Gerotor Pump CFD Simulation, ANSYS Fluent Training

$240.00 Student Discount

- The problem numerically simulates the Gerotor Pump using ANSYS Fluent software.

- We design the 2-D model with the Design Modeler software.

- We mesh the model with ANSYS Meshing software, and the element number equals 511,82.

- We perform this simulation as unsteady (Transient).

- We use the Dynamic Mesh Model to define deforming and moving zones.

- We use the user-defined function (UDF) to define the rotational motion of gears.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

This project is related to the numerical simulation of the Gerotor Pump using ANSYS Fluent software.

A pump is a mechanical device for moving and transferring all liquids from one place to another. In this way, by increasing the pressure, pumps cause liquids to move to a higher height (by increasing the head) and even lower (such as tanks). The pump takes mechanical energy from an external source, such as a motor, and transfers it to the fluid passing through it.

As a result, the energy of the fluid increases after leaving the pump.

The energy transfer to the pump fluid is done in two dynamic and displacement methods. Therefore, pumps are divided into positive displacement pumps and dynamic or non-positive displacement pumps. Positive displacement pumps are divided into two groups: rotary (such as gear, lobe, and vane) and reciprocating (piston and diaphragm).

One of the most common pumps to increase the hydraulic power of a fluid is a gerotor pump. Gerotor pumps move liquids using gears.

Gerotor pumps consist of two gears that rotate in the same direction, so one gear is inside the other. When two gears make contact with their teeth, fluid is trapped. Now, when the teeth are separated from each other due to rotation, high-pressure fluid is rotated through the ribs to the outlet.

Gerotor pumps are similar to internal gear pumps, with one difference. Gerotor pumps are internal gear pumps without a crescent.

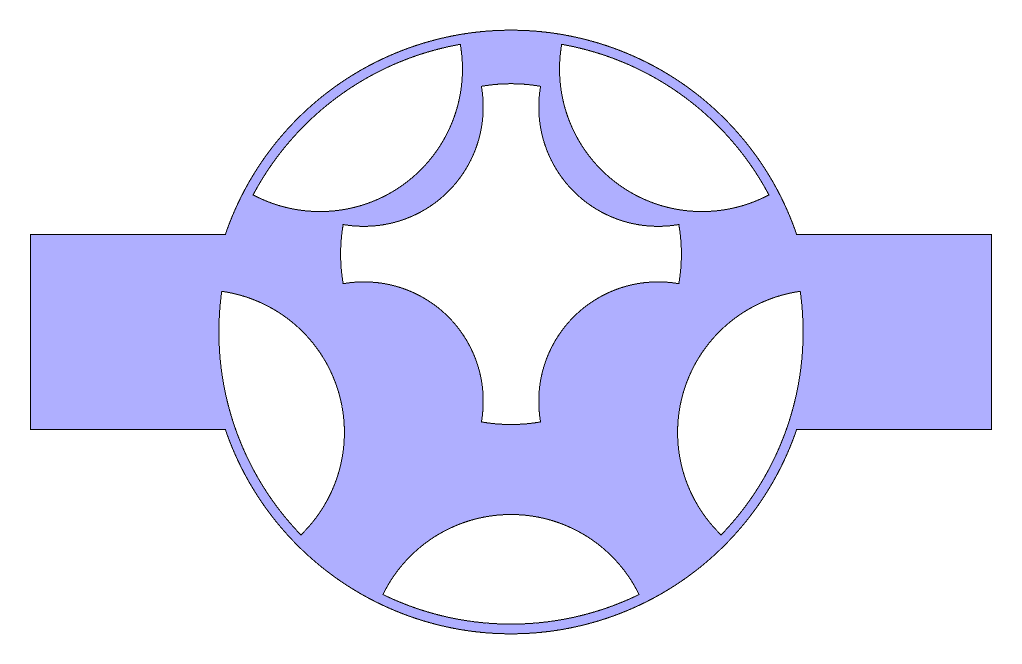

In this project, we simulated the water flow inside a gerotor pump. We aim to model the rotation of two gears inside the pump. The gears’ rotation changes the fluid’s behavior in the pump momentarily. So, the mesh of the computing domain deforms over time.

We modeled the geometry of the project using Design Modeler software. The geometry is related to a gerotor pump. The computational domain includes the internal space of the pump with two non-concentric gears inside each other. Then we meshed the model with ANSYS Meshing software. The model mesh is unstructured, and the number of cells equals 511,82.

Gerotor Pump Methodology

The Dynamic Mesh Model is used for the simulation. We generally use a dynamic mesh whenever we have a moving boundary or a deforming zone.

Here, two gears are rotating in the same direction. So this causes the mesh to deform over time. Therefore, we define a Rigid Body to define the rotational motion of the gears. We use a user-defined function (UDF) to define the motion of the rigid body.

According to the rotational motion of the gears as a rigid body, the mesh zone around the gears is deforming. So, for this zone, we use the Deforming option.

Due to the nature of this modeling, fluid behavior is time-dependent. Hence, we use the unsteady (Transient) solver.

Gerotor Pump Conclusion

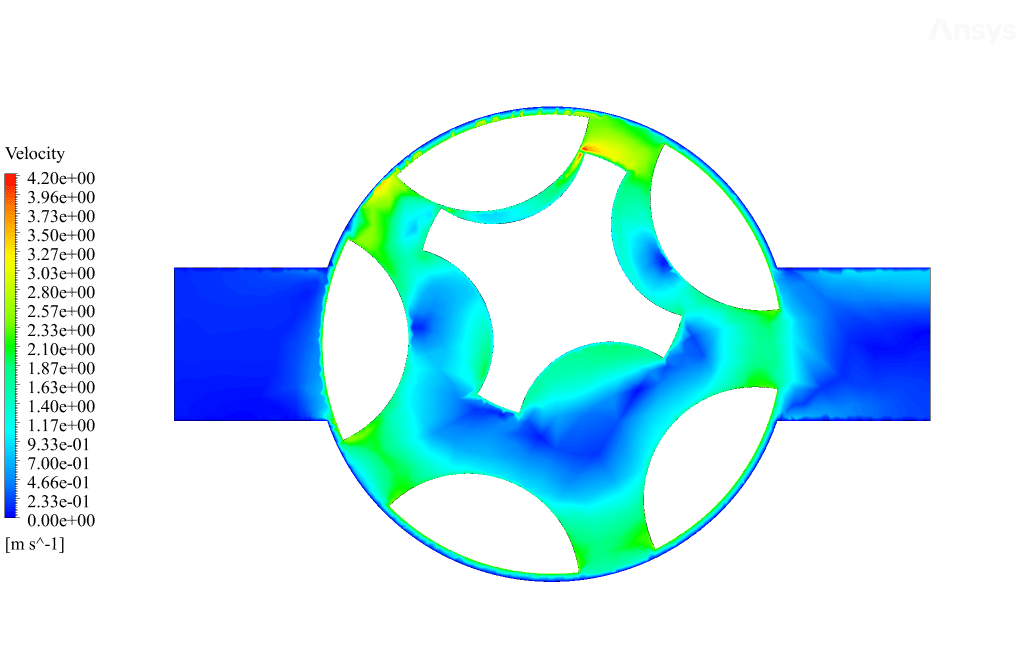

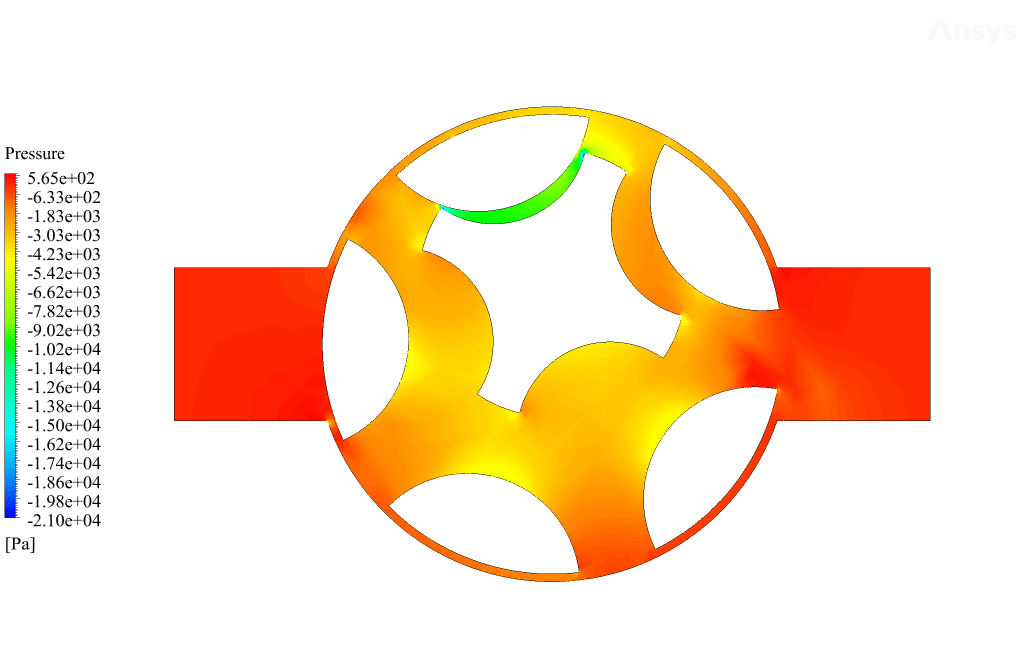

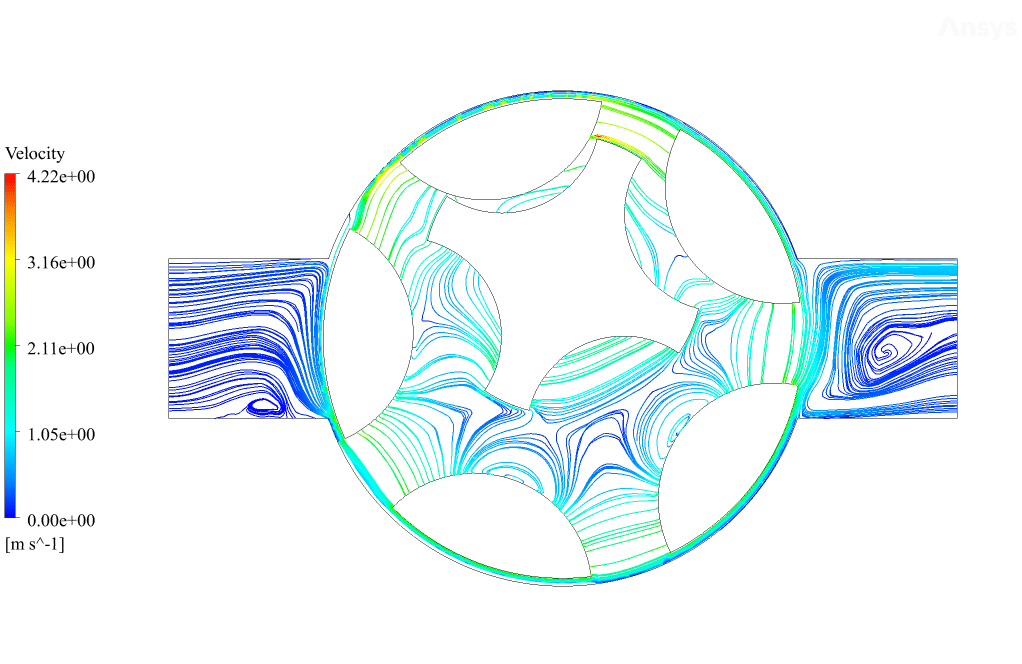

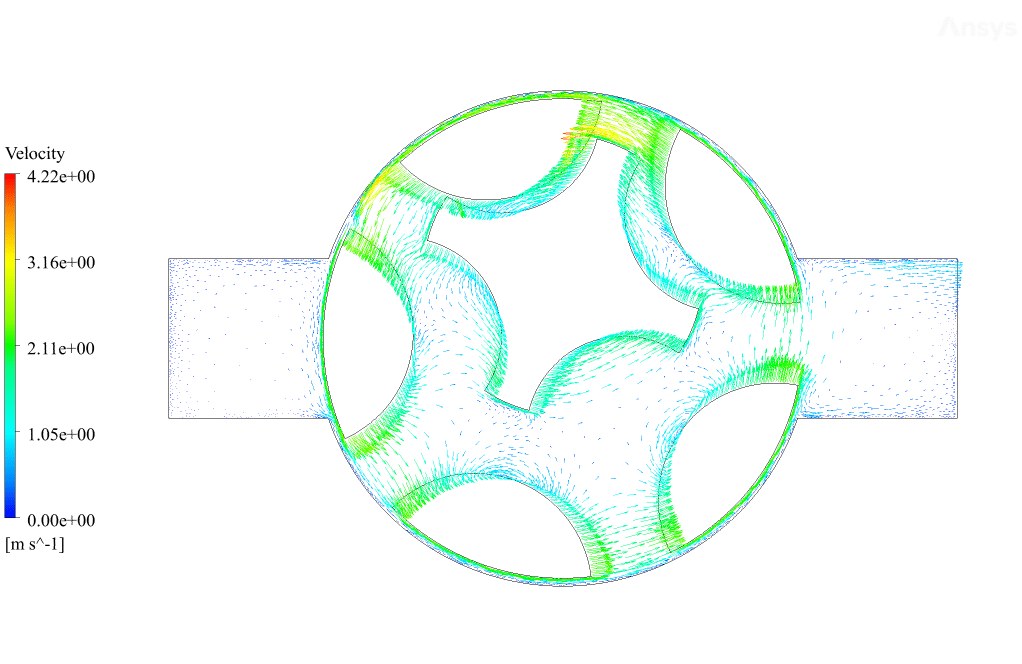

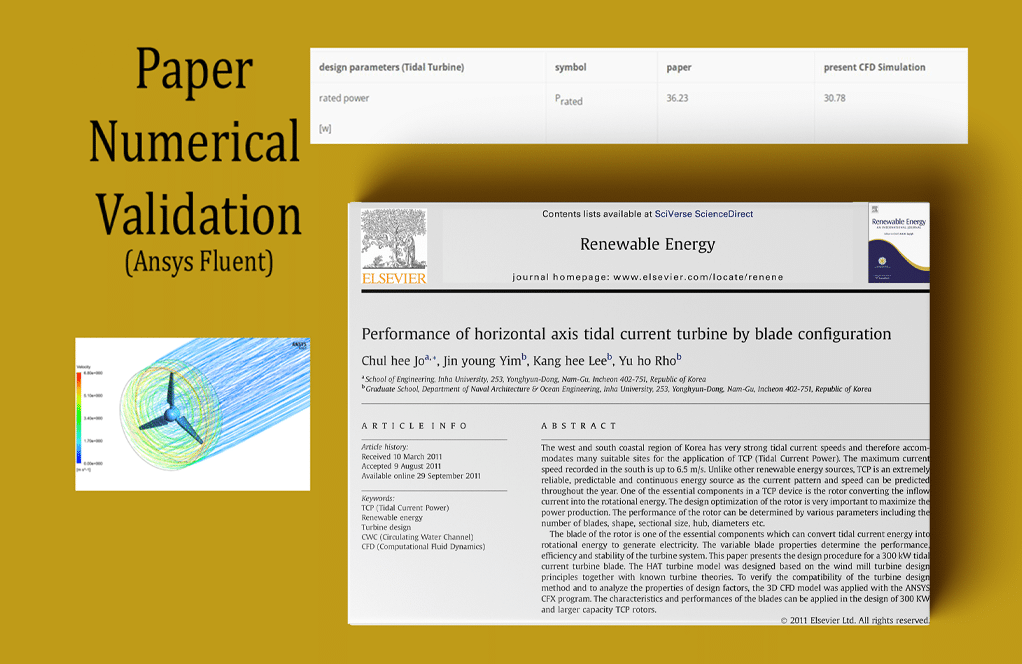

After the solution, we obtained pressure, velocity contours, and velocity vectors. Because the gears rotate over time, we obtained the velocity and pressure contours and the velocity vector animation.

The results show that this gerotor pump is working correctly. This pump can transfer the fluid well and increase the fluid’s pressure. The fluid is trapped in the space between the gears in contact. Then this fluid is pushed towards the outlet with high pressure.

Kristina Klein –

The training material on Gerotor Pump CFD simulation using ANSYS Fluent described the process really well. It detailed the setup and types of meshes used along with the function of each part of the pump. Props to the MR CFD team for creating such easy to understand and well-structured training content!

MR CFD Support –

Thank you for taking the time to leave a positive review on our Gerotor Pump CFD Simulation using ANSYS Fluent training course. It’s great to hear that our material met your expectations and was helpful in furthering your understanding. We always strive to present complex concepts in a clear and accessible way. We appreciate your support and are glad you found the course beneficial!

Carey Stanton –

I was truly impressed by how detailed the simulation of the Gerotor Pump was using ANSYS Fluent. The dynamic mesh model sounded fascinating and the way the gears’ rotation was factored into the model is commendable. It’s great to see such an intricate process being modeled so efficiently.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you appreciate the complexity and detail of the Gerotor Pump CFD Simulation. Our goal is to provide thorough and precise simulations to our users, and we’re glad that was reflected in your experience with our product. If you have any further questions or need further assistance, please don’t hesitate to reach out.

Lue Wolf –

What software package was used to create the user-defined function (UDF) for controlling the gerotor pump gears’ movement?

MR CFD Support –

In this project, the user-defined function (UDF) for controlling the gerotor pump gears’ movement was created using the C programming language integrated within the ANSYS Fluent software environment.

Davin Kulas –

What an excellent and detailed explanation! I have a much better understanding of how gerotor pumps work thanks to your simulation. The use of dynamic mesh to replicate the movement of the gears is particularly impressive.

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that our simulation helped enhance your understanding of gerotor pumps. It’s always rewarding to know that our efforts to accurately simulate real-world mechanics are appreciated.

Kristin Doyle –

I’m truly impressed by the dynamic mesh model used for the Gerotor Pump simulation. It’s fascinating to think about how the rotating gears impact fluid behavior. Well done on demonstrating the workings of this pump through your simulations!

MR CFD Support –

Thank you for your kind words! We’re elated to hear that the Gerotor Pump simulation met your expectations and provided valuable insights into the interaction between the rotating gears and the fluid within the pump. We believe simulations are a powerful tool to visualize and understand complex mechanical phenomena, and we’re glad you found it fascinating!

Jace Robel MD –

What a fantastic learning tool! The Gerotor Pump CFD Simulation training really enhanced my understanding of pump operations and the use of ANSYS Fluent. It was particularly enlightening to see how fluid dynamics can be captured and analyzed using simulation techniques, especially the pressure and velocity changes through the pump. Great job to the MR CFD team for creating a product that is not only informative but also incredibly interesting to work with!

MR CFD Support –

Thank you for taking the time to review our Gerotor Pump CFD Simulation training product. We’re thrilled to hear that it contributed significantly to your understanding of pump dynamics and the practical application of ANSYS Fluent for simulation purposes. We aim to provide detailed and clear resources, and knowing that you found it both enlightening and enjoyable is wonderful. If you have any further questions or need additional support, please don’t hesitate to reach out. Thanks again for your positive feedback!