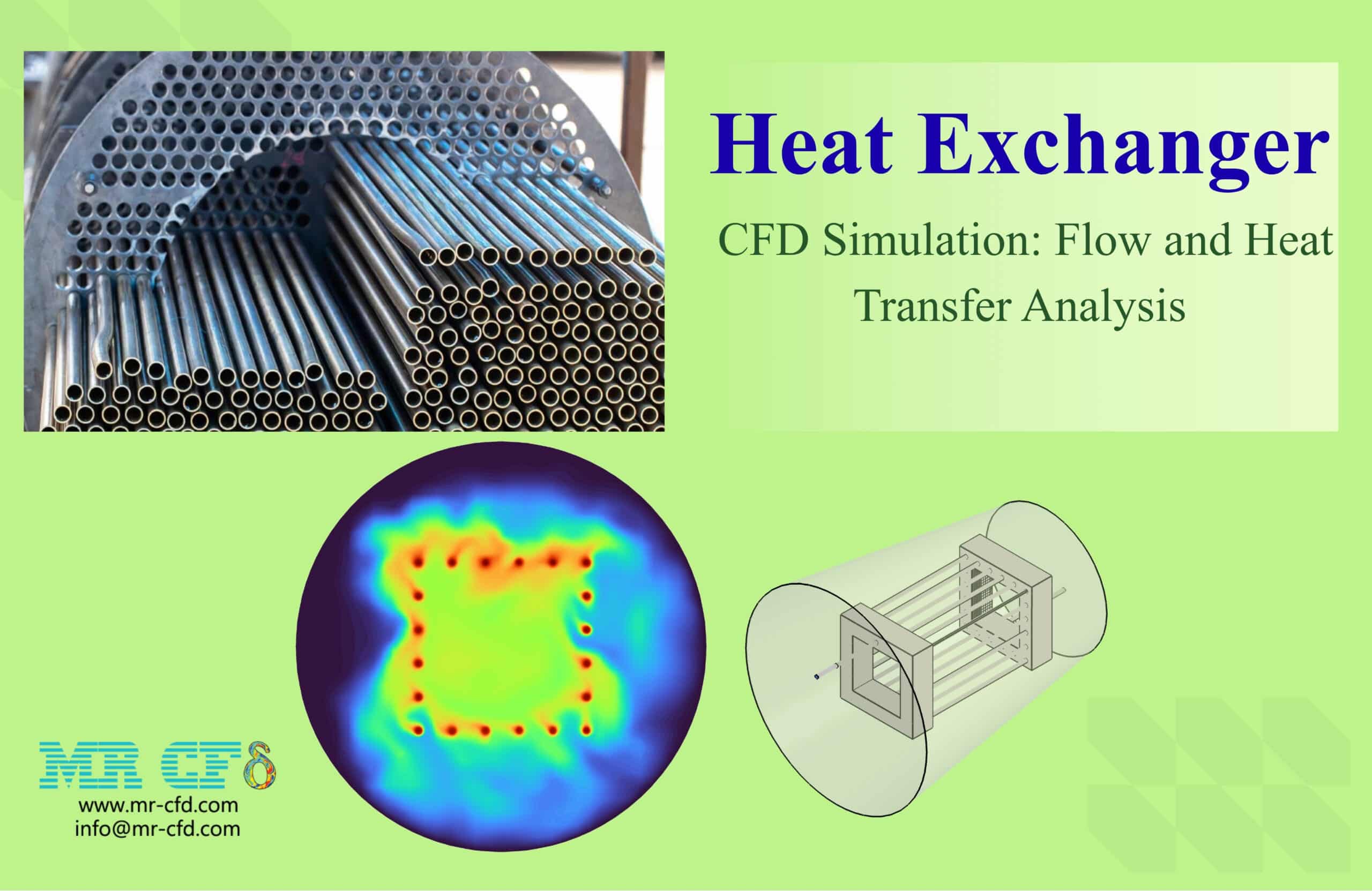

Heat Exchanger CFD Simulation: Flow and Heat Transfer Analysis

$80.00 $32.00 HPC

- This project simulates a shell-and-tube heat exchanger in ANSYS Fluent to analyze coupled flow and heat transfer of water.

- A pressure-based steady RANS approach with the k–ω SST turbulence model is used, with coupled pressure–velocity solution.

- The geometry includes shell and tube zones plus a Sterling valve region; a ~2,000,000-cell mesh with inflation layers resolves near-wall gradients.

- Boundary conditions: velocity inlet (0.3 m/s, 45 °C), pressure outlet, no-slip walls, and cooled valve/tank walls at 13 °C.

- Results show inlet acceleration, tube-bundle mixing, and progressive cooling, yielding realistic temperature and velocity fields.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Heat Exchanger CFD Study: Velocity and Temperature Distributions

Description

This project simulates a shell-and-tube heat exchanger using ANSYS. The objective is to resolve the internal flow and heat transfer between a hot water stream and the cooled boundaries so we can visualize the velocity field, identify recirculation within the bundle, and evaluate the temperature field through the shell. The workflow follows a standard CFD pipeline: geometry creation in DesignModeler, mesh generation in ANSYS Meshing, steady RANS solution with a pressure-based solver, and post-processing of streamlines and scalar contours (velocity and temperature) to interpret performance and flow features.

Geometry & Mesh

The geometry of heat exchanger consists of a cylindrical shell with an internal tube/bundle zone bounded by two plates, representing a typical shell-and-tube arrangement. Inlets, outlets, and wall features (including the valve region) were modeled to capture realistic entrance and exit effects. The computational grid was generated in ANSYS Meshing with approximately 2 million cells, providing adequate resolution of the core flow while keeping the cost practical. Inflation layers were applied along the tube/pipe walls to resolve near-wall gradients critical for heat transfer and the k–ω SST model’s wall treatment. Mesh quality (skewness/orthogonality) was checked to ensure solver robustness.

Physical Model & Solver Settings

A pressure-based, steady solver was used with the k–ω SST turbulence model to capture both adverse-pressure-gradient behavior and near-wall effects in the exchanger. The working fluid in both the shell and tube regions is water. Boundary conditions are: Velocity Inlet with speed 0.3 m·s⁻¹ and 45 °C temperature; Pressure Outlet at the downstream end; no-slip on all shell/tube walls. The valve region is modeled as a Sterling valve, and the tank/valve wall is held at a constant 13 °C to impose cooling. Coupled pressure–velocity coupling was employed to accelerate convergence and improve robustness of the steady solution.

Results

Streamlines and velocity contours of heat exchanger show acceleration at tube entrances and localized recirculation pockets near the baffle/plate regions, typical of shell-and-tube devices. The temperature field indicates effective cooling as the 45 °C inlet water exchanges heat with the 13 °C valve/tank boundaries: near the cooled walls, the temperature drops markedly. At the same time, warmer cores persist along the main flow passages. Cross-sectional temperature maps reveal thermal boundary layers forming around the tubes and baffles, with hot spots at stagnation/impingement zones and cooler wakes downstream. Overall, the solution captures the expected trends, momentum diffusion in the bundle, mixing induced by geometry, and progressive bulk-fluid cooling.

You must be logged in to post a review.

Reviews

There are no reviews yet.