Heat Exchanger with Inner Fins CFD Simulation

$80.00 Student Discount

The present problem is to simulate a heat exchanger using ANSYS Fluent software.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Heat Exchanger with Inner Fins, ANSYS Fluent CFD Simulation Training

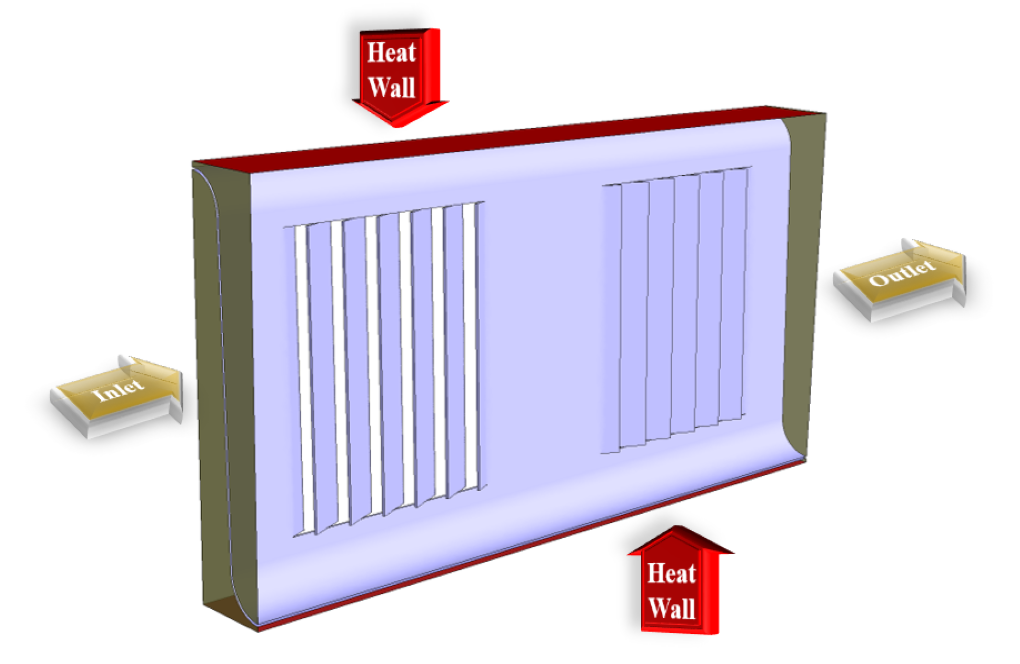

The present problem is to simulate a heat exchanger using ANSYS Fluent software. In this simulation, airflow enters the device at a velocity of 22 m.s-1 and a temperature of 313 K and exits the exchanger at a pressure equal to atmospheric pressure. For the operating mechanism of the device, it is assumed that the upper and lower surfaces of the device have a thermal boundary condition of the constant temperature type equivalent to a temperature of 323 K. Also, a curved central wall in this device with several rows of blades and fins is designed to help better airflow and better heat transfer.

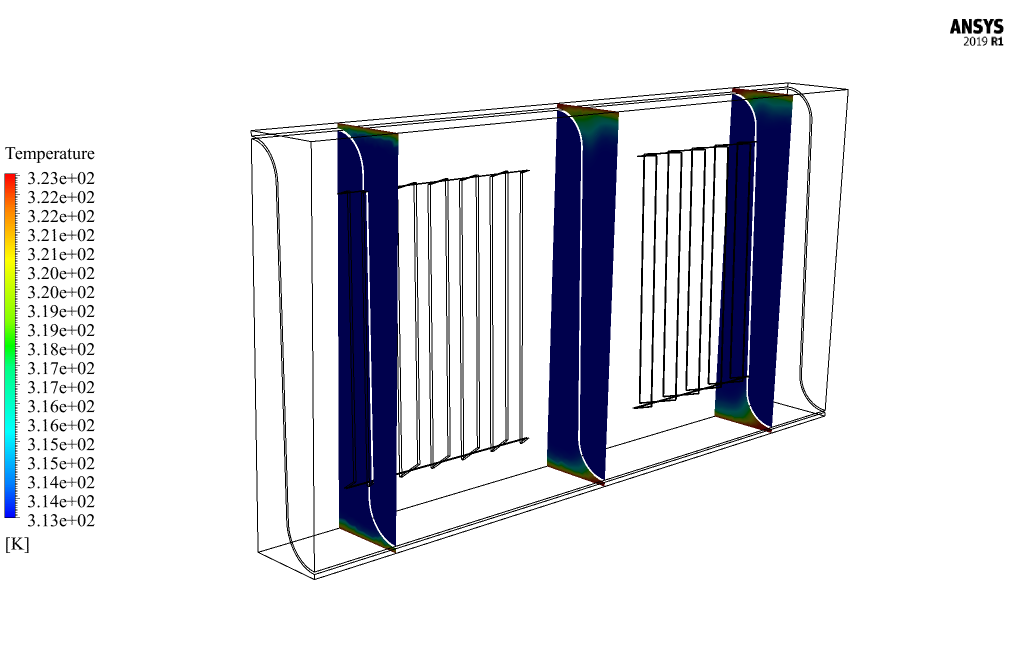

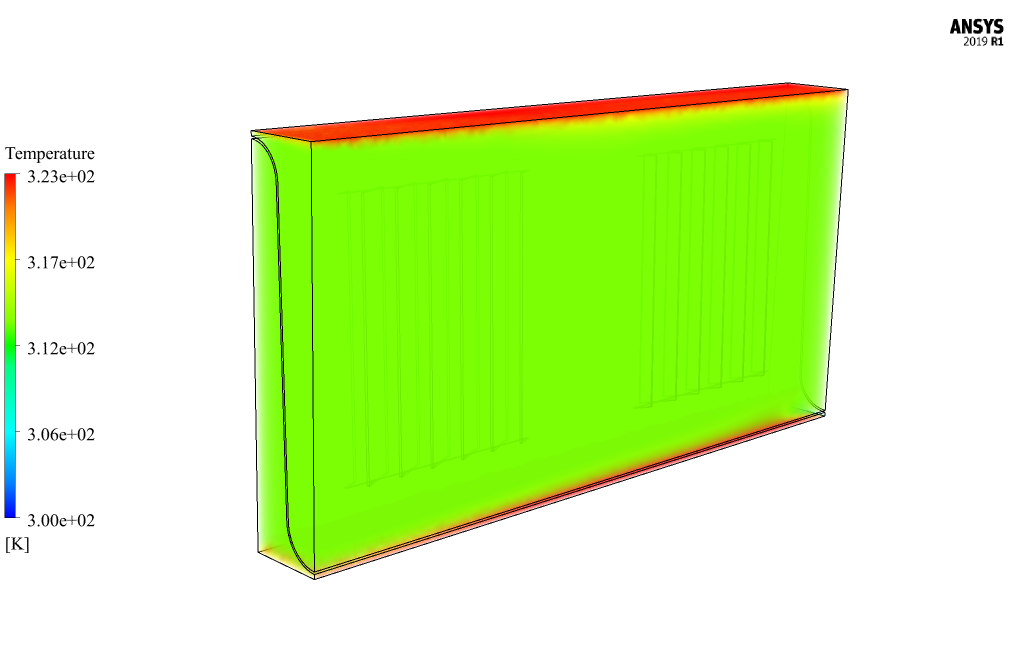

This work aims to investigate the effect of high-temperature walls on the airflow temperature through the heat exchanger’s interior.

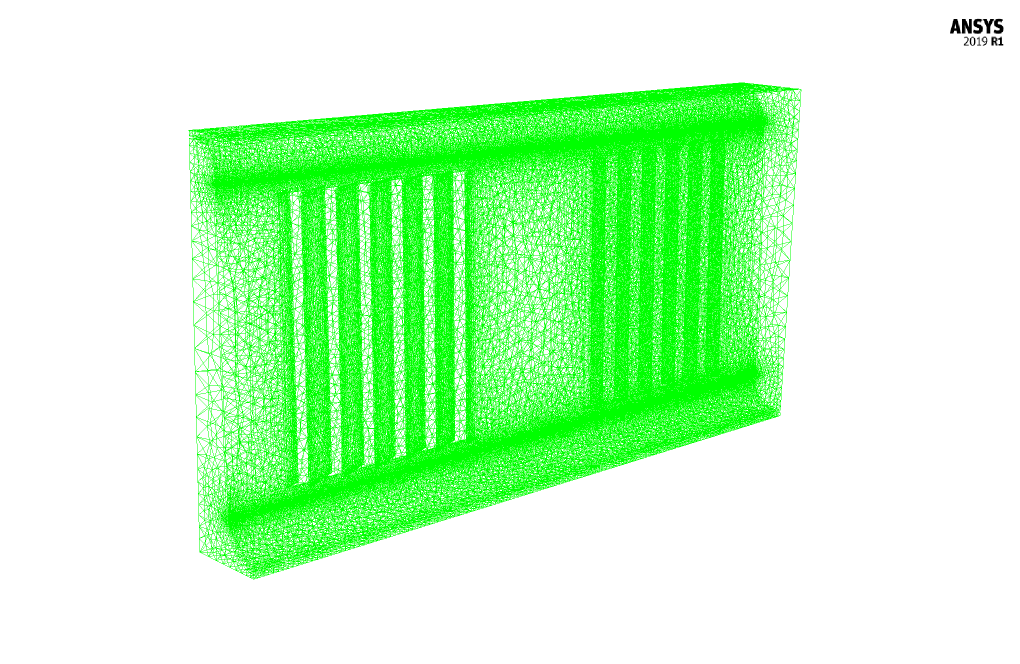

Heat Exchanger Geometry & Mesh

The present model is designed in three dimensions using Design Modeler software. The model includes a heat exchanger with dimensions of 0.0018 m, 0.0082 m, and 0.0162 m; So that its inlet and outlet ducts are on both sides, and a curved inner wall with several rows of fins is located inside it, and its upper and lower walls are distinguished as surfaces with temperature condition.

We carry out the meshing of the model using ANSYS Meshing software, and the mesh type is unstructured. The element number is 2039783. The following figure shows the mesh.

Heat Exchanger CFD Simulation

We consider several assumptions to simulate the present model:

- We perform a pressure-based solver.

- The simulation is steady.

- The gravity effect on the fluid is ignored.

The following table represents a summary of the defining steps of the problem and its solution:

| Models (Heat Exchanger) |

||

| Viscous | k-epsilon | |

| k-epsilon model | standard | |

| near wall treatment | standard wall function | |

| Energy | On | |

| Boundary conditions (Heat Exchanger) |

||

| Inlet | Velocity Inlet | |

| velocity magnitude | 22 m.s-1 | |

| temperature | 313 K | |

| Outlet | Pressure Outlet | |

| gauge pressure | 0 Pascal | |

| Solid Wall | (CFD Simulation) | Wall |

| wall motion | stationary wall | |

| heat flux | 0 W.m-2 | |

| Heat Wall | Wall | |

| wall motion | stationary wall | |

| temperature | 323 K | |

| Methods (Heat Exchanger) |

||

| Pressure-Velocity Coupling | SIMPLE | |

| Pressure | second order | |

| momentum | second order upwind | |

| turbulent kinetic energy | first order upwind | |

| turbulent dissipation rate | first order upwind | |

| energy | second order upwind | |

| Initialization (Heat Exchanger) |

||

| Initialization methods | Standard | |

| gauge pressure | 0 pascal | |

| x-velocity & y-velocity | 0 m.s-1 | |

| z-velocity | 22 m.s-1 | |

| temperature | 313 K | |

Results

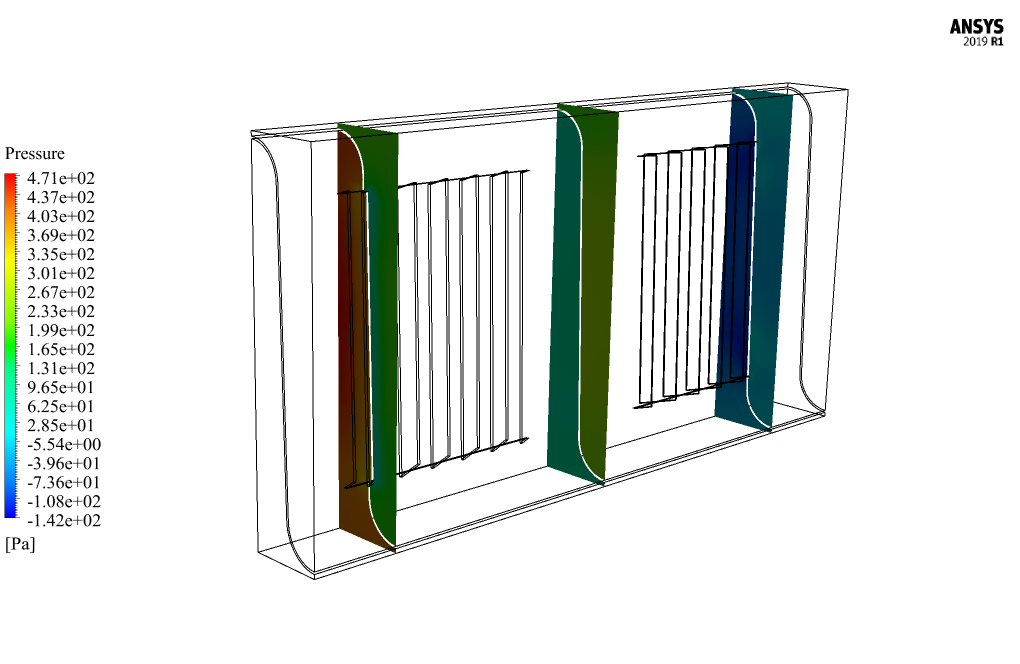

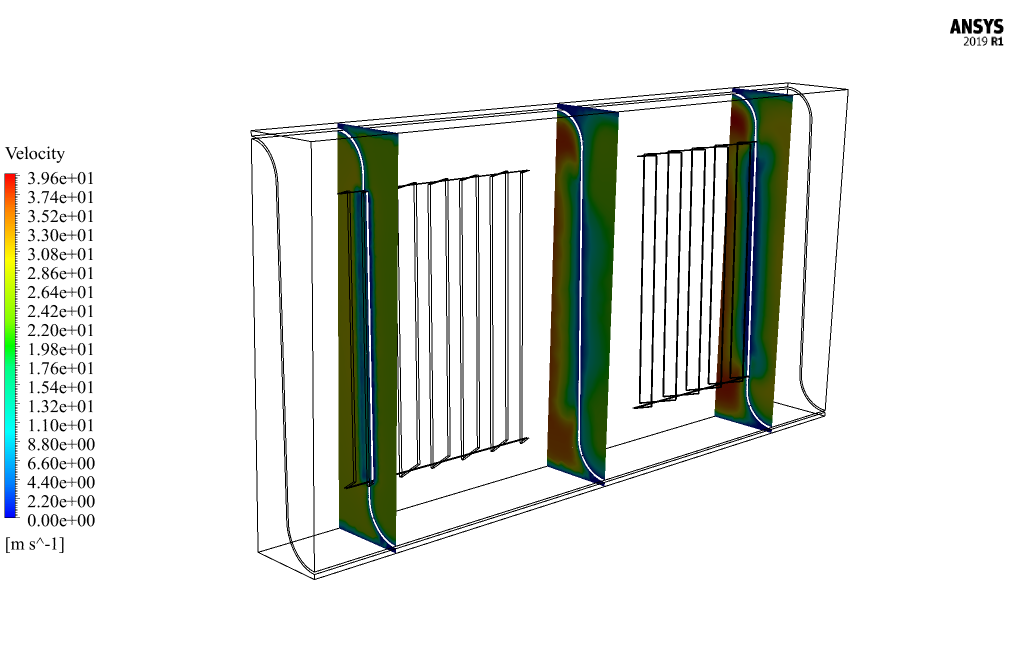

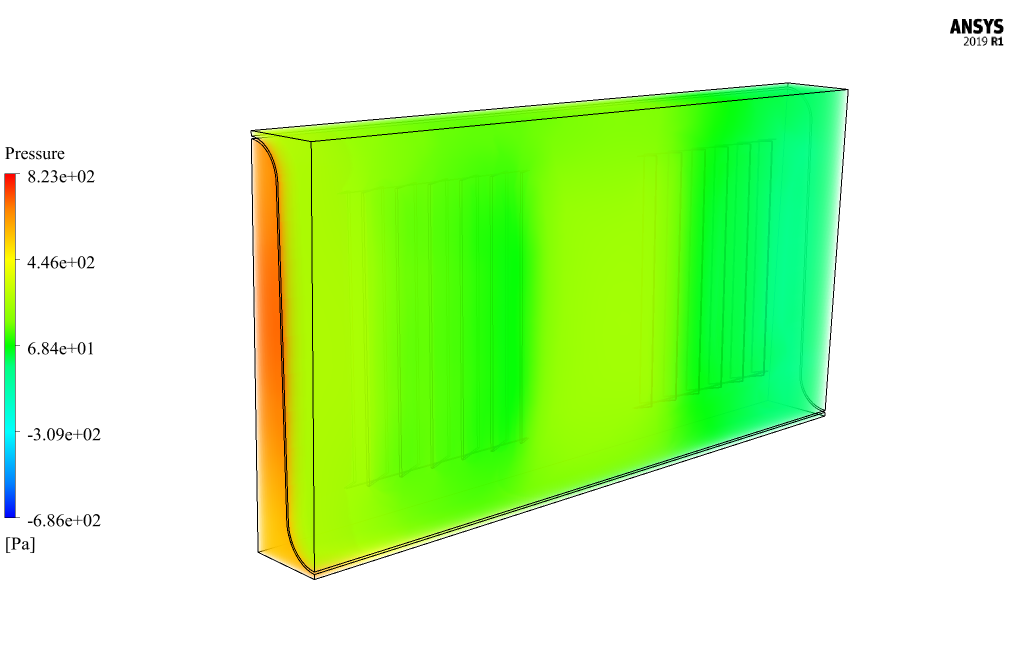

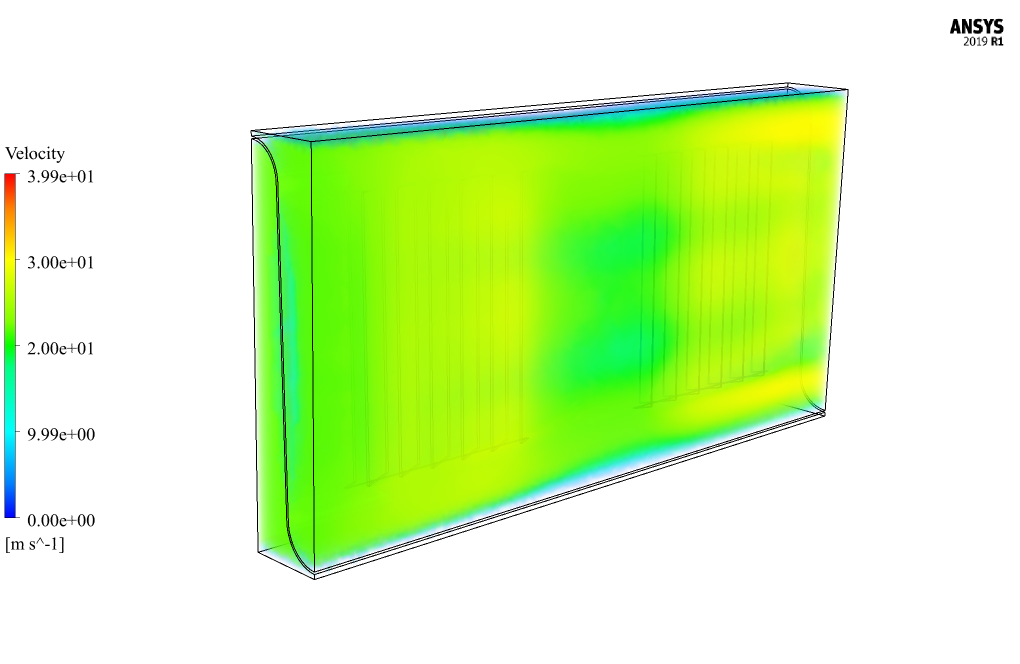

At the end of the solving process, three-dimensional and two-dimensional contours related to pressure, velocity and temperature are obtained. The contours show that the incoming air flow to the heat exchanger is affected by the hot walls and its temperature increases.

You can obtain Geometry & Mesh file and a comprehensive Training Movie that presents how to solve the problem and extract all desired results.

Dallas Lowe –

How does the simulation account for the effects of radiation?

MR CFD Support –

The current simulation primarily focuses on conduction and convection. However, we can modify the model to include radiation effects upon request.

Payton Baumbach –

I appreciated how the simulation captures the heat transfer within the exchange with inner fins. The detail on the airflow impact due to the high-temperature walls was particularly key. It’s impressive to see the contours showing effective temperature management.

MR CFD Support –

Thank you so much for your kind words! We’re delighted to hear you found the simulation informative and the visualization of the temperature changes useful. Your feedback motivates us to keep delivering high-quality CFD training materials.

Dr. Sammy Bode –

This training was incredibly detailed and clear. Because of the step-by-step guidance and comprehensive training movie, I was able to understand the setup and simulation process without much prior experience in CFD. Impressed by how the simulation reflects the heat exchange process. The post-processing contours for temperature, velocity, and pressure helped visualize the physics at play. Thank you for providing such a high-quality learning tool!

MR CFD Support –

Thank you so much for your positive feedback! We’re thrilled to hear that our training material was clear and helpful for you. It’s great to know that the step-by-step guidance and the training movie made it easy for beginners to follow along. We take pride in creating high-quality educational content for CFD enthusiasts like you. If you ever have more questions or need further assistance with other simulations, feel free to reach out. Your success is our priority!

Zelda Balistreri –

After completing this simulation, how should I adjust the cold-side inlet velocities to achieve a more efficient heat transfer without changing other parameters?

MR CFD Support –

To fine-tune the heat transfer efficiency, considering all other parameters remain constant, you can incrementally increase or decrease the cold-side inlet velocity and observe the effects on the temperature contours. By monitoring these results, you can determine the optimum velocity for maximum efficiency in your heat exchanger simulation.

Arvel Armstrong –

What kind of meshing strategy was employed for the heat exchanger geometry?

MR CFD Support –

A structured meshing strategy was employed for the heat exchanger geometry. This strategy provides a high-quality mesh that is efficient for CFD simulations.

Dr. Maybelle Wisoky II –

The provided training was extremely enlightening. It helped me grasp the fundamentals of setting up a heat exchanger model in Fluent with an impressive level of precision. The meshing details were particularly useful to ensure quality results. Is there any information available on how to evaluate the efficiency of the heat exchanger using the simulation results obtained from Fluent?

MR CFD Support –

I’m glad to hear the information was helpful. Evaluating efficiency typically involves comparing the temperature increase of the airflow to the theoretical maximum temperature change, given the temperatures and the properties of the airflow. This can be done post-processing within Fluent or by using the data exported from Fluent and calculating in a programming or spreadsheet environment. For heat exchanger efficiency, you’d look at the effectiveness, which is a measure of how close the heat transfer approaches the maximal possible for a given set up.

Brayan Feest –

I enjoyed learning about simulation from this training. The details on the velocity and temperature change across the heat exchanger were especially useful for my project.

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear that our training has been useful for your project and that the details provided on velocity and temperature changes across the heat exchanger were especially helpful. We appreciate you choosing our resources, and if you have further project needs or questions, please do not hesitate to reach out.

Prof. Llewellyn Upton Sr. –

This training session was incredibly detailed and informative! Wonderful to see the intricate interaction of airflow within the heat exchanger and how the fins alter the temperature distribution. The simulation results were clearly depicted through the contours, making it easier to comprehend the heat transfer process.

MR CFD Support –

Thank you for your kind words! We’re pleased to hear that you found the training session detailed and informative. It’s great to know that our efforts in providing clear visual representations of the simulation results helped enhance your understanding of the heat exchange process.

Walter Gleason II –

The training has been outstanding! Seeing the temperature contours clearly show how the hot walls impact the airflow was enlightening. I do wonder if you have resources available for optimization? Specifically, how one could experiment with fin design or placement for better performance.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear you found the visualization of the temperature contours and the impact of hot walls on airflow enlightening. Regarding your question about optimization resources, MR CFD Company indeed provides advanced training that covers optimization strategies, including experimentation with fin design and placement to enhance heat exchanger performance. We highly recommend checking out our additional courses or consulting services dedicated to optimization for more in-depth learning and practical implementation tips.

George Thompson –

The training for this simulation seems comprehensive. I particularly appreciated how the detailed explanation of setup, boundary conditions, and results facilitated a deeper understanding of interactions within the heat exchanger.

MR CFD Support –

Thank you for your positive review. We’re glad to hear that the detailed steps and tutorials were helpful and that you gained a thorough understanding of the heat exchanger’s simulation. Should you have any further questions in the future or need assistance with similar products, please don’t hesitate to reach out.

Mrs. Carlie Terry I –

What fantastic detail! I was particularly impressed with how the fins affect airflow and heat transfer inside the exchanger. The setup clearly illustrates the complex interplay between structure and function in thermal systems. Great job!

MR CFD Support –

Thank you very much for your kind words and for noticing the level of detail in our Heat Exchanger with Inner Fins CFD Simulation training! We strive to provide comprehensive and illustrative examples that effectively demonstrate the principles of thermal systems in a realistic setting. Your appreciation motivates us to continue delivering high-quality learning materials.

Pete Crooks I –

This training was extremely helpful for understanding the heat exchanger with inner fins concept. The detailed steps and clear explanation made the process easy to follow. Thank you!

MR CFD Support –

We are thrilled to hear that our ANSYS Fluent CFD Simulation Training for the heat exchanger with inner fins was helpful to you! If you have any more questions or need further assistance, feel free to reach out. Thank you for your positive feedback!

Hilma Schneider –

Can the simulation handle different types of heat exchangers, like shell-and-tube or plate heat exchangers?

MR CFD Support –

The current model is specific to a particular type of heat exchanger, but we can modify the simulation to handle other types of heat exchangers, such as shell-and-tube or plate heat exchangers. We are open to contributions and can accommodate your specific requirements.

Jayne Osinski –

The description of this Heat Exchanger CFD Simulation training product was wonderful and very detailed! The intricate mesh design and comprehensive use of various ANSYS Fluent models show the product’s depth and complexity. It’s fascinating how the temperature effects are highlighted and the process to obtain the results seems well thought out.

MR CFD Support –

Thank you so much for your positive feedback! We’re delighted to hear you appreciated the detail and complexity of our Heat Exchanger with Inner Fins CFD simulation training. Our goal is always to provide thorough and in-depth perspectives on how to perform and analyze simulations, so we’re glad the product met your expectations.

Raphaelle Hahn –

I’m impressed by the level of detail in preparing the simulation for the heat exchanger. The precise velocity and temperature at the inlet, coupled with the solid wall boundary conditions, really bring out the effectiveness of the inner fins design. It’s great to see the documentation of a steady pressure-based solver and the wall temperature settings, producing a clear visualization of the resultant temperature distribution within the airflow. Excellent work demonstrating the capabilities of ANSYS Fluent in modeling complex thermal systems!

MR CFD Support –

Thank you so much for your kind review! We are thrilled to hear that you appreciate the detailed setup and results of our heat exchanger simulation. It’s our aim to provide comprehensive and clear simulations that show the full potential of CFD analysis using ANSYS Fluent. Your feedback serves as a great motivation for us to keep delivering high-quality simulations! If you have any more questions or need further assistance, feel free to reach out.