling, a combination of air and h2O is defined in the computational zone of the model, and for this reason, we use the species transport model.

It is also assumed that these spherical seeds are in the form of porous mediums where moisture has penetrated the cavities inside these mediums.

Also, the porosity coefficient of these mediums is equal to 0.418. Note that, the seed zone is wet and has initial moisture which needs to be dried.

Results

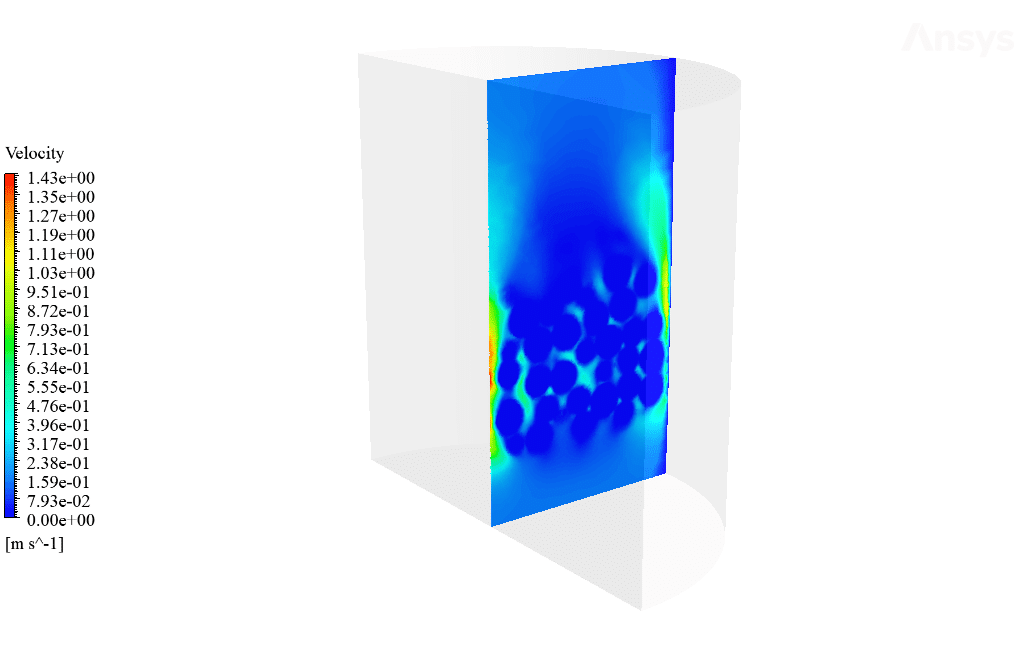

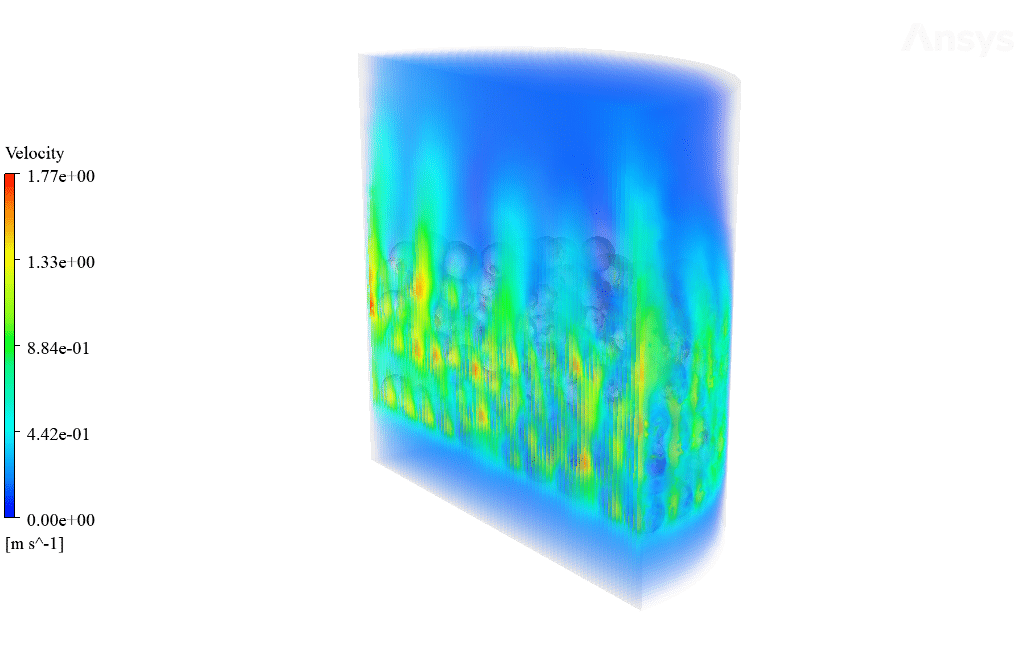

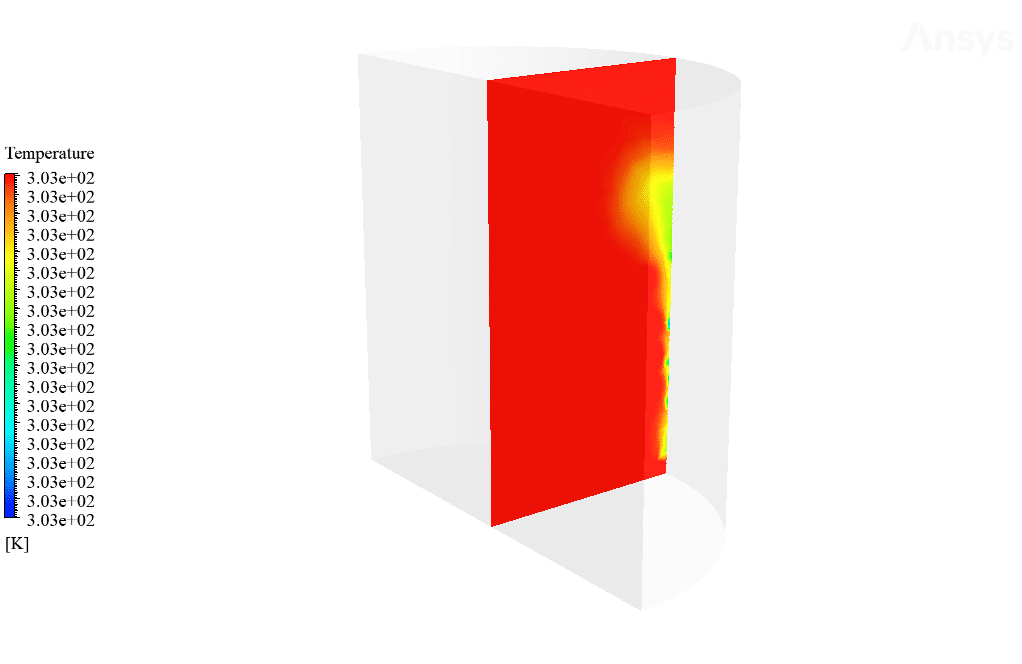

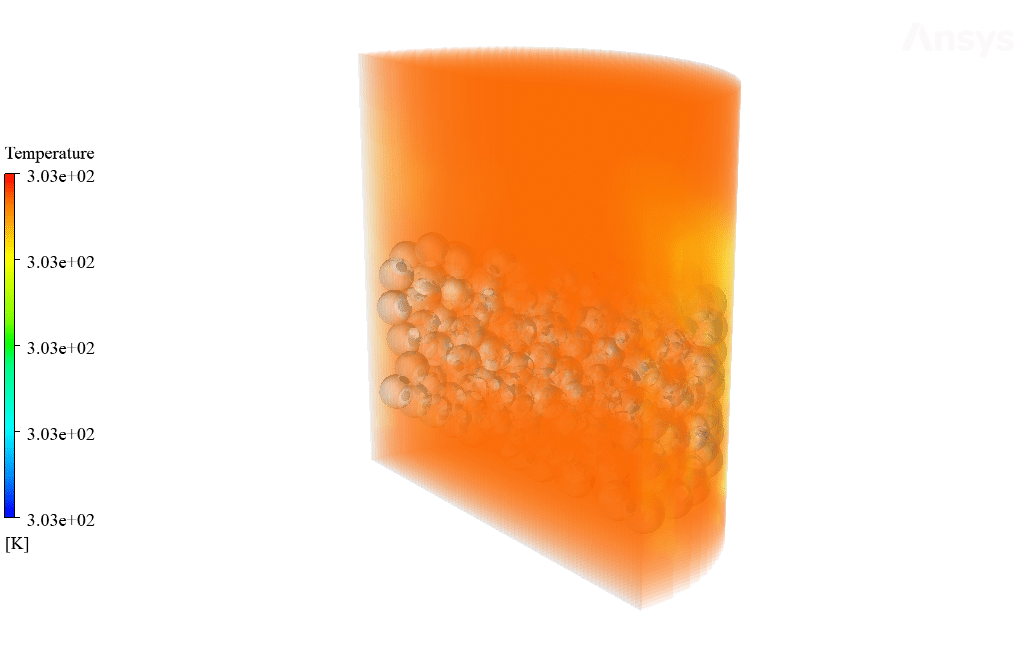

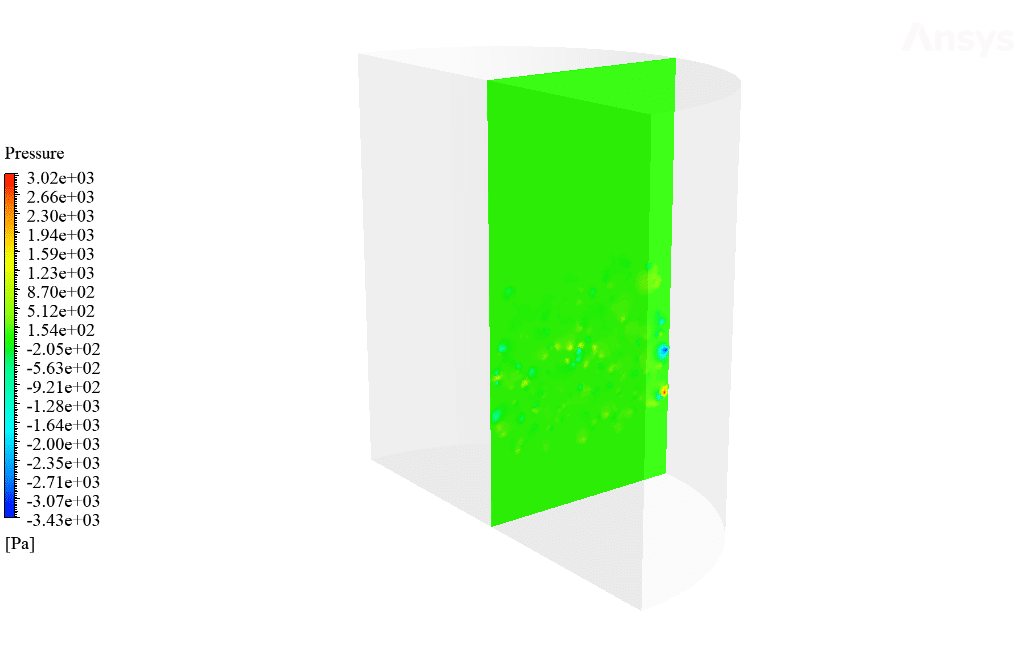

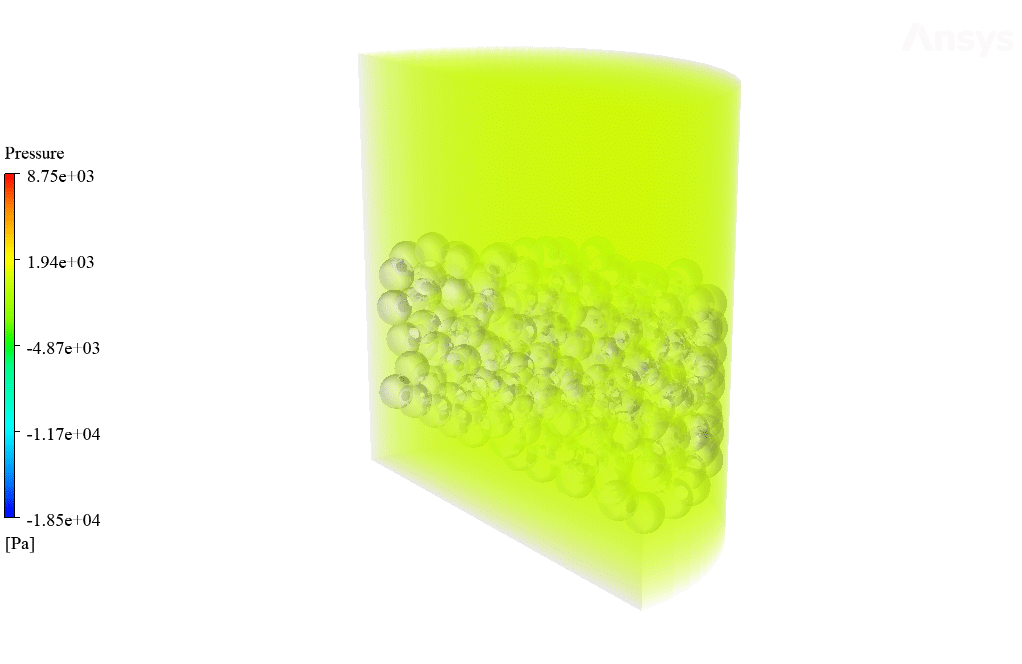

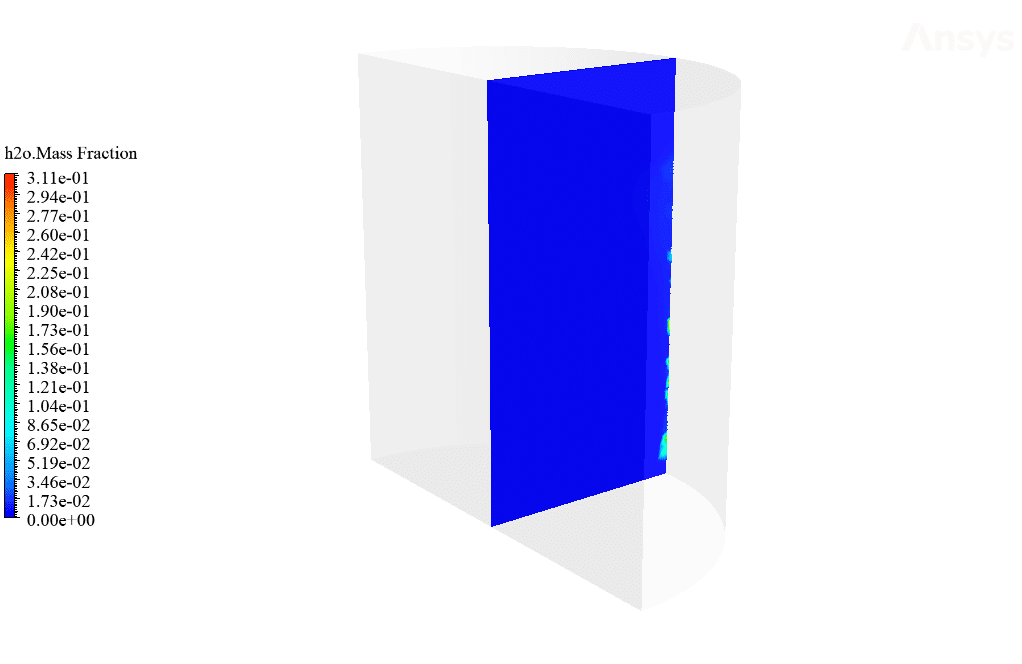

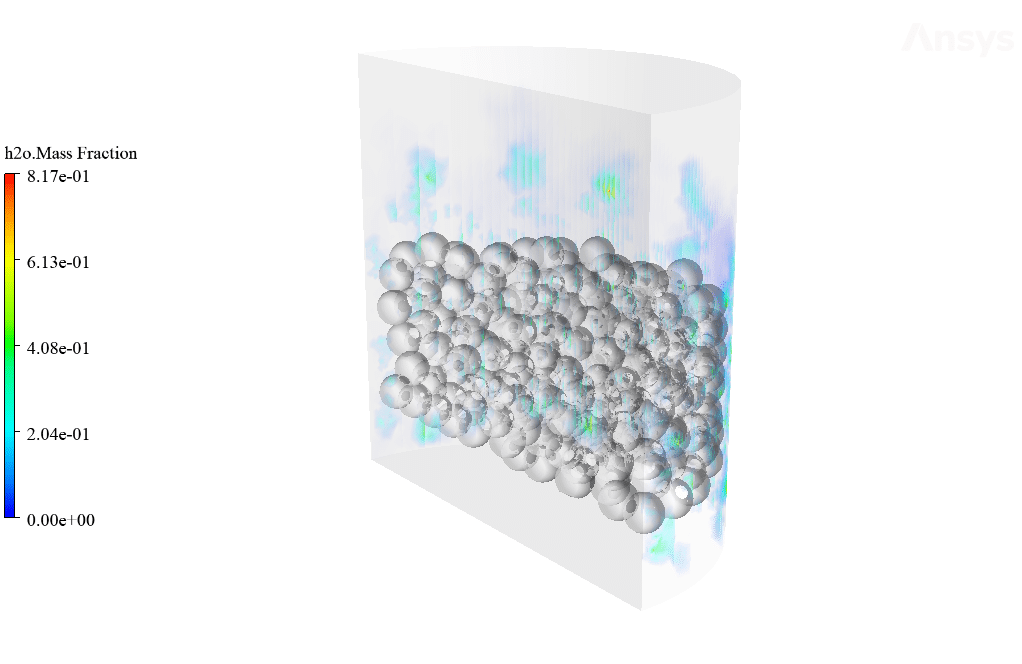

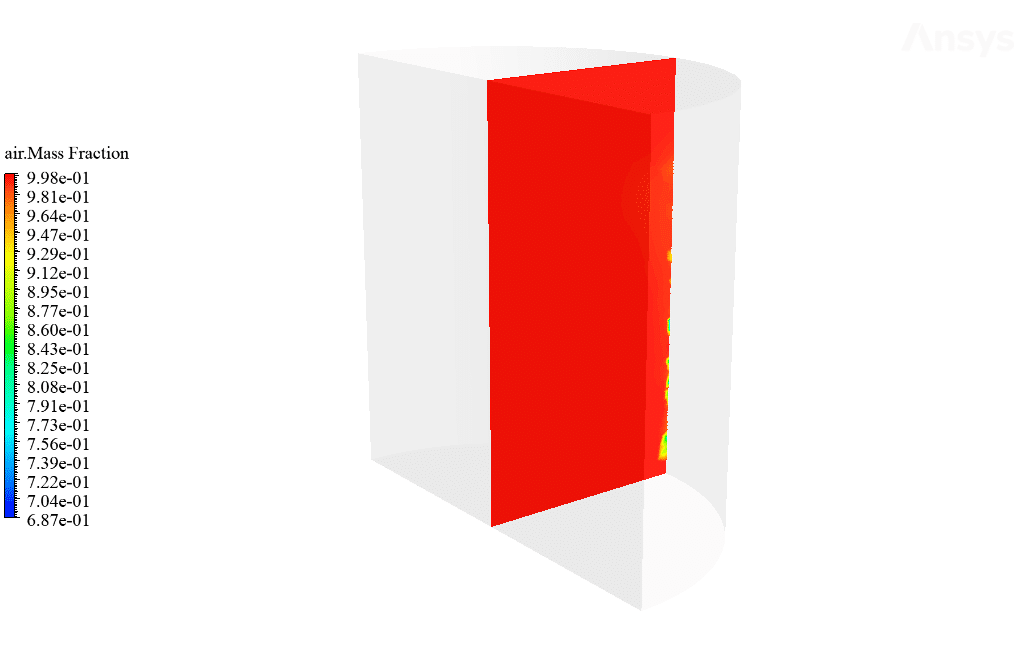

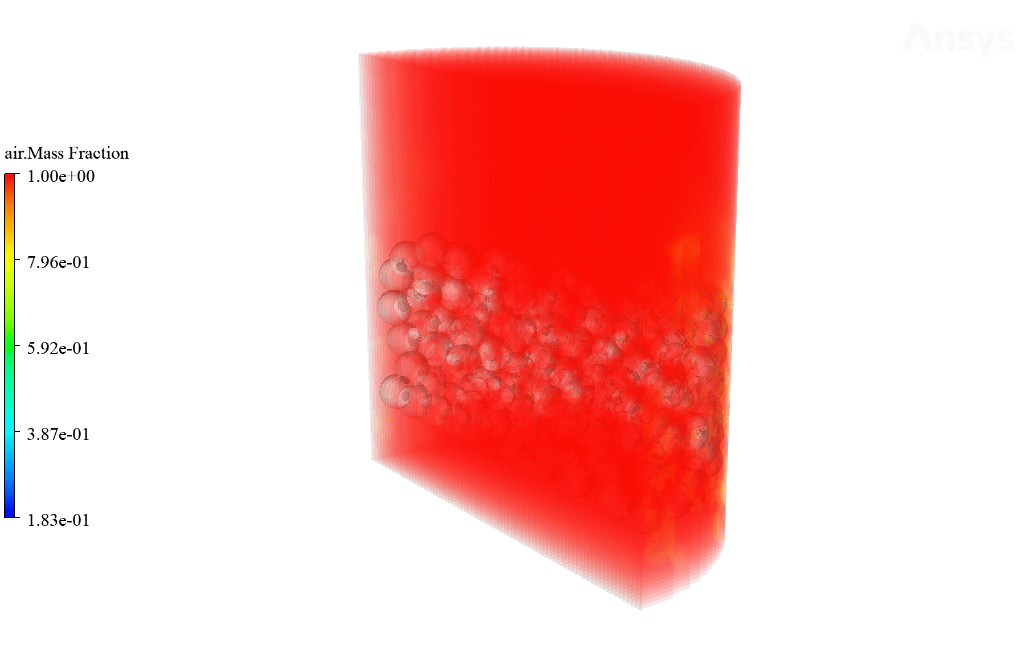

After calculation, 2D and 3D contours related to temperature, pressure, and velocity are obtained. The contours show that the moisture or h2O in the seeds inside the chamber decreases by moving the hot air stream upwards.

Prof. Regan Toy IV –

Can I adjust the initial moisture level of the seeds in this simulation to match different types of seeds?

MR CFD Support –

Absolutely, within the settings of the simulation, you can specify different initial moisture content levels for the spherical seeds. This flexibility allows you to simulate drying for various seed types with their unique moisture characteristics.

Adah Sanford –

The description talks about a ‘hydraulic mechanism of drying’ for seeds; could you clarify what exactly is meant by that term?

MR CFD Support –

In the context of this simulation, ‘hydraulic mechanism of drying’ refers to the transport of moisture from the wet seeds to the surrounding air without active evaporation. The hot air moving through the seed chamber allows for the transfer of moisture from the seeds, simulating a drying process that is different from traditional evaporation-driven techniques.

Garett Bahringer –

I am fascinated by the use of the hydraulic mechanism for drying seeds! Does this process of drying affect the quality or viability of the seeds compared to evaporation methods?

MR CFD Support –

Yes, the process of drying can indeed affect the quality and viability of the seeds. The hydraulic mechanism tends to be gentler, as there is no phase change involved, which can sometimes be beneficial for preserving the integrity of the seeds. However, the efficiency and effectiveness of the drying process are highly dependable on the specific conditions such as air temperature, flow rate, and seed type. Additionally, while the hydraulic mechanism can be more efficient in energy use, it may not be as effective in removing moisture as quickly as evaporation-based methods, which could lead to longer drying times. It is highly recommended to evaluate both methods considering the nature and sensitivity of the seeds you are working with.

Shyann Lockman –

What happens if the airflow temperature is increased beyond 303.15 K during the simulation? Would it enhance the drying process?

MR CFD Support –

Increasing the airflow temperature beyond 303.15 K can potentially enhance the drying process by increasing the moisture carrying capacity of the air, thus speeding up moisture removal from the seeds. However, it is important to consider the optimal temperature range to avoid damaging the seeds due to excessive heat.

River Blick PhD –

The detailed simulations of the seed drying process are fantastic. I loved how the system managed to realistically model the hydraulic mechanism of drying without the need for evaporation, and the option to view similar evaporation-based projects adds great value. The complex considerations like the porosity coefficient incorporated in the seeds make the CFD model incredibly useful for practical applications. Well done on creating such a refined and practical simulation tool!

MR CFD Support –

We are thrilled to hear that you appreciated the attention to detail in our seed drying via hydraulic mechanism simulation! Your positive feedback on the modeling of non-evaporative moisture transfer and the careful consideration of factors like seed porosity is highly appreciated. Thank you for recognizing the practical value of our CFD tool and for your enthusiastic review!

Lawson Hagenes –

I am thrilled with how the seed drying process is thoroughly simulated, guaranteeing seed viability during storage! The detail in moisture reduction within the seeds is remarkable.

MR CFD Support –

Thank you for your positive feedback! It’s our pleasure to know that our CFD simulation for the seed drying process met your expectations and offered comprehensive insights. We strive to provide detailed and accurate simulations to ensure the best results for your projects.