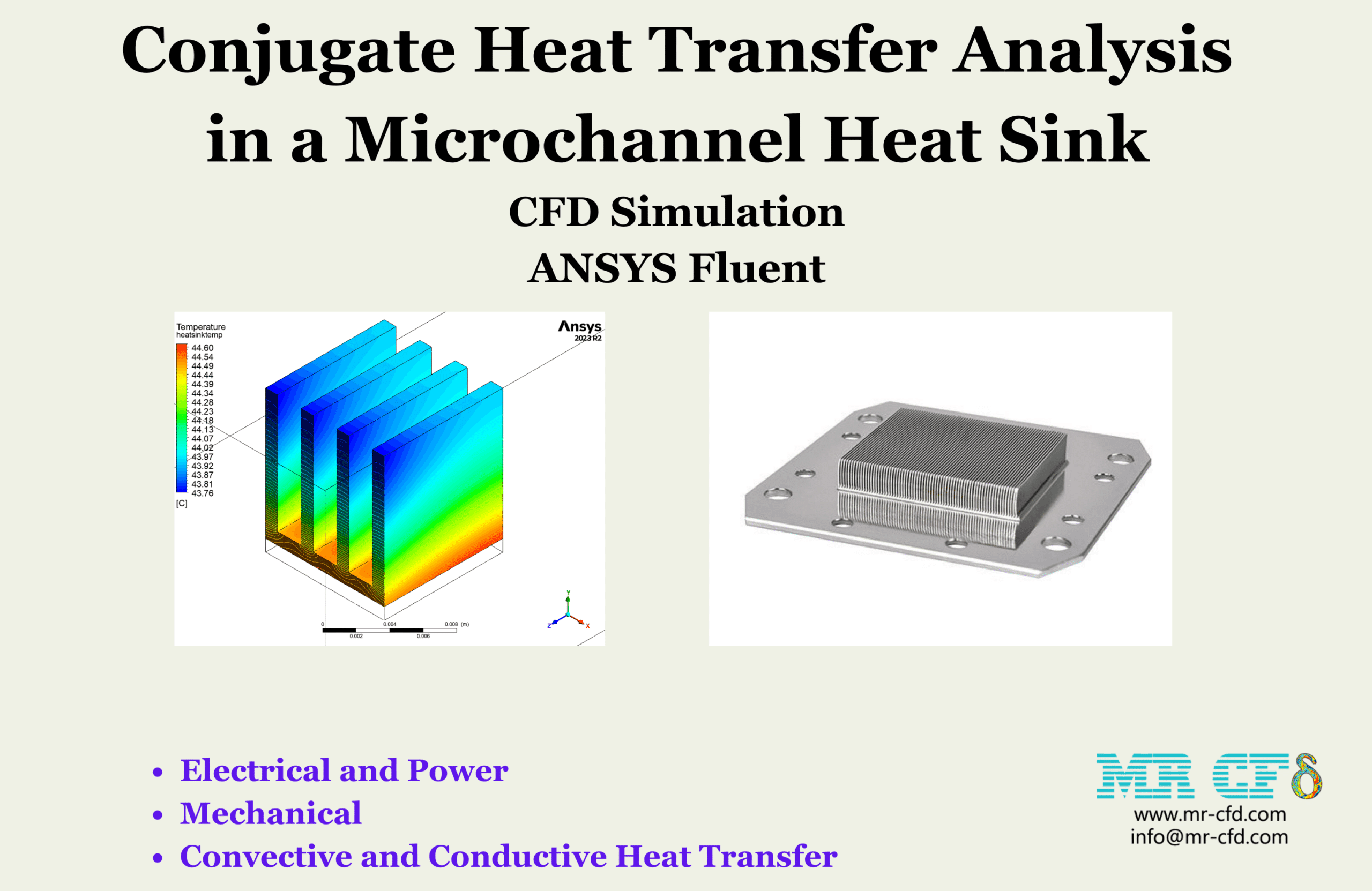

Conjugate Heat Transfer Analysis in a Microchannel Heat Sink, ANSYS Fluent

$80.00 Student Discount

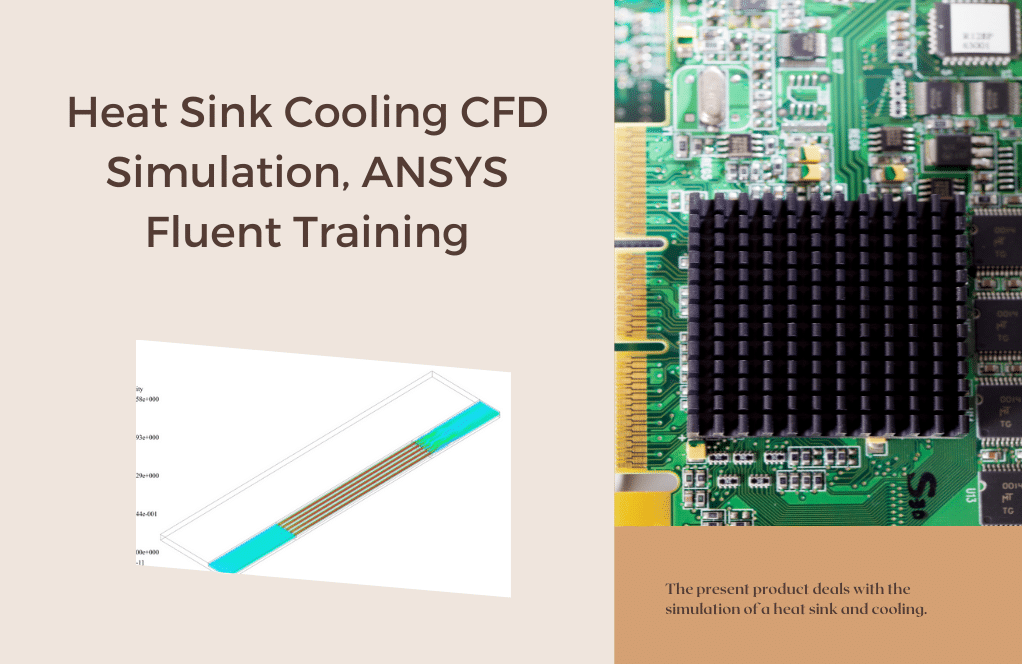

- The problem numerically simulates a Microchannel Heat Sink in ANSYS Fluent software investigating heat transfer and temperature distribution.

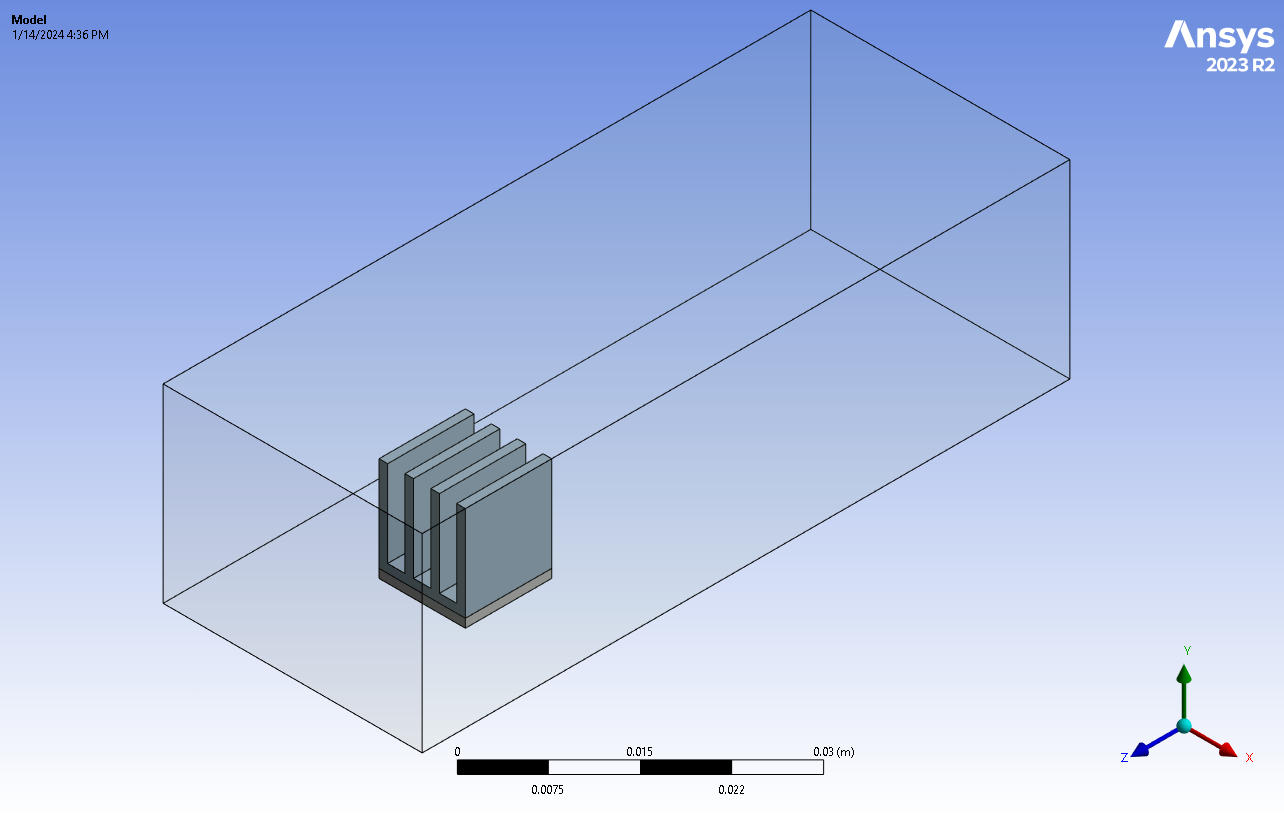

- The geometry of the model is created using SpaceClaim software.

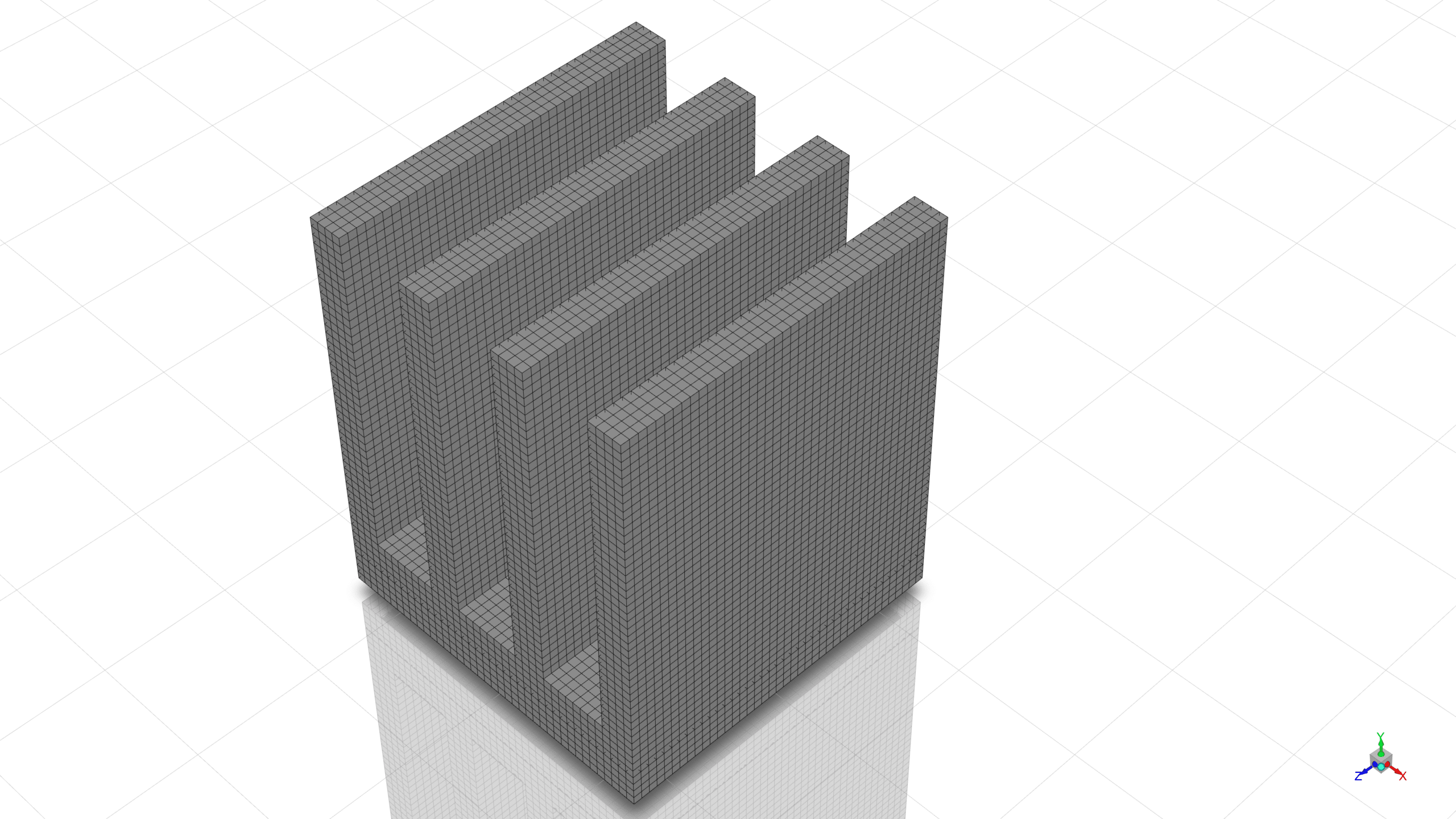

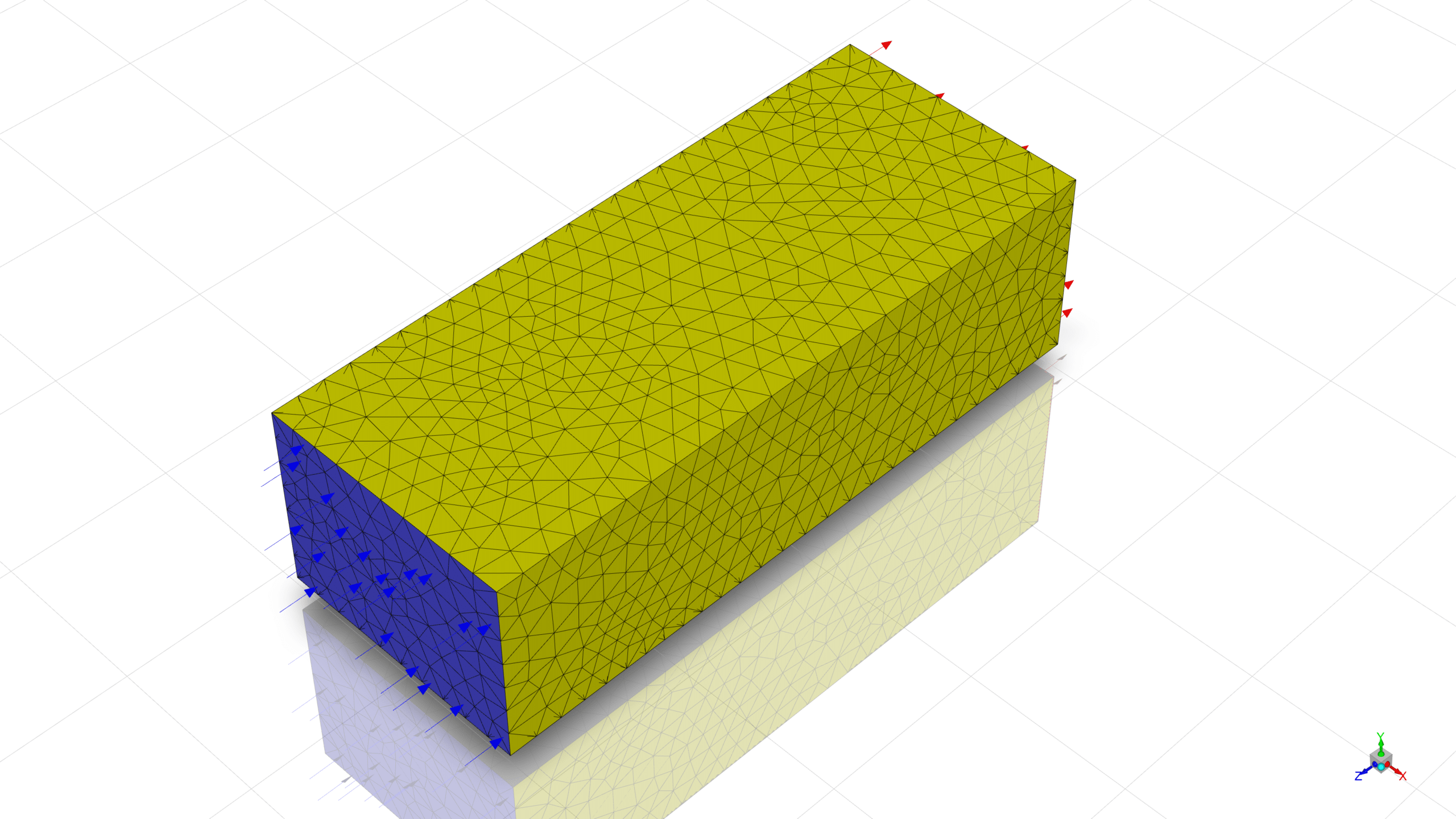

- The model is meshed in ANSYS Meshing, creating a structured mesh with 440,000 elements.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

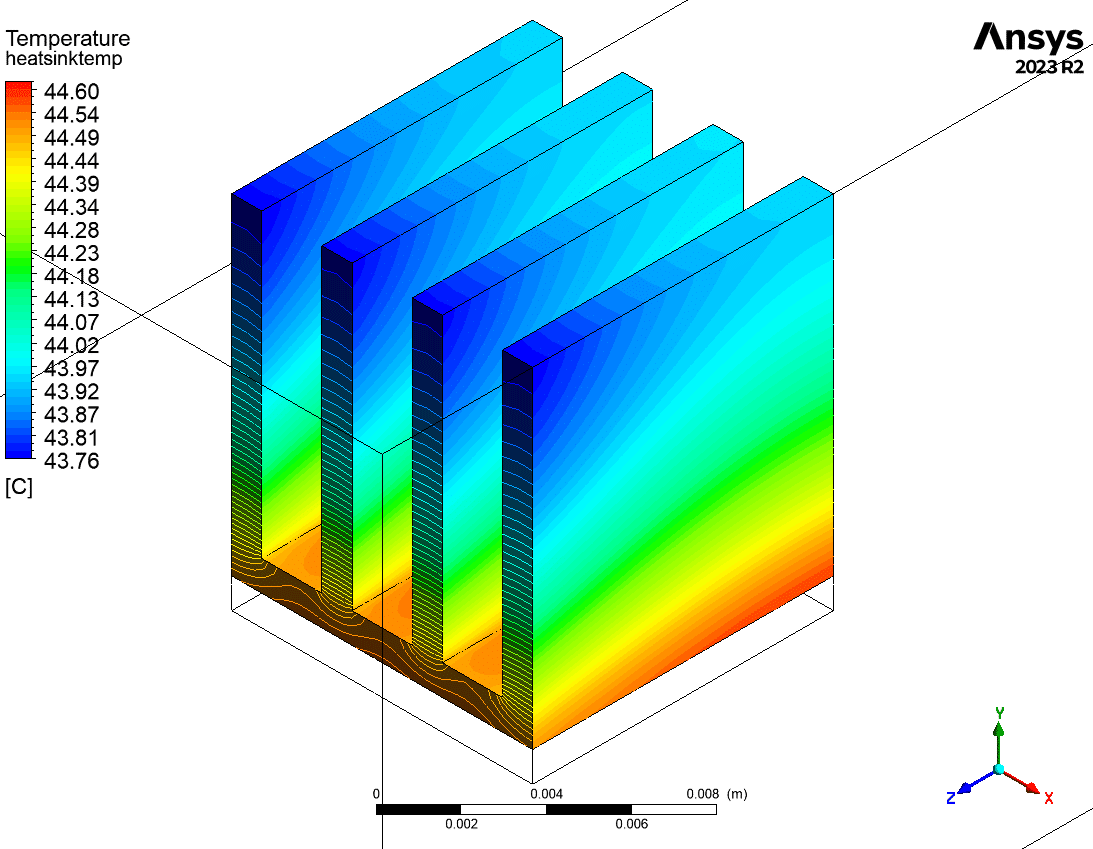

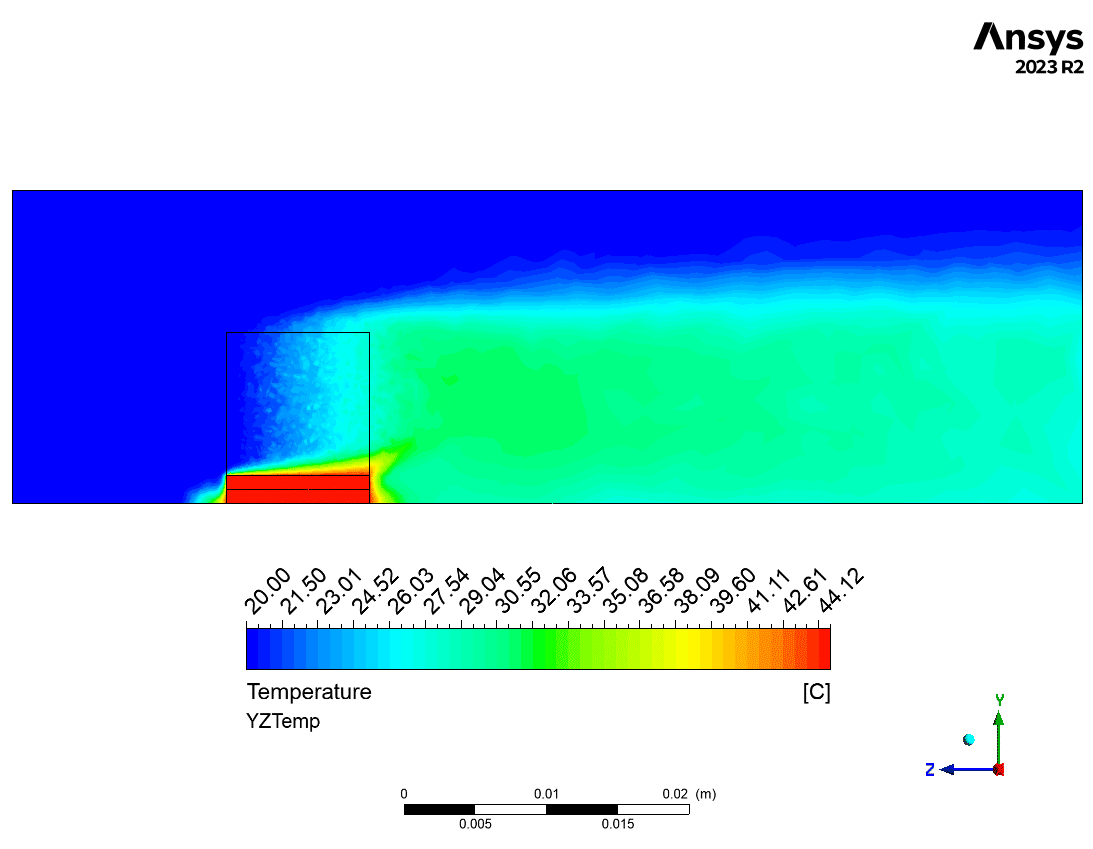

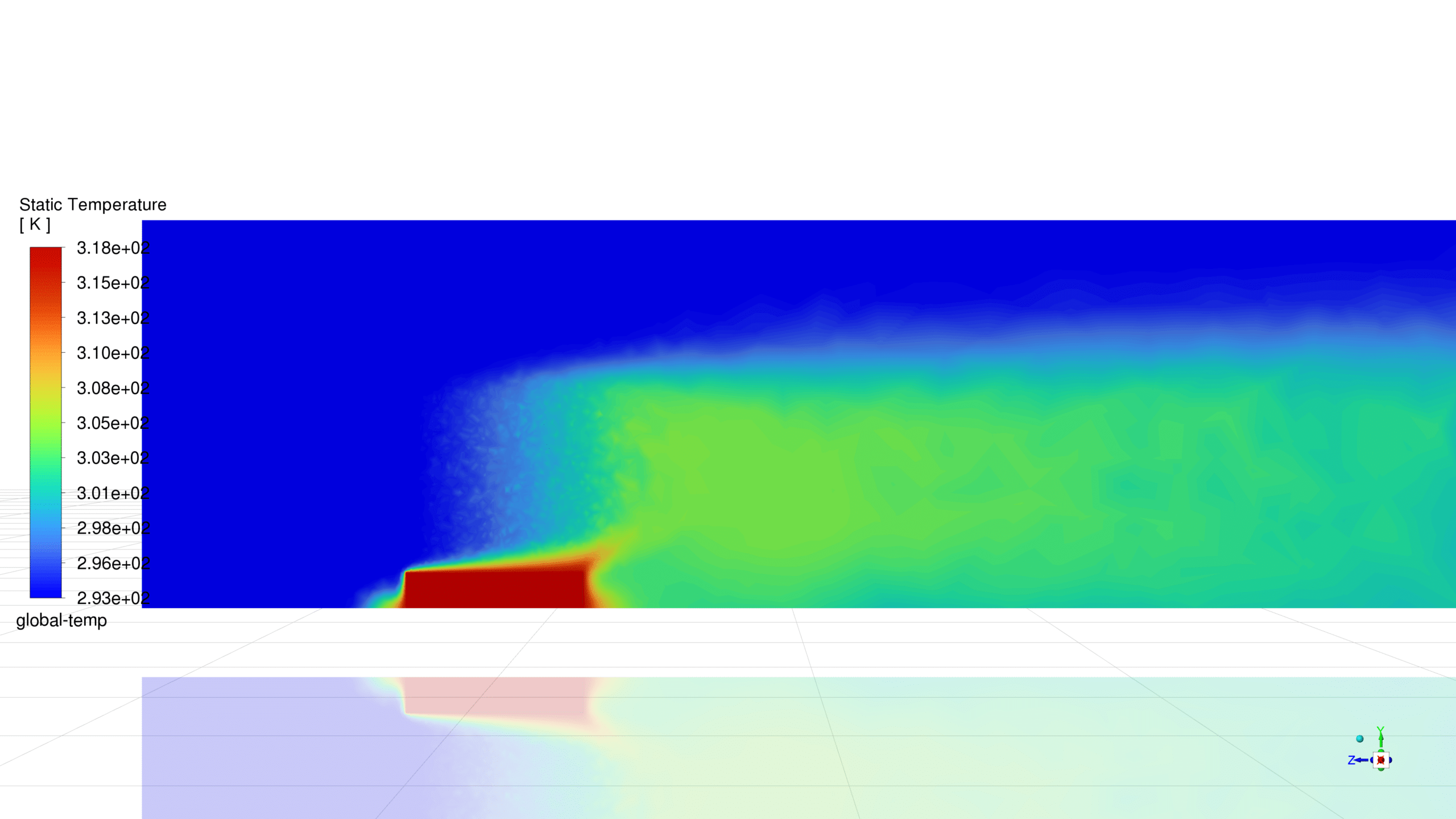

In this project, we will use ANSYS Fluent, a computational fluid dynamics (CFD) software, to simulate and analyze the fluid flow and conjugate heat transfer within a microchannel heat sink. The main objective is to study the temperature distribution across the microchannel. This simulation will help to understand the effectiveness of microchannel heat sinks in dissipating heat from electronic components. In this problem heat transfer occurs via two mechanisms. The first one is conduction in which the heat is transferred via solid then reaching the wall adjacent to the fluid. Then this heat is transferred from solid to the fluid by convection mechanism as the air flows along the channel.

The present model is designed in three dimensions using SpaceClaim software. The meshing of the model has been done using ANSYS Meshing software. The mesh type is Unstructured, and the element number is 440,000.

Methodology

We perform the simulation steadily, pressure based solution is considered. and the gravity effect is ignored. The laminar airflow enters the inlet boundary with a velocity of 1 [m/s] and a temperature of 293.15K and leaves the computational domain through an outlet flow boundary. The energy source for the Chip on the microchannel wall is equal to 10,000,000 W/m2.

Conclusion

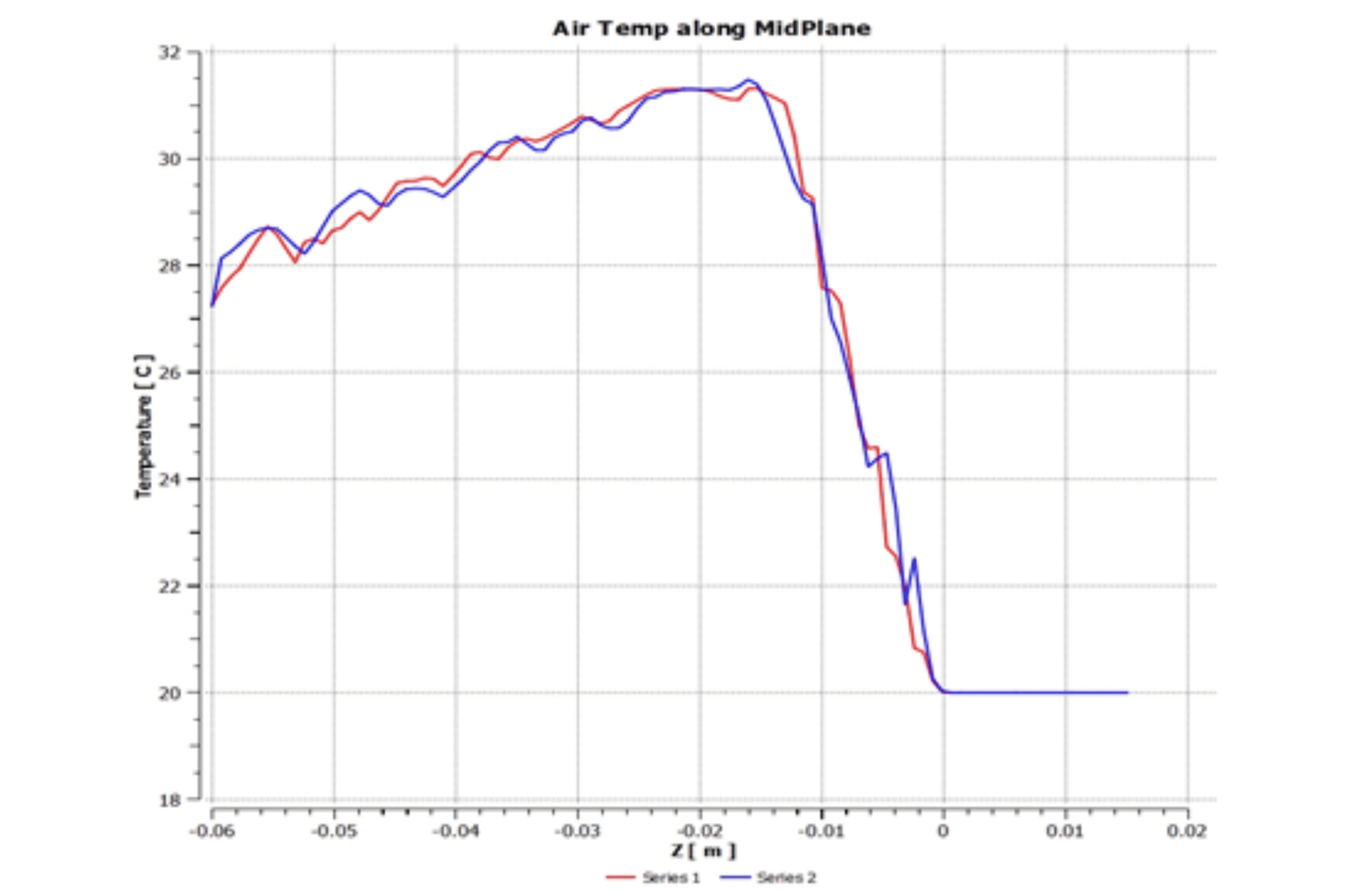

Finally, the contours related to pressure, velocity, temperature, and velocity vectors are obtained. As is seen in the temperature contour, the airflow has reduced the microchannel temperature, indicating its ability to cool down electronic devices. As temperature plot along the channel length shows, the heat flux absorbed by the airflow causes its temperature to increase from 293.15 k on the inlet to 302k on the outlet. Consequently by increasing the fluid temperature, meaning that the heat dissipation from electronic component is occurred properly, the bottom wall of heat sink’s maximum temperature is controlled so that the electronic component is not disturbed.

Reviews

There are no reviews yet.