Generator Room Ventilation Applying Fans, ANSYS Fluent CFD Simulation Tutorial

$180.00 Student Discount

- The problem numerically simulates Generator Room Ventilation Applying Fans using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 3854957.

- Several small and large fans are placed inside the generator room to investigate their effect on heat transfer.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

In this project, an industrial Generator room ventilation has been simulated, and the results of this simulation have been investigated by ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

Generators are one of the most widely used and essential sources of Electricity in various industries. Generators generate much heat, affecting thermal comfort if several generators are together. Therefore, operators can not approach the generators in summer due to extreme heat.

So to solve this problem, several fans are placed inside the generator room to make the indoor temperature suitable for the operators.

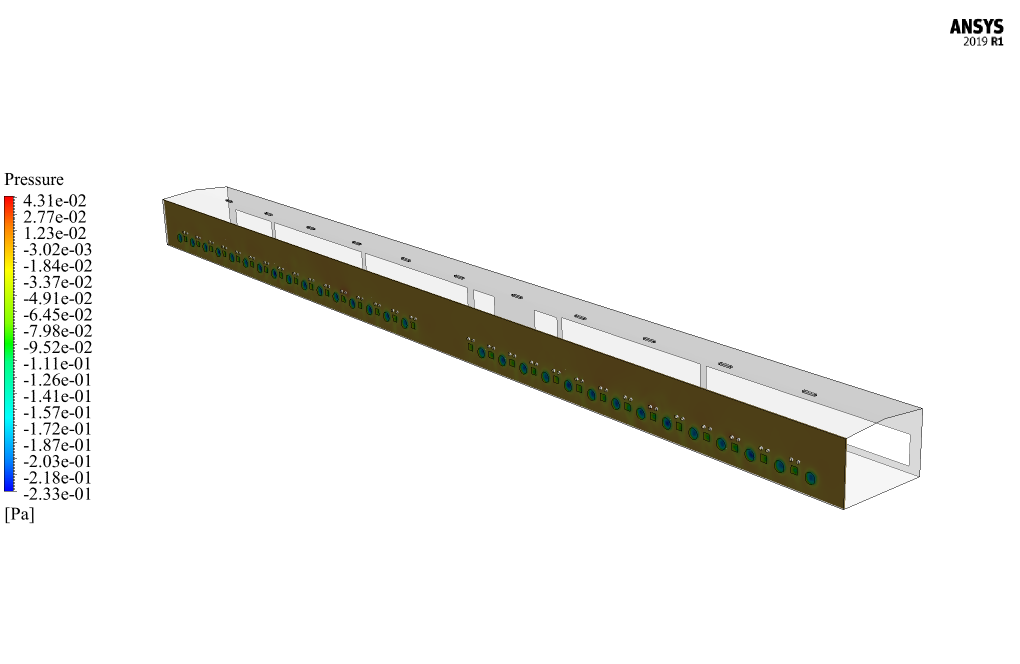

The present model is designed in three dimensions using Design Modeler software. The geometry for analyzing this simulation consists of a rectangular space in which 32 diesel generators are placed.

The meshing of the model has been done using ANSYS Meshing software. The element number is 3854957.

Generator Methodology

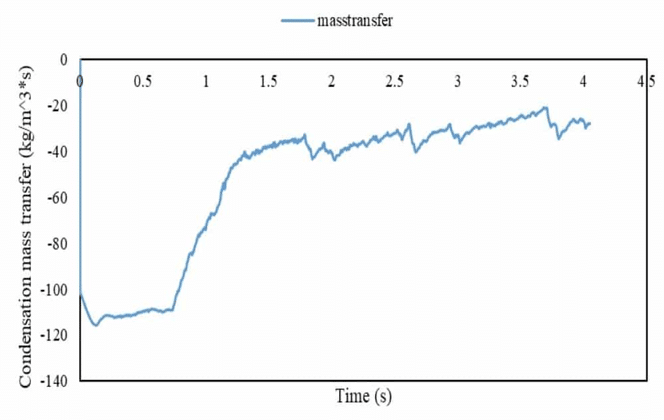

In this project, a generator room’s heating, ventilation, and air conditioning (HVAC) are simulated using Ansys Fluent software.

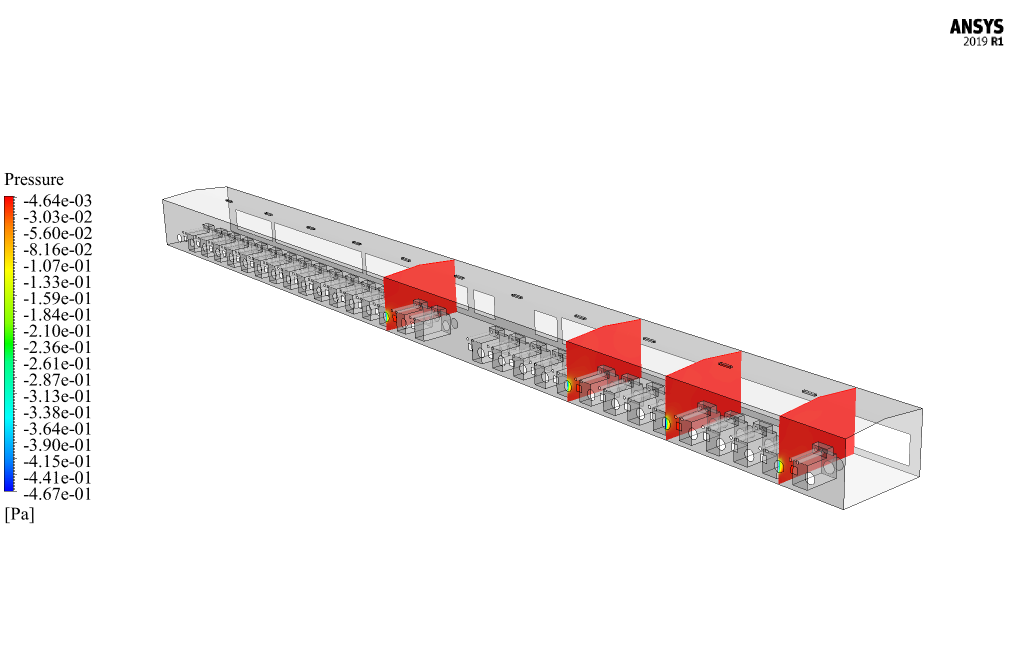

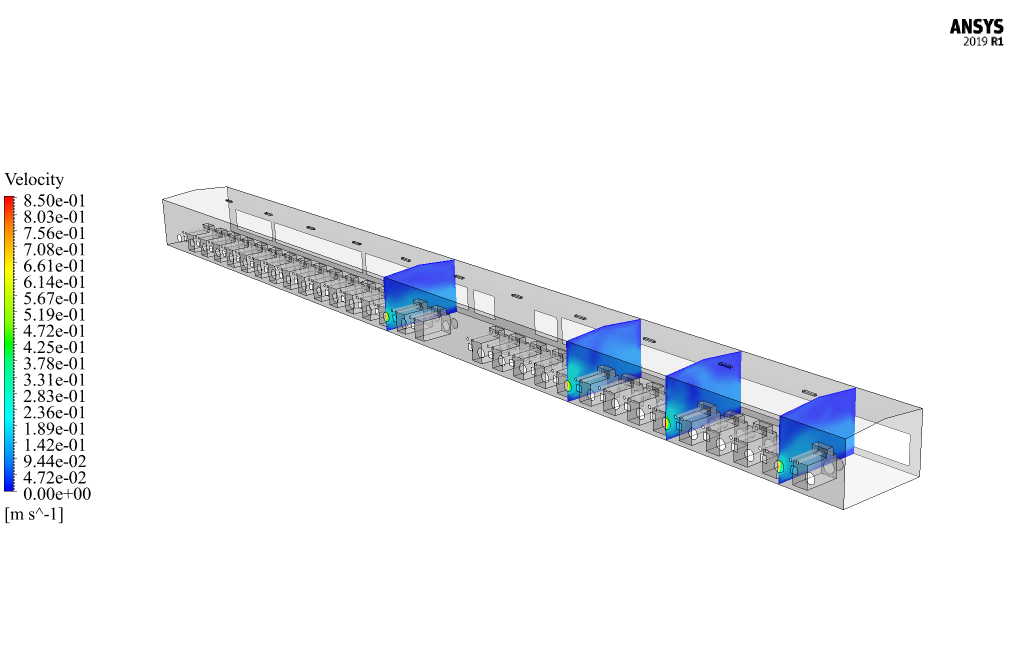

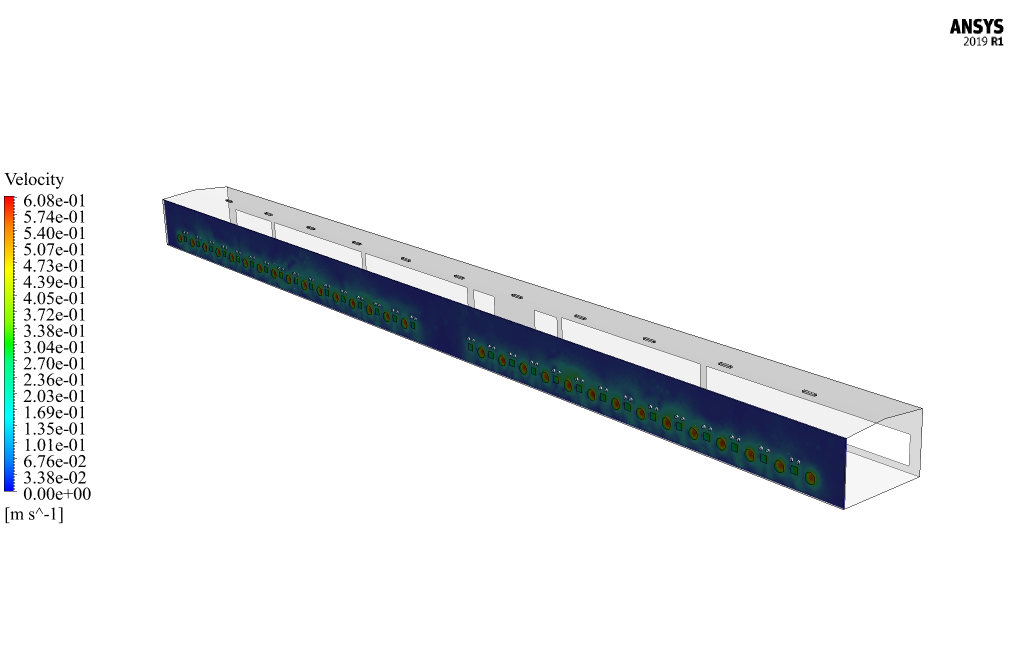

The generator room is initially simulated without a fan; it is observed that the room temperature with 32 generators is very high. Thirty-two fans with 11,000 CFM are then used, which decreases the temperature considerably.

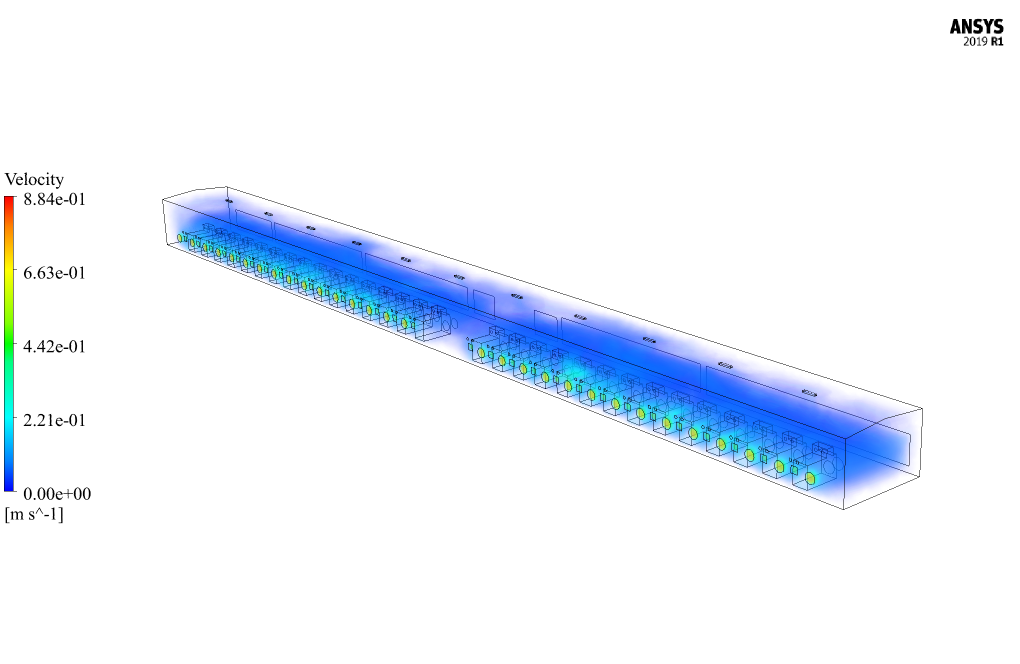

However, to improve ventilation and temperature and obtain the desired thermal comfort between generator rows, 32 fans with 36,500 CFM have been added.

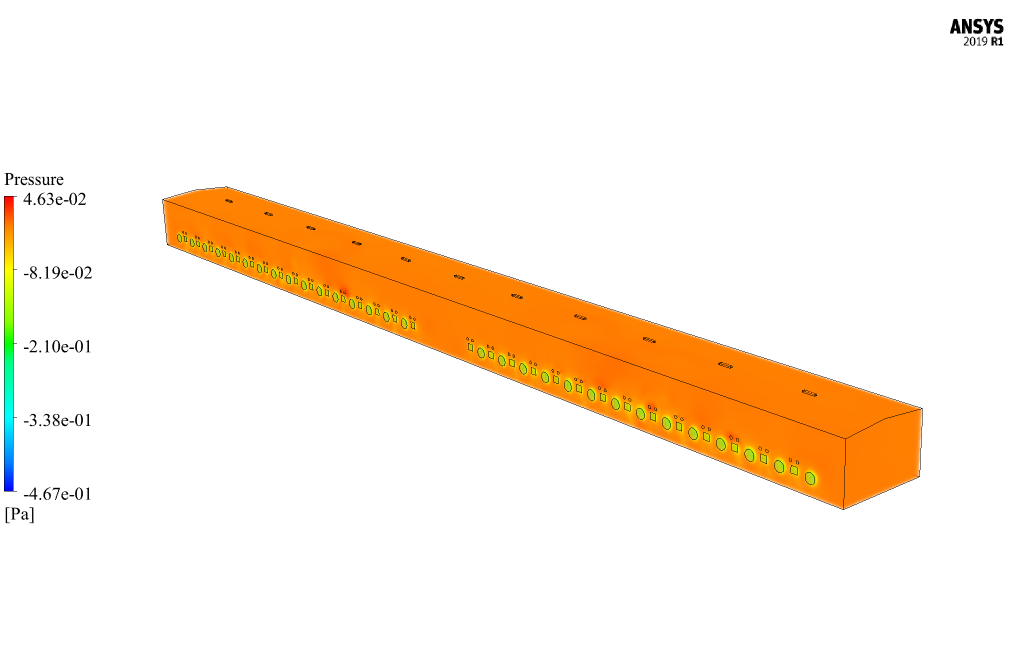

The realizable k-epsilon model is used to solve turbulent fluid equations, and the energy equation has also been enabled to calculate the temperature change with the generator room.

Generator Conclusion

This project aimed to provide suitable thermal comfort for the generator room. In the first simulation, when no fan was on, it was observed that the temperature between the generators was more than 49 ° C.

Therefore, it was decided to use a fan to reduce the temperature. Thus, 32 small fans are used in the second simulation, each with 11,000 CFM. It is concluded that the room temperature was improved and reduced to 36 ° C.

Then, it was decided to use 64 fans (32 fans of 11,000 CFM and 32 fans of 13,500 CFM) to improve the thermal comfort of the generator room in the next simulation.

The latest simulation results show that the airflow velocity inside the room has improved compared to the previous simulation, and the temperature between the generators is equal to the outside temperature (30 ° C).

Logan Zieme –

This is a hugely informative and well-explained CFD tutorial! I found your step-by-step approach and detailed review of settings very helpful. It clarified HVAC applications in industrial contexts, and the role of ventilation with fans. Great job!

MR CFD Support –

Thank you for taking the time to review our Generator Room Ventilation tutorial! We are thrilled to hear that the explanations and methodology were clear and helpful. Please let us know if there’s anything else we can assist you with.

Derrick Dare –

The tutorial for the generator room ventilation is comprehensive. The use of different fan configurations and their impact on improving thermal comfort is valuable information for practical HVAC applications.

MR CFD Support –

Thank you for your positive feedback! We’re glad the tutorial on the generator room ventilation simulation was informative and applicable to real-world HVAC challenges. Your appreciation motivates us to continue providing high-quality CFD learning materials.

Lesly Graham –

The tutorial was fantastic in improving my understanding of workspace ventilation! I applied similar solutions for my workshop’s ventilation and saw significant changes. It’s good to see theory applied effectively in practical situations.

MR CFD Support –

Thank you for your feedback! We’re delighted to hear that our tutorial was not only informative but also practically beneficial for your workshop’s ventilation needs. If you have any further questions or need assistance with other simulations, please let us know!

Ursula Wolf –

I really appreciate how you identified and solved the thermal comfort problem in the generator room. The step-by-step approach of using fans of various capacities to eventually cool the room down to the outside temperature is impressive.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you found the step-by-step simulation approach effective in addressing the thermal comfort issue in the generator room. Ensuring a practical solution that helps make work environments safer and more comfortable is crucial for us, and it’s great to know our products are up to the mark. If you have any more feedback or need further assistance, please feel free to reach out.

Miss Delta Schimmel –

The simulations with varying fan configurations are incredibly informative! How were different fan strengths integrated into the model? Did you use separate simulations for each or integrate all options into a single model for comparison?

MR CFD Support –

In the simulations, different fan strengths were modeled individually with their respective CFM values and added sequentially across various simulations. First, the environment was simulated without fans, followed by simulations that introduced fans with 11,000 CFM and later additional fans of 36,500 CFM strength. Each configuration was simulated and analyzed separately for its impact on the airflow and temperature distribution within the generator room, imparting a clear comparison across the distinct scenarios.

Harmony Trantow –

Fantastic learning product! It was fascinating to see how the fan placement and capacity affect the overall temperature in a generator room. The step-by-step increase in cooling power provided a great demonstration of fluid dynamics principles and heat transfer in an enclosed space. Kudos on the comprehensive presentation of the problem, methodology, and results in the tutorial.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you found the tutorial on Generator Room Ventilation informative and beneficial for understanding the complexities of HVAC systems in industrial settings. Stay tuned for more engaging and educational content from MR CFD Company.

Miss Sonia Hirthe –

I appreciate the comprehensive detail provided in the simulation for the generator room. The approach used to enhance the thermal comfort levels was clear, and it was great to see the incremental improvements towards the temperature goals with each additional simulation. Effective HVAC solutions are critical for industrial safety and productivity, and it seems MR CFD’s tutorial illuminates this process well.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you found the simulation details comprehensive and our approach clearly outlined. Ensuring industrial safety and productivity through education on effective HVAC solutions is an essential part of our tutorials. We appreciate your comments and look forward to providing more valuable learning experiences.

Alva Emard III –

I was amazed by the detailed analysis of the generator room ventilation simulation! The use of various fan configurations to achieve the ideal temperature was particularly insightful.

MR CFD Support –

Thank you for your kind words! We’re pleased to hear that our simulation met your expectations and provided useful insights into effective ventilation strategies for generator rooms.

Miss Eula Brown –

I am thoroughly impressed with the detail in the Generator Room Ventilation tutorial! It clearly showed the importance of adequate ventilation and how powerful CFD tools like ANSYS Fluent can optimize real-world industrial scenarios. The step-by-step approach and the explanation of implementing fans in stages were eye-opening. It was fascinating to see the temperature gradually coming down with increasing CFM of the fans, bringing it to a fair level for operator safety. Great job on the tutorial – it was educational and demonstrated complicated thermal systems in an accessible way.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that the tutorial was comprehensive and educational for you. Our goal is always to provide clear and detailed instructions to help our users understand and apply CFD simulations effectively. It’s gratifying to know that the tutorial helped elucidate the importance of proper ventilation and fan implementation in thermal comfort for industrial environments. We appreciate your recognition and are encouraged to continue delivering high-quality CFD learning content. If you have any further questions or need assistance with future projects, please don’t hesitate to reach out.

Felton Upton –

I’m extremely satisfied with the tutorial for simulating a generator room’s ventilation with fans in ANSYS Fluent. The detailed steps provided enormous help in understanding the setup and the outcome of the CFD project. I can now efficiently run thermal comfort simulations and make informed decisions regarding HVAC systems in industrial settings.

MR CFD Support –

We’re delighted to hear that you found our tutorial on simulating a generator room’s ventilation insightful and useful for your thermal comfort CFD projects. Thank you for taking the time to share your positive feedback, and we’re glad we could assist in enhancing your CFD analysis skills for HVAC systems. If you have any more questions or if there’s another topic you’re interested in, don’t hesitate to reach out. Your success is our goal!

Tristin Welch –

Great work on providing ventilation solutions. Could you detail how the addition of the 64 fans affected the distribution of the airflow within the generator room compared to using 32 fans?

MR CFD Support –

In the simulation with 64 fans, the airflow velocity inside the generator room was significantly enhanced, leading to a more even distribution of air and efficient removal of hot air around the generators. The use of additional fans helps create an effective air circulation pattern that improves thermal comfort by maintaining a consistent temperature, closer to the outside temperature, throughout the room.

Clair Reichert –

This tutorial was so informative! The steps for ventilating the generator room were clearly presented and the impact of various fan configurations was thoroughly explained. It was interesting to see the temperature changes and how the addition of different fans yielded such substantial improvements in thermal comfort.

MR CFD Support –

We’re delighted to hear that our tutorial on Generator Room Ventilation was helpful and informative. Thank you for taking the time to provide your positive feedback. It means a lot to us that our product could assist in better understanding HVAC simulations using ANSYS Fluent. Your satisfaction with the learning process and the clarity of the information presented is our top priority. We appreciate your review!