Axial Segregation of a Binary mixture in a rotating tumbler, DEM, Paper Numerical Validation

$320.00 Student Discount

- The current CFD Analysis numerically validates the Paper “Axial segregation of a binary mixture in a rotating tumbler with non-spherical particles: Experiments and DEM model validation” via ANSYS Fluent software.

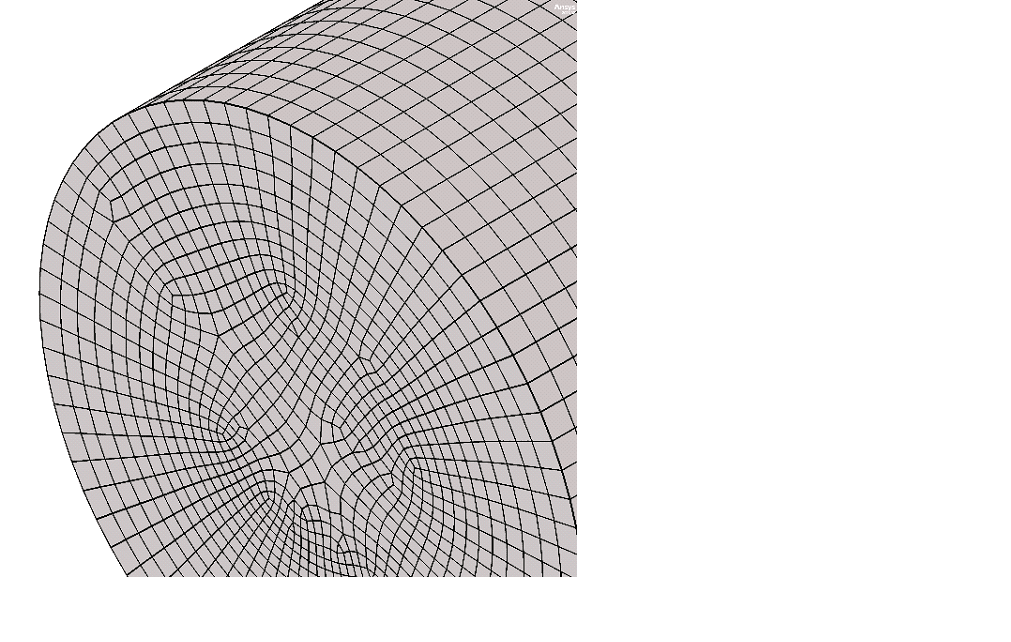

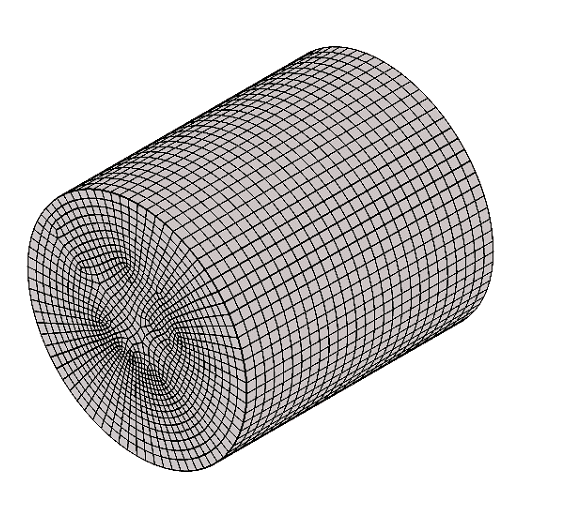

- We have designed and meshed the geometry using SpaceClaim and ANSYS Meshing producing 31,428 elements.

- Mesh Motion is used to simulate rotation of the tumbler.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Axial Segregation of a Binary mixture in a rotating tumbler with non-spherical particles, DEM, Paper Validation, ANSYS Fluent

Description

This project presents the computational fluid dynamics (CFD) analysis conducted to validate the results obtained in the paper “Axial segregation of a binary mixture in a rotating tumbler with non-spherical particles: Experiments and DEM model validation“. The project’s main objective was to replicate the experimental findings using Ansys software tools, including SpaceClaim for geometry creation, Ansys Meshing for mesh generation, and Fluent for solving the transient problem.

The geometry of the rotating tumbler was designed in SpaceClaim, ensuring it closely resembled the setup described in the reference article. Ansys Meshing was employed to generate a high-quality mesh for the computational domain. The mesh consists of 31,428 cells.

Methodology

The Fluent solver was set up to operate in transient mode with a pressure-based algorithm, suitable for the flow conditions within the tumbler. The following key settings and models were utilized. The gravity model was activated to account for the buoyancy forces affecting the particle motion. Discrete Phase Model (DPM) was enabled to simulate the interaction between the particles and the continuous phase. The DEM Collision model was activated to simulate the contact and collision between non-spherical particles accurately. To replicate the rotation of the tumbler, mesh motion was used with a set rotational speed of 40 rpm.

Results and Validation

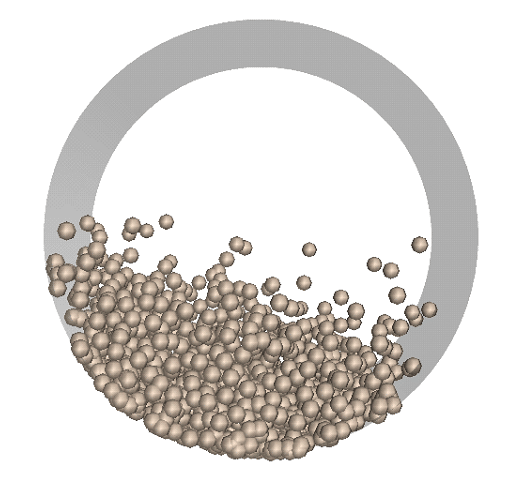

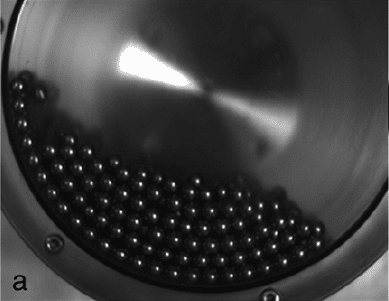

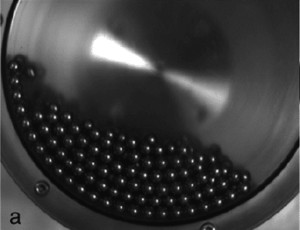

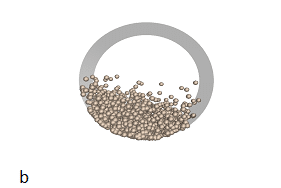

The simulation results were focused on replicating Figure 7 from the reference article. The transient behavior of the binary mixture and the axial segregation patterns were analyzed over the simulation period. The comparison between the simulation results and the experimental data from the reference article revealed a high degree of similarity, indicating a successful validation of the CFD model (Following pictures: (a) from the paper and (b) from our simulation).Also The particle segregation patterns and the evolution of the mixture over time closely matched the findings reported in the literature.

Reviews

There are no reviews yet.