Planar Heat Exchanger with Mixing Tabs Simulation, ANSYS Fluent Training

$80.00 Student Discount

- The problem numerically simulates Planar Heat Exchanger with Mixing Tabs using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 4017548.

- The Energy Equation is activated to consider heat transfer in the heat exchanger.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

This simulation is about a Planar Heat Exchanger via ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

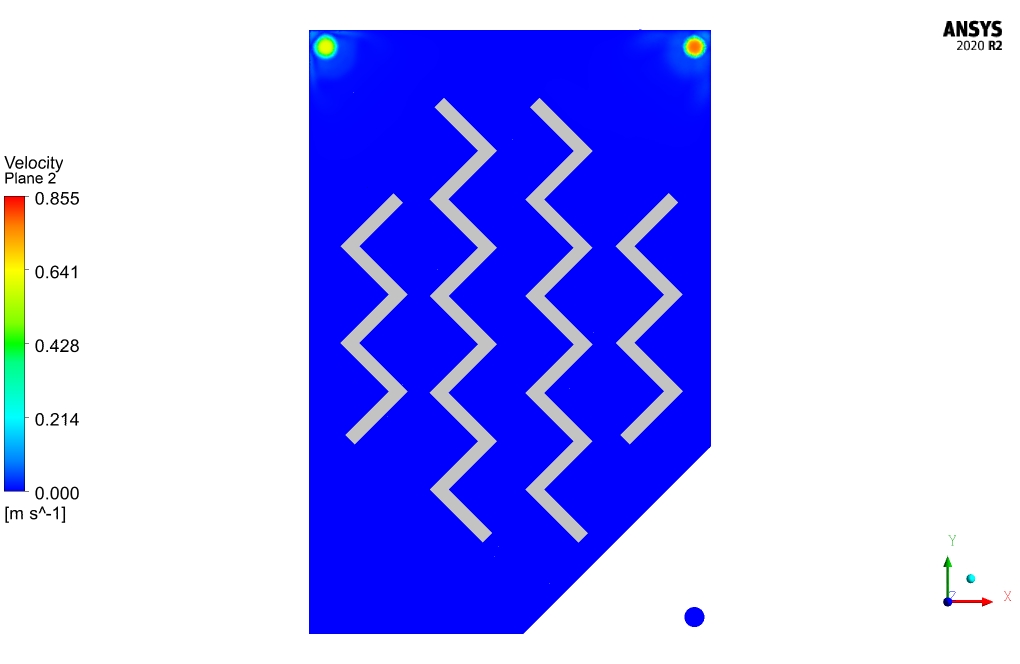

This project investigates a 4-layer planar heat exchanger with zigzag fins in each layer. Steady hot (T=286.5K) and cold (T=276.5K) water flow enter the planar domain, moving through the heat exchanging region and generating vortex flow by colliding with zigzag fins.

Also, the residence time of the fluids and the contact surfaces increase in the existence of these zigzag fans, which leads to a more heat transfer between the hot and cold flows.

Both flows exit the heat exchanging domain with approximately equal temperature (T=282K).

The geometry of the present model is drawn by Design Modeler software. The model is then meshed by ANSYS Meshing software. The model mesh is unstructured, and 4017548 cells have been created.

Planar Heat Exchanger Method

In this simulation, the energy model is activated because the main goal of this project is heat transfer. Also, since we have a multi-layer heat exchanger, the model consists of several computational zones. Water flows in all layers but at different temperatures to transfer heat between the layers.

Planar Heat Exchanger Conclusion

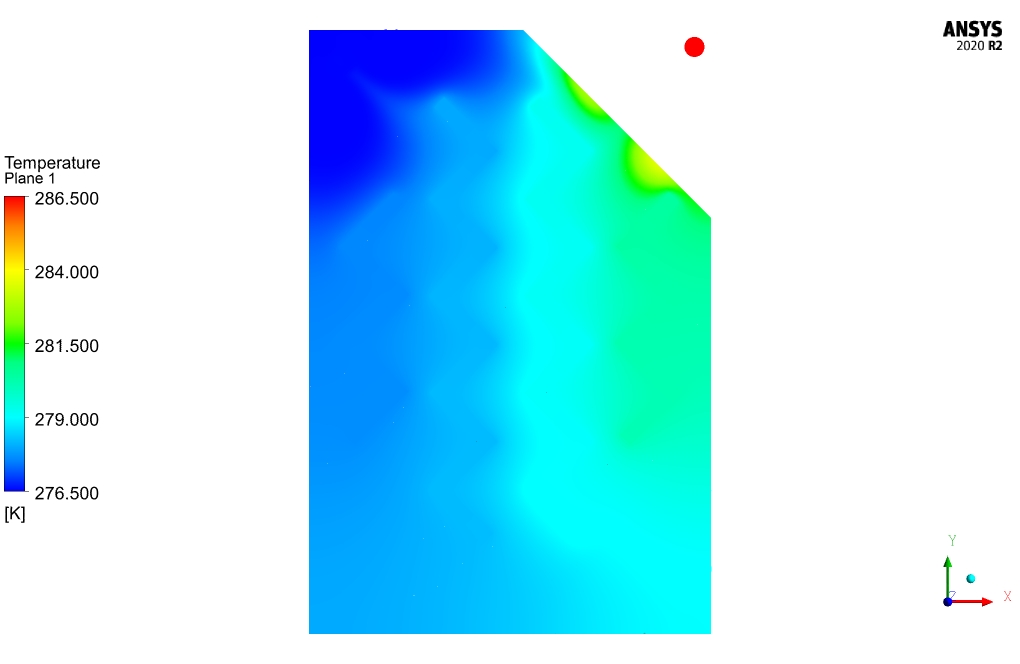

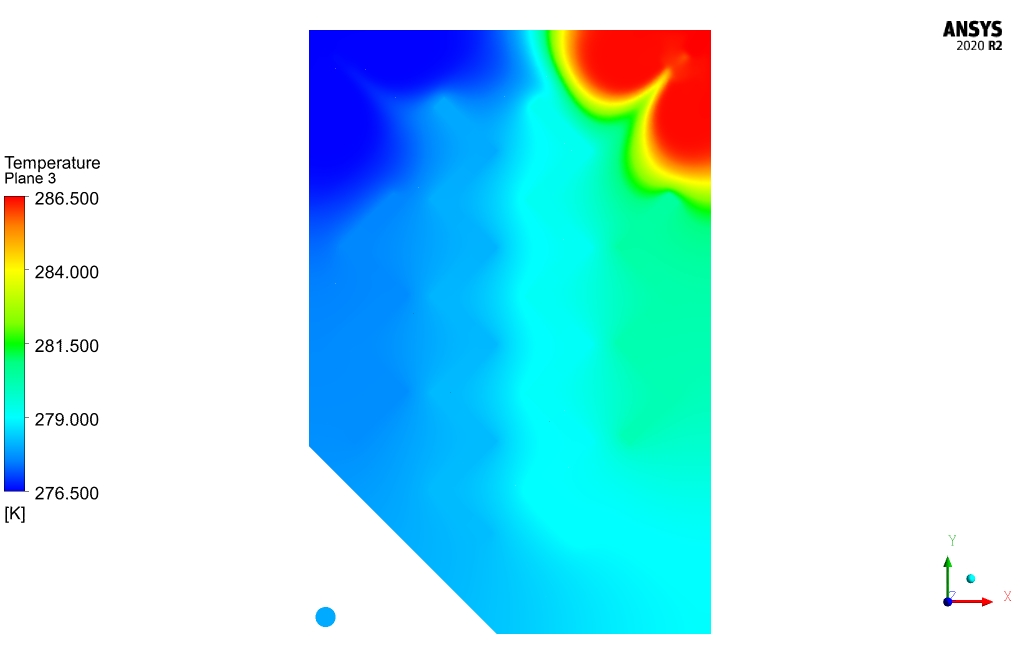

After simulation, the contours of temperature, velocity, and pressure for each heat exchanger layer are obtained. After simulation, the contours of temperature, velocity, and pressure for each heat exchanger layer are obtained.

Layers are planes parallel to the XY plane, which are assigned 1 to 4 as the increase of their Z. Layers 1 and 3 are regions where cold flow is heated up, and layers 2 and 4 are regions where hot flow is cooled down. The hot flow’s temperature at the inlet and outlet is 286.2 K and 282.213 K, respectively.

The cold flow’s temperature at the inlet and outlet is 276.5 K and 282.325 K, respectively. Using it, the heat transfer rate from the hot flow is equal to 93.8503W, and the heat transfer rate from the cold flow is equal to -94.754W, which can be considered equal with a reasonable approximation.

Prof. Tracey Rowe Sr. –

The detailed results in this review are very helpful! It served me well in understanding the practical impacts of mixing tabs in heat exchangers.

MR CFD Support –

Thank you for your feedback! We’re really glad to hear that our project on the Planar Heat Exchanger with mixing tabs was informative and helpful for you. If there’s anything more that you wish to learn or any other assistance you require, feel free to reach out to us!

Israel Schroeder –

I followed the step-by-step guidance for the Planar Heat Exchanger simulation, and the tutorials made the process quite straightforward. The details on how the zigzag fins enhance heat transfer efficiency were particularly enlightening. The visualization of temperature variation across the heat exchanger clearly demonstrated how effective the design is. The final temperatures and the heat transfer rates validated the design’s efficacy as well. Great job on such an instructive product!

MR CFD Support –

We’re thrilled to hear that our Planar Heat Exchanger simulation tutorial was clear and helped you understand the significance of the zigzag fins in heat transfer. It’s wonderful to know that the visual results and the validation of the heat transfer rates provided you with the insights you needed. Your feedback is greatly appreciated, and we thank you for taking the time to share your positive experience with our learning product!

Bertha Ratke –

I’ve been interested in heat exchanger simulations for a while. The results you obtained look impressive! The balanced temperature at the outlets suggest a highly efficient design. Can you tell me how did the inclusion of zigzag fins impacted the heat transfer effectiveness compared to traditional fin designs?

MR CFD Support –

Thank you for your compliment! The zigzag fins increase the turbulence within the fluid flow, enhancing the convective heat transfer by disrupting the boundary layer formation. This design leads to prolonged contact surfaces and residence times compared to straight fin designs. The increase in the fluid mixing and disruption in the flow patterns contributes significantly to the planar heat exchanger’s heat transfer effectiveness, making it more effective in transferring heat than traditional fin designs.

Dr. Jaqueline Marks III –

The tutorial on the Planar Heat Exchanger simulation with Mixing Tabs was incredibly detailed and easy to follow. I appreciated the systematic approach to setting up the model and the clear explanation of the physics involved in the heat transfer processes. The results section was particularly helpful, with the inclusion of temperature and velocity contours aiding in a thorough understanding of the heat exchanger’s performance. Superb training material indeed!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you found the training material on the Planar Heat Exchanger with Mixing Tabs comprehensive and instructional. Our goal is always to provide clear and detailed information to facilitate a complete understanding of the simulation process and outcomes. We appreciate you taking the time to share your experience and are glad that the results and explanations were helpful for you. If you have any more questions or need further assistance with your simulations, don’t hesitate to reach out to us.

Mr. Rogers Kutch –

The simulation was a game changer for visualizing the heat exchange process in the fins. Learned so much about vortex flow influence on the heat transfer rate. Use of zigzag fins in real-world designs is now crystal clear to me—temp results are pretty impressive!

MR CFD Support –

Thank you for your enthusiastic feedback! We’re thrilled to hear that our simulation has provided you with valuable insights into the heat exchange process and the impact of vortex flow on heat transfer. It’s always rewarding to know when our products can clarify concepts and aid in understanding complex designs. We appreciate your recognition of our work, and hope our training continues to support your learning journey!

Dakota Dooley –

Just finished the Planar Heat Exchanger with Mixing Tabs simulation training and had to express how impressed I am! The level of detail in setting up the simulation, examining heat transfer and fluid dynamics, was remarkable. I especially appreciated the clear demonstration of energy model activation and layer analysis which enhanced my understanding. The visuals for temperature, velocity, and pressure were absolutely enlightening and showed the effectiveness of the mixing tabs vividly. Stellar job on making CFD analysis this accessible and educational!

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that you’re impressed with our Planar Heat Exchanger simulation training and found the details and visualization helpful for your understanding of CFD analysis. It’s great that it enhanced your knowledge of heat transfer phenomena and fluid dynamics in the context of heat exchangers. Your feedback is much appreciated, and we hope our products continue to support your learning journey!

Krista Purdy –

I just completed my study on the Planar Heat Exchanger simulation using your ANSYS Fluent Learning Product. The results were amazing! Seeing how the zigzag fins influenced the flow and enhanced heat transfer was very insightful. Plus, the temperature equalization between hot and cold flows was a critical learning outcome. It gave a practical example of efficient design in heat exchangers that I’ll definitely use in my future work.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that the Planar Heat Exchanger simulation provided valuable insights and that you could witness the effects of the design modifications directly. If our learning product has enriched your understanding and will be helpful in your future endeavors, we consider that a great success. Should you have any more feedback or need further assistance, feel free to reach out. We wish you all the best in your future design projects!

Erich Wolff –

I’m impressed by the thoroughness of the temperature control across all the layers in the simulation. Great job!

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear you’re impressed by the precise temperature control and heat transfer analysis demonstrated in our simulation. If you have any more questions or need further assistance on this topic, feel free to reach out.

Domenico Windler –

The Planar Heat Exchanger simulation results look impressive! The detailed temperature gradient and flow pattern visualization in both hot and cold flows provided real insights into the heat transfer process. It’s quite beneficial for understanding how the interaction of fluids with zigzag fins enhances the efficiency of heat exchange. Moreover, it’s fascinating to see how the heat transfer rates from hot to cold flows are almost equal, emphasizing system balance. Great job by MR CFD on this innovative approach to studying planar heat exchangers!

MR CFD Support –

Thank you for your positive feedback! We at MR CFD are delighted to hear that our simulation could provide you with clear insights into the heat transfer process within the Planar Heat Exchanger. Our goal is always to offer comprehensive understanding through detailed analyses. Your appreciation means a lot to us, and we continue to commit ourselves to deliver high-quality CFD training products. If you need further assistance or have more questions in the future, please do not hesitate to ask.

Patrick Kihn –

I’m really impressed by the level of detail provided in this simulation of the planar heat exchanger. The use of mixing tabs to enhance heat transfer efficiency is a clever approach that likely contributes to the effective evening out of temperatures between the hot and cold flows. It’s incredible that the simulation manages to achieve a near-equal temperature (T=282K) at the outlets of both flows, indicating a well-balanced heat exchange process. The comprehensive analysis of the temperature, pressure, and velocity profiles within the heat exchange layers demonstrates an in-depth understanding of the dynamics involved. Kudos to the team for implementing an unstructured mesh with over 4 million cells, ensuring that the intricacies of flow and thermal distribution are well-captured. This simulation surely provides valuable insights for those interested in the design and optimization of heat exchangers!

MR CFD Support –

We’re thrilled to see that you appreciate the thoroughness we’ve put into the simulation of the planar heat exchanger with mixing tabs. Our goal is always to provide a detailed understanding of the concepts and dynamics involved, and it’s great to know that you’ve recognized the balance and intricacy captured in the model. Thank you for your positive feedback; we’re dedicated to offering valuable insights and training for heat exchanger design and optimization!

Novella Koelpin –

I am honestly impressed with the detail in the simulation results for the Planar Heat Exchanger training module. The use of unstructured meshing and complex geometrical configurations such as zigzag fins have evidently provided a rich understanding of the vortex flow and effective heat transfer. Great job on providing such comprehensive learning materials!

MR CFD Support –

Thank you for recognizing the efforts put into creating the Planar Heat Exchanger simulation training module. We are thrilled to hear that the details provided have contributed to a better understanding of the subject matter. It is wonderful to know that our materials are valuable to our customers. Appreciate your positive feedback!

Prof. Albertha Ward –

I’m impressed with the level of detail in the temperature, velocity, and pressure contours. It seems like the heat exchanger’s design was quite effective. Wonderful job on the simulation!

MR CFD Support –

We appreciate your positive feedback! We’re thrilled to hear that the details provided in the simulations and the effectiveness of the heat exchanger’s design met your expectations. Your satisfaction is our priority, and your review encourages us to keep delivering high-quality simulations. Thank you for choosing our training for your CFD analysis needs.

Ms. Marilou Friesen –

I am totally impressed by how effective the mixing tabs are in the planar heat exchanger simulation. The results show almost equal outlet temperatures, which means it’s doing an excellent job at transferring heat. The entire design seems ingenious!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you are impressed with the design and effectiveness of the heat exchanger simulation incorporating mixing tabs. It’s always our goal to provide simulations that reflect accurate and optimal performance. Your observation about the equal outlet temperatures reinforces the quality of our CFD project. We appreciate you taking the time to recognize the efforts of our team at MR CFD Company.

Katelin Shanahan PhD –

The content and outcomes of this planar heat exchanger CFD simulation by MR CFD have impressed me significantly. The detailed attention to temperature gradients and the impact of the zigzag fins on fluid dynamics and heat transfer showcases the company’s expertise in CFD analysis. Moreover, the heat transfer rate being almost equal for hot and cold flows illustrates a well-designed simulation project that provides practical insights for industrial heat exchanger designs. Great work!

MR CFD Support –

Thank you for your positive feedback on our Planar Heat Exchanger CFD simulation project. We’re thrilled to hear that the details and results have made such a good impression. Our team at MR CFD is committed to delivering comprehensive simulations that not only model physical phenomena accurately but also provide actionable insights for real-world applications. Your acknowledgment reaffirms our dedication to quality and precision in the field of computational fluid dynamics. If you need further assistance or have more interest in our projects, feel free to reach out. We’re here to help!

Jed Vandervort –

What exactly do the mixing tabs do in this heat exchanger simulation? It’s fascinating how they seem to improve heat transfer.

MR CFD Support –

The mixing tabs in this heat exchanger simulation serve to disrupt the laminar flow, creating vortices that enhance mixing of the fluid streams. This increased turbulence improves the heat transfer efficiency by promoting more uniform temperature distribution and increasing the thermal contact time between the hot and cold water.

Darrel Stehr –

The in-depth analysis and detailed explanation of the Planar Heat Exchanger simulation showcased in your training materials made understanding the complex heat transfer processes very approachable. It was particularly impressive to see how the zigzag fins increase the efficiency of the heat exchanger by enhancing contact surfaces and vortex flow—outstanding application of CFD principles!

MR CFD Support –

Thank you for your positive review. We’re glad to hear that the materials provided an accessible explanation of the heat transfer enhanced by the zigzag fins design. Our goal is to help users understand complex CFD concepts, and it’s rewarding to know that our efforts are appreciated. If there’s anything more you’re curious about or other simulation products you’re interested in, please let us know!

Wallace Kuphal –

The detailed results are quite impressive! I learned a lot from the step-by-step simulation process and the clear explanation on heat transfer efficiency in the planar heat exchanger.

MR CFD Support –

Thank you so much for your kind review! We are thrilled to hear that you found the simulation process and the explanation on heat transfer efficiency informative and helpful. We strive to provide clear and detailed analysis in all our training materials. Should you have any further interest in similar CFD projects or need assistance, feel free to reach out to us!

Gerry Barrows –

I just wanted to share how impressed I am with the Planar Heat Exchanger simulation project. The detailed setup leading to the precise temperature equilibration is fascinating. Learning from this has been amazing!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you found the Planar Heat Exchanger simulation project educational and impressive. It’s always rewarding to know our courses effectively facilitate learning and provide thorough insights into complex simulations. If you have any more questions or need further assistance, feel free to reach out.