Heller Indirect Dry Cooling Tower Transient Simulation

$100.00 Student Discount

In this project, the transient simulation of the Heller cooling tower is investigated.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Heller Indirect Dry Cooling Tower Transient Simulation, ANSYS Fluent Training

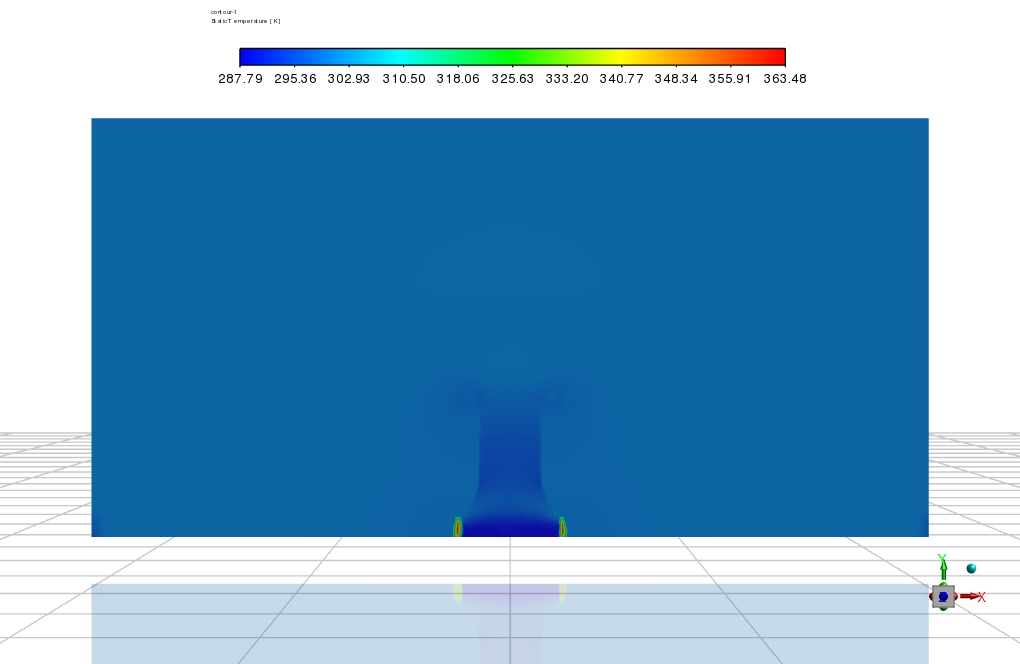

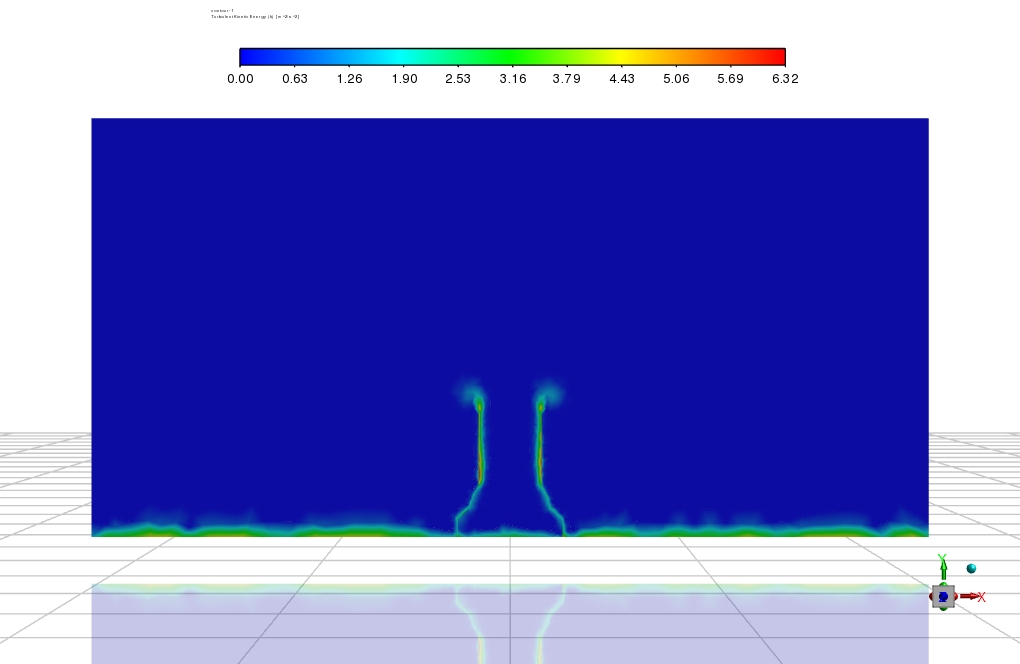

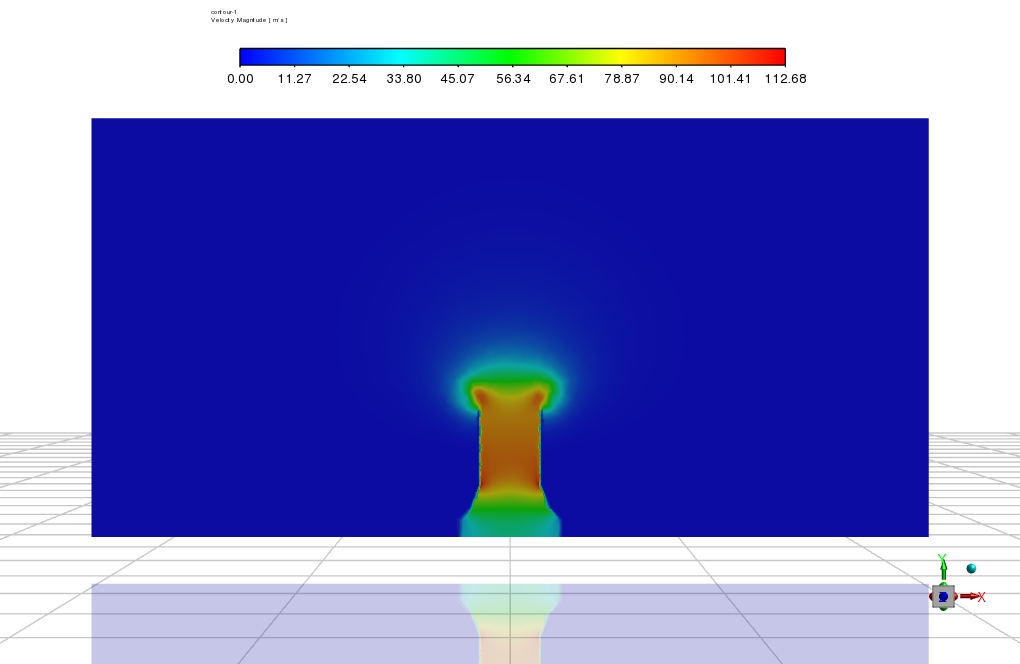

In this project, the transient simulation of the Heller cooling tower is investigated by ANSYS Fluent software. Heller cooling tower is an indirect heat exchanging mechanism in which airflow over the water stream and heat exchange process density decreases, and an upward flow is generated. In the present work, an ideal gas model is used for air density modeling. The ideal gas density model is based on the relationship between density and local fluid temperature. Higher the temperature, the lower the density, and the higher the upward force on fluid volume due to buoyancy effects.

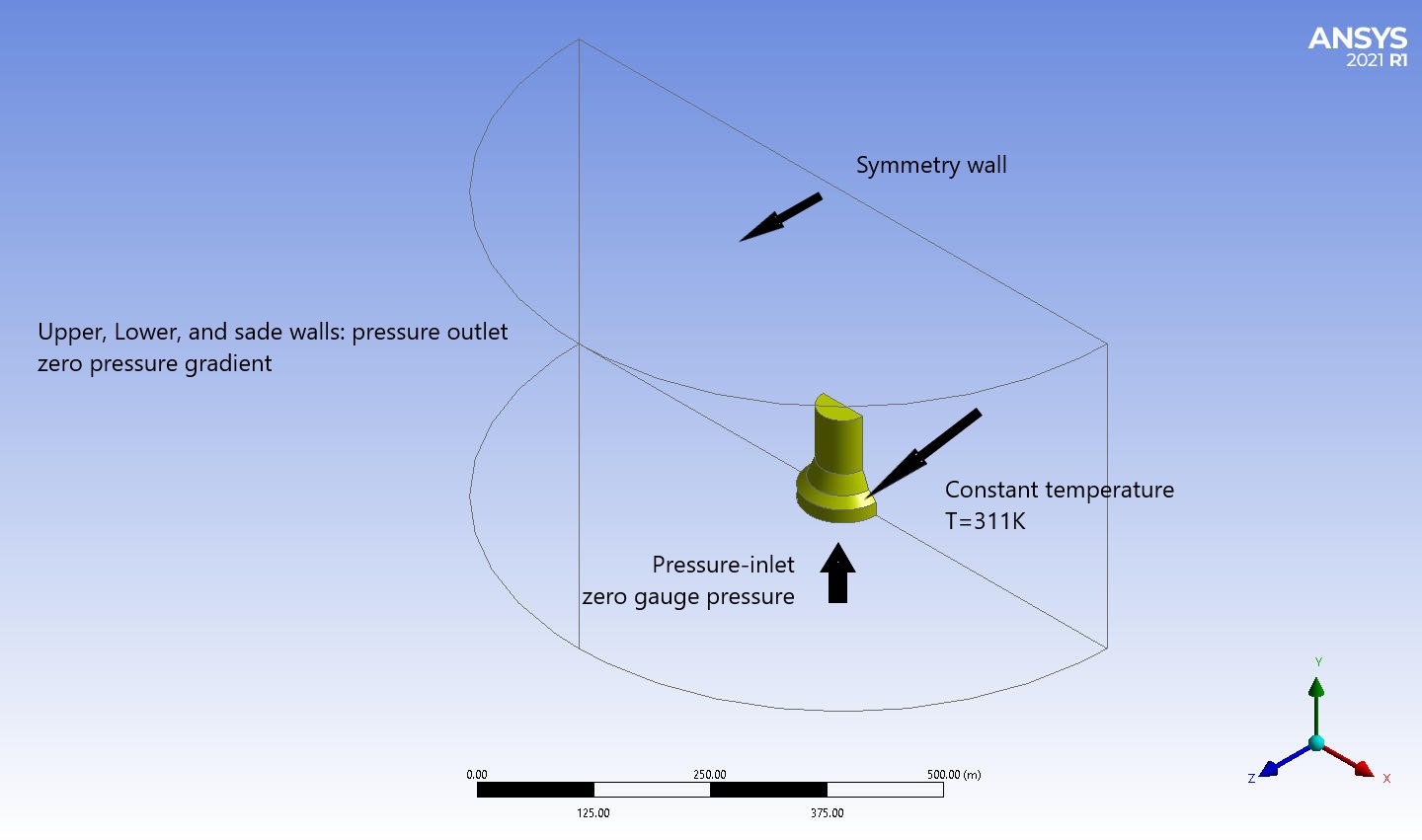

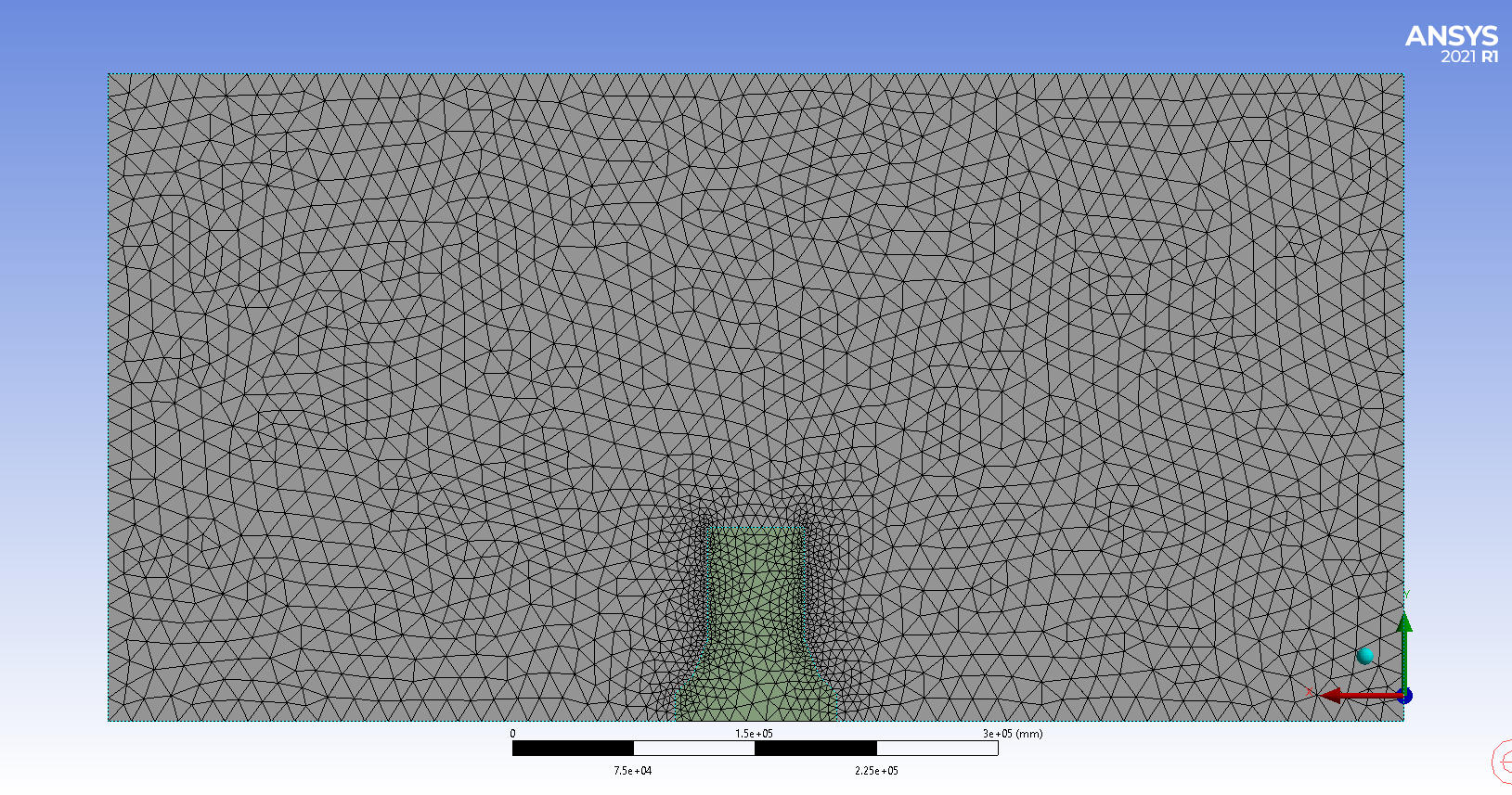

Heller Geometry and mesh

The fluid domain’s geometry is designed in Design Modeler, and the computational grid is generated using Ansys Meshing. The mesh type is unstructured, and the element number is 230000.

Heller CFD Simulation

Critical assumptions:

- The solver type is assumed density Based.

- Time formulation is assumed unsteady.

- Gravity effects are considered in the Y direction equal to –9.81 m/s2.

The following table represents a summary of the defining steps of the problem and its solution.

| Models (Heller) | ||

| Viscous | K-epsilon | Standard |

| Near wall treatment | Standard wall treatment | |

| Energy | on | |

| Materials (Heller) | ||

| Fluid | Definition method | FLUENT database |

| Material name | air | |

| Density model | Ideal gas | |

| Boundary conditions | ||

| Inlet | Type | Pressure inlet |

| Gauge pressure | 0 kPa | |

| Thermal | 288.61 K | |

| Radiator | Type | Wall |

| Thermal | 311.2 K | |

| Wall thickness | 1 m | |

| Heat generation rate | 51352 W/m3 | |

| Solver configurations (Heller) | ||

| Formulation | Implicit | |

| Flux type | Roe-FDS | |

| Spatial discretization | Gradient | Least square cell-based |

| Momentum | Second-order Upwind | |

| K | First-order Upwind | |

| Epsilon | First-order Upwind | |

| Run calculation | Time step size | Adaptive |

| Total time | 1000 s | |

| No. of fixed time steps | 2 | |

| Initial time step size | 10e-5 | |

| Max items per time step | 20 | |

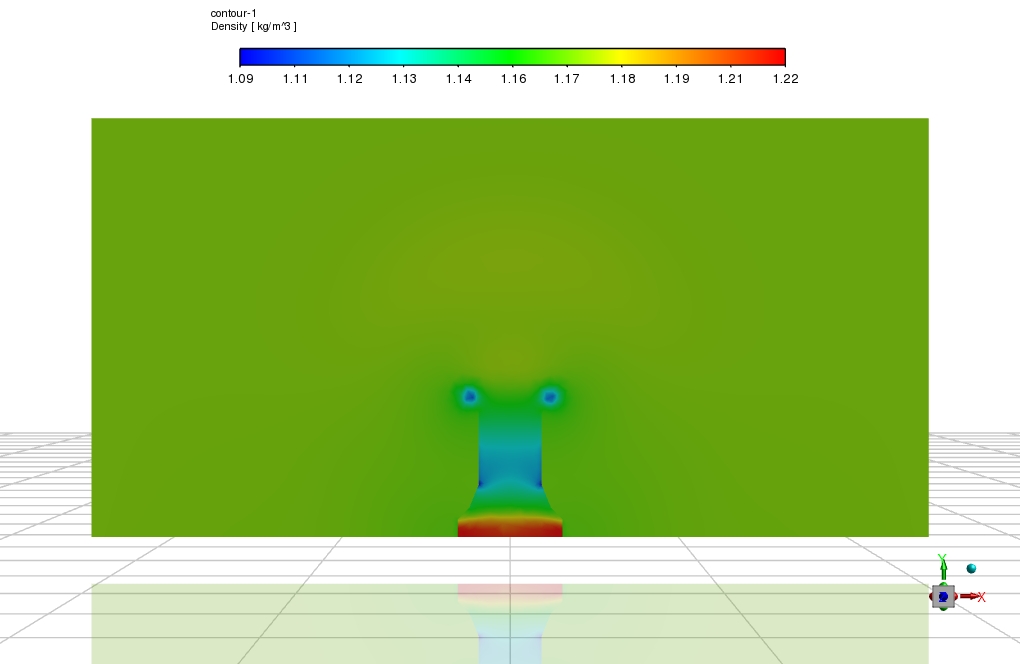

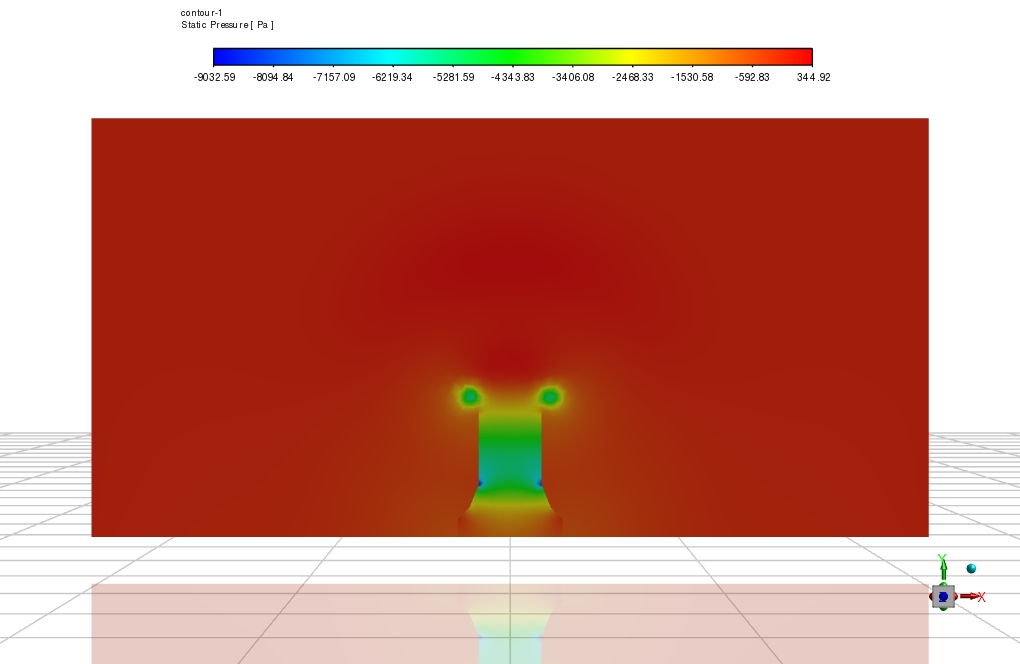

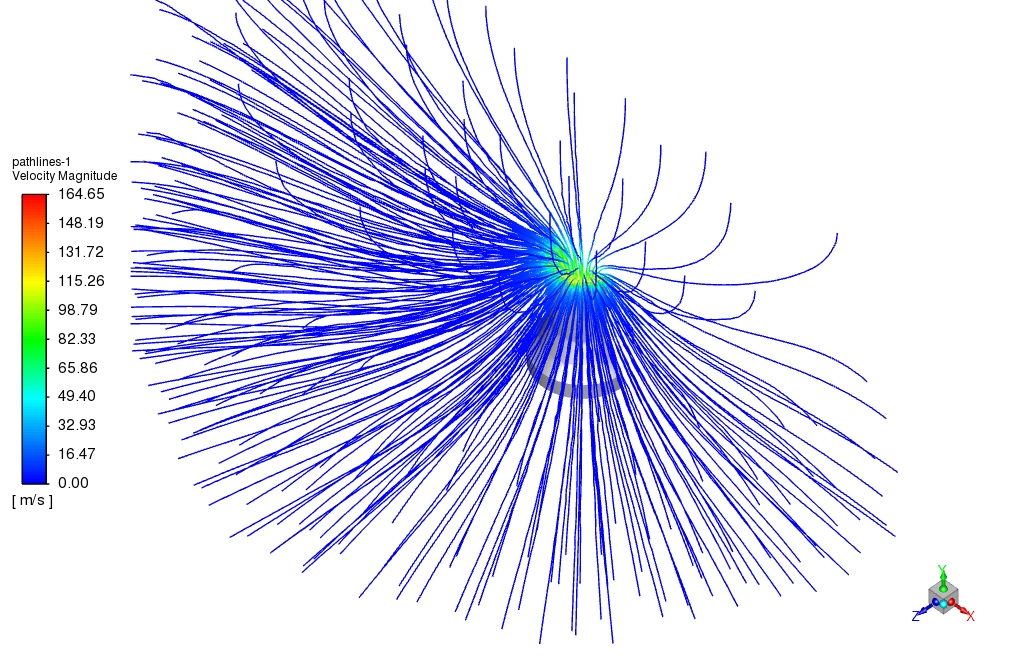

Results and discussion

The pressure difference in orders of 10kPa is generated inside the cooling tower. The velocity of air, only under the influence of buoyancy force, reaches 90 m/s inside the cooling tower and reaches a maximum of 170 m/s on the edge of the cooling tower exit.

Mona Denesik –

Can the simulation provide insights into the cooling tower’s performance under peak load conditions?

MR CFD Support –

Yes, the transient simulation can provide insights into the cooling tower’s performance under peak load conditions. This can help you ensure that the cooling tower can handle peak loads effectively.

Mr. Ewell Huels IV –

Can the simulation provide insights into the cooling tower’s performance during startup and shutdown?

MR CFD Support –

Yes, the transient simulation can provide insights into the cooling tower’s performance during startup and shutdown. This can help you optimize these processes to minimize energy consumption and wear and tear.

Thora West –

Can the simulation model the effect of different operating conditions on the cooling tower performance?

MR CFD Support –

Yes, the simulation can model the effect of different operating conditions on the cooling tower performance. We can adjust the simulation parameters based on your specific operating conditions.

Carlie Quigley –

The Heller cooling tower simulation was meticulously laid out and effectively illustrated the core principles involved. The careful attention to detail in every step, from setup to analysis, vividly demonstrates the functionality of ANSYS Fluent in handling complex, transient simulations. The comprehensive results display the dynamic behavior of the cooling tower effectively.

MR CFD Support –

Thank you for your thoughtful evaluation of our Heller Indirect Dry Cooling Tower simulation course! We’re pleased to hear that the materials met your expectations and provided clear and informative insights into the simulation process with ANSYS Fluent. Your feedback is greatly appreciated and motivates us to continue delivering high-quality educational content.

Brandy Dooley –

The training materials and simulation results for the Heller Indirect Dry Cooling Tower were outstanding. I was particularly impressed with the level of detail in the airflow dynamics and the clear demonstration of buoyancy effects in the cooling process. The application of the ideal gas model for air density was well-explained and effectively showcased in the results.

MR CFD Support –

Thank you for your positive feedback on our Heller Indirect Dry Cooling Tower Transient Simulation training materials. We’re glad to hear that you found the explanations and simulations regarding airflow dynamics and buoyancy effects informative and clear. If you have any further questions or need more insight into our CFD products, feel free to reach out to us!

Casey Cormier –

This project does an excellent job showing the complex dynamics within a Heller Indirect Dry Cooling Tower. The unstructured mesh allows for great detail, and the clear explanation of the simulation setup helps me understand the transient behavior of the cooling process. Impressive work demonstrating the potential of CFD in industrial applications!

MR CFD Support –

Thank you for your kind words. We’re glad to hear that our product met your expectations and provided you with a clear understanding of the CFD simulation for the Heller Indirect Dry Cooling Tower. It’s our pleasure to assist customers like you in grasping the intricate details of industrial applications through practical CFD training.

Ken Wunsch DDS –

The detail and clarity in this tutorial are impressive! Heartening to see such byzantine topics distilled into digestible learning experiences.

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that you found our training on the Heller Indirect Dry Cooling Tower comprehensive and easy to understand. Our goal is to empower users like you to delve into complex subjects with confidence. Your feedback is much appreciated!

Mollie Adams –

This Heller Indirect Dry Cooling Tower project was thorough and insightful. Learning to simulate the transient behavior in such a complex system was fascinating. The careful consideration of the buoyancy effects and the clarification of the relationship between temperature and density certainly helped with understanding the ideal gas model in a dynamic system like this. Thank you for making the ANSYS Fluent processes more approachable and easier to understand.

MR CFD Support –

We are thrilled to have provided you with a valuable learning experience through our Heller Indirect Dry Cooling Tower Transient Simulation project. It is our pleasure to assist in deepening your understanding of ANSYS Fluent and dynamic system simulations. Thank you for sharing your positive feedback with us!

Carmel Smith –

The thoroughness of this project is impressive! It’s fantastic how detailed the simulation parameters and the treatment of fluid dynamics are presented. Particularly, the application of the ideal gas density model to account for the temperature-density relationship demonstrates prowess in capturing realistic buoyancy effects. The meticulous configuration of solver and boundary conditions vouches for the level of precision aimed for in the transient simulation. Excellent work!

MR CFD Support –

Thank you for your kind words! We are delighted to hear that you’re impressed with the detail and accuracy of the Heller Indirect Dry Cooling Tower transient simulation. Our team strives to provide comprehensive simulations that capture the complexities of real-world physic to support meaningful analysis and benefits for our clients. If you have any further needs or questions about our products, please feel free to reach out to us.

Mr. Jayme Bechtelar I –

The detailed explanation of boundary conditions and solver configurations really enhanced my understanding of the simulation process. The achievement of realistic airflow patterns solely through buoyancy forces is impressive. Great job on portraying such a dynamic system!

MR CFD Support –

Thank you for your review and appreciation! We strive to provide detailed and accurate information in our training materials to ensure a comprehensive learning experience. It’s exciting to hear that the Heller Indirect Dry Cooling Tower Transient Simulation provided you with enhanced insights into the CFD process. If you have any further feedback or need assistance, feel free to reach out!

Jennie Bartoletti –

This course modelled some impressive computational fluid dynamics! How do time steps affect the accuracy and computational expense in a transient simulation like this one?

MR CFD Support –

Happy to hear you’re impressed! In transient simulations like that of the Heller cooling cooling tower, time step size is critical for both accuracy and computational cost. Smaller time steps can lead to more accurate results since they capture transient effects better, but they can vastly increase computational time. Larger time steps, on the other hand, reduce computation time but may miss quick-changing phenomena, leading to less accurate results. The adaptive time step method here attempts to balance accuracy with computational efficiency by adjusting the time step size based on the flow’s transient nature.

Bria Metz II –

The Heller cooling tower project provided an in-depth and dynamic learning experience. The balance between theory and practical application through the use of software simulation made the complex concepts accessible. The data provided allowed for a thorough understanding of the interactions between air flow and heat exchange, which was further supported by the use of real-world physics, such as the buoyancy effect in airflow. I felt engaged with the material throughout the course, and the step-by-step guidance was particularly helpful. The transient nature of the simulation added another layer of realism, as understanding how conditions change over time is crucial in actual engineering scenarios. This level of detail and clarity throughout the course was highly appreciated.

MR CFD Support –

Thank you for your positive feedback. We’re delighted to hear that the simulation project on the Heller Indirect Dry Cooling Tower was informative and engaging. It’s wonderful to know that our balance between theoretical concepts and practical applications helped enhance your understanding. We strive to provide clear, hands-on learning experiences with real-world applications, and it’s gratifying to hear that we’ve succeeded. Your compliments are greatly appreciated, and we’re pleased that the course met your expectations. Thank you for choosing MR CFD for your training; we look forward to assisting you in future learning ventures!

Marquise Wisozk Jr. –

I’m impressed by the detailed simulation of the Heller Indirect Dry Cooling Tower. Especially the inclusion of transient state simulation, gravity effects, and consideration of the density-temperature relationship using the ideal gas model, indicative of the comprehensive nature of the study. The adaptive time step and pressure difference observations showcase the dynamic analysis capability of the software and the user’s expertise. Well done!

MR CFD Support –

Thank you for your positive feedback. We are pleased to know that you appreciated the level of detail and comprehensive analysis provided in the Heller Indirect Dry Cooling Tower simulation study. Your acknowledgment of the transient state simulation and other simulation aspects means a lot to us. If you ever have more questions or need further assistance, don’t hesitate to reach out. Thanks again for choosing our learning products for your studies!

Prof. Carmen Schimmel MD –

This simulation’s focus on buoyancy effects is impressive. The review would benefit from detailing how these buoyancy effects impact the overall efficiency of the cooling tower. Are there results available that show the relationship between the buoyancy-induced velocity and the cooling tower efficiency at different operation conditions?

MR CFD Support –

Thank you for the positive feedback and interesting inquiry! The results in this simulation demonstrate the buoyancy effects and the resultant airflow velocities inside the Heller cooling tower. While the presented data highlights the successful simulation of airflow dynamics, additional simulations would be required to explicitly correlate these velocities with cooling tower efficiency at various operational conditions. Such analyses could include evaluation of heat transfer rates, cooling capacity, and tower performance in different ambient conditions, which are beyond the scope of the summarized results provided.

Larue Jacobson –

I found the transient simulation of the Heller cooling tower fascinating. The airflow dynamic changes and the results of the upward force affecting the fluid volume was illustrated clearly through the simulation. The switch from a standard to an unstructured mesh also intrigued me – it seemed very effective for modeling the complexity of the Heller geometry. Great work on explaining the entire process in such an accessible manner!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you found our simulation study on the Heller Indirect Dry Cooling Tower so insightful and easy to understand. Our team devotes a lot of effort to ensure our simulations vividly illustrate these complex dynamics and structural elements, providing a clear understanding of fluid behaviours in industrial applications. We appreciate your feedback, and it motivates us to continue delivering high-quality, accessible CFD training and simulations. If you have any further inquiries or need more details, please feel welcome to reach out!

Rossie Kunze –

The product was really detailed and the description provided me with a clear understanding of the CFD process used for the Heller Indirect Dry Cooling Tower Transient Simulation. Great work on illustrating the ideal gas assumption for the air density modeling which affects the upward force in the buoyancy-driven flow.

MR CFD Support –

We appreciate your positive feedback! We’re thrilled to hear you found the description clear and helpful. Understanding the modeling of air density and its impact on buoyancy forces is crucial in simulations like this, and we’re glad it was well-explained. Thanks for choosing our learning products!

Fanny DuBuque –

I tried to follow the steps outlined in the training for setting up my own simulation using a similar geometry. However, I’m not sure if I should always use an unstructured mesh like in the project, could you specify when it’s preferable to use unstructured over structured mesh?

MR CFD Support –

Whether to use an unstructured or structured mesh depends on the geometric complexity of the domain and the flow characteristics. Unstructured meshes are preferred in complex geometries or where local refinement is needed, as they are flexible in covering irregular shapes. Structured meshes are typically used for simpler, more regular geometries and can provide more accurate solutions with fewer cells. However, they are difficult to generate for complex shapes. For transient simulations of a Heller tower, an unstructured mesh might be preferred due to the potential complexity of the domain.

Griffin Johnston –

The project details are incredibly informative. I was especially impressed with the handling of buoyancy effects through the ideal gas density model and the comprehensive description of boundary conditions. Great job!

MR CFD Support –

Thank you for the positive feedback! It’s rewarding to hear when our customers appreciate the detail and effort that goes into our CFD simulations and training material. If you have any further questions or need assistance with other projects, we’re here to help.

Felicita Jones –

I learned so much from the ‘Heller Indirect Dry Cooling Tower Transient Simulation’ training. The detail given to the CFD process and the logical step-by-step explanation really helped solidify my understanding of transient simulations in ANSYS Fluent. The animations included were intuitive and visually explanatory. Great job by the MR CFD team!

MR CFD Support –

Thank you for sharing your positive experience! It’s fulfilling to know that our training helped enhance your understanding of transient simulations. We’re glad you found the animations useful and you felt supported by our step-by-step guidance. At MR CFD, we strive to deliver high-quality, educational material. Looking forward to supporting your continuous learning journey!

Dr. Austen Mueller PhD –

This training facilitated my grasp on transient simulations. The level of detail, especially in explaining settings and assumptions, was top-notch. I particularly enjoyed the use of adaptive time steps for capturing the tower’s complex dynamics effectively.

MR CFD Support –

We’re thrilled to hear that our Heller Indirect Dry Cooling Tower Transient Simulation training was helpful and that the in-depth explanations contributed to your understanding! It’s always great to receive such positive feedback. Thank you for taking the time to let us know—your enthusiasm for CFD learning makes our efforts even more worthwhile!

Peggie Bashirian –

I’m impressed by the detail provided in the simulation work for the Heller Indirect Dry Cooling Tower. How accurate would you say is the transient simulation in forecasting the performance of the actual tower operation?

MR CFD Support –

The transient simulation provides a detailed and dynamic analysis of the performance, giving insights that can closely predict actual performance. However, the accuracy is dependent upon the precision of the input parameters and how well the constructed model represents the complexity of the real-world design and operational conditions.

Mrs. Amiya Hickle IV –

I’m thrilled with the training content! The explanations were clear, and the methodology made the simulation process much easier to follow. My simulations are improving because of this course.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our Heller Indirect Dry Cooling Tower Transient Simulation training with ANSYS Fluent has greatly enhanced your simulation skills. Keep up the great work and don’t hesitate to reach out if you have any more questions or need further assistance. Your success is our priority!

Dr. Magdalen Sauer DDS –

The Heller cooling tower project was truly fascinating! The consideration of varying air density using the ideal gas model adds a touch of realism that greatly aids in understanding the physics behind cooling towers. It’s incredible how the buoyancy effects drive the upward flow of the air with such varying speeds inside the tower. I’m particularly impressed by the detailed boundary conditions and solver configurations that help to accurately capture the complex transient behaviour of the flow and temperature fields within the cooling tower. Fantastic work on achieving significant velocity, highlighting the efficiency and effectiveness of the tower design!

MR CFD Support –

Thank you so much for your kind words and for recognizing the detail and effort put into the Heller cooling tower simulation project. It’s fantastic to hear that you were impressed with the realism and depth of the simulation. We strive to provide precise and reliable results, and your feedback is greatly appreciated. If you find yourself interested in any other specifics of our simulations or have further questions, do not hesitate to reach out!

Yesenia Willms –

The focus on buoyancy effects in this simulation is fascinating! I imagine getting airflow right is crucial in the efficiency of the system.

MR CFD Support –

Thank you for your positive feedback! Matching the physical phenomena, including buoyancy, with high accuracy is indeed a pivotal factor in these simulations to assure the correctness of the solution and thus maximize the cooling tower efficiency. We’re delighted you found the project’s approach engaging.

Julian Mann –

Really detailed and useful simulation! I was especially impressed by the pressure differences and velocity outputs in the Heller cooling tower model. Great job MR CFD Company.

MR CFD Support –

Thank you for your kind words and appreciation for our Heller Indirect Dry Cooling Tower Transient Simulation! We are thrilled to hear that you found the details and simulation results impressive and useful. Your positive feedback is incredibly motivating for our team. We continuously strive to provide high-quality training and simulation results. If there is anything more you’d like to learn or any further assistance we can offer, please don’t hesitate to reach out!

Dora McLaughlin –

I found the provided results for the velocity inside the cooling tower fascinating, especially when driven by buoyancy alone. Were simulations also conducted with variable ambient temperatures to observe their impact on the cooling tower’s performance?

MR CFD Support –

The simulation you are referring to was specifically set under certain controlled conditions and only examined the effects of buoyancy within those parameters. If ambient temperature variations are to be investigated, additional simulations would need to be conducted considering those variables to understand their impact on the performance of the cooling tower.

Euna Smitham –

The training module was thorough and well-designed. The simulation process was clearly outlined and easy to understand. Excellent job detailing the setup for complex systems!

MR CFD Support –

Thank you for your kind words and positive review! We’re glad to hear that you found the module to be thorough and understandable. It’s great to know that the content was clear even when handling complex simulation setups. Your feedback is appreciated!

Harmony Pacocha –

This simulation seems quite comprehensive! Can you tell me the significance of the wall thickness parameter in the simulation?

MR CFD Support –

In this simulation, the wall thickness parameter directly impacts the process of heat transfer within the cooling tower. It represents the physical width of the tower’s walls where the heat generation rate has been defined. The provided heat generation rate and wall thickness value together govern how much heat is conducted and then released into the air, which influences the air’s temperature, density, and movement as per the simulation’s parameters.

Dr. Savanah Hagenes V –

The level of detail in this simulation is impressive. Amazing insight into thermodynamics and buoyancy effects within cooling towers!

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that our simulation provided you with comprehensive insights and helped you understand the complex dynamics of cooling towers.

Shany Kihn –

I’m utterly thrilled with the skill development I got from the Heller Indirect Dry Cooling Tower Transient Simulation training. The depth and attention to detail by using the ideal gas model really allowed me to understand heat exchange and flow dynamics. The hands-on experience with mesh generation and boundary condition setup was invaluable, and manipulating solver settings was a challengingly rewarding learning experience.

MR CFD Support –

We’re overjoyed to hear about your positive learning experience with our Heller cooling tower simulation training. It’s fantastic to learn that the detailed approach to ideal gas modeling and flow dynamics was beneficial to you. We strive to provide comprehensive learning tools and it sounds like the combination of practical examples and solver strategy tips were a solid foundation for your development. Thank you for choosing our training materials, and we’re here for any further studies you plan to pursue.

Dr. Chelsey Yundt I –

This product taught me so much about transient simulation in ANSYS Fluent! I especially loved learning about the impact of the buoyancy effect on airflow. Every step of the simulation was clear and it helped me understand the concepts behind Heller Indirect Dry Cooling Towers better.

MR CFD Support –

Thank you sincerely for your positive review of our Heller Indirect Dry Cooling Tower Transient Simulation training. We’re thrilled to hear about your successful learning experience and the clarity you gained on the buoyancy effects in simulations. Your feedback is greatly appreciated!

Violet McKenzie –

The technical depth and results provided in the training were exceptional. Grasping the concepts of how to manipulate the fluid dynamics software to simulate buoyancy effects has enhanced my understanding of cooling tower behaviors. The combination of adaptive time-stepping and unsteady solver usage to capture transient effects was especially enlightening.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our training provided you with a clear understanding of the cooling tower simulation and that you found the topics of buoyancy effects, adaptive time-stepping, and unsteady solver usage helpful. We always strive to deliver comprehensive and practical knowledge to our customers. Your enthusiasm for learning these concepts is the reason we continue to evolve and refine our educational materials. If you have any more insights to share or need further assistance, please let us know!

Keshawn Donnelly Jr. –

The level of detail in both the simulation setup and the methodology is astonishing. I’m especially impressed by the incorporation of gravity effects and the utilization of an ideal gas density model to accurately simulate airflow. Truly remarkable work.

MR CFD Support –

Thank you for taking the time to leave such a wonderful review! We’re thrilled that you’re impressed with the details of the Heller cooling tower simulation setup and methodology. If you have any more questions or need further information, feel free to reach out. Your feedback is greatly appreciated!