Particle Emission from a Bursting Fire Extinguisher CFD Simulation, ANSYS Fluent

$80.00 Student Discount

- In this project, the Particle Emission from a Bursting Fire Extinguisher is modeled using ANSYS Fluent.

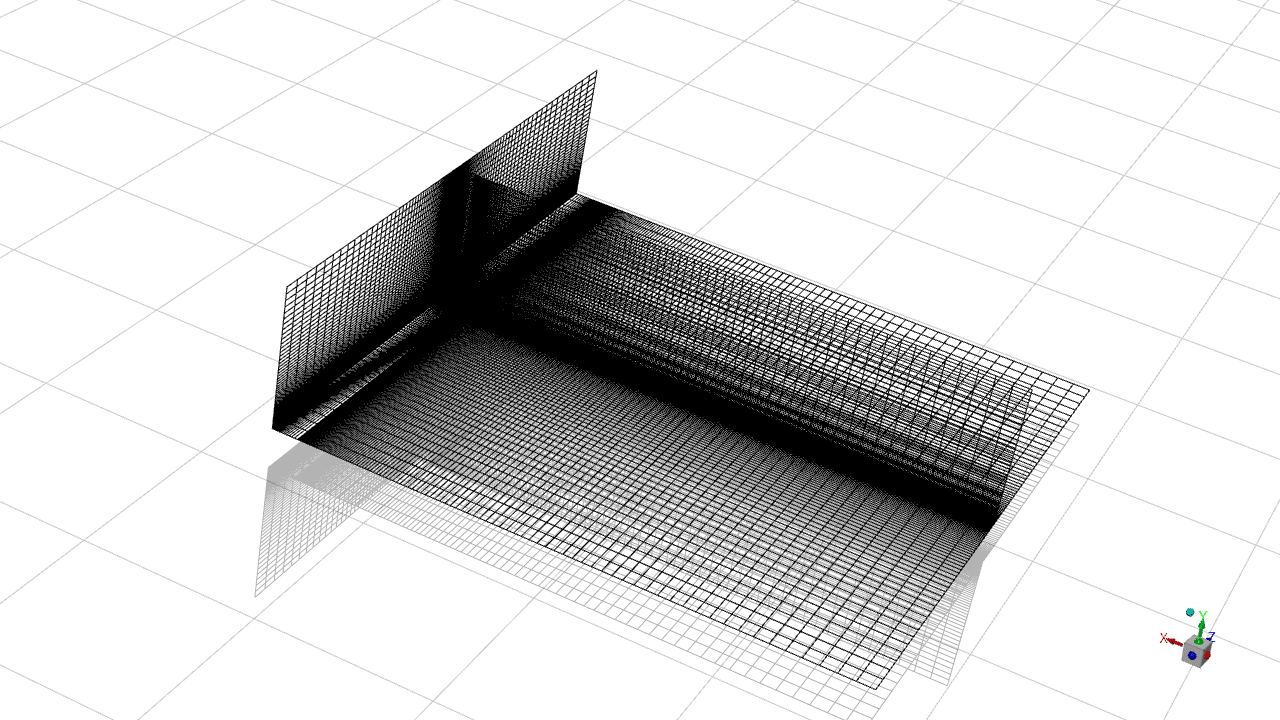

- The geometry was created in SpaceClaim, and a mesh consisting of 1,172,162 elements was generated using ANSYS Meshing.

- The Discrete Phase Model (DPM) was chosen to simulate emission released from capsule.

- The turbulence effect is modeled with the k-ε standard model.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

Fire extinguishers contains a variety of different materials. In this simulation, we will consider the powder fire extinguisher. The main material in these capsules is “ammonium dihydrogen phosphate” with a density of 1800 kg/m³. This material is stable until 200°C, and beyond that limit, it decomposes into NH₃ and H₃PO₄. Also, this material is soluble in water, and when it dissolves, it imparts an acidic property to the water, so it can be dangerous to nature. In cylindrical capsules, the greatest tension is created in the vertical direction in their walls, so the capsules are almost always damaged in this direction.

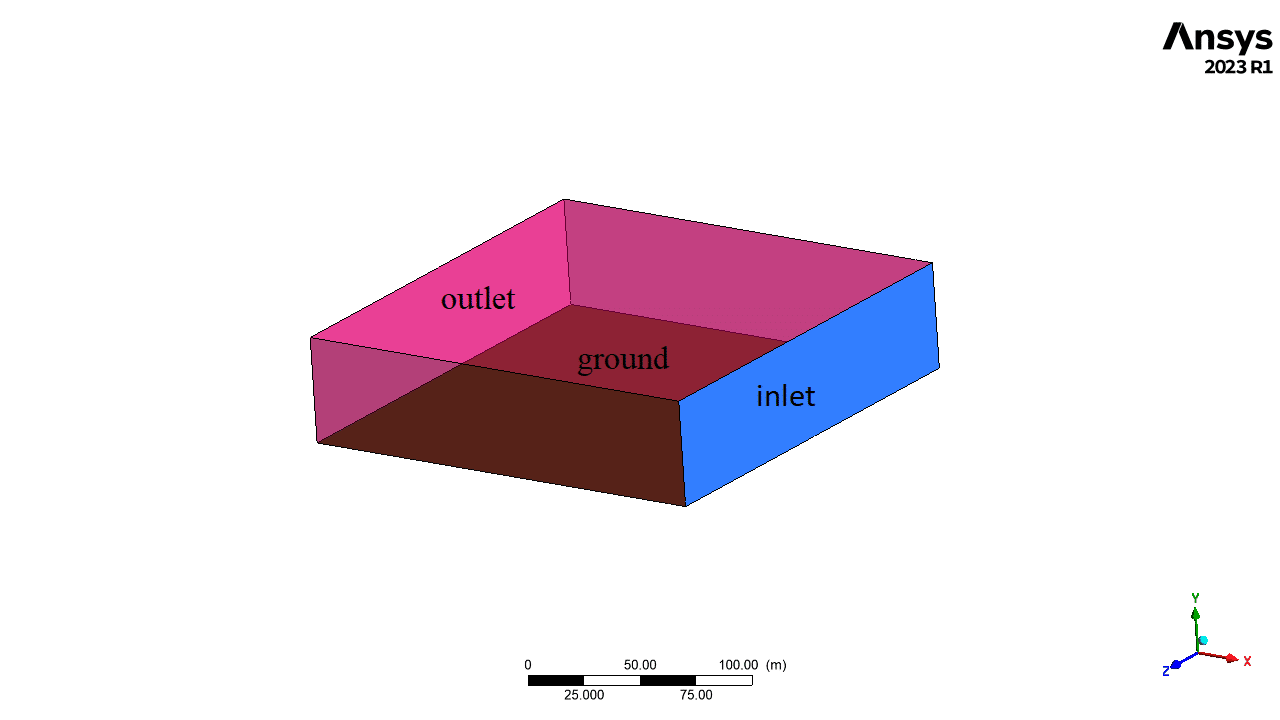

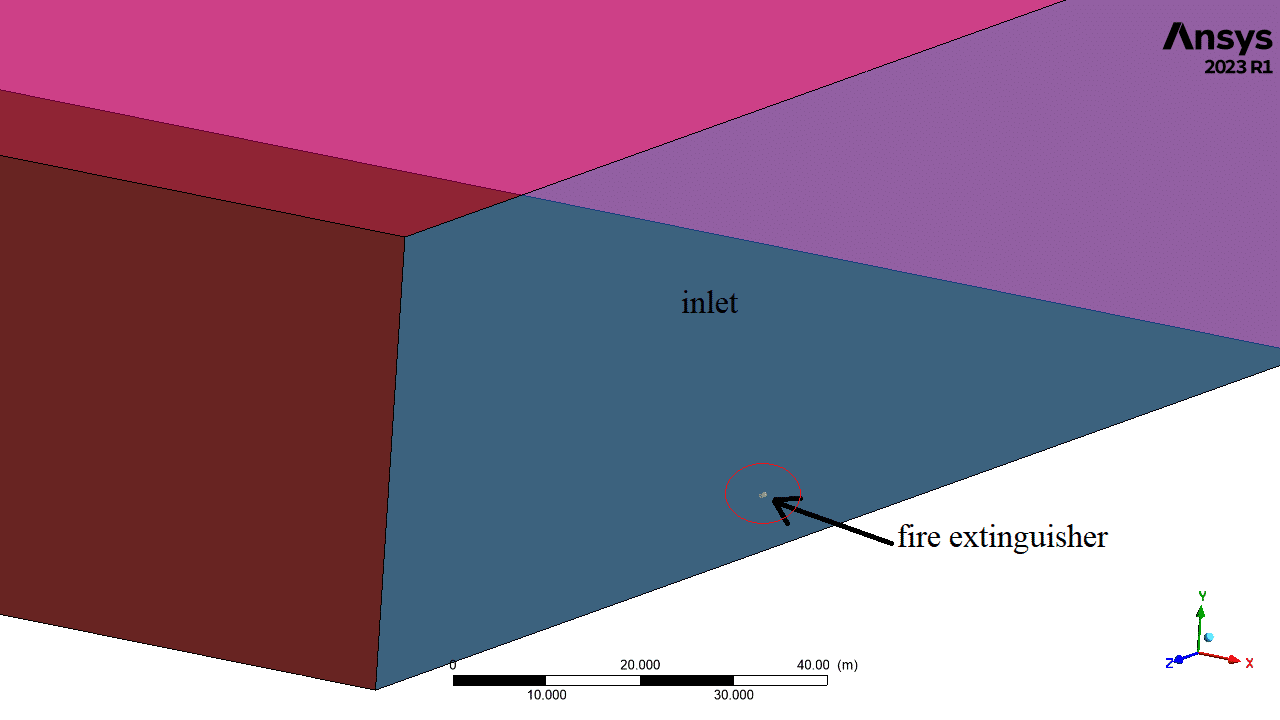

In this simulation, the crack on the cylinder is modeled in the same direction. A capsule with a 40 cm diameter and 80 cm length is considered and simulated in a domain with dimensions of 200*200*50 meters to determine how far its content can disperse when the fire extinguisher is damaged, with a 15 m/s wind blowing in the area.

The fire extinguishers are usually pressurized to 50 atm, so the emitted substance’s velocity can be around 100 m/s.

The geometry is designed in SpaceClaim® and meshed using ANSYS Meshing®. The mesh is unstructured around the capsule and structured in most of the domain, with the 1,172,162 produced elements.

Methodology

In this simulation, the turbulence effect is modeled with the k-ε standard model, and emissions are simulated using the Discrete Phase Method (DPM) along with inert particle models of 0.7 mm diameter. In boundary condition section the wall DPM boundary is set to trap the particles.

Results

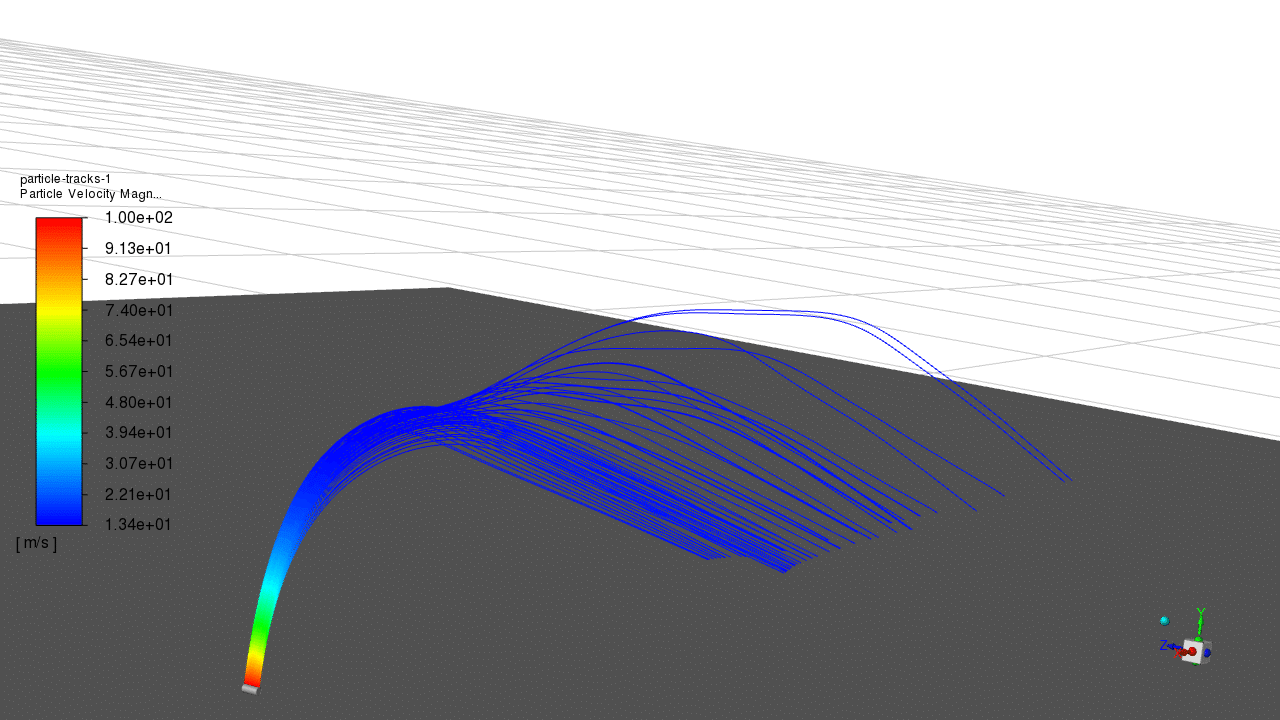

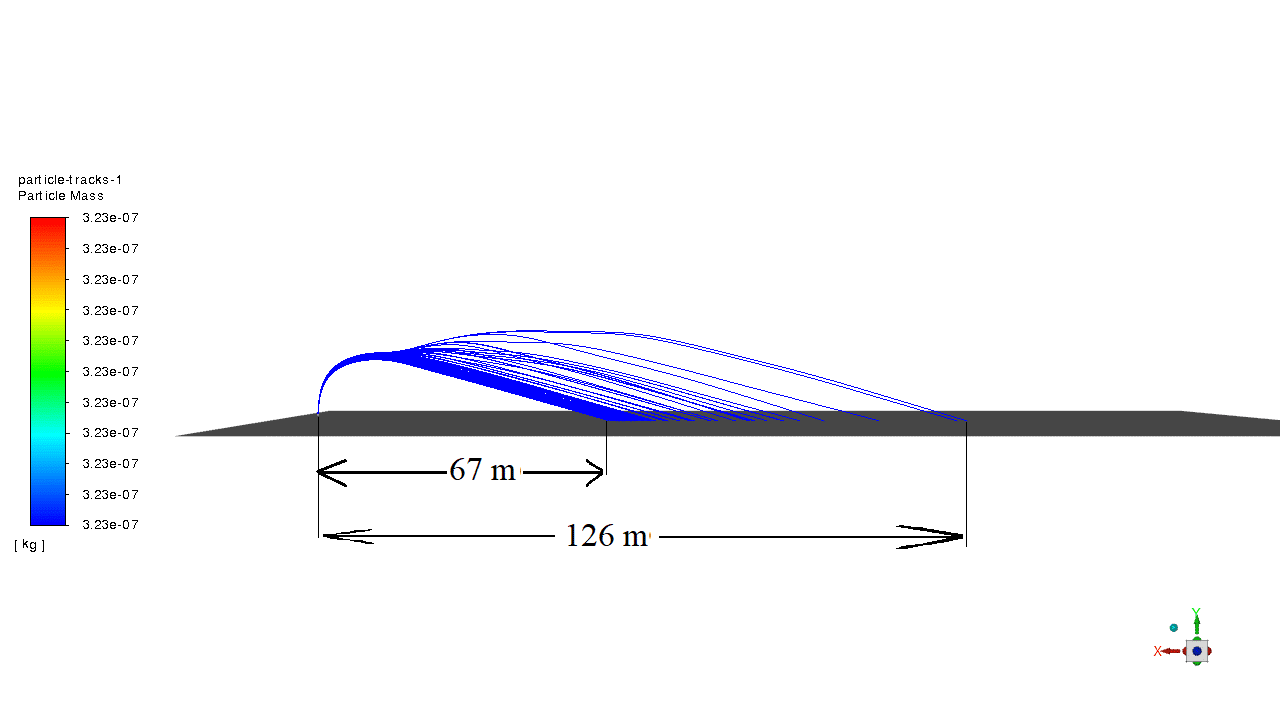

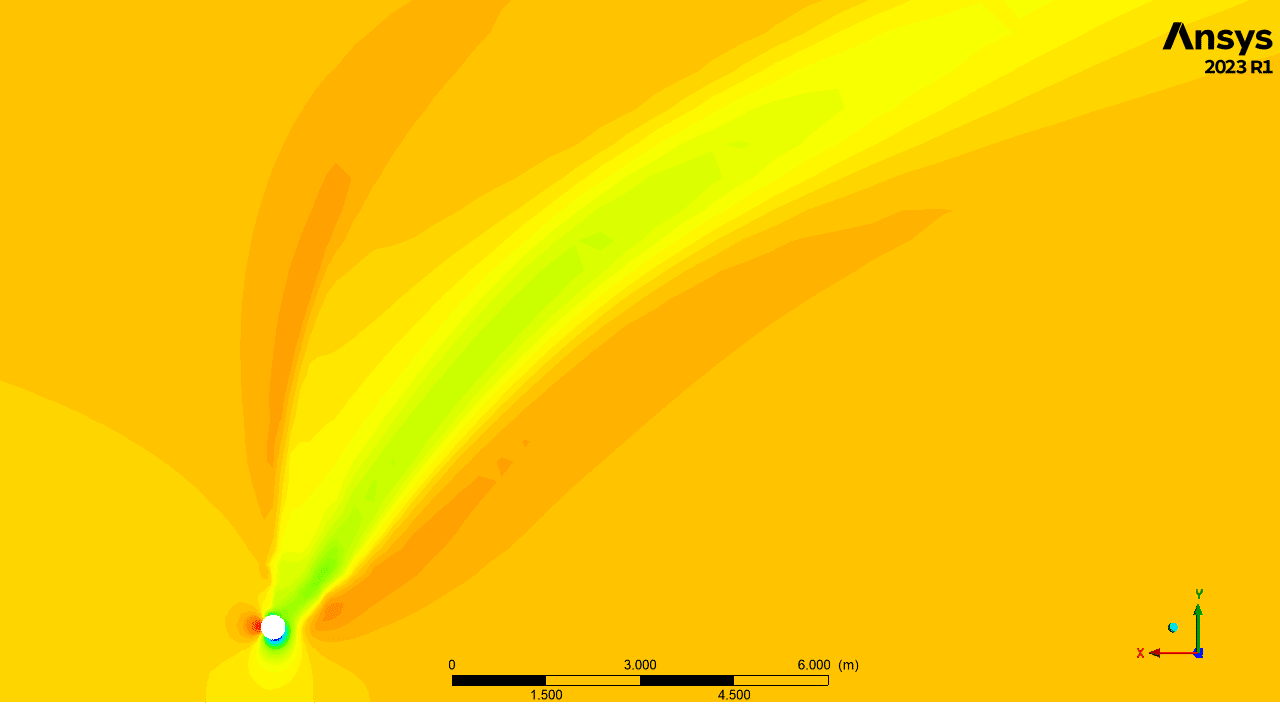

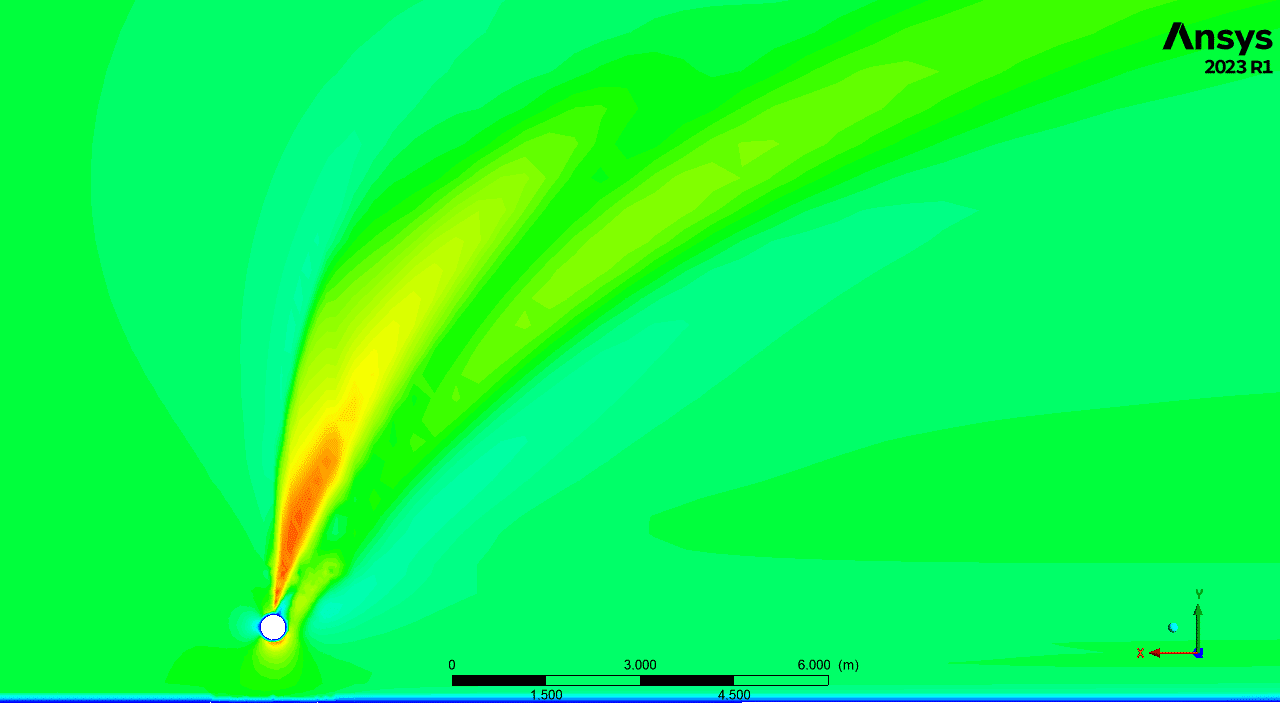

Contours of velocity and pressure around the capsule are presented in the cross section plane. Also, particle pathways are tracked, and the results show that emissions can travel between 67 to 126 meters downstream before settling on the ground.

Initially, the particles’ initial velocity causes them to elevate, and the force of gravity eventually pulls them back to the ground. However, this process takes time, and during this period, the drag force acting between the particles and the free-stream air pushes them downstream, away from the capsule.

Reviews

There are no reviews yet.